Assess Lithium Mine Ore Blending Strategies for Grade Uniformity

OCT 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Ore Blending Background and Objectives

Lithium mining has evolved significantly over the past decades, transitioning from a niche industry to a critical component of the global energy transition. The extraction and processing of lithium-bearing ores have historically been characterized by inconsistent grade quality, leading to inefficiencies in downstream processing and reduced economic returns. The practice of ore blending emerged as a strategic approach to address these challenges, aiming to achieve consistent lithium concentrations in feed material for processing plants.

The evolution of lithium ore blending techniques has paralleled advancements in mining technology and analytical capabilities. Early blending strategies relied heavily on visual inspection and basic sampling methods, resulting in substantial grade variability. The introduction of real-time ore grade analysis technologies in the 1990s marked a significant turning point, enabling more precise blending decisions based on quantitative data rather than qualitative assessments.

Recent technological developments have further refined blending approaches, incorporating advanced geological modeling, drone-based surveying, and machine learning algorithms to predict optimal blending ratios. These innovations have collectively contributed to more sophisticated blending strategies that can accommodate the inherent heterogeneity of lithium deposits while maintaining grade uniformity.

The primary objective of modern lithium ore blending is to achieve consistent feed grade to processing facilities, thereby optimizing recovery rates, reducing reagent consumption, and minimizing energy requirements. Secondary objectives include extending mine life through the utilization of lower-grade resources that would otherwise be classified as waste, and reducing the environmental footprint of operations through more efficient resource utilization.

Current industry trends indicate a growing emphasis on dynamic blending strategies that can adapt to changing ore characteristics throughout the mine life cycle. This approach represents a departure from traditional static blending plans, which often failed to account for geological uncertainties and operational constraints. The trend toward adaptive blending is particularly relevant for lithium operations, where deposit complexity and market volatility necessitate flexible processing solutions.

Looking forward, the technical trajectory of lithium ore blending is moving toward integrated systems that combine real-time grade control, automated material handling, and predictive analytics. These systems aim to optimize not only grade uniformity but also other critical parameters such as mineralogical composition, impurity levels, and physical properties that affect downstream processing efficiency. The ultimate goal is to establish a continuous improvement framework for blending strategies that can evolve with advancing technology and changing market requirements.

The evolution of lithium ore blending techniques has paralleled advancements in mining technology and analytical capabilities. Early blending strategies relied heavily on visual inspection and basic sampling methods, resulting in substantial grade variability. The introduction of real-time ore grade analysis technologies in the 1990s marked a significant turning point, enabling more precise blending decisions based on quantitative data rather than qualitative assessments.

Recent technological developments have further refined blending approaches, incorporating advanced geological modeling, drone-based surveying, and machine learning algorithms to predict optimal blending ratios. These innovations have collectively contributed to more sophisticated blending strategies that can accommodate the inherent heterogeneity of lithium deposits while maintaining grade uniformity.

The primary objective of modern lithium ore blending is to achieve consistent feed grade to processing facilities, thereby optimizing recovery rates, reducing reagent consumption, and minimizing energy requirements. Secondary objectives include extending mine life through the utilization of lower-grade resources that would otherwise be classified as waste, and reducing the environmental footprint of operations through more efficient resource utilization.

Current industry trends indicate a growing emphasis on dynamic blending strategies that can adapt to changing ore characteristics throughout the mine life cycle. This approach represents a departure from traditional static blending plans, which often failed to account for geological uncertainties and operational constraints. The trend toward adaptive blending is particularly relevant for lithium operations, where deposit complexity and market volatility necessitate flexible processing solutions.

Looking forward, the technical trajectory of lithium ore blending is moving toward integrated systems that combine real-time grade control, automated material handling, and predictive analytics. These systems aim to optimize not only grade uniformity but also other critical parameters such as mineralogical composition, impurity levels, and physical properties that affect downstream processing efficiency. The ultimate goal is to establish a continuous improvement framework for blending strategies that can evolve with advancing technology and changing market requirements.

Market Demand Analysis for Uniform Lithium Grades

The global lithium market has witnessed unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. This surge has created a critical demand for consistent, high-quality lithium supplies with uniform grades. Battery manufacturers, which represent approximately 74% of lithium end-use, require stringent specifications for lithium concentrates to ensure optimal battery performance, safety, and longevity.

Market research indicates that premium pricing for uniform lithium grades can exceed standard market rates by 15-20%, highlighting the economic incentive for mining operations to implement effective ore blending strategies. The consistency in chemical composition directly impacts downstream processing efficiency, with uniform feeds reducing processing costs by an estimated 8-12% across the value chain.

Battery technology advancements are further intensifying grade uniformity requirements. Next-generation lithium-ion batteries demand increasingly precise lithium carbonate and hydroxide specifications, with allowable impurity variations narrowing from ±2.5% to ±0.8% over the past five years. This trend is expected to continue as solid-state battery technologies approach commercial viability.

Regional market analysis reveals significant differences in uniformity requirements. Asian markets, particularly China, Japan, and South Korea, which collectively process over 85% of global lithium, maintain the strictest specifications. European manufacturers are rapidly adopting similar standards as domestic battery production capacity expands, while North American specifications are becoming increasingly stringent with the implementation of the Inflation Reduction Act incentives for domestic battery production.

Supply chain dynamics further emphasize the importance of grade uniformity. Contract structures increasingly include penalties for grade variability, with major battery manufacturers implementing sophisticated quality control systems that can detect minor inconsistencies. Long-term supply agreements, which now constitute approximately 67% of lithium transactions, typically include detailed grade uniformity clauses with performance metrics.

The market for technologies supporting ore blending optimization is experiencing parallel growth, with investments in real-time analysis systems, AI-driven blending algorithms, and automated stockpile management solutions increasing by 35% annually. Mining companies implementing comprehensive blending strategies report reduced customer complaints, stronger long-term contracts, and improved operational efficiency.

Forecasts suggest that by 2030, nearly 90% of lithium supply contracts will include specific grade uniformity requirements, compared to approximately 60% today. This market evolution underscores the strategic importance of developing sophisticated ore blending capabilities as a competitive advantage in the rapidly expanding lithium market.

Market research indicates that premium pricing for uniform lithium grades can exceed standard market rates by 15-20%, highlighting the economic incentive for mining operations to implement effective ore blending strategies. The consistency in chemical composition directly impacts downstream processing efficiency, with uniform feeds reducing processing costs by an estimated 8-12% across the value chain.

Battery technology advancements are further intensifying grade uniformity requirements. Next-generation lithium-ion batteries demand increasingly precise lithium carbonate and hydroxide specifications, with allowable impurity variations narrowing from ±2.5% to ±0.8% over the past five years. This trend is expected to continue as solid-state battery technologies approach commercial viability.

Regional market analysis reveals significant differences in uniformity requirements. Asian markets, particularly China, Japan, and South Korea, which collectively process over 85% of global lithium, maintain the strictest specifications. European manufacturers are rapidly adopting similar standards as domestic battery production capacity expands, while North American specifications are becoming increasingly stringent with the implementation of the Inflation Reduction Act incentives for domestic battery production.

Supply chain dynamics further emphasize the importance of grade uniformity. Contract structures increasingly include penalties for grade variability, with major battery manufacturers implementing sophisticated quality control systems that can detect minor inconsistencies. Long-term supply agreements, which now constitute approximately 67% of lithium transactions, typically include detailed grade uniformity clauses with performance metrics.

The market for technologies supporting ore blending optimization is experiencing parallel growth, with investments in real-time analysis systems, AI-driven blending algorithms, and automated stockpile management solutions increasing by 35% annually. Mining companies implementing comprehensive blending strategies report reduced customer complaints, stronger long-term contracts, and improved operational efficiency.

Forecasts suggest that by 2030, nearly 90% of lithium supply contracts will include specific grade uniformity requirements, compared to approximately 60% today. This market evolution underscores the strategic importance of developing sophisticated ore blending capabilities as a competitive advantage in the rapidly expanding lithium market.

Current Blending Technologies and Challenges

Lithium ore blending in mining operations currently employs several established technologies, each with specific advantages and limitations. Homogenization stockpiles represent one of the most traditional approaches, where different ore types are layered in controlled patterns and then reclaimed perpendicular to the layers. This method effectively reduces grade variability but requires substantial land area and material handling resources, limiting its application in operations with space constraints.

Computer-aided blending systems have emerged as a technological advancement, utilizing sophisticated algorithms to optimize blending decisions based on real-time grade data. These systems can significantly improve grade consistency but depend heavily on accurate sampling and analysis. The reliability of these systems is directly proportional to the quality of input data, creating a critical dependency that can become problematic when dealing with heterogeneous lithium deposits.

In-pit blending represents another approach where selective mining and immediate blending occur at the extraction point. This technique reduces transportation costs and allows for rapid adjustments but requires extensive geological knowledge and precise operational coordination. The effectiveness of in-pit blending diminishes considerably when dealing with complex lithium pegmatite formations with highly variable mineralogy.

Pre-concentration technologies have gained traction in recent years, where ore sorting and sensor-based separation methods are employed before the main blending process. These technologies can remove waste material early in the process, improving the overall grade before blending, but their application to lithium ores remains challenging due to the subtle mineralogical differences in lithium-bearing minerals.

Despite technological advances, the lithium mining industry faces several persistent challenges in blending operations. The inherent geological variability of lithium deposits, particularly in pegmatite formations, creates unpredictable grade fluctuations that are difficult to manage with current blending strategies. The mineralogical complexity of lithium ores, where valuable minerals may be intimately associated with gangue materials, further complicates effective blending.

Sampling and analytical limitations represent another significant challenge. The time lag between sampling and receiving analytical results often exceeds the operational timeframe for blending decisions, forcing operators to work with outdated information. Additionally, the industry lacks standardized protocols for lithium ore characterization, leading to inconsistent approaches across different operations.

Economic constraints also impact blending strategies, as the capital-intensive nature of advanced blending technologies must be balanced against operational benefits. Many lithium operations, particularly those in emerging markets, struggle to justify the substantial investment required for state-of-the-art blending facilities, resulting in suboptimal grade control practices.

Computer-aided blending systems have emerged as a technological advancement, utilizing sophisticated algorithms to optimize blending decisions based on real-time grade data. These systems can significantly improve grade consistency but depend heavily on accurate sampling and analysis. The reliability of these systems is directly proportional to the quality of input data, creating a critical dependency that can become problematic when dealing with heterogeneous lithium deposits.

In-pit blending represents another approach where selective mining and immediate blending occur at the extraction point. This technique reduces transportation costs and allows for rapid adjustments but requires extensive geological knowledge and precise operational coordination. The effectiveness of in-pit blending diminishes considerably when dealing with complex lithium pegmatite formations with highly variable mineralogy.

Pre-concentration technologies have gained traction in recent years, where ore sorting and sensor-based separation methods are employed before the main blending process. These technologies can remove waste material early in the process, improving the overall grade before blending, but their application to lithium ores remains challenging due to the subtle mineralogical differences in lithium-bearing minerals.

Despite technological advances, the lithium mining industry faces several persistent challenges in blending operations. The inherent geological variability of lithium deposits, particularly in pegmatite formations, creates unpredictable grade fluctuations that are difficult to manage with current blending strategies. The mineralogical complexity of lithium ores, where valuable minerals may be intimately associated with gangue materials, further complicates effective blending.

Sampling and analytical limitations represent another significant challenge. The time lag between sampling and receiving analytical results often exceeds the operational timeframe for blending decisions, forcing operators to work with outdated information. Additionally, the industry lacks standardized protocols for lithium ore characterization, leading to inconsistent approaches across different operations.

Economic constraints also impact blending strategies, as the capital-intensive nature of advanced blending technologies must be balanced against operational benefits. Many lithium operations, particularly those in emerging markets, struggle to justify the substantial investment required for state-of-the-art blending facilities, resulting in suboptimal grade control practices.

Current Ore Blending Solutions and Techniques

01 Ore blending optimization algorithms

Advanced algorithms and computational methods are used to optimize lithium ore blending strategies. These systems analyze various ore characteristics and determine optimal mixing ratios to achieve consistent grade targets. The algorithms consider multiple variables including mineral composition, impurity levels, and processing requirements to create blending plans that maximize resource utilization while maintaining uniform quality output.- Ore blending optimization algorithms: Advanced algorithms and computational methods are employed to optimize lithium ore blending strategies. These systems analyze various ore characteristics and determine optimal mixing ratios to achieve consistent grade targets. The algorithms consider multiple variables including mineral composition, impurity levels, and processing requirements to create blends that maintain uniform lithium content while maximizing resource utilization and economic value.

- Real-time monitoring and control systems: Implementation of real-time monitoring technologies enables continuous assessment of ore quality during the blending process. These systems utilize sensors, analyzers, and automated sampling to track lithium content and adjust blending parameters accordingly. The integration of IoT devices and data analytics allows for immediate corrective actions when deviations from target grades are detected, ensuring consistent product quality throughout the mining operation.

- Multi-source ore stockpile management: Strategic management of ore stockpiles from different mining zones or deposits is crucial for maintaining grade uniformity. This approach involves creating dedicated stockpiles based on ore characteristics, implementing systematic reclaiming methods, and establishing buffer zones to mitigate variability. By carefully managing multiple ore sources, mining operations can blend materials with complementary properties to achieve consistent lithium concentrations despite natural geological variations.

- Predictive modeling for grade control: Predictive modeling techniques are applied to forecast ore quality variations and plan blending strategies proactively. These models incorporate geological data, historical mining information, and statistical analysis to predict lithium content in different mining areas. By anticipating grade fluctuations, operations can develop preemptive blending plans that maintain uniformity despite changing ore characteristics, reducing the need for reactive adjustments during processing.

- Selective mining and pre-concentration techniques: Selective mining approaches combined with pre-concentration methods help improve feed quality before the main blending process. These techniques involve identifying high-grade zones within deposits, implementing targeted extraction methods, and applying preliminary sorting or beneficiation to remove waste material. By enhancing the quality of input materials, these approaches reduce variability in the feed stream, making subsequent blending operations more effective at maintaining consistent lithium grades.

02 Real-time monitoring and control systems

Implementation of real-time monitoring technologies enables continuous assessment of ore quality during the blending process. These systems use sensors, analyzers, and automated sampling to track lithium content and impurity levels throughout production. The collected data feeds into control systems that can make immediate adjustments to blending ratios, ensuring grade uniformity is maintained despite variations in incoming ore quality.Expand Specific Solutions03 Pre-blending stockpile management

Strategic management of pre-blending stockpiles helps achieve grade uniformity in lithium mining operations. This approach involves creating homogenized stockpiles of different ore grades that can be reclaimed in controlled proportions. By establishing multiple stockpiles with characterized properties, mining operations can draw from these reserves in calculated ratios to maintain consistent feed grade to processing plants, reducing variability in lithium content.Expand Specific Solutions04 Selective mining and ore classification

Selective mining techniques combined with advanced ore classification systems enable more precise control over lithium ore quality before blending. This approach involves detailed geological mapping, grade control drilling, and in-pit analysis to categorize ore bodies based on lithium content and impurity profiles. By identifying and segregating different ore types at the extraction stage, more effective blending strategies can be implemented to achieve grade uniformity.Expand Specific Solutions05 Multi-stage blending processes

Multi-stage blending processes incorporate sequential mixing operations at different points in the production chain. This approach may include primary blending at the mine site, secondary blending during crushing and screening, and final adjustment blending before concentration processes. Each stage provides an opportunity to correct deviations and progressively improve grade uniformity, resulting in more consistent lithium content in the final product.Expand Specific Solutions

Key Industry Players in Lithium Mining and Processing

The lithium mine ore blending market is in a growth phase, driven by increasing demand for lithium in battery technologies. The global market is expanding rapidly, with projections indicating significant growth as electric vehicle adoption accelerates. Technologically, the sector shows varying maturity levels across players. Companies like XTC New Energy Materials and Guangdong Bangpu Recycling Technology demonstrate advanced capabilities in resource optimization, while MineSense Technologies offers innovative sensor-based sorting solutions. Traditional mining entities such as Poseidon Nickel and Sinosteel Maanshan are adapting conventional blending approaches. Research institutions including Korea Institute of Geoscience & Mineral Resources and Kunming University of Science & Technology are advancing fundamental technologies, creating a competitive landscape balanced between established mining operations and technology-focused innovators.

Shenzhen Dynanonic Co., Ltd.

Technical Solution: Shenzhen Dynanonic has developed a specialized lithium ore blending technology called "LithiumBlend+" that focuses on optimizing feed material for battery-grade lithium production. Their system employs a multi-parameter approach that considers not only lithium grade but also impurity profiles critical for battery applications. The technology utilizes portable laser-induced breakdown spectroscopy (LIBS) analyzers to rapidly assess ore composition at multiple points in the mining and processing chain. Dynanonic's proprietary algorithm calculates optimal blending ratios to achieve consistent chemical composition while minimizing problematic elements like iron, magnesium, and calcium that affect battery performance. Their solution incorporates a digital stockpile management system that tracks material movement and maintains a real-time inventory of available ore grades for blending decisions. The company has also developed specialized blending equipment with precision feeding mechanisms that ensure accurate execution of calculated blend recipes. Implementation data shows their approach can reduce grade variability by up to 35% while simultaneously reducing energy consumption in downstream processing by maintaining consistent mineralogical characteristics in the feed material.

Strengths: Specialized focus on battery-grade lithium requirements ensures blending strategies are aligned with end-product specifications. Their integration of analytical technology with physical blending equipment provides a complete solution rather than just advisory software. Weaknesses: Their technology may be optimized primarily for spodumene-dominant deposits, potentially limiting effectiveness with other lithium mineral assemblages like clay-hosted or brine deposits.

Anglo American Technical & Sustainability Services Ltd.

Technical Solution: Anglo American has developed a comprehensive lithium ore blending strategy called "GradeControl+" that combines geological modeling, real-time sensing, and advanced analytics. Their approach begins with detailed geological block modeling that incorporates spatial variability of lithium grades and mineralogical characteristics. The system employs a network of sensors throughout the mining and crushing circuits that continuously monitor ore properties, including lithium content, gangue minerals, and moisture levels. Anglo American's proprietary algorithm optimizes blending decisions based on multiple parameters including grade targets, processing constraints, and economic factors. The technology incorporates weather forecasting data to adjust blending strategies during wet seasons when ore characteristics may change. Their solution also features a digital control room where operators can visualize the entire blending process and make adjustments based on AI-generated recommendations. Implementation at their operations has demonstrated the ability to maintain grade variability within ±5% of target specifications, significantly improving recovery rates in downstream processing.

Strengths: Holistic approach that integrates geological understanding with operational execution, creating a comprehensive blending strategy. Their global scale provides extensive operational data for algorithm refinement across diverse lithium deposits. Weaknesses: The system's complexity requires significant technical expertise to maintain and optimize, potentially limiting its applicability for smaller mining operations without substantial technical resources.

Critical Technologies for Grade Control in Lithium Mining

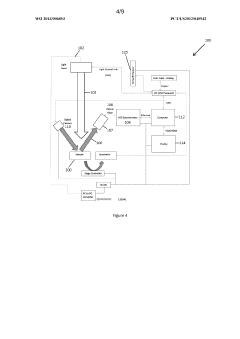

Spectroscopic analysis of oil sands ore face for real time ore blend management

PatentWO2013006853A1

Innovation

- A signal processing module and apparatus that analyze ore samples in real-time using imaging and spectroscopic techniques to determine bitumen content, providing real-time ore face ore grade visualization and Total Bitumen Content by percentage weight, enabling accurate and consistent ore blend management through instruments like portable analyzers and drive-through devices.

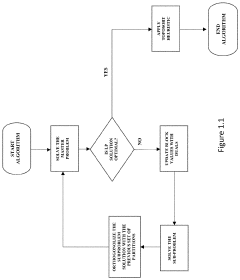

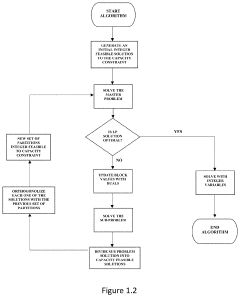

Systems and methods for maximizing mine production scheduling

PatentInactiveUS20210398157A1

Innovation

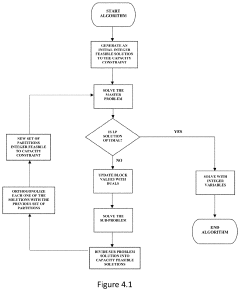

- The Bienstock-Zuckerberg decomposition algorithm is augmented to split the problem into master and subproblems, with subproblem solutions partitioned into integer feasible sub-closures to honor capacity constraints, ensuring the solution space captures both LP optimality and integer feasibility.

Environmental Impact of Blending Operations

Lithium ore blending operations, while essential for achieving grade uniformity, carry significant environmental implications that must be carefully assessed and managed. The environmental footprint of blending activities extends across multiple ecological domains, creating both direct and indirect impacts on surrounding ecosystems, water resources, and atmospheric conditions.

The physical disturbance caused by blending operations represents a primary environmental concern. The movement and mixing of large volumes of ore material typically requires heavy machinery and extensive land use, leading to habitat fragmentation and soil compaction. These activities can disrupt local biodiversity and alter natural drainage patterns, potentially affecting downstream water systems and dependent ecological communities.

Dust generation during blending processes poses another substantial environmental challenge. Fine particulate matter released during crushing, transportation, and mixing of lithium ores can contain potentially harmful elements that may be transported by wind to surrounding areas. This airborne contamination can affect air quality, settle on vegetation reducing photosynthetic capacity, and potentially enter water systems through deposition, creating cascading ecological effects beyond the immediate operational area.

Water resource impacts constitute a critical environmental consideration in blending operations. The process often requires significant water inputs for dust suppression and material handling, potentially competing with other local water needs in what are frequently arid regions where many lithium deposits are found. Additionally, runoff from blending areas may contain elevated levels of minerals and processing chemicals that can contaminate surface and groundwater if not properly managed.

Energy consumption associated with blending activities contributes to the carbon footprint of lithium production. The operation of heavy machinery, conveyor systems, and processing equipment requires substantial energy inputs, typically derived from fossil fuels in remote mining locations. This energy use translates directly to greenhouse gas emissions that contribute to broader climate change concerns, creating an environmental impact that extends far beyond the immediate operational area.

Advanced blending strategies that optimize grade uniformity can potentially mitigate some environmental impacts through increased operational efficiency. By reducing the need for reprocessing off-specification material, optimized blending can decrease overall energy consumption, water usage, and physical disturbance. Furthermore, precision blending technologies that minimize excess material handling can significantly reduce dust generation and associated air quality impacts.

Regulatory frameworks increasingly require comprehensive environmental management plans specifically addressing blending operations. These typically include mandatory monitoring programs, dust suppression protocols, water management systems, and rehabilitation strategies designed to minimize and mitigate environmental impacts throughout the operational lifecycle and post-closure period.

The physical disturbance caused by blending operations represents a primary environmental concern. The movement and mixing of large volumes of ore material typically requires heavy machinery and extensive land use, leading to habitat fragmentation and soil compaction. These activities can disrupt local biodiversity and alter natural drainage patterns, potentially affecting downstream water systems and dependent ecological communities.

Dust generation during blending processes poses another substantial environmental challenge. Fine particulate matter released during crushing, transportation, and mixing of lithium ores can contain potentially harmful elements that may be transported by wind to surrounding areas. This airborne contamination can affect air quality, settle on vegetation reducing photosynthetic capacity, and potentially enter water systems through deposition, creating cascading ecological effects beyond the immediate operational area.

Water resource impacts constitute a critical environmental consideration in blending operations. The process often requires significant water inputs for dust suppression and material handling, potentially competing with other local water needs in what are frequently arid regions where many lithium deposits are found. Additionally, runoff from blending areas may contain elevated levels of minerals and processing chemicals that can contaminate surface and groundwater if not properly managed.

Energy consumption associated with blending activities contributes to the carbon footprint of lithium production. The operation of heavy machinery, conveyor systems, and processing equipment requires substantial energy inputs, typically derived from fossil fuels in remote mining locations. This energy use translates directly to greenhouse gas emissions that contribute to broader climate change concerns, creating an environmental impact that extends far beyond the immediate operational area.

Advanced blending strategies that optimize grade uniformity can potentially mitigate some environmental impacts through increased operational efficiency. By reducing the need for reprocessing off-specification material, optimized blending can decrease overall energy consumption, water usage, and physical disturbance. Furthermore, precision blending technologies that minimize excess material handling can significantly reduce dust generation and associated air quality impacts.

Regulatory frameworks increasingly require comprehensive environmental management plans specifically addressing blending operations. These typically include mandatory monitoring programs, dust suppression protocols, water management systems, and rehabilitation strategies designed to minimize and mitigate environmental impacts throughout the operational lifecycle and post-closure period.

Resource Optimization Strategies for Lithium Extraction

Optimizing lithium extraction processes requires a comprehensive approach to resource management that balances economic viability with technical efficiency. Current optimization strategies focus on maximizing recovery rates while minimizing environmental impact and operational costs. The industry has evolved from traditional acid leaching methods to more sophisticated approaches including direct lithium extraction (DLE) technologies that offer higher selectivity and reduced water consumption.

Key optimization strategies include selective mining techniques that prioritize high-grade ore bodies, reducing waste material processing. Advanced ore sorting technologies utilizing sensors and machine learning algorithms enable real-time grade control, significantly improving resource utilization efficiency. These systems can detect lithium concentrations with increasing accuracy, allowing for more precise blending decisions.

Ore blending strategies represent a critical component of resource optimization, as they directly impact processing efficiency and final product quality. Strategic blending of high and low-grade ores maintains consistent feed quality to processing plants, reducing operational variability and improving recovery rates. Mathematical modeling and simulation tools now enable predictive blending plans that can be adjusted based on real-time mining conditions and market demands.

Water management innovations have become increasingly important in lithium extraction optimization, particularly in water-scarce regions. Closed-loop systems that recycle process water can reduce freshwater consumption by up to 60%, while advanced filtration technologies minimize discharge of contaminated effluents. These approaches not only conserve resources but also reduce operational costs and environmental liabilities.

Energy efficiency improvements represent another frontier in lithium extraction optimization. Renewable energy integration at mining sites reduces carbon footprint while providing cost stability against fluctuating fuel prices. Innovations in grinding and crushing technologies have reduced energy consumption in these traditionally energy-intensive processes by 15-30%, according to recent industry benchmarks.

Waste valorization strategies are transforming what was once considered tailings into potential revenue streams. Research indicates that lithium mine tailings often contain recoverable quantities of other valuable minerals including potassium, boron, and magnesium. Advanced separation technologies now make secondary recovery economically viable in many operations, improving overall resource utilization and reducing waste storage requirements.

Digital transformation through integrated mine-to-market platforms provides unprecedented visibility across the entire value chain, enabling dynamic optimization of extraction strategies based on market conditions and operational constraints. These systems incorporate real-time data from mining operations, processing facilities, and market intelligence to continuously refine resource allocation decisions.

Key optimization strategies include selective mining techniques that prioritize high-grade ore bodies, reducing waste material processing. Advanced ore sorting technologies utilizing sensors and machine learning algorithms enable real-time grade control, significantly improving resource utilization efficiency. These systems can detect lithium concentrations with increasing accuracy, allowing for more precise blending decisions.

Ore blending strategies represent a critical component of resource optimization, as they directly impact processing efficiency and final product quality. Strategic blending of high and low-grade ores maintains consistent feed quality to processing plants, reducing operational variability and improving recovery rates. Mathematical modeling and simulation tools now enable predictive blending plans that can be adjusted based on real-time mining conditions and market demands.

Water management innovations have become increasingly important in lithium extraction optimization, particularly in water-scarce regions. Closed-loop systems that recycle process water can reduce freshwater consumption by up to 60%, while advanced filtration technologies minimize discharge of contaminated effluents. These approaches not only conserve resources but also reduce operational costs and environmental liabilities.

Energy efficiency improvements represent another frontier in lithium extraction optimization. Renewable energy integration at mining sites reduces carbon footprint while providing cost stability against fluctuating fuel prices. Innovations in grinding and crushing technologies have reduced energy consumption in these traditionally energy-intensive processes by 15-30%, according to recent industry benchmarks.

Waste valorization strategies are transforming what was once considered tailings into potential revenue streams. Research indicates that lithium mine tailings often contain recoverable quantities of other valuable minerals including potassium, boron, and magnesium. Advanced separation technologies now make secondary recovery economically viable in many operations, improving overall resource utilization and reducing waste storage requirements.

Digital transformation through integrated mine-to-market platforms provides unprecedented visibility across the entire value chain, enabling dynamic optimization of extraction strategies based on market conditions and operational constraints. These systems incorporate real-time data from mining operations, processing facilities, and market intelligence to continuously refine resource allocation decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!