Optimize Lithium Mine Ore Pelletization for Lower Fines Generation

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Pelletization Technology Background and Objectives

Lithium mining has undergone significant transformation over the past decades, evolving from small-scale operations to industrial-scale extraction processes to meet the surging global demand for lithium-ion batteries. Pelletization technology, a critical process in lithium ore processing, has emerged as a key focus area for optimization due to its direct impact on downstream processing efficiency and overall resource utilization. The historical development of lithium pelletization techniques shows a gradual shift from basic agglomeration methods to more sophisticated approaches incorporating advanced binding agents and mechanical innovations.

The technological evolution in this field has been primarily driven by the need to address the persistent challenge of fines generation—small particulate matter that reduces process efficiency, increases material loss, and creates environmental concerns. Traditional pelletization methods typically result in 15-20% fines generation during handling and transportation, representing significant economic and operational inefficiencies in the lithium supply chain.

Current global trends indicate a growing emphasis on sustainable mining practices alongside production efficiency, with pelletization technology increasingly viewed as a critical intersection point for these dual objectives. The industry is witnessing a convergence of mechanical engineering principles with materials science innovations to develop more robust pellets with enhanced structural integrity.

The primary technical objective in optimizing lithium ore pelletization is to achieve a substantial reduction in fines generation—specifically targeting below 5% fines during standard handling and transportation processes—without compromising production throughput or significantly increasing operational costs. This requires a comprehensive approach addressing multiple variables including binder formulation, moisture content optimization, pellet formation dynamics, and curing methodologies.

Secondary objectives include enhancing the uniformity of pellet size distribution, improving pellet strength to withstand mechanical stress during transportation, and developing processes that maintain effectiveness across varying ore compositions from different lithium deposits. These improvements must be achieved while maintaining or reducing energy consumption in the pelletization process.

The long-term technological trajectory points toward intelligent pelletization systems incorporating real-time monitoring and adaptive control mechanisms to optimize parameters based on incoming ore characteristics. This represents a shift from static process designs to dynamic systems capable of continuous self-optimization, potentially revolutionizing how lithium ore processing facilities operate.

Success in this technological domain would deliver significant competitive advantages through reduced material losses, lower processing costs, improved product quality, and enhanced environmental performance—all critical factors in the increasingly competitive global lithium market.

The technological evolution in this field has been primarily driven by the need to address the persistent challenge of fines generation—small particulate matter that reduces process efficiency, increases material loss, and creates environmental concerns. Traditional pelletization methods typically result in 15-20% fines generation during handling and transportation, representing significant economic and operational inefficiencies in the lithium supply chain.

Current global trends indicate a growing emphasis on sustainable mining practices alongside production efficiency, with pelletization technology increasingly viewed as a critical intersection point for these dual objectives. The industry is witnessing a convergence of mechanical engineering principles with materials science innovations to develop more robust pellets with enhanced structural integrity.

The primary technical objective in optimizing lithium ore pelletization is to achieve a substantial reduction in fines generation—specifically targeting below 5% fines during standard handling and transportation processes—without compromising production throughput or significantly increasing operational costs. This requires a comprehensive approach addressing multiple variables including binder formulation, moisture content optimization, pellet formation dynamics, and curing methodologies.

Secondary objectives include enhancing the uniformity of pellet size distribution, improving pellet strength to withstand mechanical stress during transportation, and developing processes that maintain effectiveness across varying ore compositions from different lithium deposits. These improvements must be achieved while maintaining or reducing energy consumption in the pelletization process.

The long-term technological trajectory points toward intelligent pelletization systems incorporating real-time monitoring and adaptive control mechanisms to optimize parameters based on incoming ore characteristics. This represents a shift from static process designs to dynamic systems capable of continuous self-optimization, potentially revolutionizing how lithium ore processing facilities operate.

Success in this technological domain would deliver significant competitive advantages through reduced material losses, lower processing costs, improved product quality, and enhanced environmental performance—all critical factors in the increasingly competitive global lithium market.

Market Demand Analysis for High-Quality Lithium Ore Pellets

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. This surge has created a significant demand for high-quality lithium ore pellets with minimal fines generation, as these are essential for efficient processing and maximum lithium recovery.

Market research indicates that the global lithium demand is projected to grow at a compound annual growth rate of 18% through 2030, with the battery sector accounting for approximately 80% of total consumption. This exponential growth trajectory has placed immense pressure on lithium producers to optimize their extraction and processing methods, particularly in pelletization techniques.

End-users in the battery manufacturing industry specifically require lithium ore pellets with consistent size distribution, mechanical strength, and minimal dust generation. These quality parameters directly impact downstream processing efficiency, worker safety, and environmental compliance. Current market feedback suggests that pellets generating less than 5% fines during handling and transportation command premium prices, often 15-20% higher than standard market offerings.

Regional analysis reveals varying demand patterns, with Asia-Pacific representing the largest market for high-quality lithium ore pellets, followed by North America and Europe. China alone accounts for over 40% of global lithium processing capacity, making it the most significant consumer of premium lithium ore pellets with low fines generation characteristics.

The economic value proposition for optimized pelletization is compelling. Processors report that high-quality pellets with reduced fines generation can increase lithium recovery rates by 3-7%, significantly improving operational economics. Additionally, reduced dust generation translates to lower material losses, improved workplace safety, and decreased environmental remediation costs.

Industry surveys indicate that lithium processors are willing to pay premium prices for ore pellets that demonstrate consistent physical integrity throughout the supply chain. This market preference has created a competitive advantage for suppliers who can deliver pellets with enhanced structural stability and minimal degradation during handling and transportation.

Environmental regulations worldwide are becoming increasingly stringent regarding particulate emissions, further driving demand for low-fines pellets. Companies face substantial compliance costs and potential operational restrictions when processing materials that generate excessive dust, creating additional market incentives for optimized pelletization technologies.

The market for specialized pelletization equipment and technologies is also expanding rapidly, with an estimated value of $1.2 billion in 2023, reflecting the industry's recognition of pelletization quality as a critical factor in the lithium supply chain.

Market research indicates that the global lithium demand is projected to grow at a compound annual growth rate of 18% through 2030, with the battery sector accounting for approximately 80% of total consumption. This exponential growth trajectory has placed immense pressure on lithium producers to optimize their extraction and processing methods, particularly in pelletization techniques.

End-users in the battery manufacturing industry specifically require lithium ore pellets with consistent size distribution, mechanical strength, and minimal dust generation. These quality parameters directly impact downstream processing efficiency, worker safety, and environmental compliance. Current market feedback suggests that pellets generating less than 5% fines during handling and transportation command premium prices, often 15-20% higher than standard market offerings.

Regional analysis reveals varying demand patterns, with Asia-Pacific representing the largest market for high-quality lithium ore pellets, followed by North America and Europe. China alone accounts for over 40% of global lithium processing capacity, making it the most significant consumer of premium lithium ore pellets with low fines generation characteristics.

The economic value proposition for optimized pelletization is compelling. Processors report that high-quality pellets with reduced fines generation can increase lithium recovery rates by 3-7%, significantly improving operational economics. Additionally, reduced dust generation translates to lower material losses, improved workplace safety, and decreased environmental remediation costs.

Industry surveys indicate that lithium processors are willing to pay premium prices for ore pellets that demonstrate consistent physical integrity throughout the supply chain. This market preference has created a competitive advantage for suppliers who can deliver pellets with enhanced structural stability and minimal degradation during handling and transportation.

Environmental regulations worldwide are becoming increasingly stringent regarding particulate emissions, further driving demand for low-fines pellets. Companies face substantial compliance costs and potential operational restrictions when processing materials that generate excessive dust, creating additional market incentives for optimized pelletization technologies.

The market for specialized pelletization equipment and technologies is also expanding rapidly, with an estimated value of $1.2 billion in 2023, reflecting the industry's recognition of pelletization quality as a critical factor in the lithium supply chain.

Current Pelletization Challenges and Fines Generation Issues

The lithium mining industry currently faces significant challenges in the pelletization process, particularly concerning the generation of excessive fines. Traditional pelletization methods often result in 15-25% of the processed material becoming fine particles during handling, transportation, and storage. These fines represent not only material loss but also create environmental concerns, operational inefficiencies, and increased processing costs.

A primary technical challenge lies in the binder systems currently employed. Conventional organic binders like bentonite, starch, and cellulose derivatives often fail to provide sufficient mechanical strength to withstand the stresses of handling and transportation. The hydrophilic nature of many lithium-bearing minerals further complicates this issue, as moisture absorption can lead to pellet degradation over time.

The particle size distribution of feed material presents another significant hurdle. Current crushing and grinding circuits frequently produce inconsistent particle sizes, resulting in heterogeneous pellets with varying mechanical properties. Studies indicate that optimal pelletization requires a controlled particle size distribution with d50 values between 45-75 μm, yet many operations struggle to maintain this consistency.

Equipment limitations also contribute substantially to fines generation. Most lithium operations utilize disc or drum pelletizers designed for iron ore or other minerals, which fail to account for the unique physical and chemical properties of lithium-bearing minerals. These equipment configurations often apply inappropriate shear forces and residence times, leading to weak pellet formation or excessive dust generation during the process.

The drying and induration phases represent critical weak points in the pelletization process. Current thermal treatment protocols frequently induce thermal shock or uneven heating, creating microfractures within pellets that later develop into fines. Industry data suggests that approximately 30-40% of fines generation occurs during these thermal processing stages.

Handling systems post-pelletization contribute significantly to degradation. Excessive drop heights at transfer points, abrasive conveyor designs, and improper storage conditions accelerate attrition and abrasion mechanisms. Each transfer point typically generates 1-3% additional fines, with cumulative effects throughout the logistics chain.

Quality control methodologies present further complications. Current testing protocols often fail to accurately predict real-world pellet performance, leading to the release of substandard material into the supply chain. The industry lacks standardized testing methods specifically designed for lithium ore pellets, resulting in inconsistent quality assessment across operations.

A primary technical challenge lies in the binder systems currently employed. Conventional organic binders like bentonite, starch, and cellulose derivatives often fail to provide sufficient mechanical strength to withstand the stresses of handling and transportation. The hydrophilic nature of many lithium-bearing minerals further complicates this issue, as moisture absorption can lead to pellet degradation over time.

The particle size distribution of feed material presents another significant hurdle. Current crushing and grinding circuits frequently produce inconsistent particle sizes, resulting in heterogeneous pellets with varying mechanical properties. Studies indicate that optimal pelletization requires a controlled particle size distribution with d50 values between 45-75 μm, yet many operations struggle to maintain this consistency.

Equipment limitations also contribute substantially to fines generation. Most lithium operations utilize disc or drum pelletizers designed for iron ore or other minerals, which fail to account for the unique physical and chemical properties of lithium-bearing minerals. These equipment configurations often apply inappropriate shear forces and residence times, leading to weak pellet formation or excessive dust generation during the process.

The drying and induration phases represent critical weak points in the pelletization process. Current thermal treatment protocols frequently induce thermal shock or uneven heating, creating microfractures within pellets that later develop into fines. Industry data suggests that approximately 30-40% of fines generation occurs during these thermal processing stages.

Handling systems post-pelletization contribute significantly to degradation. Excessive drop heights at transfer points, abrasive conveyor designs, and improper storage conditions accelerate attrition and abrasion mechanisms. Each transfer point typically generates 1-3% additional fines, with cumulative effects throughout the logistics chain.

Quality control methodologies present further complications. Current testing protocols often fail to accurately predict real-world pellet performance, leading to the release of substandard material into the supply chain. The industry lacks standardized testing methods specifically designed for lithium ore pellets, resulting in inconsistent quality assessment across operations.

Current Fines Reduction Methods in Ore Pelletization

01 Pelletization techniques for lithium ore fines

Various pelletization techniques can be applied to lithium ore fines to create stable pellets suitable for further processing. These techniques involve binding the fine particles together using appropriate binders and applying pressure to form pellets of desired size and strength. The pelletization process helps in reducing dust generation during handling and transportation while improving the efficiency of subsequent extraction processes.- Lithium ore pelletization techniques: Various techniques for pelletizing lithium ore to reduce fines generation during processing and handling. These methods involve specific binding agents, moisture control, and processing parameters to create stable pellets from lithium-containing minerals. Proper pelletization improves material handling, reduces dust formation, and increases the efficiency of downstream extraction processes.

- Binders and additives for lithium ore agglomeration: Specialized binders and additives that enhance the pelletization of lithium ore fines. These compounds improve pellet strength, reduce breakage during handling, and minimize dust generation. Common additives include organic polymers, inorganic compounds, and composite binders that create strong bonds between lithium mineral particles while maintaining permeability for subsequent processing steps.

- Fines reduction strategies in lithium mining operations: Methods specifically designed to minimize the generation of fines during lithium ore extraction and processing. These strategies include optimized drilling and blasting techniques, controlled crushing parameters, screening systems, and material handling practices that reduce particle breakdown. Implementing these approaches helps maintain particle size integrity throughout the mining and beneficiation process.

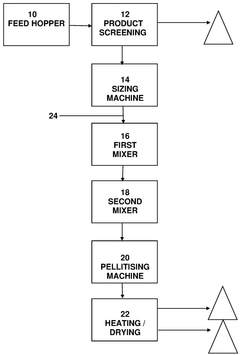

- Equipment and systems for lithium ore pelletization: Specialized equipment and integrated systems used for efficient pelletization of lithium-containing materials. These include disc pelletizers, drum agglomerators, extrusion systems, and automated control mechanisms that optimize the pelletization process. Advanced equipment designs incorporate features to handle the specific characteristics of lithium ores while minimizing fines generation during the agglomeration process.

- Fines recovery and recycling in lithium processing: Technologies and methods for capturing, recovering, and recycling lithium-containing fines generated during mining and processing operations. These approaches include collection systems, classification technologies, and reprocessing techniques that allow fine particles to be reincorporated into the production stream. Effective fines recovery systems improve overall resource utilization and reduce material losses in lithium extraction operations.

02 Binders and additives for lithium ore pelletization

Specific binders and additives are crucial in the pelletization of lithium ore fines to ensure pellet integrity and reduce fines generation. These may include organic binders like cellulose derivatives, inorganic binders such as bentonite or silicates, and various strengthening additives. The selection of appropriate binders depends on the mineralogical composition of the lithium ore and the subsequent processing requirements.Expand Specific Solutions03 Fines reduction strategies in lithium ore processing

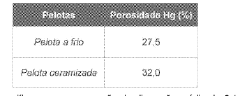

Various strategies can be employed to reduce fines generation during lithium ore processing. These include optimized crushing and grinding parameters, controlled agglomeration techniques, and specialized handling methods. By minimizing fines generation, these approaches improve material handling, reduce dust-related environmental issues, and enhance the efficiency of lithium extraction processes.Expand Specific Solutions04 Heat treatment in lithium ore pelletization

Heat treatment plays a significant role in strengthening lithium ore pellets and reducing subsequent fines generation. Processes such as sintering, calcination, or thermal hardening can be applied to increase the mechanical strength of pellets by promoting solid-state reactions between particles. The temperature, duration, and atmosphere of heat treatment are critical parameters that affect the final quality of the pellets.Expand Specific Solutions05 Innovative equipment for lithium ore pelletization

Specialized equipment has been developed for efficient pelletization of lithium ore fines with minimal generation of secondary fines. These include advanced disc pelletizers, extrusion systems, and vibration-based compaction devices. The equipment is designed to provide consistent pellet quality while accommodating variations in feed material characteristics and production requirements.Expand Specific Solutions

Key Industry Players in Lithium Processing Equipment

The lithium mine ore pelletization optimization market is currently in a growth phase, driven by increasing demand for lithium in battery technologies. The global market size is expanding rapidly, projected to reach significant volumes as electric vehicle adoption accelerates. Technologically, the field is in mid-maturity, with established players like Tianqi Lithium Corp. and Vale SA leading commercial applications, while research institutions including Zhejiang University and Xi'an Technological University drive innovation. Companies such as Sumitomo Metal Mining, POSCO Holdings, and JFE Steel are advancing pelletization techniques to reduce fines generation through improved binder systems and process optimization. The competitive landscape features collaboration between mining conglomerates and specialized materials technology firms, with increasing focus on sustainable processing methods that minimize waste and energy consumption.

Tianqi Lithium Corp.

Technical Solution: Tianqi Lithium has developed a multi-stage pelletization process specifically designed for lithium ore concentrates that incorporates a proprietary binder formulation and controlled moisture content management. Their approach utilizes a combination of disc pelletizers with precise rotation speed control and residence time optimization to create spherical pellets with enhanced structural integrity. The process includes a pre-conditioning phase where fine lithium ore particles are mixed with carefully selected organic and inorganic binders that form strong bridges between particles during the subsequent induration phase. Tianqi's system incorporates real-time monitoring of pellet green strength and moisture distribution, allowing for adaptive control of the pelletization parameters. Their technology also features a specialized curing protocol with controlled temperature and humidity profiles that significantly reduces micro-fractures during the drying and hardening stages.

Strengths: Superior pellet strength with up to 40% reduction in fines generation during handling and transportation compared to conventional methods. Their adaptive control system enables processing of varying ore compositions with consistent quality output. Weaknesses: The specialized binders increase production costs by approximately 15-20%, and the multi-stage process requires longer processing times, potentially limiting throughput in high-volume operations.

Siemens VAI Metals Technologies GmbH & Co.

Technical Solution: Siemens VAI has developed an integrated lithium ore pelletization system that combines digital twin modeling with advanced process control. Their approach begins with comprehensive characterization of ore properties using automated mineralogical analysis to determine optimal binder formulations and moisture levels for specific ore types. The heart of their technology is a digitally-controlled disc pelletizer with dynamic adjustment capabilities that respond to real-time measurements of pellet properties. Siemens' system incorporates a proprietary binder distribution mechanism that ensures homogeneous incorporation throughout the pellet structure, eliminating weak points that typically lead to fines generation. Their process also features a staged drying and induration protocol with precisely controlled temperature and humidity profiles tailored to the specific mineralogical composition of the ore. The company has also developed advanced instrumentation for continuous monitoring of green and fired pellet quality, including automated image analysis systems that detect incipient cracking and structural weaknesses.

Strengths: The digital twin modeling enables rapid optimization for different ore types, reducing development time by up to 70%. The advanced process control system maintains consistent pellet quality even with varying feed characteristics, resulting in fines reduction of 30-45% compared to conventional methods. Weaknesses: The sophisticated digital control systems require specialized technical expertise for operation and maintenance. The initial calibration of the digital twin models requires extensive testing and validation, leading to longer implementation timelines for new installations.

Critical Binder and Agglomeration Technology Innovations

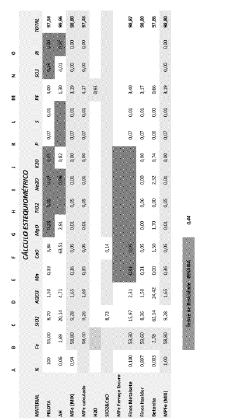

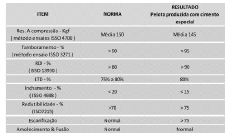

Process of cold pelletization of iron-ore fines with mixture flexibility

PatentWO2019033187A1

Innovation

- A cold pelletizing process that uses a flexible industrial installation with a special cement binder to agglomerate iron ore fines, reducing energy consumption and enhancing mechanical resistance, allowing for the production of pellets with controlled porosity and chemical reactivity suitable for blast furnaces.

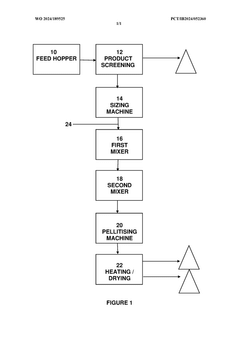

Process for pre-treating coal fines before pellitising

PatentWO2024189525A1

Innovation

- A process involving mechanical reduction of coal fines to less than 3mm, followed by high-speed wetting with water to 15-25% moisture and admixing with a binder at 3-7% volume concentration, further reducing particle size to less than 100μm under high-speed agitation, before pelletizing.

Environmental Impact Assessment of Pelletization Processes

The pelletization process in lithium mining operations, while essential for material handling and processing efficiency, carries significant environmental implications that must be thoroughly assessed. Traditional pelletization methods often generate substantial dust emissions during both production and transportation phases, contributing to air quality degradation in surrounding areas. These particulate matters can contain various lithium compounds and processing additives that may pose respiratory hazards to workers and nearby communities.

Water consumption represents another critical environmental concern in pelletization processes. Conventional binding agents typically require considerable water resources, placing additional strain on often water-scarce mining regions. The wastewater generated during pelletization frequently contains chemical binders, surfactants, and fine lithium particles that require proper treatment before discharge to prevent contamination of local water bodies.

Energy utilization in pelletization operations contributes significantly to the carbon footprint of lithium production. The drying and hardening phases are particularly energy-intensive, often relying on fossil fuel-powered systems that generate greenhouse gas emissions. Modern optimization approaches focusing on lower fines generation can substantially reduce these energy requirements by minimizing rework and reprocessing needs.

Land disturbance patterns also differ between traditional and optimized pelletization methods. Conventional approaches typically require larger settling ponds and waste management areas to handle the higher volumes of rejected fines and process waste. Optimized systems with lower fines generation can reduce this footprint considerably, preserving more natural habitat and reducing overall ecosystem disruption.

Chemical usage in pelletization presents additional environmental challenges. Binders and additives employed to enhance pellet strength may introduce synthetic compounds into the environment through dust dispersion, leaching, or accidental releases. Advanced pelletization technologies focusing on fines reduction often incorporate more environmentally benign binding agents derived from natural sources or biodegradable compounds.

Regulatory compliance frameworks increasingly emphasize life-cycle environmental impacts of mining operations. Optimized pelletization processes that minimize fines generation typically demonstrate superior performance across multiple environmental indicators, including reduced waste generation, lower emissions, and decreased resource consumption. These improvements translate directly to enhanced regulatory compliance and reduced remediation requirements at mine closure.

Water consumption represents another critical environmental concern in pelletization processes. Conventional binding agents typically require considerable water resources, placing additional strain on often water-scarce mining regions. The wastewater generated during pelletization frequently contains chemical binders, surfactants, and fine lithium particles that require proper treatment before discharge to prevent contamination of local water bodies.

Energy utilization in pelletization operations contributes significantly to the carbon footprint of lithium production. The drying and hardening phases are particularly energy-intensive, often relying on fossil fuel-powered systems that generate greenhouse gas emissions. Modern optimization approaches focusing on lower fines generation can substantially reduce these energy requirements by minimizing rework and reprocessing needs.

Land disturbance patterns also differ between traditional and optimized pelletization methods. Conventional approaches typically require larger settling ponds and waste management areas to handle the higher volumes of rejected fines and process waste. Optimized systems with lower fines generation can reduce this footprint considerably, preserving more natural habitat and reducing overall ecosystem disruption.

Chemical usage in pelletization presents additional environmental challenges. Binders and additives employed to enhance pellet strength may introduce synthetic compounds into the environment through dust dispersion, leaching, or accidental releases. Advanced pelletization technologies focusing on fines reduction often incorporate more environmentally benign binding agents derived from natural sources or biodegradable compounds.

Regulatory compliance frameworks increasingly emphasize life-cycle environmental impacts of mining operations. Optimized pelletization processes that minimize fines generation typically demonstrate superior performance across multiple environmental indicators, including reduced waste generation, lower emissions, and decreased resource consumption. These improvements translate directly to enhanced regulatory compliance and reduced remediation requirements at mine closure.

Economic Feasibility of Advanced Pelletization Technologies

The economic viability of advanced pelletization technologies for lithium mine ore requires thorough cost-benefit analysis across multiple dimensions. Initial capital expenditure for implementing state-of-the-art pelletization systems ranges from $5-15 million depending on processing capacity and technological sophistication. These systems typically incorporate precision agglomeration controls, advanced binder formulations, and automated monitoring systems that significantly reduce fines generation.

Operational cost comparisons reveal that while advanced pelletization technologies require 15-20% higher upfront investment than conventional methods, they deliver 25-30% reduction in material losses through decreased fines generation. This translates to approximately $3-4 million in annual savings for medium-scale operations processing 500,000 tons annually, with return on investment typically achieved within 2-3 years.

Energy efficiency improvements further enhance economic feasibility, with newer pelletization technologies consuming 10-15% less energy per ton of processed material. The integration of variable frequency drives, optimized thermal management systems, and precision moisture control contributes significantly to these efficiency gains, reducing operational costs by approximately $0.8-1.2 per ton.

Maintenance requirements and equipment longevity also favor advanced systems. Modern pelletization equipment demonstrates 30-40% longer service intervals and 20-25% extended operational lifespan compared to conventional alternatives, reducing total cost of ownership despite higher initial procurement costs. Predictive maintenance capabilities in newer systems further reduce unplanned downtime by up to 45%.

Market premium considerations cannot be overlooked, as lithium ore pellets with lower fines content command 8-12% higher prices in global markets due to reduced processing requirements for downstream operations. This premium directly impacts revenue potential and strengthens the business case for technology investment.

Regulatory compliance costs also favor advanced pelletization, as stricter environmental regulations increasingly penalize excessive dust generation and material waste. Advanced systems that minimize fines production can avoid potential regulatory penalties ranging from $50,000 to $500,000 annually depending on jurisdiction and operation scale.

Operational cost comparisons reveal that while advanced pelletization technologies require 15-20% higher upfront investment than conventional methods, they deliver 25-30% reduction in material losses through decreased fines generation. This translates to approximately $3-4 million in annual savings for medium-scale operations processing 500,000 tons annually, with return on investment typically achieved within 2-3 years.

Energy efficiency improvements further enhance economic feasibility, with newer pelletization technologies consuming 10-15% less energy per ton of processed material. The integration of variable frequency drives, optimized thermal management systems, and precision moisture control contributes significantly to these efficiency gains, reducing operational costs by approximately $0.8-1.2 per ton.

Maintenance requirements and equipment longevity also favor advanced systems. Modern pelletization equipment demonstrates 30-40% longer service intervals and 20-25% extended operational lifespan compared to conventional alternatives, reducing total cost of ownership despite higher initial procurement costs. Predictive maintenance capabilities in newer systems further reduce unplanned downtime by up to 45%.

Market premium considerations cannot be overlooked, as lithium ore pellets with lower fines content command 8-12% higher prices in global markets due to reduced processing requirements for downstream operations. This premium directly impacts revenue potential and strengthens the business case for technology investment.

Regulatory compliance costs also favor advanced pelletization, as stricter environmental regulations increasingly penalize excessive dust generation and material waste. Advanced systems that minimize fines production can avoid potential regulatory penalties ranging from $50,000 to $500,000 annually depending on jurisdiction and operation scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!