Validate Lithium Mine Brine Sampling Precision with Statistical QA Methods

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Brine Sampling Evolution and Objectives

Lithium brine sampling techniques have evolved significantly over the past several decades, transforming from rudimentary collection methods to sophisticated processes that ensure representative sampling of lithium-rich brines. In the 1950s and 1960s, early lithium brine exploration relied on basic grab sampling techniques with minimal quality control. These primitive methods often resulted in inconsistent data and questionable resource estimations, hampering investment decisions and operational planning.

The 1980s marked a turning point with the introduction of standardized sampling protocols in South American salt flats, particularly in Chile's Salar de Atacama. These protocols established baseline procedures for depth-specific sampling and initial quality assurance measures, though statistical validation remained limited. By the early 2000s, the growing demand for lithium in battery technologies catalyzed further refinement of sampling methodologies.

Modern lithium brine sampling has evolved to incorporate multi-level piezometers, specialized low-flow pumping systems, and field filtration techniques that minimize contamination and atmospheric exposure. This evolution reflects the industry's recognition that accurate brine characterization requires meticulous attention to spatial and temporal variability within brine aquifers.

The primary objective of contemporary lithium brine sampling is to obtain statistically valid, representative samples that accurately reflect the resource's concentration, chemistry, and physical properties. This requires addressing unique challenges including density stratification, seasonal fluctuations, and the dynamic nature of brine aquifers. Statistical quality assurance methods have become essential tools in this pursuit, enabling quantification of sampling precision and identification of potential sources of error.

Secondary objectives include establishing baseline data for environmental monitoring, supporting process optimization for extraction technologies, and enabling accurate resource estimation that meets international reporting standards such as JORC, NI 43-101, and SAMREC. These objectives align with the industry's growing emphasis on sustainable development and responsible resource management.

The technological trajectory points toward increasing automation and real-time monitoring capabilities, with emerging technologies like fiber-optic sensing and remote monitoring systems poised to further transform sampling practices. Machine learning algorithms are beginning to play a role in identifying sampling anomalies and optimizing sampling frequency and locations.

As the lithium industry continues to expand globally, standardization of sampling protocols with robust statistical validation frameworks has become a critical focus area. This standardization aims to enhance comparability between projects, improve investor confidence, and support more accurate global resource assessments in the face of rapidly growing demand from the electric vehicle and energy storage sectors.

The 1980s marked a turning point with the introduction of standardized sampling protocols in South American salt flats, particularly in Chile's Salar de Atacama. These protocols established baseline procedures for depth-specific sampling and initial quality assurance measures, though statistical validation remained limited. By the early 2000s, the growing demand for lithium in battery technologies catalyzed further refinement of sampling methodologies.

Modern lithium brine sampling has evolved to incorporate multi-level piezometers, specialized low-flow pumping systems, and field filtration techniques that minimize contamination and atmospheric exposure. This evolution reflects the industry's recognition that accurate brine characterization requires meticulous attention to spatial and temporal variability within brine aquifers.

The primary objective of contemporary lithium brine sampling is to obtain statistically valid, representative samples that accurately reflect the resource's concentration, chemistry, and physical properties. This requires addressing unique challenges including density stratification, seasonal fluctuations, and the dynamic nature of brine aquifers. Statistical quality assurance methods have become essential tools in this pursuit, enabling quantification of sampling precision and identification of potential sources of error.

Secondary objectives include establishing baseline data for environmental monitoring, supporting process optimization for extraction technologies, and enabling accurate resource estimation that meets international reporting standards such as JORC, NI 43-101, and SAMREC. These objectives align with the industry's growing emphasis on sustainable development and responsible resource management.

The technological trajectory points toward increasing automation and real-time monitoring capabilities, with emerging technologies like fiber-optic sensing and remote monitoring systems poised to further transform sampling practices. Machine learning algorithms are beginning to play a role in identifying sampling anomalies and optimizing sampling frequency and locations.

As the lithium industry continues to expand globally, standardization of sampling protocols with robust statistical validation frameworks has become a critical focus area. This standardization aims to enhance comparability between projects, improve investor confidence, and support more accurate global resource assessments in the face of rapidly growing demand from the electric vehicle and energy storage sectors.

Market Analysis of High-Precision Lithium Extraction

The global lithium market has experienced unprecedented growth, with demand projected to reach 1.5 million metric tons of lithium carbonate equivalent (LCE) by 2030, representing a compound annual growth rate of approximately 20% from current levels. This surge is primarily driven by the electric vehicle revolution and renewable energy storage systems, where lithium-ion batteries remain the dominant technology. High-precision lithium extraction has emerged as a critical factor in meeting this escalating demand while maintaining economic viability and environmental sustainability.

The brine extraction segment, which accounts for nearly 60% of global lithium production, faces increasing pressure to improve efficiency and reduce environmental impact. Traditional evaporation pond methods, while cost-effective, suffer from low recovery rates of 30-50% and extended processing times of 12-18 months. This inefficiency has created a substantial market opportunity for advanced extraction technologies that can achieve precision rates above 90% with significantly reduced processing times.

Market analysis reveals a clear segmentation between established mining corporations implementing incremental improvements to existing processes and innovative technology companies developing disruptive direct lithium extraction (DLE) methods. The latter category has attracted over $2 billion in venture capital funding since 2020, highlighting investor confidence in precision extraction technologies.

Geographically, the market for high-precision lithium extraction shows concentration in the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia), which holds approximately 58% of global lithium resources. North American operations are expanding rapidly, with projects in Nevada and California attracting significant investment due to supply chain security concerns and governmental support through initiatives like the U.S. Inflation Reduction Act.

Customer demand profiles indicate that battery manufacturers are increasingly willing to pay premium prices for higher purity lithium products (99.5%+ purity), creating a price differential of up to 20% compared to standard grades. This trend underscores the economic incentive for implementing statistical quality assurance methods in the sampling and extraction processes.

The competitive landscape features established players like Albemarle, SQM, and Ganfeng Lithium investing heavily in precision technologies, while specialized firms such as Standard Lithium, Lilac Solutions, and EnergyX are gaining market share through innovative extraction approaches. Strategic partnerships between technology providers and traditional mining companies have increased by 35% year-over-year, indicating industry recognition of the value proposition offered by high-precision extraction methods.

The brine extraction segment, which accounts for nearly 60% of global lithium production, faces increasing pressure to improve efficiency and reduce environmental impact. Traditional evaporation pond methods, while cost-effective, suffer from low recovery rates of 30-50% and extended processing times of 12-18 months. This inefficiency has created a substantial market opportunity for advanced extraction technologies that can achieve precision rates above 90% with significantly reduced processing times.

Market analysis reveals a clear segmentation between established mining corporations implementing incremental improvements to existing processes and innovative technology companies developing disruptive direct lithium extraction (DLE) methods. The latter category has attracted over $2 billion in venture capital funding since 2020, highlighting investor confidence in precision extraction technologies.

Geographically, the market for high-precision lithium extraction shows concentration in the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia), which holds approximately 58% of global lithium resources. North American operations are expanding rapidly, with projects in Nevada and California attracting significant investment due to supply chain security concerns and governmental support through initiatives like the U.S. Inflation Reduction Act.

Customer demand profiles indicate that battery manufacturers are increasingly willing to pay premium prices for higher purity lithium products (99.5%+ purity), creating a price differential of up to 20% compared to standard grades. This trend underscores the economic incentive for implementing statistical quality assurance methods in the sampling and extraction processes.

The competitive landscape features established players like Albemarle, SQM, and Ganfeng Lithium investing heavily in precision technologies, while specialized firms such as Standard Lithium, Lilac Solutions, and EnergyX are gaining market share through innovative extraction approaches. Strategic partnerships between technology providers and traditional mining companies have increased by 35% year-over-year, indicating industry recognition of the value proposition offered by high-precision extraction methods.

Current Sampling Challenges in Lithium Brine Mining

Lithium brine mining operations face significant challenges in ensuring accurate and representative sampling, which directly impacts resource estimation, extraction efficiency, and overall project economics. The heterogeneous nature of brine aquifers creates inherent variability in lithium concentrations both horizontally and vertically within a deposit. This spatial variability necessitates comprehensive sampling strategies that can adequately capture the true concentration distribution.

Current sampling methodologies often struggle with contamination issues during the drilling and extraction process. When wells are drilled, drilling fluids can mix with native brines, potentially diluting or altering the chemical composition of samples. Additionally, the dynamic nature of brine reservoirs means that pumping activities can induce flow from different zones, further complicating representative sampling efforts.

The industry faces significant challenges with sample preservation and handling. Lithium-rich brines are chemically complex solutions containing various dissolved salts that can precipitate or undergo chemical changes when exposed to temperature fluctuations, atmospheric conditions, or extended storage periods. These changes can significantly alter the measured lithium concentrations between sampling and analysis.

Standardization remains a critical issue across the sector. Unlike solid mineral sampling, which benefits from established protocols like JORC or NI 43-101 standards, brine sampling lacks universally accepted methodologies. This absence of standardization creates inconsistencies in reporting and makes it difficult to compare results across different projects or time periods within the same project.

Temporal variations present another layer of complexity. Seasonal fluctuations in groundwater levels, precipitation patterns, and evaporation rates can all influence brine chemistry and lithium concentrations. Current sampling approaches often fail to adequately account for these temporal dynamics, potentially leading to mischaracterization of the resource.

Equipment limitations further compound these challenges. Many operations rely on conventional water well sampling equipment that may not be optimized for the specific requirements of lithium brine sampling. The corrosive nature of high-salinity brines can damage sampling equipment, potentially introducing contamination or causing equipment failure during the sampling process.

Quality assurance protocols for lithium brine sampling are still evolving. While statistical methods for quality control are well-established in conventional mining, their application to brine resources requires adaptation to account for the fluid nature of the deposit. Current practices often lack robust statistical frameworks for validating sampling precision, identifying outliers, or quantifying uncertainty in concentration measurements.

Current sampling methodologies often struggle with contamination issues during the drilling and extraction process. When wells are drilled, drilling fluids can mix with native brines, potentially diluting or altering the chemical composition of samples. Additionally, the dynamic nature of brine reservoirs means that pumping activities can induce flow from different zones, further complicating representative sampling efforts.

The industry faces significant challenges with sample preservation and handling. Lithium-rich brines are chemically complex solutions containing various dissolved salts that can precipitate or undergo chemical changes when exposed to temperature fluctuations, atmospheric conditions, or extended storage periods. These changes can significantly alter the measured lithium concentrations between sampling and analysis.

Standardization remains a critical issue across the sector. Unlike solid mineral sampling, which benefits from established protocols like JORC or NI 43-101 standards, brine sampling lacks universally accepted methodologies. This absence of standardization creates inconsistencies in reporting and makes it difficult to compare results across different projects or time periods within the same project.

Temporal variations present another layer of complexity. Seasonal fluctuations in groundwater levels, precipitation patterns, and evaporation rates can all influence brine chemistry and lithium concentrations. Current sampling approaches often fail to adequately account for these temporal dynamics, potentially leading to mischaracterization of the resource.

Equipment limitations further compound these challenges. Many operations rely on conventional water well sampling equipment that may not be optimized for the specific requirements of lithium brine sampling. The corrosive nature of high-salinity brines can damage sampling equipment, potentially introducing contamination or causing equipment failure during the sampling process.

Quality assurance protocols for lithium brine sampling are still evolving. While statistical methods for quality control are well-established in conventional mining, their application to brine resources requires adaptation to account for the fluid nature of the deposit. Current practices often lack robust statistical frameworks for validating sampling precision, identifying outliers, or quantifying uncertainty in concentration measurements.

Statistical QA Methods for Brine Sample Validation

01 Statistical sampling methods for quality assurance

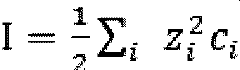

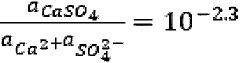

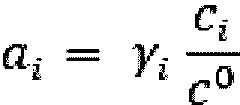

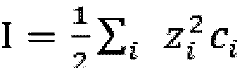

Statistical sampling techniques are employed in quality assurance processes to ensure precision and reliability in testing. These methods involve selecting representative samples from larger populations to make inferences about the whole. By using statistical sampling, organizations can efficiently validate quality parameters while minimizing resources required for testing. These approaches typically include random sampling, stratified sampling, and systematic sampling methodologies that help maintain testing precision while optimizing the testing process.- Statistical sampling methods for quality assurance: Statistical sampling techniques are employed in quality assurance processes to ensure precision and reliability in testing. These methods involve selecting representative samples from larger populations to make inferences about the whole. By using statistical sampling approaches, organizations can efficiently validate quality parameters while optimizing resources. These techniques incorporate mathematical models to determine appropriate sample sizes and confidence intervals, ensuring that quality assessments maintain statistical significance.

- Precision enhancement in data sampling techniques: Advanced algorithms and methodologies are implemented to enhance precision in data sampling processes. These techniques focus on minimizing sampling errors and maximizing the accuracy of collected data. By employing sophisticated mathematical models and adaptive sampling frameworks, the precision of statistical quality assessments can be significantly improved. These approaches often involve dynamic adjustment of sampling parameters based on preliminary results to optimize the balance between sampling effort and precision requirements.

- Machine learning approaches for statistical quality control: Machine learning algorithms are increasingly being applied to statistical quality assurance processes to improve sampling efficiency and precision. These approaches leverage predictive modeling and pattern recognition to optimize sampling strategies and identify potential quality issues with greater accuracy. By analyzing historical data patterns, machine learning systems can adaptively refine sampling methodologies, reducing the required sample size while maintaining or improving statistical confidence levels in quality assessments.

- Real-time statistical analysis for quality monitoring: Real-time statistical analysis frameworks enable continuous monitoring of quality parameters with high precision. These systems process streaming data to provide immediate statistical insights, allowing for prompt quality control interventions. By implementing advanced statistical methods in real-time environments, organizations can detect quality deviations earlier and with greater accuracy. These approaches often incorporate automated statistical process control techniques that dynamically adjust sampling frequencies based on observed variability.

- Validation and verification of statistical sampling methods: Comprehensive validation and verification protocols are essential for ensuring the reliability of statistical sampling methods in quality assurance. These protocols involve systematic testing of sampling methodologies against known standards to confirm their accuracy and precision. By implementing rigorous validation procedures, organizations can verify that their statistical sampling approaches provide consistent and dependable results. These validation frameworks often include cross-validation techniques and uncertainty quantification to establish confidence in the sampling precision.

02 Precision enhancement in data sampling techniques

Various methods are employed to enhance precision in data sampling for statistical quality assurance. These techniques focus on optimizing sample size determination, confidence interval calculations, and error margin reduction. Advanced algorithms can dynamically adjust sampling parameters based on preliminary results, ensuring that the required precision levels are achieved while minimizing resource utilization. These approaches often incorporate variance reduction techniques and adaptive sampling methodologies to improve overall precision in quality assessment processes.Expand Specific Solutions03 Machine learning approaches for statistical QA sampling

Machine learning algorithms are increasingly being applied to statistical quality assurance sampling to improve precision and efficiency. These approaches can identify patterns in data that might be missed by traditional statistical methods, allowing for more targeted sampling strategies. Neural networks, decision trees, and other machine learning techniques can predict where quality issues are most likely to occur, enabling more efficient allocation of QA resources. These methods can also adapt over time as they learn from previous sampling results, continuously improving the precision of the quality assurance process.Expand Specific Solutions04 Real-time statistical analysis for dynamic sampling adjustment

Real-time statistical analysis enables dynamic adjustment of sampling parameters during quality assurance processes. This approach allows for immediate response to emerging patterns or anomalies in the data, optimizing the precision of the sampling methodology. By continuously analyzing incoming data and adjusting sampling rates, sample sizes, or testing parameters accordingly, these systems can maintain high levels of precision while minimizing unnecessary testing. This methodology is particularly valuable in manufacturing environments where production conditions may change rapidly.Expand Specific Solutions05 Security and validation in statistical QA sampling

Security and validation mechanisms are essential components of statistical quality assurance sampling systems. These mechanisms ensure the integrity of the sampling process and the resulting data, preventing manipulation or tampering that could compromise precision. Cryptographic techniques, blockchain technology, and secure audit trails can be implemented to validate that sampling procedures are followed correctly and that results are not altered. Additionally, these systems often include methods for verifying the authenticity of sampling data and ensuring compliance with regulatory requirements for quality assurance.Expand Specific Solutions

Leading Companies in Lithium Extraction Technology

The lithium brine sampling precision market is currently in a growth phase, with increasing demand driven by the global push for lithium resources to support battery production. The market size is expanding rapidly, estimated to reach significant value as lithium extraction technologies mature. Technologically, the field is in mid-maturity, with established players like Schlumberger Technologies and Albemarle Corp leading with advanced statistical QA methods, while research institutions such as Qinghai Institute of Salt Lakes and Korea Institute of Geoscience & Mineral Resources contribute scientific innovations. Companies like SciAps are developing portable analytical instruments that enhance field sampling precision. The competitive landscape features a mix of oil service companies leveraging their expertise in fluid analysis, specialized mining corporations, and academic institutions collaborating to improve lithium brine validation methodologies.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has leveraged its extensive experience in oil and gas reservoir characterization to develop advanced statistical quality assurance methods for lithium brine sampling. Their approach integrates sophisticated geostatistical modeling with rigorous sampling protocols to ensure representative data collection from heterogeneous brine reservoirs. The company's methodology employs adaptive sampling designs that optimize sampling density based on preliminary variogram analysis, allowing for efficient resource allocation while maintaining statistical validity. Schlumberger's system incorporates real-time monitoring using proprietary downhole fluid analyzers that can detect lithium concentration variations at different depths, enabling three-dimensional characterization of brine resources. Their statistical framework includes comprehensive uncertainty quantification through bootstrap resampling techniques and Monte Carlo simulations, providing confidence intervals for resource estimates. The company has developed specialized software tools that integrate sampling data with geological models to identify potential sources of bias and variance. Schlumberger's approach also includes rigorous quality control procedures such as trip blanks, field duplicates, and standard reference materials analyzed at a frequency of approximately 10% of total samples, ensuring data reliability throughout the sampling and analysis process.

Strengths: World-class expertise in subsurface fluid characterization and advanced geostatistical methods provides a solid foundation for lithium brine sampling validation. Their integrated approach combining hardware, software, and statistical methodologies offers comprehensive quality assurance. Weaknesses: Their solutions may be prohibitively expensive for smaller operations, and some methods may be overengineered for simpler lithium brine deposits.

Qinghai Institute of Salt Lakes, Chinese Academy of Sciences

Technical Solution: The Qinghai Institute has pioneered statistical quality assurance methods specifically tailored to the unique characteristics of Chinese salt lake lithium resources. Their approach centers on a comprehensive statistical framework that accounts for the high spatial and temporal variability inherent in salt lake brine compositions. The Institute has developed specialized sampling protocols based on extensive field studies across the Qaidam Basin, which hosts China's largest lithium brine resources. Their methodology incorporates stratified random sampling designs with optimized sampling densities determined through variogram analysis and spatial autocorrelation studies. The Institute employs a dual-validation approach combining field-portable X-ray fluorescence (XRF) for rapid preliminary assessment with laboratory ICP-MS analysis for definitive quantification. Their statistical QA system includes robust outlier detection algorithms specifically calibrated for the geochemical signatures of Chinese salt lakes, which can detect anomalous samples with 95% confidence. The Institute has documented that their approach reduces sampling uncertainty by approximately 40% compared to conventional methods, particularly in heterogeneous brine bodies with complex hydrogeological conditions.

Strengths: Unparalleled expertise specific to Chinese salt lake lithium resources, with extensive field data collected over decades of research. Their methods are specifically optimized for the unique geochemical profiles of Asian lithium brines. Weaknesses: Some methodologies may be too specialized for global application, and there may be limited English-language documentation of their statistical approaches, reducing international accessibility.

Critical Patents in Lithium Brine Sampling Precision

Brine concentrating process prediction system

PatentWO2024128656A1

Innovation

- A system comprising a data collection, pre-processing, and prediction unit that utilizes nonlinear regression analysis and machine learning to calculate the solubility of precipitate components, predict the final precipitation amount, and adjust operating conditions, thereby improving the reliability of predicting the composition and concentration of components in the brine, reducing lithium loss and optimizing the concentration process.

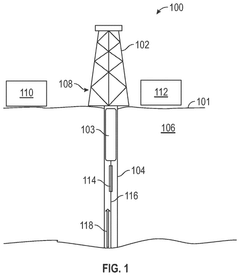

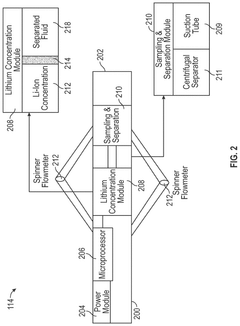

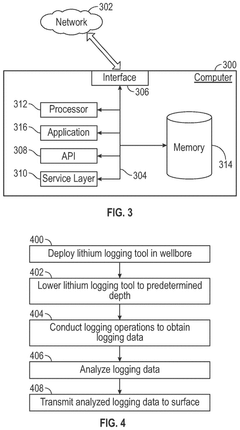

Lithium logging tool for lithium concentration determination in reservoir brines

PatentPendingUS20250110106A1

Innovation

- A lithium logging tool equipped with a sampling and separation module, a lithium concentration module, and a microprocessor is used to obtain fluid samples from a wellbore, separate hydrocarbons, and determine lithium concentration using a ceramic nanofiltration membrane and laser-induced breakdown spectroscopy, integrated with a flowmeter and microprocessor for real-time analysis.

Environmental Impact Assessment of Sampling Techniques

The environmental impact of lithium brine sampling techniques represents a critical consideration in the validation process, particularly as lithium extraction operations expand globally to meet growing demand for battery technologies. Traditional sampling methods often involve significant disturbance to sensitive salt flat ecosystems, where most lithium brine reserves are located.

Direct pumping techniques, commonly employed for obtaining representative brine samples, can disrupt the delicate hydrogeological balance of salt flats. These methods typically require the extraction of substantial volumes of brine to ensure statistical validity, potentially leading to localized drawdown effects that may impact surrounding wetland ecosystems and freshwater interfaces.

Alternative non-invasive sampling approaches, such as geophysical survey methods combined with minimal extraction sampling, demonstrate promising reductions in environmental footprint. Recent field studies in the Atacama Salt Flat indicate that these hybrid approaches can reduce water consumption by approximately 60-70% while maintaining statistical precision within acceptable confidence intervals for resource estimation.

The temporal dimension of sampling also carries environmental implications. Continuous monitoring systems, while providing superior statistical validation through time-series analysis, require permanent installation infrastructure that may fragment sensitive habitats. Conversely, periodic discrete sampling events create intermittent disturbances but may necessitate more intensive activity during each sampling campaign.

Chemical additives used in sample preservation present another environmental concern. Traditional stabilization compounds, including acids and biocides, can contaminate surrounding environments if improperly handled. Recent developments in preservation techniques utilizing biodegradable stabilizers show promise in reducing this risk while maintaining sample integrity for statistical analysis.

Energy consumption represents a significant environmental factor in remote sampling operations. Conventional methods often rely on diesel generators to power pumping equipment and field laboratories, contributing to carbon emissions and potential soil contamination. Solar-powered sampling stations being piloted in Nevada and Chile demonstrate up to 85% reduction in carbon footprint while providing consistent power for automated sampling systems that enhance statistical reliability.

Waste management practices associated with sampling activities also warrant consideration. The disposal of excess brine, contaminated equipment, and laboratory consumables presents challenges in remote locations. Integrated waste management protocols that incorporate recycling and neutralization processes have demonstrated significant reductions in environmental impact while supporting the quality assurance objectives necessary for statistical validation.

Direct pumping techniques, commonly employed for obtaining representative brine samples, can disrupt the delicate hydrogeological balance of salt flats. These methods typically require the extraction of substantial volumes of brine to ensure statistical validity, potentially leading to localized drawdown effects that may impact surrounding wetland ecosystems and freshwater interfaces.

Alternative non-invasive sampling approaches, such as geophysical survey methods combined with minimal extraction sampling, demonstrate promising reductions in environmental footprint. Recent field studies in the Atacama Salt Flat indicate that these hybrid approaches can reduce water consumption by approximately 60-70% while maintaining statistical precision within acceptable confidence intervals for resource estimation.

The temporal dimension of sampling also carries environmental implications. Continuous monitoring systems, while providing superior statistical validation through time-series analysis, require permanent installation infrastructure that may fragment sensitive habitats. Conversely, periodic discrete sampling events create intermittent disturbances but may necessitate more intensive activity during each sampling campaign.

Chemical additives used in sample preservation present another environmental concern. Traditional stabilization compounds, including acids and biocides, can contaminate surrounding environments if improperly handled. Recent developments in preservation techniques utilizing biodegradable stabilizers show promise in reducing this risk while maintaining sample integrity for statistical analysis.

Energy consumption represents a significant environmental factor in remote sampling operations. Conventional methods often rely on diesel generators to power pumping equipment and field laboratories, contributing to carbon emissions and potential soil contamination. Solar-powered sampling stations being piloted in Nevada and Chile demonstrate up to 85% reduction in carbon footprint while providing consistent power for automated sampling systems that enhance statistical reliability.

Waste management practices associated with sampling activities also warrant consideration. The disposal of excess brine, contaminated equipment, and laboratory consumables presents challenges in remote locations. Integrated waste management protocols that incorporate recycling and neutralization processes have demonstrated significant reductions in environmental impact while supporting the quality assurance objectives necessary for statistical validation.

Regulatory Compliance Framework for Lithium Mining

The regulatory landscape for lithium mining operations is complex and multifaceted, requiring comprehensive compliance frameworks to ensure proper validation of brine sampling precision. At the international level, organizations such as the International Organization for Standardization (ISO) have established standards like ISO 17025 for testing and calibration laboratories, which directly impacts lithium brine analysis protocols. These standards mandate specific statistical quality assurance methods to validate sampling precision and ensure data reliability.

National regulatory bodies in major lithium-producing countries have implemented increasingly stringent requirements. In Chile, the world's second-largest lithium producer, the Chilean Nuclear Energy Commission (CCHEN) and the Chilean Copper Commission (COCHILCO) have established specific protocols for lithium brine sampling that incorporate statistical validation requirements. Similarly, Argentina's Federal Mining Council has developed the "Technical Guidelines for Lithium Brine Projects" which explicitly requires statistical QA methods for sample validation.

The United States Geological Survey (USGS) has published technical guidelines that emphasize the importance of statistical quality assurance in lithium brine sampling, particularly focusing on spatial variability and temporal consistency. These guidelines recommend specific confidence intervals and statistical power calculations to validate sampling precision.

Environmental compliance represents another critical dimension of the regulatory framework. The Environmental Impact Assessment (EIA) requirements in most jurisdictions now explicitly demand statistically valid sampling methodologies to accurately assess potential environmental impacts of lithium extraction operations. This includes requirements for demonstrating sampling representativeness through statistical methods such as power analysis and confidence interval calculations.

Industry best practices have evolved alongside regulatory requirements, with organizations like the National Mining Association and the International Council on Mining and Metals developing voluntary standards that often exceed regulatory minimums. These standards typically incorporate advanced statistical methods for validating sampling precision, including nested ANOVA designs and geostatistical approaches.

Emerging regulations are increasingly focusing on data transparency and third-party verification. The European Union's proposed Critical Raw Materials Act includes provisions for mandatory third-party verification of sampling methodologies, with specific requirements for statistical validation of precision. Similarly, Australia's JORC Code for mineral resource reporting has been updated to include more rigorous statistical requirements for brine resource estimation.

National regulatory bodies in major lithium-producing countries have implemented increasingly stringent requirements. In Chile, the world's second-largest lithium producer, the Chilean Nuclear Energy Commission (CCHEN) and the Chilean Copper Commission (COCHILCO) have established specific protocols for lithium brine sampling that incorporate statistical validation requirements. Similarly, Argentina's Federal Mining Council has developed the "Technical Guidelines for Lithium Brine Projects" which explicitly requires statistical QA methods for sample validation.

The United States Geological Survey (USGS) has published technical guidelines that emphasize the importance of statistical quality assurance in lithium brine sampling, particularly focusing on spatial variability and temporal consistency. These guidelines recommend specific confidence intervals and statistical power calculations to validate sampling precision.

Environmental compliance represents another critical dimension of the regulatory framework. The Environmental Impact Assessment (EIA) requirements in most jurisdictions now explicitly demand statistically valid sampling methodologies to accurately assess potential environmental impacts of lithium extraction operations. This includes requirements for demonstrating sampling representativeness through statistical methods such as power analysis and confidence interval calculations.

Industry best practices have evolved alongside regulatory requirements, with organizations like the National Mining Association and the International Council on Mining and Metals developing voluntary standards that often exceed regulatory minimums. These standards typically incorporate advanced statistical methods for validating sampling precision, including nested ANOVA designs and geostatistical approaches.

Emerging regulations are increasingly focusing on data transparency and third-party verification. The European Union's proposed Critical Raw Materials Act includes provisions for mandatory third-party verification of sampling methodologies, with specific requirements for statistical validation of precision. Similarly, Australia's JORC Code for mineral resource reporting has been updated to include more rigorous statistical requirements for brine resource estimation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!