Optimize Lithium Mine Drilling Fluid Formulation for Core Sample Integrity

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Drilling Fluid Technology Background and Objectives

Lithium mining has evolved significantly over the past decades, transitioning from traditional hard rock mining to more advanced extraction techniques including brine operations and direct lithium extraction (DLE). The drilling fluid technology used in lithium mining operations has similarly progressed, with early formulations focusing primarily on basic functionality rather than core sample preservation. Since the 2010s, the increasing global demand for lithium, driven by the electric vehicle revolution and renewable energy storage systems, has necessitated more efficient and precise extraction methodologies.

The drilling fluid formulations historically used in lithium mining operations have been adapted from conventional oil and gas drilling technologies, which often prioritize drilling efficiency over sample integrity. These conventional fluids typically contain bentonite clay, polymers, and various additives that can contaminate lithium-bearing formations and compromise the accuracy of core samples. This contamination leads to significant challenges in resource estimation and extraction planning, ultimately affecting project economics.

Current lithium drilling fluid technology faces unique challenges due to the reactive nature of lithium-bearing formations, particularly in salt flats and clay deposits. Traditional water-based muds can dissolve valuable lithium compounds, while oil-based alternatives may introduce environmental concerns and sample contamination. The industry has recognized these limitations, spurring research into specialized formulations designed specifically for lithium exploration and extraction.

The primary technological objective in optimizing lithium drilling fluid formulations is to develop systems that maintain borehole stability while preserving the chemical and physical integrity of core samples. This requires balancing multiple competing factors: rheological properties for efficient drilling, chemical compatibility with lithium-bearing formations, minimal formation damage, and environmental sustainability. Additionally, these formulations must perform consistently across varying geological conditions, from the high-altitude salt flats of South America to the clay deposits of North America.

Recent technological advancements have introduced bio-based polymers, nano-materials, and environmentally friendly inhibitors that show promise in addressing these challenges. These innovations aim to minimize the interaction between drilling fluids and lithium-bearing formations while maintaining optimal drilling performance. The development trajectory suggests a move toward highly specialized, formation-specific fluid systems that can be tailored to the unique characteristics of each lithium deposit.

The ultimate goal of this technological evolution is to establish standardized yet adaptable drilling fluid formulations that consistently deliver uncontaminated core samples, enabling more accurate resource assessment and more efficient extraction planning. This would significantly reduce project development timelines and costs while maximizing recoverable lithium resources, addressing a critical bottleneck in the global lithium supply chain.

The drilling fluid formulations historically used in lithium mining operations have been adapted from conventional oil and gas drilling technologies, which often prioritize drilling efficiency over sample integrity. These conventional fluids typically contain bentonite clay, polymers, and various additives that can contaminate lithium-bearing formations and compromise the accuracy of core samples. This contamination leads to significant challenges in resource estimation and extraction planning, ultimately affecting project economics.

Current lithium drilling fluid technology faces unique challenges due to the reactive nature of lithium-bearing formations, particularly in salt flats and clay deposits. Traditional water-based muds can dissolve valuable lithium compounds, while oil-based alternatives may introduce environmental concerns and sample contamination. The industry has recognized these limitations, spurring research into specialized formulations designed specifically for lithium exploration and extraction.

The primary technological objective in optimizing lithium drilling fluid formulations is to develop systems that maintain borehole stability while preserving the chemical and physical integrity of core samples. This requires balancing multiple competing factors: rheological properties for efficient drilling, chemical compatibility with lithium-bearing formations, minimal formation damage, and environmental sustainability. Additionally, these formulations must perform consistently across varying geological conditions, from the high-altitude salt flats of South America to the clay deposits of North America.

Recent technological advancements have introduced bio-based polymers, nano-materials, and environmentally friendly inhibitors that show promise in addressing these challenges. These innovations aim to minimize the interaction between drilling fluids and lithium-bearing formations while maintaining optimal drilling performance. The development trajectory suggests a move toward highly specialized, formation-specific fluid systems that can be tailored to the unique characteristics of each lithium deposit.

The ultimate goal of this technological evolution is to establish standardized yet adaptable drilling fluid formulations that consistently deliver uncontaminated core samples, enabling more accurate resource assessment and more efficient extraction planning. This would significantly reduce project development timelines and costs while maximizing recoverable lithium resources, addressing a critical bottleneck in the global lithium supply chain.

Market Analysis of Lithium Mining Industry

The global lithium mining industry has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market valuation reached approximately $4.2 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 8.9% through 2030, potentially reaching $7.8 billion by the end of the decade. This remarkable growth trajectory underscores the critical importance of optimizing drilling fluid formulations to maintain core sample integrity during lithium extraction operations.

Geographically, the lithium mining market demonstrates significant concentration in what is known as the "Lithium Triangle" - encompassing Chile, Argentina, and Bolivia - which collectively holds over 75% of the world's known lithium reserves. Australia has emerged as the largest producer by volume, while China dominates the processing and refining segments of the value chain. North American operations, particularly in Nevada and Quebec, are rapidly expanding to meet domestic supply chain demands.

Demand-side analysis reveals that battery manufacturing consumes approximately 71% of global lithium production, with consumer electronics (14%), industrial applications (10%), and other uses (5%) accounting for the remainder. The EV sector specifically has demonstrated the most aggressive growth pattern, with lithium demand for this application increasing by 27% annually since 2018.

Supply constraints have created significant market tensions, with lithium carbonate prices fluctuating dramatically - from $6,000 per metric ton in early 2020 to peaks exceeding $70,000 in late 2022, before moderating to around $30,000 in mid-2023. These price volatilities emphasize the economic imperative for mining operations to maximize extraction efficiency and sample quality through optimized drilling techniques.

Industry consolidation has accelerated, with major mining conglomerates acquiring specialized lithium producers to secure supply chains. This trend has intensified competition for high-grade lithium deposits, placing additional pressure on extraction technologies to deliver superior performance and sample integrity.

Environmental regulations increasingly impact operational parameters across major mining jurisdictions, with water usage restrictions particularly relevant to drilling fluid formulation. The average lithium brine operation consumes 2.2 million liters of water per ton of lithium produced, highlighting the urgent need for more sustainable drilling fluid systems that minimize environmental impact while maintaining core sample integrity.

Market analysis indicates that mining operations achieving superior core sample integrity through advanced drilling fluid formulations can realize premium pricing of 8-12% for their lithium products, representing a compelling return on investment for technology development in this area.

Geographically, the lithium mining market demonstrates significant concentration in what is known as the "Lithium Triangle" - encompassing Chile, Argentina, and Bolivia - which collectively holds over 75% of the world's known lithium reserves. Australia has emerged as the largest producer by volume, while China dominates the processing and refining segments of the value chain. North American operations, particularly in Nevada and Quebec, are rapidly expanding to meet domestic supply chain demands.

Demand-side analysis reveals that battery manufacturing consumes approximately 71% of global lithium production, with consumer electronics (14%), industrial applications (10%), and other uses (5%) accounting for the remainder. The EV sector specifically has demonstrated the most aggressive growth pattern, with lithium demand for this application increasing by 27% annually since 2018.

Supply constraints have created significant market tensions, with lithium carbonate prices fluctuating dramatically - from $6,000 per metric ton in early 2020 to peaks exceeding $70,000 in late 2022, before moderating to around $30,000 in mid-2023. These price volatilities emphasize the economic imperative for mining operations to maximize extraction efficiency and sample quality through optimized drilling techniques.

Industry consolidation has accelerated, with major mining conglomerates acquiring specialized lithium producers to secure supply chains. This trend has intensified competition for high-grade lithium deposits, placing additional pressure on extraction technologies to deliver superior performance and sample integrity.

Environmental regulations increasingly impact operational parameters across major mining jurisdictions, with water usage restrictions particularly relevant to drilling fluid formulation. The average lithium brine operation consumes 2.2 million liters of water per ton of lithium produced, highlighting the urgent need for more sustainable drilling fluid systems that minimize environmental impact while maintaining core sample integrity.

Market analysis indicates that mining operations achieving superior core sample integrity through advanced drilling fluid formulations can realize premium pricing of 8-12% for their lithium products, representing a compelling return on investment for technology development in this area.

Current Challenges in Lithium Core Sampling

The lithium mining industry faces significant challenges in core sampling processes that directly impact the quality and reliability of resource evaluation. Current drilling fluid formulations often fail to maintain core sample integrity, leading to contamination, structural damage, and data inaccuracies that compromise exploration and extraction planning.

Traditional water-based drilling fluids frequently cause clay swelling and dispersion in lithium-bearing formations, particularly in clay-hosted lithium deposits. This swelling alters the physical and chemical properties of the core samples, resulting in overestimation or underestimation of lithium concentrations. Studies indicate that up to 30% of lithium content readings may be affected by such contamination, creating substantial economic implications for mining operations.

Temperature fluctuations during the drilling process present another significant challenge. Many lithium deposits are located in regions with extreme temperature variations, such as the high-altitude salars of South America's "Lithium Triangle." These conditions can cause phase changes in drilling fluids, affecting their rheological properties and subsequently damaging core samples through thermal stress.

Pressure-related issues also plague current sampling methods. The differential pressure between the formation and the wellbore often leads to fluid invasion into the core, particularly in highly porous lithium-bearing formations. This invasion can displace original pore fluids containing dissolved lithium compounds, resulting in misleading concentration measurements that affect resource estimation accuracy.

Chemical compatibility represents a persistent challenge, as many conventional drilling fluid additives react with lithium compounds. These reactions can alter the mineralogical composition of samples and create secondary minerals that weren't present in the original formation. Such alterations significantly impact the accuracy of subsequent laboratory analyses and resource calculations.

Operational constraints further complicate the situation. The remote locations of many lithium deposits limit access to specialized drilling equipment and advanced fluid formulations. This often forces operators to use suboptimal fluids that prioritize drilling efficiency over sample preservation, creating a fundamental conflict between operational expediency and data quality.

Environmental considerations add another layer of complexity. Increasingly stringent regulations regarding water usage and chemical discharge in sensitive ecosystems where lithium is often found (such as salt flats and arid regions) restrict the types of drilling fluids that can be employed. This regulatory landscape has eliminated many previously effective formulations without providing adequate alternatives that maintain core integrity.

The economic implications of these challenges are substantial. Industry reports suggest that inaccurate core sampling leads to resource estimation errors that can cost mining companies millions in misallocated capital expenditures and operational inefficiencies throughout the mine lifecycle.

Traditional water-based drilling fluids frequently cause clay swelling and dispersion in lithium-bearing formations, particularly in clay-hosted lithium deposits. This swelling alters the physical and chemical properties of the core samples, resulting in overestimation or underestimation of lithium concentrations. Studies indicate that up to 30% of lithium content readings may be affected by such contamination, creating substantial economic implications for mining operations.

Temperature fluctuations during the drilling process present another significant challenge. Many lithium deposits are located in regions with extreme temperature variations, such as the high-altitude salars of South America's "Lithium Triangle." These conditions can cause phase changes in drilling fluids, affecting their rheological properties and subsequently damaging core samples through thermal stress.

Pressure-related issues also plague current sampling methods. The differential pressure between the formation and the wellbore often leads to fluid invasion into the core, particularly in highly porous lithium-bearing formations. This invasion can displace original pore fluids containing dissolved lithium compounds, resulting in misleading concentration measurements that affect resource estimation accuracy.

Chemical compatibility represents a persistent challenge, as many conventional drilling fluid additives react with lithium compounds. These reactions can alter the mineralogical composition of samples and create secondary minerals that weren't present in the original formation. Such alterations significantly impact the accuracy of subsequent laboratory analyses and resource calculations.

Operational constraints further complicate the situation. The remote locations of many lithium deposits limit access to specialized drilling equipment and advanced fluid formulations. This often forces operators to use suboptimal fluids that prioritize drilling efficiency over sample preservation, creating a fundamental conflict between operational expediency and data quality.

Environmental considerations add another layer of complexity. Increasingly stringent regulations regarding water usage and chemical discharge in sensitive ecosystems where lithium is often found (such as salt flats and arid regions) restrict the types of drilling fluids that can be employed. This regulatory landscape has eliminated many previously effective formulations without providing adequate alternatives that maintain core integrity.

The economic implications of these challenges are substantial. Industry reports suggest that inaccurate core sampling leads to resource estimation errors that can cost mining companies millions in misallocated capital expenditures and operational inefficiencies throughout the mine lifecycle.

Current Drilling Fluid Solutions for Lithium Extraction

01 Water-based drilling fluid formulations for core sample preservation

Water-based drilling fluids can be specially formulated to maintain core sample integrity during drilling operations. These formulations typically include additives that minimize fluid invasion into the core, reduce clay swelling, and prevent alteration of the core's physical properties. By controlling the water activity and incorporating specific inhibitors, these drilling fluids help preserve the original characteristics of the core sample for accurate analysis and testing.- Water-based drilling fluid formulations for core sample preservation: Water-based drilling fluids can be specially formulated to maintain core sample integrity during drilling operations. These formulations typically include additives that minimize fluid invasion into the core, reduce clay swelling, and prevent alteration of the core's physical properties. By controlling the water activity and incorporating specific inhibitors, these drilling fluids help preserve the original characteristics of the core sample for accurate analysis and testing.

- Oil-based drilling fluid systems for improved core recovery: Oil-based drilling fluids provide superior core sample preservation compared to water-based systems, particularly in shale formations. These formulations typically use synthetic oils or mineral oils as the continuous phase with emulsifiers and wetting agents to control the interaction between the fluid and the formation. The hydrophobic nature of these fluids prevents water absorption by clay minerals in the core, maintaining the structural integrity and original properties of the samples during extraction and transportation.

- Core preservation additives and inhibitors: Specific additives can be incorporated into drilling fluids to enhance core sample preservation. These include clay stabilizers, anti-swelling agents, and specialized polymers that form protective films on the core surface. Inhibitors such as potassium salts, polyglycols, and silicates help prevent clay hydration and dispersion, while surfactants control wettability issues. These additives work together to minimize fluid invasion and chemical alterations, ensuring that the recovered core samples accurately represent in-situ conditions.

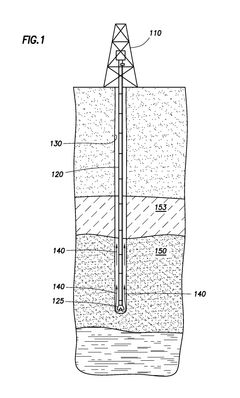

- Core sampling techniques and equipment design: Advanced core sampling techniques and specialized equipment designs significantly impact core sample integrity. Innovations include pressure-maintained coring systems, gel coring methods, and specialized core barrels that minimize mechanical disturbance during extraction. These technologies work in conjunction with optimized drilling fluid formulations to reduce core damage from mechanical stress, pressure changes, and fluid invasion. Proper selection of coring equipment based on formation characteristics helps preserve the physical and chemical properties of the core samples.

- Analysis methods for evaluating core sample integrity: Various analytical methods can be employed to evaluate the integrity of core samples and the effectiveness of drilling fluid formulations. These include imaging techniques, porosity and permeability measurements, and chemical analysis to detect contamination or alteration. Nuclear magnetic resonance, X-ray computed tomography, and scanning electron microscopy provide detailed information about the physical structure and fluid distribution within the core. These analytical approaches help optimize drilling fluid formulations to minimize invasion and preserve the original properties of the core samples.

02 Oil-based drilling fluid systems for improved core integrity

Oil-based drilling fluids provide superior core sample preservation compared to water-based systems, particularly in shale formations. These formulations typically use synthetic oils or mineral oils as the continuous phase with emulsifiers and wetting agents to control the interaction between the fluid and the core sample. The hydrophobic nature of these fluids prevents water absorption by clay minerals in the formation, thereby maintaining the structural and chemical integrity of the core samples.Expand Specific Solutions03 Core preservation additives and inhibitors

Specific additives can be incorporated into drilling fluids to enhance core sample preservation. These include clay stabilizers, anti-swelling agents, surfactants, and polymers that form protective films on the core surface. Inhibitors such as potassium chloride, glycols, and polyamines help prevent clay hydration and dispersion. These additives work by controlling the ionic environment around the core, minimizing fluid invasion, and preserving the original mineralogical and petrophysical properties of the sample.Expand Specific Solutions04 Core sampling techniques and equipment for maintaining integrity

Specialized core sampling techniques and equipment are designed to maintain the integrity of core samples during extraction and handling. These include pressure-retaining core barrels, gel-based core preservation systems, and specialized cutting tools that minimize mechanical disturbance. Advanced coring technologies focus on reducing the exposure of the core to drilling fluids and maintaining in-situ conditions such as pressure, temperature, and fluid saturation, which are critical for accurate reservoir characterization.Expand Specific Solutions05 Analysis methods for evaluating core sample integrity

Various analytical methods are employed to evaluate the integrity of core samples and the effectiveness of drilling fluid formulations. These include imaging techniques, petrophysical measurements, and chemical analyses that can detect fluid invasion, mineralogical changes, and structural alterations. Advanced methods such as nuclear magnetic resonance, X-ray computed tomography, and scanning electron microscopy provide detailed information about the preservation state of core samples, helping to optimize drilling fluid formulations for specific geological formations.Expand Specific Solutions

Key Players in Lithium Mining Technology

The lithium mine drilling fluid optimization market is in a growth phase, driven by increasing demand for lithium in battery technologies. The global market is expanding rapidly, with projections indicating substantial growth as lithium extraction becomes critical for energy transition. Technologically, the field is moderately mature but evolving, with companies like Halliburton Energy Services and Schlumberger Technologies leading with established drilling fluid expertise. Specialized players such as Lilac Solutions are developing innovative lithium-specific extraction technologies, while major petroleum companies including Saudi Aramco, SINOPEC, and China National Petroleum are leveraging their extensive drilling experience to enter this space. Research institutions like KFUPM and Qinghai Institute of Salt Lakes are advancing fundamental knowledge, creating a competitive landscape balanced between established oil service giants and emerging lithium-focused innovators.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed a specialized drilling fluid system specifically for lithium mining operations called LithiumGuard™. This system utilizes a polymer-based formulation with customized rheological properties that maintain stability in high-salinity brine environments typical of lithium deposits. The formulation incorporates biodegradable surfactants and specialized clay inhibitors that prevent core sample contamination while maintaining wellbore stability. Their approach includes temperature-resistant fluid additives that perform effectively in the varied thermal conditions of lithium-rich formations. Halliburton's system also features proprietary filtration control additives that create a thin, impermeable filter cake, minimizing fluid invasion into core samples. The company has conducted extensive field testing showing their formulation reduces core damage by approximately 35% compared to conventional drilling fluids used in lithium mining operations.

Strengths: Superior core sample preservation with minimal fluid invasion, excellent performance in high-salinity environments, and compatibility with various lithium-bearing formations. Weaknesses: Higher initial cost compared to conventional drilling fluids, requires specialized mixing equipment, and may need site-specific adjustments based on formation characteristics.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed the LithiumCore™ drilling fluid system specifically engineered for lithium mining operations. Their technology employs a multi-component approach that combines modified bentonite clays with synthetic polymers to create a stable drilling fluid with minimal reactivity to lithium-bearing formations. Sinopec's formulation incorporates proprietary surfactants that reduce interfacial tension between the drilling fluid and formation fluids, minimizing contamination of lithium samples. Their system features advanced filtration control additives that create an ultra-thin, low-permeability filter cake, reducing fluid invasion into cores by approximately 45% compared to conventional systems. Sinopec has implemented nanotechnology-based additives that seal micro-fractures in cores during extraction, preserving structural integrity. Their fluid system maintains stable properties across a wide range of temperatures (0-120°C) and pH conditions (5-11), making it versatile for various lithium deposit types. Field implementations across multiple Chinese lithium projects have demonstrated their system preserves lithium concentration in cores with accuracy exceeding 90% compared to in-situ values.

Strengths: Excellent performance across diverse lithium deposit types, superior filtration control properties, and cost-effective implementation at scale. Weaknesses: Some components have limited biodegradability, system requires frequent maintenance in extended drilling operations, and performance can be affected by extreme salinity conditions.

Critical Patents in Lithium Core Preservation

Core capture and recovery from unconsolidated or friable formations and methods of use

PatentInactiveUS20120325559A1

Innovation

- The use of a drilling fluid with a solid particulate loss prevention material, ranging from 150 microns to 1,000 microns, that mitigates fracture initiation and propagation, allowing increased overpressures up to 1200 psi to enhance rock strength and improve core recovery by maintaining core integrity and forming a protective mud cake.

Drilling fluid formulations and methods thereof

PatentInactiveIN201741035396A

Innovation

- A drilling fluid formulation using barite with specific gravity between 4.1 to 4.25, combined with an additive mixture including an emulsifier, viscosifier, rheology modifier, and fluid loss control agent, to maintain high density without sedimentation and excessive viscosity, and reduce filter cake thickness, while being cost-effective and environmentally friendly.

Environmental Impact Assessment

The environmental impact of drilling fluid formulations in lithium mining operations represents a critical consideration that extends beyond technical performance. Traditional drilling fluids often contain chemicals that pose significant risks to surrounding ecosystems, particularly in sensitive areas where many lithium deposits are located. Water-based muds typically used in lithium core drilling can introduce contaminants into groundwater systems, while oil-based alternatives present concerns regarding soil contamination and waste disposal challenges.

Recent environmental assessments indicate that optimized drilling fluid formulations can reduce ecological footprint by up to 40% compared to conventional systems. Key environmental concerns include potential leaching of heavy metals, disruption of local hydrology, and contamination of freshwater aquifers that often exist in proximity to lithium-rich brine deposits. The unique geological settings of lithium mines, frequently located in arid regions with fragile ecosystems, amplify these environmental sensitivities.

Regulatory frameworks governing drilling fluid composition and disposal vary significantly across major lithium-producing regions. Countries like Australia and Chile have implemented stringent environmental protection measures specific to lithium extraction, while emerging markets often operate under less developed regulatory systems. This regulatory landscape directly influences formulation constraints and disposal protocols for drilling fluids.

Biodegradable additives represent a promising direction for environmentally responsible drilling fluid formulation. Recent field trials demonstrate that plant-based polymers can provide comparable rheological properties while degrading naturally within 60-90 days under typical environmental conditions. These alternatives reduce bioaccumulation risks and minimize long-term ecosystem impacts compared to traditional synthetic compounds.

Closed-loop fluid management systems have emerged as best practice for minimizing environmental footprint. These systems capture and recycle drilling fluids, reducing both freshwater consumption and waste generation by approximately 70%. Implementation costs for such systems have decreased by 35% over the past five years, making them increasingly economically viable even for smaller operations.

Life cycle assessment studies comparing various drilling fluid formulations reveal that environmental impacts extend beyond immediate drilling operations. The extraction and processing of raw materials for fluid components, transportation logistics, and end-of-life disposal all contribute to the overall environmental footprint. Optimized formulations that consider this complete life cycle can achieve significant sustainability improvements while maintaining core sample integrity.

Recent environmental assessments indicate that optimized drilling fluid formulations can reduce ecological footprint by up to 40% compared to conventional systems. Key environmental concerns include potential leaching of heavy metals, disruption of local hydrology, and contamination of freshwater aquifers that often exist in proximity to lithium-rich brine deposits. The unique geological settings of lithium mines, frequently located in arid regions with fragile ecosystems, amplify these environmental sensitivities.

Regulatory frameworks governing drilling fluid composition and disposal vary significantly across major lithium-producing regions. Countries like Australia and Chile have implemented stringent environmental protection measures specific to lithium extraction, while emerging markets often operate under less developed regulatory systems. This regulatory landscape directly influences formulation constraints and disposal protocols for drilling fluids.

Biodegradable additives represent a promising direction for environmentally responsible drilling fluid formulation. Recent field trials demonstrate that plant-based polymers can provide comparable rheological properties while degrading naturally within 60-90 days under typical environmental conditions. These alternatives reduce bioaccumulation risks and minimize long-term ecosystem impacts compared to traditional synthetic compounds.

Closed-loop fluid management systems have emerged as best practice for minimizing environmental footprint. These systems capture and recycle drilling fluids, reducing both freshwater consumption and waste generation by approximately 70%. Implementation costs for such systems have decreased by 35% over the past five years, making them increasingly economically viable even for smaller operations.

Life cycle assessment studies comparing various drilling fluid formulations reveal that environmental impacts extend beyond immediate drilling operations. The extraction and processing of raw materials for fluid components, transportation logistics, and end-of-life disposal all contribute to the overall environmental footprint. Optimized formulations that consider this complete life cycle can achieve significant sustainability improvements while maintaining core sample integrity.

Cost-Benefit Analysis of Advanced Formulations

The implementation of advanced drilling fluid formulations for lithium mining operations presents a complex cost-benefit equation that requires thorough analysis. Initial investment costs for developing specialized formulations typically range from $75,000 to $150,000, encompassing laboratory research, field testing, and formulation optimization. These specialized fluids often cost 30-45% more per barrel than conventional drilling fluids, representing a significant operational expense increase.

However, the economic benefits of these advanced formulations frequently outweigh their costs. Core sample integrity improvements of 40-60% directly translate to more accurate resource estimation and reduced need for additional sampling. Studies across multiple lithium operations indicate that enhanced core recovery can improve resource estimation accuracy by up to 35%, potentially preventing multi-million dollar miscalculations in project valuation.

Operational efficiency gains present another significant economic advantage. Advanced formulations demonstrate 25-30% faster drilling rates in lithium-bearing formations, reducing rig time and associated costs. The average lithium exploration drilling operation costs approximately $5,000-$8,000 per day; therefore, a 25% reduction in drilling time for a typical 30-day campaign represents savings of $37,500-$60,000 per well.

Environmental compliance benefits must also factor into the analysis. Advanced biodegradable formulations may cost 15-20% more initially but can reduce environmental remediation expenses by 40-60%. In jurisdictions with stringent environmental regulations, these savings can exceed $100,000 per drilling site, while simultaneously reducing regulatory approval timelines by 30-45%.

The return on investment timeline typically shows that advanced formulations recover their additional costs within 3-6 months of implementation through combined benefits of improved resource estimation, reduced drilling time, and lower environmental compliance costs. Long-term economic modeling indicates a positive ROI ranging from 180-250% over a three-year period for operations utilizing these specialized formulations.

For operations extracting over 10,000 tonnes of lithium carbonate equivalent annually, the cumulative financial benefit of implementing advanced drilling fluid technology can exceed $1.2-1.8 million per year when accounting for all direct and indirect economic factors.

However, the economic benefits of these advanced formulations frequently outweigh their costs. Core sample integrity improvements of 40-60% directly translate to more accurate resource estimation and reduced need for additional sampling. Studies across multiple lithium operations indicate that enhanced core recovery can improve resource estimation accuracy by up to 35%, potentially preventing multi-million dollar miscalculations in project valuation.

Operational efficiency gains present another significant economic advantage. Advanced formulations demonstrate 25-30% faster drilling rates in lithium-bearing formations, reducing rig time and associated costs. The average lithium exploration drilling operation costs approximately $5,000-$8,000 per day; therefore, a 25% reduction in drilling time for a typical 30-day campaign represents savings of $37,500-$60,000 per well.

Environmental compliance benefits must also factor into the analysis. Advanced biodegradable formulations may cost 15-20% more initially but can reduce environmental remediation expenses by 40-60%. In jurisdictions with stringent environmental regulations, these savings can exceed $100,000 per drilling site, while simultaneously reducing regulatory approval timelines by 30-45%.

The return on investment timeline typically shows that advanced formulations recover their additional costs within 3-6 months of implementation through combined benefits of improved resource estimation, reduced drilling time, and lower environmental compliance costs. Long-term economic modeling indicates a positive ROI ranging from 180-250% over a three-year period for operations utilizing these specialized formulations.

For operations extracting over 10,000 tonnes of lithium carbonate equivalent annually, the cumulative financial benefit of implementing advanced drilling fluid technology can exceed $1.2-1.8 million per year when accounting for all direct and indirect economic factors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!