Lithium Mine Evaporation Pond vs Climate Conditions: Efficiency Comparison

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Evaporation Technology Background and Objectives

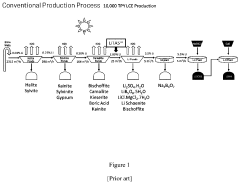

Lithium extraction through evaporation ponds represents one of the most established methods for obtaining this critical element from brine resources. The technology dates back to the 1950s when commercial lithium production began in the Atacama Desert of Chile, evolving significantly over subsequent decades. This natural evaporation process harnesses solar energy and wind to concentrate lithium-rich brines, offering a relatively low-cost extraction method compared to hard-rock mining alternatives.

The evolution of lithium evaporation technology has been closely tied to growing global demand for lithium compounds, particularly driven by the rechargeable battery industry since the 1990s. Traditional evaporation methods typically achieve recovery rates of 40-50%, presenting significant opportunities for efficiency improvements. Recent technological innovations have focused on enhancing evaporation rates, reducing processing time, and minimizing freshwater consumption in these water-intensive operations.

Climate conditions play a crucial role in evaporation pond efficiency, with factors such as solar radiation, ambient temperature, humidity, wind speed, and precipitation patterns directly impacting evaporation rates and overall lithium recovery. The most productive lithium brine operations are strategically located in arid regions with high solar radiation and low precipitation, such as the "Lithium Triangle" spanning Chile, Argentina, and Bolivia, which currently accounts for approximately 58% of global lithium resources.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of lithium evaporation pond efficiency across diverse climate conditions. This analysis aims to quantify the impact of specific climate variables on evaporation rates, concentration gradients, and ultimate lithium recovery percentages. By establishing clear correlations between climate parameters and operational performance, we seek to develop predictive models that can optimize pond design and operational protocols for specific geographic locations.

Secondary objectives include identifying innovative technologies that can supplement traditional solar evaporation to mitigate climate-related inefficiencies, evaluating the environmental footprint of evaporation operations across different climate zones, and assessing the economic viability of implementing enhanced evaporation technologies in suboptimal climate regions. This research will provide valuable insights for strategic planning of future lithium extraction facilities and guide optimization efforts at existing operations facing climate-related challenges.

The evolution of lithium evaporation technology has been closely tied to growing global demand for lithium compounds, particularly driven by the rechargeable battery industry since the 1990s. Traditional evaporation methods typically achieve recovery rates of 40-50%, presenting significant opportunities for efficiency improvements. Recent technological innovations have focused on enhancing evaporation rates, reducing processing time, and minimizing freshwater consumption in these water-intensive operations.

Climate conditions play a crucial role in evaporation pond efficiency, with factors such as solar radiation, ambient temperature, humidity, wind speed, and precipitation patterns directly impacting evaporation rates and overall lithium recovery. The most productive lithium brine operations are strategically located in arid regions with high solar radiation and low precipitation, such as the "Lithium Triangle" spanning Chile, Argentina, and Bolivia, which currently accounts for approximately 58% of global lithium resources.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of lithium evaporation pond efficiency across diverse climate conditions. This analysis aims to quantify the impact of specific climate variables on evaporation rates, concentration gradients, and ultimate lithium recovery percentages. By establishing clear correlations between climate parameters and operational performance, we seek to develop predictive models that can optimize pond design and operational protocols for specific geographic locations.

Secondary objectives include identifying innovative technologies that can supplement traditional solar evaporation to mitigate climate-related inefficiencies, evaluating the environmental footprint of evaporation operations across different climate zones, and assessing the economic viability of implementing enhanced evaporation technologies in suboptimal climate regions. This research will provide valuable insights for strategic planning of future lithium extraction facilities and guide optimization efforts at existing operations facing climate-related challenges.

Global Market Demand for Lithium Resources

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Annual demand for lithium reached approximately 86,000 metric tons of lithium carbonate equivalent (LCE) in 2021, with projections indicating a potential surge to over 1.5 million metric tons by 2030, representing a compound annual growth rate exceeding 25%.

The EV sector remains the dominant consumer of lithium resources, accounting for nearly 74% of global lithium demand. This trend is expected to intensify as major automotive manufacturers worldwide commit to electrification targets, with several pledging to phase out internal combustion engines entirely within the next decade. Battery energy storage systems (BESS) constitute the second-largest demand segment at 15%, followed by consumer electronics at 8%.

Geographically, demand distribution shows significant concentration in Asia, particularly China, which currently consumes approximately 39% of global lithium production. Europe follows at 27%, with North America at 21%. However, recent policy initiatives such as the US Inflation Reduction Act and European Critical Raw Materials Act are expected to shift this distribution by incentivizing domestic battery production and resource security.

Supply-side dynamics reveal potential challenges in meeting projected demand growth. Current global lithium production capacity stands at approximately 540,000 metric tons LCE annually, with brine operations accounting for 66% and hard rock mining for 34%. Industry analysts project a potential supply deficit of 300,000 to 400,000 metric tons by 2025 if new production capacity is not developed rapidly.

Price volatility has characterized the lithium market, with spot prices for battery-grade lithium carbonate fluctuating between $8,000 and $80,000 per metric ton over the past five years. This volatility underscores the importance of developing more efficient extraction technologies, particularly for evaporation pond operations which currently dominate production in South America's "Lithium Triangle" comprising Chile, Argentina, and Bolivia.

The efficiency of evaporation pond operations under varying climate conditions has emerged as a critical factor in addressing supply constraints. Traditional evaporation methods require 18-24 months to concentrate lithium, with significant variations in yield depending on precipitation, temperature, and humidity levels. Enhancing evaporation pond efficiency could potentially increase global production capacity by 15-20% without requiring new resource discovery, making it a strategic priority for major producers.

The EV sector remains the dominant consumer of lithium resources, accounting for nearly 74% of global lithium demand. This trend is expected to intensify as major automotive manufacturers worldwide commit to electrification targets, with several pledging to phase out internal combustion engines entirely within the next decade. Battery energy storage systems (BESS) constitute the second-largest demand segment at 15%, followed by consumer electronics at 8%.

Geographically, demand distribution shows significant concentration in Asia, particularly China, which currently consumes approximately 39% of global lithium production. Europe follows at 27%, with North America at 21%. However, recent policy initiatives such as the US Inflation Reduction Act and European Critical Raw Materials Act are expected to shift this distribution by incentivizing domestic battery production and resource security.

Supply-side dynamics reveal potential challenges in meeting projected demand growth. Current global lithium production capacity stands at approximately 540,000 metric tons LCE annually, with brine operations accounting for 66% and hard rock mining for 34%. Industry analysts project a potential supply deficit of 300,000 to 400,000 metric tons by 2025 if new production capacity is not developed rapidly.

Price volatility has characterized the lithium market, with spot prices for battery-grade lithium carbonate fluctuating between $8,000 and $80,000 per metric ton over the past five years. This volatility underscores the importance of developing more efficient extraction technologies, particularly for evaporation pond operations which currently dominate production in South America's "Lithium Triangle" comprising Chile, Argentina, and Bolivia.

The efficiency of evaporation pond operations under varying climate conditions has emerged as a critical factor in addressing supply constraints. Traditional evaporation methods require 18-24 months to concentrate lithium, with significant variations in yield depending on precipitation, temperature, and humidity levels. Enhancing evaporation pond efficiency could potentially increase global production capacity by 15-20% without requiring new resource discovery, making it a strategic priority for major producers.

Current Evaporation Pond Technologies and Climate Challenges

Evaporation ponds represent the cornerstone technology in lithium brine extraction operations, functioning as large-scale solar concentrators that leverage natural evaporation to increase lithium concentration. Traditional pond systems typically consist of a series of interconnected shallow basins where brine progressively concentrates as it moves through the system. These ponds generally range from 0.5 to 2 meters in depth, with surface areas spanning several hectares to square kilometers depending on production capacity requirements.

The efficiency of evaporation ponds is heavily influenced by climate conditions, particularly solar radiation, ambient temperature, humidity, and wind patterns. In optimal arid environments like Chile's Atacama Desert, evaporation rates can reach 3,500 mm per year, allowing for relatively efficient concentration processes. However, in regions with seasonal rainfall or higher humidity, such as Argentina's Puna Plateau or China's Qinghai Province, evaporation rates may drop significantly, extending processing times from 12-18 months to 24 months or longer.

Recent technological innovations have emerged to address climate-related challenges. Enhanced evaporation systems incorporating wind barriers, selective covers, and optimized pond geometry have demonstrated 15-30% improvements in evaporation rates. Some operations have implemented pond liners with specialized thermal properties to increase heat absorption and retention, boosting nighttime evaporation efficiency by up to 20% in cooler climates.

Climate variability presents significant operational challenges for evaporation pond management. Unexpected rainfall events can dilute brines and introduce contaminants, while seasonal temperature fluctuations affect crystallization sequences of various salts. Data from major lithium operations indicates that production efficiency can vary by 25-40% between optimal and suboptimal seasons, necessitating adaptive management strategies.

Humidity levels critically impact evaporation rates, with each 10% increase in relative humidity potentially reducing evaporation efficiency by 5-8%. Wind patterns present a double-edged sword - moderate winds (3-7 m/s) enhance evaporation through increased air circulation, while excessive winds can cause operational disruptions including dust contamination and uneven brine distribution.

Advanced monitoring systems have become essential components of modern evaporation pond operations. Satellite imagery analysis, drone-based multispectral monitoring, and IoT sensor networks now enable real-time tracking of evaporation rates, brine chemistry, and weather conditions. These technologies allow operators to implement dynamic management protocols that adjust pond operations based on changing climate conditions, potentially reducing climate-related efficiency losses by 15-25%.

The industry is increasingly exploring hybrid systems that combine traditional evaporation ponds with mechanical or chemical concentration technologies to reduce climate dependency. These hybrid approaches, though more energy-intensive, provide greater operational stability across varying climate conditions and can reduce overall processing time by 30-50% compared to conventional evaporation-only methods.

The efficiency of evaporation ponds is heavily influenced by climate conditions, particularly solar radiation, ambient temperature, humidity, and wind patterns. In optimal arid environments like Chile's Atacama Desert, evaporation rates can reach 3,500 mm per year, allowing for relatively efficient concentration processes. However, in regions with seasonal rainfall or higher humidity, such as Argentina's Puna Plateau or China's Qinghai Province, evaporation rates may drop significantly, extending processing times from 12-18 months to 24 months or longer.

Recent technological innovations have emerged to address climate-related challenges. Enhanced evaporation systems incorporating wind barriers, selective covers, and optimized pond geometry have demonstrated 15-30% improvements in evaporation rates. Some operations have implemented pond liners with specialized thermal properties to increase heat absorption and retention, boosting nighttime evaporation efficiency by up to 20% in cooler climates.

Climate variability presents significant operational challenges for evaporation pond management. Unexpected rainfall events can dilute brines and introduce contaminants, while seasonal temperature fluctuations affect crystallization sequences of various salts. Data from major lithium operations indicates that production efficiency can vary by 25-40% between optimal and suboptimal seasons, necessitating adaptive management strategies.

Humidity levels critically impact evaporation rates, with each 10% increase in relative humidity potentially reducing evaporation efficiency by 5-8%. Wind patterns present a double-edged sword - moderate winds (3-7 m/s) enhance evaporation through increased air circulation, while excessive winds can cause operational disruptions including dust contamination and uneven brine distribution.

Advanced monitoring systems have become essential components of modern evaporation pond operations. Satellite imagery analysis, drone-based multispectral monitoring, and IoT sensor networks now enable real-time tracking of evaporation rates, brine chemistry, and weather conditions. These technologies allow operators to implement dynamic management protocols that adjust pond operations based on changing climate conditions, potentially reducing climate-related efficiency losses by 15-25%.

The industry is increasingly exploring hybrid systems that combine traditional evaporation ponds with mechanical or chemical concentration technologies to reduce climate dependency. These hybrid approaches, though more energy-intensive, provide greater operational stability across varying climate conditions and can reduce overall processing time by 30-50% compared to conventional evaporation-only methods.

Climate-Specific Evaporation Pond Solutions

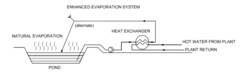

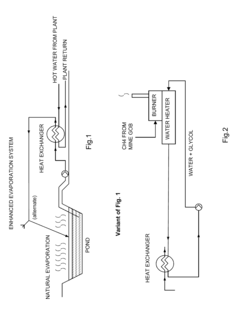

01 Enhanced evaporation systems for lithium extraction

Advanced evaporation systems can significantly improve the efficiency of lithium extraction from brine. These systems utilize specialized equipment and processes to accelerate evaporation rates, reducing the time required for lithium concentration. Technologies include solar-powered evaporation enhancers, optimized pond designs, and integrated evaporation systems that maximize surface area exposure while minimizing land usage. These enhancements can increase lithium recovery rates and reduce the overall production cycle.- Enhanced evaporation systems for lithium extraction: Advanced evaporation systems can significantly improve the efficiency of lithium extraction from brine. These systems utilize specialized equipment such as enhanced evaporators, heat exchangers, and circulation mechanisms to accelerate the natural evaporation process. By optimizing the evaporation rate, these systems reduce the time required for lithium concentration and increase overall yield from evaporation ponds. Some designs incorporate multi-stage evaporation processes that progressively concentrate the lithium brine through a series of controlled environments.

- Solar energy utilization in evaporation ponds: Solar energy plays a crucial role in improving the efficiency of lithium evaporation ponds. By optimizing pond design to maximize solar absorption, the natural evaporation process can be significantly enhanced. Techniques include using dark-colored pond liners to increase heat absorption, implementing solar collectors to concentrate energy, and designing pond geometry to maximize sun exposure throughout the day. Some systems incorporate solar-powered circulation systems that ensure even distribution of brine and prevent stratification, leading to more consistent evaporation rates across the pond surface.

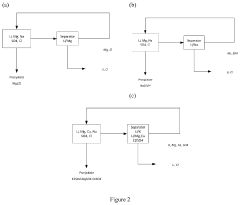

- Membrane and filtration technologies: Advanced membrane and filtration technologies can be integrated into evaporation pond systems to enhance lithium recovery efficiency. These technologies include selective membranes that allow for preferential extraction of lithium ions while excluding unwanted elements, pressure-driven filtration systems that accelerate the concentration process, and specialized adsorption materials that selectively capture lithium from brine solutions. By implementing these technologies, the overall processing time can be reduced while increasing the purity of the lithium compounds obtained from the evaporation process.

- Pond design and construction optimization: The physical design and construction of evaporation ponds significantly impact their efficiency in lithium extraction operations. Optimized designs include multi-compartment pond systems that allow for staged evaporation and concentration, specialized pond liners that prevent seepage and contamination, and engineered flow patterns that maximize surface area exposure. Some designs incorporate variable depths to control evaporation rates and implement wind barriers to reduce unwanted cooling effects. Proper pond sizing, orientation, and interconnection can dramatically improve the overall efficiency of the lithium concentration process.

- Monitoring and control systems for evaporation efficiency: Advanced monitoring and control systems play a crucial role in optimizing lithium evaporation pond efficiency. These systems utilize sensors to continuously track key parameters such as brine concentration, temperature, evaporation rate, and weather conditions. Automated control mechanisms can adjust flow rates, pond levels, and circulation patterns based on real-time data to maintain optimal evaporation conditions. Some systems incorporate predictive algorithms that account for weather forecasts to proactively manage the evaporation process. By implementing comprehensive monitoring and control systems, operators can maximize lithium recovery while minimizing resource consumption.

02 Temperature control and thermal management techniques

Temperature control systems play a crucial role in optimizing evaporation pond efficiency for lithium extraction. These techniques include thermal energy storage, heat exchange systems, and controlled heating mechanisms that maintain optimal temperature conditions regardless of ambient weather. By regulating temperature fluctuations, these systems ensure consistent evaporation rates throughout seasonal changes, improving the predictability and efficiency of the lithium concentration process.Expand Specific Solutions03 Brine circulation and distribution innovations

Innovative brine circulation and distribution systems enhance the efficiency of lithium evaporation ponds by ensuring optimal brine flow patterns. These systems include advanced pumping mechanisms, strategic distribution channels, and automated flow control systems that maintain ideal brine depths and concentration gradients. By optimizing brine movement throughout the pond network, these innovations promote uniform evaporation, prevent salt crystallization in undesired areas, and improve overall lithium recovery rates.Expand Specific Solutions04 Pond design and construction improvements

Advanced pond design and construction techniques significantly impact lithium evaporation efficiency. These improvements include specialized liner materials that enhance heat absorption, optimized pond geometry that maximizes sun exposure, and compartmentalized designs that facilitate sequential concentration. Strategic pond layouts with consideration for prevailing winds, solar angles, and land topography can substantially increase evaporation rates while reducing land requirements and environmental impact.Expand Specific Solutions05 Monitoring and automation systems for evaporation control

Sophisticated monitoring and automation systems enable precise control of the lithium evaporation process. These technologies include sensor networks that track brine concentration, temperature, and weather conditions in real-time, coupled with automated response systems that adjust operational parameters accordingly. Advanced analytics and predictive modeling help optimize the evaporation schedule, while automated brine transfer systems ensure timely movement between ponds based on concentration levels, significantly improving overall efficiency and lithium yield.Expand Specific Solutions

Major Lithium Producers and Competitive Landscape

The lithium mine evaporation pond efficiency market is currently in a growth phase, with increasing demand driven by the global electric vehicle boom. The market size is expanding rapidly, projected to reach significant scale as lithium demand triples by 2025. Technologically, the sector is transitioning from traditional evaporation methods to more advanced extraction techniques. Companies like Energy Exploration Technologies and Novalith Technologies are pioneering direct lithium extraction technologies that reduce environmental impact and processing time compared to conventional evaporation ponds. Meanwhile, established players such as POSCO Holdings and BYD are investing in research to optimize evaporation efficiency under various climate conditions. International Battery Metals and Schlumberger are developing hybrid approaches that combine traditional evaporation with advanced filtration systems, demonstrating the industry's evolution toward more climate-adaptive extraction methods.

Energy Exploration Technologies, Inc.

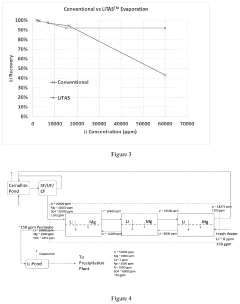

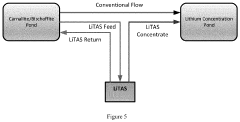

Technical Solution: Energy Exploration Technologies (EnergyX) has developed a proprietary Direct Lithium Extraction (DLE) technology called LiTAS (Lithium Ion Transport and Separation) that significantly reduces evaporation pond dependency. Their system uses a specialized membrane technology that selectively extracts lithium ions from brine solutions regardless of climate conditions. The technology can operate in various temperatures and humidity levels, making it adaptable across different geographical regions. EnergyX's approach reduces water consumption by over 90% compared to traditional evaporation ponds, while increasing lithium recovery rates to more than 90% (versus 30-40% in conventional methods). Their modular system design allows for scalable implementation and can be integrated with existing operations to enhance efficiency in various climate zones.

Strengths: Climate-independent operation allowing year-round production; significantly reduced water footprint; higher lithium recovery rates; modular and scalable design. Weaknesses: Higher initial capital investment compared to traditional evaporation ponds; requires specialized maintenance expertise; energy requirements may be higher than passive evaporation systems.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: The Qinghai Institute of Salt Lakes has developed advanced evaporation pond technologies specifically optimized for the unique high-altitude, cold climate conditions of the Qinghai-Tibet Plateau, home to China's largest lithium brine resources. Their approach combines traditional solar evaporation with innovative pond design modifications including specialized heat-absorbing materials and optimized pond depth configurations that enhance thermal efficiency. The institute has pioneered multi-stage evaporation systems with selective crystallization pathways that improve lithium concentration even during colder months. Their research has led to the implementation of semi-transparent covers that create greenhouse effects while allowing solar radiation penetration, extending the effective evaporation season by approximately 30%. Additionally, they've developed specialized anti-freezing additives that lower the freezing point of brine solutions, enabling continued operation during winter months when conventional ponds would freeze. The institute has also created computational fluid dynamics models that predict evaporation rates under various climate scenarios, allowing for adaptive management of brine circulation and residence time optimization based on seasonal conditions.

Strengths: Specialized expertise in cold climate lithium extraction; integration of traditional methods with innovative technologies; locally optimized solutions for China's largest lithium resources; comprehensive climate modeling capabilities. Weaknesses: Solutions may be geographically specific to high-altitude, cold regions; some technologies may require significant energy inputs; potential environmental concerns with chemical additives; may still face seasonal production fluctuations despite improvements.

Technical Analysis of Evaporation Efficiency Factors

Method for increasing evaporation rate of an evaporative pond

PatentActiveUS20140174673A1

Innovation

- A method involving heating the pond liquor with low temperature heat or waste heat and spraying it into the evaporative pond using a spraying device, maintaining an operating temperature at least 10°C above ambient air temperature to enhance evaporation, while minimizing clogging through controlled sodium carbonate and bicarbonate concentrations and sequential over-heating.

Systems and Methods for Recovering Lithium from Brines Field

PatentPendingUS20240067530A1

Innovation

- Implementing a system with a sequence of solar evaporation ponds and a selective ion separation membrane to separate lithium from impurities, recycling the high impurity stream back into the evaporation sequence and processing the low impurity stream further to minimize lithium co-precipitation losses, thereby increasing lithium recovery and reducing environmental impact.

Environmental Impact Assessment of Evaporation Technologies

The environmental impact of evaporation technologies in lithium mining operations varies significantly across different climate conditions, necessitating comprehensive assessment to ensure sustainable extraction practices. Traditional solar evaporation ponds, while energy-efficient, occupy vast land areas and can significantly alter local ecosystems. In arid regions like the Atacama Desert in Chile, these ponds may disrupt fragile desert habitats and endemic species adapted to these unique environments.

Water consumption represents a critical environmental concern, particularly in water-stressed regions. Evaporation ponds can consume substantial quantities of groundwater, potentially depleting aquifers and affecting surrounding communities and ecosystems. The severity of this impact varies dramatically between humid climates, where natural precipitation may partially offset consumption, and arid regions where water resources are inherently scarce and slow to replenish.

Chemical contamination presents another significant environmental risk. Evaporation processes concentrate various salts and potentially toxic elements that may leach into surrounding soil and groundwater systems. Different climate conditions affect the rate and extent of this contamination, with higher precipitation areas facing increased risks of overflow and leaching during storm events.

Greenhouse gas emissions associated with evaporation technologies must also be considered in environmental impact assessments. While solar evaporation itself produces minimal direct emissions, the energy required for pumping, maintenance, and subsequent processing contributes to the carbon footprint. Climate conditions directly influence energy requirements, with colder regions often necessitating supplemental heating that increases emissions.

Biodiversity impacts vary substantially across climate zones. In tropical and temperate regions, evaporation ponds may disrupt migration patterns and breeding grounds for various species. Conversely, in certain arid environments, these artificial water bodies occasionally create novel habitats for some species, though this rarely compensates for broader ecosystem disruption.

Emerging enhanced evaporation technologies offer potential pathways to reduce environmental impacts through decreased land requirements and water consumption. However, these technologies often demand greater energy inputs, creating complex environmental trade-offs that must be evaluated within specific climatic contexts. Comprehensive life-cycle assessments that account for regional climate variations are essential for accurately determining the full environmental implications of different evaporation approaches in lithium extraction operations.

Water consumption represents a critical environmental concern, particularly in water-stressed regions. Evaporation ponds can consume substantial quantities of groundwater, potentially depleting aquifers and affecting surrounding communities and ecosystems. The severity of this impact varies dramatically between humid climates, where natural precipitation may partially offset consumption, and arid regions where water resources are inherently scarce and slow to replenish.

Chemical contamination presents another significant environmental risk. Evaporation processes concentrate various salts and potentially toxic elements that may leach into surrounding soil and groundwater systems. Different climate conditions affect the rate and extent of this contamination, with higher precipitation areas facing increased risks of overflow and leaching during storm events.

Greenhouse gas emissions associated with evaporation technologies must also be considered in environmental impact assessments. While solar evaporation itself produces minimal direct emissions, the energy required for pumping, maintenance, and subsequent processing contributes to the carbon footprint. Climate conditions directly influence energy requirements, with colder regions often necessitating supplemental heating that increases emissions.

Biodiversity impacts vary substantially across climate zones. In tropical and temperate regions, evaporation ponds may disrupt migration patterns and breeding grounds for various species. Conversely, in certain arid environments, these artificial water bodies occasionally create novel habitats for some species, though this rarely compensates for broader ecosystem disruption.

Emerging enhanced evaporation technologies offer potential pathways to reduce environmental impacts through decreased land requirements and water consumption. However, these technologies often demand greater energy inputs, creating complex environmental trade-offs that must be evaluated within specific climatic contexts. Comprehensive life-cycle assessments that account for regional climate variations are essential for accurately determining the full environmental implications of different evaporation approaches in lithium extraction operations.

Water Conservation Strategies in Lithium Extraction

Water conservation has become a critical concern in lithium extraction processes, particularly in evaporation pond operations where significant water losses occur. Traditional lithium brine extraction methods typically consume between 500,000 to 2 million gallons of water per ton of lithium produced, creating substantial environmental pressure in water-scarce regions where lithium deposits are often located.

Climate conditions significantly impact water conservation strategies in evaporation ponds. In high-temperature, low-humidity environments like Chile's Atacama Desert, evaporation rates can exceed 3,500 mm annually, accelerating lithium concentration but exacerbating water loss. Conversely, operations in more moderate climates face reduced evaporation efficiency but present opportunities for improved water management.

Advanced pond covering technologies have emerged as promising solutions across different climate zones. Selective covers that allow solar radiation while reducing evaporation can decrease water losses by 30-40% in high-evaporation regions. These systems must be engineered differently based on local wind patterns, precipitation levels, and temperature fluctuations to maximize effectiveness.

Closed-loop water recycling systems represent another significant advancement, with potential water recovery rates of 85-95%. These systems are particularly valuable in arid regions where lithium operations compete with agricultural and community water needs. Implementation costs vary substantially based on climate conditions, with higher initial investment required in extreme environments but potentially greater long-term returns.

Direct lithium extraction (DLE) technologies are revolutionizing water conservation approaches by potentially reducing water consumption by 50-90% compared to traditional evaporation methods. These technologies perform differently across climate zones, with some showing enhanced efficiency in moderate climates while others are specifically designed for extreme conditions.

Hybrid systems combining conventional evaporation with mechanical concentration techniques offer tailored solutions for specific climate challenges. In regions with seasonal climate variations, these systems can adapt operations to maximize water conservation throughout the year, potentially improving overall water efficiency by 40-60% compared to traditional methods.

The economic viability of water conservation strategies varies significantly with climate conditions, with ROI timelines ranging from 2-7 years depending on local water costs, regulatory frameworks, and climate-related operational challenges.

Climate conditions significantly impact water conservation strategies in evaporation ponds. In high-temperature, low-humidity environments like Chile's Atacama Desert, evaporation rates can exceed 3,500 mm annually, accelerating lithium concentration but exacerbating water loss. Conversely, operations in more moderate climates face reduced evaporation efficiency but present opportunities for improved water management.

Advanced pond covering technologies have emerged as promising solutions across different climate zones. Selective covers that allow solar radiation while reducing evaporation can decrease water losses by 30-40% in high-evaporation regions. These systems must be engineered differently based on local wind patterns, precipitation levels, and temperature fluctuations to maximize effectiveness.

Closed-loop water recycling systems represent another significant advancement, with potential water recovery rates of 85-95%. These systems are particularly valuable in arid regions where lithium operations compete with agricultural and community water needs. Implementation costs vary substantially based on climate conditions, with higher initial investment required in extreme environments but potentially greater long-term returns.

Direct lithium extraction (DLE) technologies are revolutionizing water conservation approaches by potentially reducing water consumption by 50-90% compared to traditional evaporation methods. These technologies perform differently across climate zones, with some showing enhanced efficiency in moderate climates while others are specifically designed for extreme conditions.

Hybrid systems combining conventional evaporation with mechanical concentration techniques offer tailored solutions for specific climate challenges. In regions with seasonal climate variations, these systems can adapt operations to maximize water conservation throughout the year, potentially improving overall water efficiency by 40-60% compared to traditional methods.

The economic viability of water conservation strategies varies significantly with climate conditions, with ROI timelines ranging from 2-7 years depending on local water costs, regulatory frameworks, and climate-related operational challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!