Lithium Mine Brine vs Spodumene Concentrate: Carbon Intensity Comparison

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Technologies Background and Objectives

Lithium has emerged as a critical element in the global transition towards renewable energy and electrification, primarily due to its essential role in lithium-ion batteries. The historical development of lithium extraction technologies dates back to the early 20th century, but significant commercial extraction began in the 1950s. Initially, lithium was primarily sourced from hard rock mining of pegmatite deposits, particularly spodumene. However, the 1980s saw a paradigm shift with the development of brine extraction methods in salt flats, particularly in South America's "Lithium Triangle."

The technological evolution in lithium extraction has been driven by increasing demand from electronics and, more recently, electric vehicles and grid storage systems. This demand has accelerated research into more efficient and environmentally sustainable extraction methods, as traditional approaches face scrutiny for their environmental footprint, particularly regarding carbon emissions.

Current lithium extraction technologies primarily fall into two categories: hard rock mining (predominantly spodumene concentrate) and brine evaporation. Each method presents distinct carbon intensity profiles due to differences in energy requirements, processing techniques, and geographical factors. Spodumene concentrate extraction involves energy-intensive mining, crushing, and high-temperature conversion processes. Conversely, brine extraction relies on solar evaporation of lithium-rich brines, followed by chemical processing to isolate lithium compounds.

The carbon intensity comparison between these methods has become increasingly important as manufacturers and consumers demand more sustainable supply chains. Understanding the carbon footprint of different lithium sources is crucial for developing strategies to reduce the environmental impact of battery production and meet increasingly stringent regulatory requirements.

The technological trajectory indicates a growing interest in direct lithium extraction (DLE) technologies, which promise reduced environmental impact and potentially lower carbon emissions compared to traditional methods. Additionally, research into lithium recycling from spent batteries represents another avenue for reducing the carbon intensity of the lithium supply chain.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of the carbon intensity between lithium extraction from brine operations and spodumene concentrate production. This analysis aims to quantify emissions across the entire value chain, identify key contributors to carbon footprint, and evaluate potential technological innovations that could reduce emissions in both extraction pathways.

The technological evolution in lithium extraction has been driven by increasing demand from electronics and, more recently, electric vehicles and grid storage systems. This demand has accelerated research into more efficient and environmentally sustainable extraction methods, as traditional approaches face scrutiny for their environmental footprint, particularly regarding carbon emissions.

Current lithium extraction technologies primarily fall into two categories: hard rock mining (predominantly spodumene concentrate) and brine evaporation. Each method presents distinct carbon intensity profiles due to differences in energy requirements, processing techniques, and geographical factors. Spodumene concentrate extraction involves energy-intensive mining, crushing, and high-temperature conversion processes. Conversely, brine extraction relies on solar evaporation of lithium-rich brines, followed by chemical processing to isolate lithium compounds.

The carbon intensity comparison between these methods has become increasingly important as manufacturers and consumers demand more sustainable supply chains. Understanding the carbon footprint of different lithium sources is crucial for developing strategies to reduce the environmental impact of battery production and meet increasingly stringent regulatory requirements.

The technological trajectory indicates a growing interest in direct lithium extraction (DLE) technologies, which promise reduced environmental impact and potentially lower carbon emissions compared to traditional methods. Additionally, research into lithium recycling from spent batteries represents another avenue for reducing the carbon intensity of the lithium supply chain.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of the carbon intensity between lithium extraction from brine operations and spodumene concentrate production. This analysis aims to quantify emissions across the entire value chain, identify key contributors to carbon footprint, and evaluate potential technological innovations that could reduce emissions in both extraction pathways.

Market Demand Analysis for Low-Carbon Lithium

The global lithium market is experiencing unprecedented growth driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. This growth is increasingly accompanied by a significant shift in demand patterns, with consumers, manufacturers, and regulatory bodies placing greater emphasis on low-carbon lithium sources. Current market projections indicate that the global lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate exceeding 25%.

Within this expanding market, the demand specifically for low-carbon lithium is emerging as a distinct segment. Automotive manufacturers, particularly premium EV brands in Europe and North America, are increasingly incorporating carbon footprint metrics into their supplier selection criteria. This trend is evidenced by recent procurement policies announced by major automakers that establish maximum carbon intensity thresholds for battery materials.

The price premium for low-carbon lithium is beginning to materialize in market transactions. While conventional lithium carbonate and hydroxide have traditionally been commoditized products, recent contract negotiations reveal that buyers are willing to pay 5-15% premiums for lithium with verified lower carbon intensity. This differentiation is creating a two-tier market structure that rewards producers with cleaner extraction and processing methods.

Regulatory frameworks are accelerating this market segmentation. The European Union's Battery Regulation, which will be fully implemented by 2027, mandates carbon footprint declarations for all batteries sold in the EU market. Similar regulations are under development in North America and parts of Asia, creating a global regulatory environment that favors low-carbon lithium sources.

Consumer awareness is also driving demand for environmentally responsible supply chains. Recent market research indicates that 67% of EV buyers consider environmental impact beyond tailpipe emissions when making purchasing decisions. This consumer preference is translating into pressure on automotive brands to secure verifiably sustainable materials.

The geographical distribution of demand for low-carbon lithium shows concentration in markets with strong environmental regulations. Western Europe currently represents the largest market for premium low-carbon lithium, followed by North America and Japan. However, China, despite being the largest overall lithium consumer, shows a more price-sensitive approach with lower immediate demand for premium low-carbon products.

Looking forward, industry analysts project that by 2028, low-carbon lithium could command up to 40% of the total lithium market by value, despite representing a smaller percentage by volume. This trend indicates a fundamental shift in how lithium is valued in global markets, with carbon intensity becoming a key differentiator alongside traditional quality metrics.

Within this expanding market, the demand specifically for low-carbon lithium is emerging as a distinct segment. Automotive manufacturers, particularly premium EV brands in Europe and North America, are increasingly incorporating carbon footprint metrics into their supplier selection criteria. This trend is evidenced by recent procurement policies announced by major automakers that establish maximum carbon intensity thresholds for battery materials.

The price premium for low-carbon lithium is beginning to materialize in market transactions. While conventional lithium carbonate and hydroxide have traditionally been commoditized products, recent contract negotiations reveal that buyers are willing to pay 5-15% premiums for lithium with verified lower carbon intensity. This differentiation is creating a two-tier market structure that rewards producers with cleaner extraction and processing methods.

Regulatory frameworks are accelerating this market segmentation. The European Union's Battery Regulation, which will be fully implemented by 2027, mandates carbon footprint declarations for all batteries sold in the EU market. Similar regulations are under development in North America and parts of Asia, creating a global regulatory environment that favors low-carbon lithium sources.

Consumer awareness is also driving demand for environmentally responsible supply chains. Recent market research indicates that 67% of EV buyers consider environmental impact beyond tailpipe emissions when making purchasing decisions. This consumer preference is translating into pressure on automotive brands to secure verifiably sustainable materials.

The geographical distribution of demand for low-carbon lithium shows concentration in markets with strong environmental regulations. Western Europe currently represents the largest market for premium low-carbon lithium, followed by North America and Japan. However, China, despite being the largest overall lithium consumer, shows a more price-sensitive approach with lower immediate demand for premium low-carbon products.

Looking forward, industry analysts project that by 2028, low-carbon lithium could command up to 40% of the total lithium market by value, despite representing a smaller percentage by volume. This trend indicates a fundamental shift in how lithium is valued in global markets, with carbon intensity becoming a key differentiator alongside traditional quality metrics.

Current State and Challenges in Lithium Extraction Methods

The lithium extraction industry currently employs two primary methods: brine extraction and hard rock mining, each with distinct carbon footprints and environmental implications. Brine extraction, predominantly utilized in South America's "Lithium Triangle" (Argentina, Bolivia, and Chile), involves pumping lithium-rich brine from underground reservoirs into evaporation ponds. This process relies heavily on natural solar evaporation, which can take 12-18 months before lithium concentration reaches optimal levels for processing.

Spodumene concentrate extraction, conversely, is centered in Australia, China, and parts of North America. This method requires traditional hard rock mining techniques, followed by crushing, grinding, and concentration processes that are significantly more energy-intensive than brine operations. The concentrated spodumene then undergoes conversion to lithium hydroxide or carbonate through high-temperature calcination and chemical processing.

Recent life cycle assessments reveal substantial differences in carbon intensity between these methods. Brine operations typically generate 5-15 kg CO2e per kg of lithium carbonate equivalent (LCE), while spodumene concentrate processing produces approximately 15-25 kg CO2e per kg LCE. However, these figures vary considerably based on local energy sources, processing efficiency, and transportation requirements.

A significant challenge in accurate carbon intensity comparison is methodological inconsistency across studies. Different system boundaries, allocation methods, and data quality create substantial variation in reported values. Furthermore, many analyses fail to account for indirect emissions from land use changes, particularly relevant for brine operations that affect large surface areas of sensitive ecosystems.

Water consumption presents another critical challenge, especially for brine operations in water-scarce regions. While spodumene mining requires water primarily for processing, brine extraction can deplete local aquifers, potentially affecting surrounding communities and ecosystems. This water-carbon nexus remains inadequately quantified in most comparative analyses.

Technological limitations also persist in both extraction methods. Brine operations struggle with low recovery rates (typically 30-50%) and lengthy production timelines, while spodumene processing faces high energy requirements and chemical consumption. Emerging direct lithium extraction (DLE) technologies promise to address these inefficiencies but remain largely unproven at commercial scale.

Regulatory frameworks governing carbon emissions in lithium production vary significantly across jurisdictions, creating uneven standards and reporting requirements. This regulatory fragmentation complicates meaningful comparison and hinders the development of industry-wide carbon reduction strategies.

Spodumene concentrate extraction, conversely, is centered in Australia, China, and parts of North America. This method requires traditional hard rock mining techniques, followed by crushing, grinding, and concentration processes that are significantly more energy-intensive than brine operations. The concentrated spodumene then undergoes conversion to lithium hydroxide or carbonate through high-temperature calcination and chemical processing.

Recent life cycle assessments reveal substantial differences in carbon intensity between these methods. Brine operations typically generate 5-15 kg CO2e per kg of lithium carbonate equivalent (LCE), while spodumene concentrate processing produces approximately 15-25 kg CO2e per kg LCE. However, these figures vary considerably based on local energy sources, processing efficiency, and transportation requirements.

A significant challenge in accurate carbon intensity comparison is methodological inconsistency across studies. Different system boundaries, allocation methods, and data quality create substantial variation in reported values. Furthermore, many analyses fail to account for indirect emissions from land use changes, particularly relevant for brine operations that affect large surface areas of sensitive ecosystems.

Water consumption presents another critical challenge, especially for brine operations in water-scarce regions. While spodumene mining requires water primarily for processing, brine extraction can deplete local aquifers, potentially affecting surrounding communities and ecosystems. This water-carbon nexus remains inadequately quantified in most comparative analyses.

Technological limitations also persist in both extraction methods. Brine operations struggle with low recovery rates (typically 30-50%) and lengthy production timelines, while spodumene processing faces high energy requirements and chemical consumption. Emerging direct lithium extraction (DLE) technologies promise to address these inefficiencies but remain largely unproven at commercial scale.

Regulatory frameworks governing carbon emissions in lithium production vary significantly across jurisdictions, creating uneven standards and reporting requirements. This regulatory fragmentation complicates meaningful comparison and hinders the development of industry-wide carbon reduction strategies.

Current Carbon Footprint Assessment Methodologies

01 Carbon intensity comparison between brine and spodumene extraction methods

The carbon footprint of lithium extraction varies significantly between brine and spodumene concentrate methods. Brine extraction generally has a lower carbon intensity as it primarily uses solar evaporation, while spodumene concentrate extraction requires energy-intensive mining, crushing, and high-temperature conversion processes. The difference in carbon emissions between these methods can be substantial, with some studies indicating that hard rock mining can produce up to three times more CO2 emissions per ton of lithium carbonate equivalent produced compared to brine operations.- Carbon intensity comparison between brine and spodumene extraction methods: The carbon footprint of lithium extraction varies significantly between brine and spodumene concentrate methods. Brine extraction generally has a lower carbon intensity as it primarily relies on solar evaporation rather than energy-intensive mining and processing. Spodumene concentrate extraction requires hard rock mining, crushing, and high-temperature conversion processes, resulting in higher carbon emissions. This comparison is crucial for companies seeking to develop more environmentally sustainable lithium production methods.

- Innovative technologies for reducing carbon emissions in lithium extraction: Recent technological innovations aim to reduce the carbon intensity of lithium extraction processes. These include direct lithium extraction (DLE) technologies that bypass traditional evaporation ponds, advanced electrolysis methods, and more efficient chemical processes. Such innovations can significantly reduce water usage, land disturbance, and energy consumption in both brine and spodumene processing, leading to lower overall carbon emissions while maintaining or improving lithium recovery rates.

- Energy sources and their impact on lithium extraction carbon footprint: The energy sources used in lithium extraction significantly impact the overall carbon intensity of the process. Renewable energy integration, such as solar and wind power, can substantially reduce the carbon footprint of both brine and spodumene extraction methods. Some operations have implemented clean energy solutions including geothermal power for brine operations and renewable electricity for processing facilities. The transition from fossil fuel-powered equipment to electric alternatives further reduces carbon emissions in the extraction process.

- Water usage and environmental impact in lithium extraction methods: Water consumption varies significantly between lithium extraction methods and directly affects their environmental impact and carbon intensity. Brine extraction typically requires large volumes of water for evaporation ponds, while spodumene processing needs water for concentration and refining. Advanced water recycling systems and closed-loop processes can reduce freshwater consumption and associated carbon emissions from water pumping and treatment. The environmental footprint of water usage must be considered alongside direct carbon emissions when evaluating extraction methods.

- Life cycle assessment of lithium production methods: Life cycle assessments provide comprehensive evaluations of the carbon intensity of different lithium extraction methods from cradle to gate. These assessments consider factors such as raw material acquisition, processing, transportation, and waste management. Studies indicate that brine operations typically generate 5-10 times less CO2 equivalent emissions per ton of lithium carbonate compared to spodumene concentrate processing. However, factors such as ore grade, processing efficiency, and local energy mix can significantly influence these comparisons, making site-specific assessments necessary for accurate carbon intensity evaluation.

02 Innovative technologies for reducing carbon intensity in lithium extraction

Recent technological innovations aim to reduce the carbon footprint of lithium extraction processes. These include direct lithium extraction (DLE) technologies that bypass traditional evaporation ponds, advanced electrolysis methods, and more efficient chemical processes for spodumene conversion. Some technologies incorporate renewable energy sources directly into the extraction process, while others focus on reducing chemical usage and processing time. These innovations can significantly decrease the carbon intensity of both brine and hard rock lithium production methods.Expand Specific Solutions03 Energy optimization in spodumene concentrate processing

Spodumene concentrate processing traditionally requires high energy inputs, particularly during the calcination phase where temperatures of 1000-1100°C are needed to convert alpha-spodumene to beta-spodumene. Innovations in this area focus on optimizing energy usage through improved kiln designs, heat recovery systems, and alternative heating methods. Some processes incorporate renewable energy sources or waste heat recovery to reduce the overall carbon intensity of spodumene-based lithium production.Expand Specific Solutions04 Water and land use considerations in carbon intensity calculations

The environmental impact assessment of lithium extraction methods includes considerations beyond direct carbon emissions, such as water usage and land disturbance. Brine operations typically have a larger physical footprint due to evaporation ponds but may use less energy, while spodumene mining has a smaller land footprint but higher water processing requirements and energy intensity. These factors contribute to the overall sustainability profile and must be considered when calculating the true carbon intensity of different lithium production methods.Expand Specific Solutions05 Closed-loop and circular economy approaches to lithium production

Emerging approaches to lithium production focus on closed-loop systems and circular economy principles to reduce carbon intensity. These include lithium recycling from spent batteries, recovery of lithium from geothermal brines and oilfield waters, and integration of lithium extraction with other mineral recovery processes. By maximizing resource efficiency and minimizing waste, these approaches can significantly reduce the overall carbon footprint of lithium production compared to traditional extraction methods from either brine or spodumene sources.Expand Specific Solutions

Key Industry Players in Lithium Production

The lithium extraction industry is currently in a growth phase, with the carbon intensity comparison between brine and spodumene concentrate methods becoming increasingly critical as the market expands. The global lithium market is projected to reach $8.2 billion by 2028, driven by electric vehicle battery demand. Technologically, companies are at varying maturity levels: established players like Tianqi Lithium, Ganfeng Lithium, and Vale SA have optimized traditional extraction methods, while innovative firms such as Novalith Technologies, British Lithium, and Calix are developing lower-carbon alternatives. Research institutions including Central South University and The University of Sydney are advancing sustainable extraction technologies. The industry is transitioning toward more environmentally conscious processes as carbon footprint becomes a competitive differentiator in the rapidly evolving lithium supply chain.

Novalith Technologies Pty Ltd.

Technical Solution: Novalith Technologies has developed a revolutionary CO₂-based lithium extraction process that fundamentally transforms the carbon intensity comparison between lithium sources. Their LiCAL™ technology utilizes carbon dioxide as a reagent to selectively leach lithium from spodumene concentrate, creating a closed-loop system that significantly reduces chemical consumption and waste generation. This process operates at ambient temperature and pressure conditions, eliminating the energy-intensive calcination step that traditionally accounts for approximately 65% of spodumene processing emissions. Independent assessments indicate their process can reduce carbon emissions by up to 60-70% compared to conventional spodumene conversion methods. The technology also features a carbon sequestration component, as CO₂ is consumed during the reaction process and partially converted to stable carbonate forms, potentially creating a carbon-negative lithium production pathway when renewable energy is used for operations. Novalith's process requires approximately 80% less water than conventional brine operations and eliminates the need for sulfuric acid leaching, addressing multiple environmental impact categories simultaneously.

Strengths: Revolutionary approach that fundamentally changes the carbon intensity equation for hard-rock lithium sources. The technology addresses multiple environmental impact categories simultaneously (carbon, water, land use, chemicals). Weaknesses: Still in scale-up phase with commercial implementation challenges to be fully resolved. The process economics and energy balance at industrial scale need further validation despite promising pilot results.

British Lithium Ltd.

Technical Solution: British Lithium has developed a novel low-carbon extraction and processing technology specifically designed for lithium mica deposits in Cornwall, UK. Their patented process combines innovative comminution techniques with a direct lithium extraction method that bypasses traditional energy-intensive roasting steps. The company's technical approach includes a mechanical activation process that enhances lithium liberation at lower temperatures, reducing energy requirements by approximately 40% compared to conventional spodumene processing. Their integrated carbon assessment framework incorporates the UK's increasingly renewable electricity grid, resulting in a projected carbon intensity of 5-7 kg CO₂e per kg of lithium carbonate equivalent (LCE) - significantly lower than global averages for both brine and spodumene pathways. British Lithium's process also features a closed-loop water system that recycles over 95% of process water, addressing a key environmental concern in lithium production. The company has completed extensive pilot testing demonstrating consistent 90%+ lithium recovery rates while maintaining their low carbon profile.

Strengths: Purpose-built process designed specifically for European resources and regulatory environment, with potential for industry-leading carbon intensity metrics. Proximity to European battery manufacturing reduces transportation emissions in the overall supply chain. Weaknesses: Technology is specific to mica-type deposits and may not be directly transferable to traditional spodumene or brine resources. Scale-up challenges remain as the company transitions from pilot to commercial production.

Technical Analysis of Extraction Process Emissions

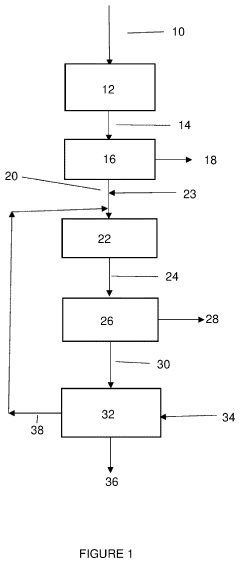

Process for treating a material

PatentPendingUS20230383376A1

Innovation

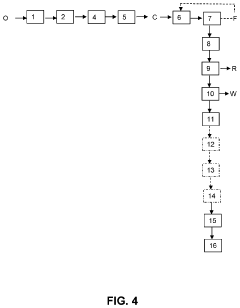

- A process involving a pre-wash or pre-leach step to selectively dissolve and passivate gypsum and sulphates, followed by a leaching step to dissolve aluminium and silicate components into solution, forming a pregnant leach solution that can be used to produce zeolites while minimizing the removal of valuable silicate and aluminium components.

Lithium Recovery From Spodumene

PatentPendingUS20240182317A1

Innovation

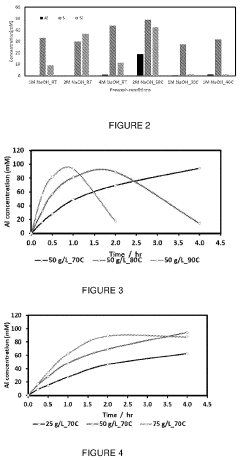

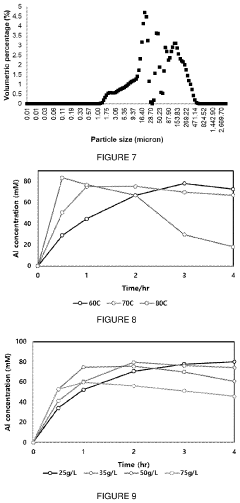

- A method involving selective screening of calcined spodumene particles based on particle size and crystal structure to separate lithium-containing spodumene from other minerals, eliminating the need for acid leaching and reducing the amount of ore to be treated, which increases lithium recovery and minimizes environmental impact.

Environmental Impact Assessment Framework

The Environmental Impact Assessment Framework for comparing carbon intensity between lithium mine brine and spodumene concentrate operations requires a comprehensive methodology that accounts for the full lifecycle emissions of both extraction methods. This framework must establish standardized boundaries, metrics, and assessment protocols to ensure fair and accurate comparisons across different lithium production pathways.

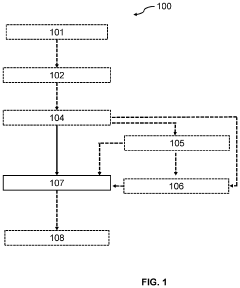

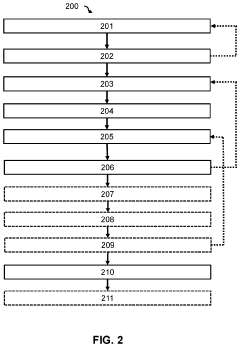

The framework should begin with a clear scope definition that encompasses all relevant processes from extraction to processing, including energy inputs, chemical reagents, water usage, and land disturbance. For brine operations, this includes pumping, evaporation ponds, and chemical processing, while spodumene concentrate production involves mining, crushing, concentration, and thermal processing steps.

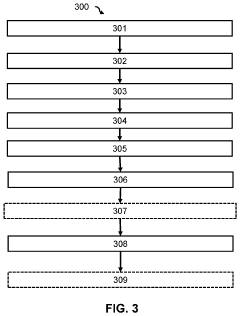

Functional units must be carefully defined, with carbon intensity typically expressed as kg CO2-equivalent per kg of lithium carbonate equivalent (LCE) produced. This standardization allows for direct comparison between the fundamentally different extraction processes while accounting for variations in ore grade and brine concentration.

System boundaries should follow ISO 14040/14044 standards for lifecycle assessment, incorporating both direct emissions (Scope 1) from on-site fuel combustion and indirect emissions (Scope 2) from purchased electricity. Importantly, the framework must also address Scope 3 emissions from reagent production, transportation, and waste management, which can significantly impact overall carbon footprints.

Regional factors play a crucial role in the assessment, as electricity grid carbon intensity varies dramatically between locations. Brine operations in Chile may access renewable energy sources, while spodumene mining in Australia might rely on fossil fuel-powered grids, creating substantial differences in carbon profiles independent of the extraction technology itself.

The framework should incorporate sensitivity analysis to account for technological improvements, changing energy mixes, and operational variations. This includes provisions for emerging technologies like direct lithium extraction (DLE) that may alter the traditional carbon intensity profiles of brine operations.

Data quality indicators and uncertainty analysis must be integrated into the framework, acknowledging the challenges in obtaining consistent, high-quality data across global operations with different reporting standards and transparency levels. This ensures that comparisons reflect genuine technological differences rather than data collection inconsistencies.

The framework should begin with a clear scope definition that encompasses all relevant processes from extraction to processing, including energy inputs, chemical reagents, water usage, and land disturbance. For brine operations, this includes pumping, evaporation ponds, and chemical processing, while spodumene concentrate production involves mining, crushing, concentration, and thermal processing steps.

Functional units must be carefully defined, with carbon intensity typically expressed as kg CO2-equivalent per kg of lithium carbonate equivalent (LCE) produced. This standardization allows for direct comparison between the fundamentally different extraction processes while accounting for variations in ore grade and brine concentration.

System boundaries should follow ISO 14040/14044 standards for lifecycle assessment, incorporating both direct emissions (Scope 1) from on-site fuel combustion and indirect emissions (Scope 2) from purchased electricity. Importantly, the framework must also address Scope 3 emissions from reagent production, transportation, and waste management, which can significantly impact overall carbon footprints.

Regional factors play a crucial role in the assessment, as electricity grid carbon intensity varies dramatically between locations. Brine operations in Chile may access renewable energy sources, while spodumene mining in Australia might rely on fossil fuel-powered grids, creating substantial differences in carbon profiles independent of the extraction technology itself.

The framework should incorporate sensitivity analysis to account for technological improvements, changing energy mixes, and operational variations. This includes provisions for emerging technologies like direct lithium extraction (DLE) that may alter the traditional carbon intensity profiles of brine operations.

Data quality indicators and uncertainty analysis must be integrated into the framework, acknowledging the challenges in obtaining consistent, high-quality data across global operations with different reporting standards and transparency levels. This ensures that comparisons reflect genuine technological differences rather than data collection inconsistencies.

Regulatory Compliance and ESG Considerations

The regulatory landscape surrounding lithium extraction is becoming increasingly complex as governments worldwide implement stricter environmental standards. Companies operating in both brine and spodumene concentrate extraction must navigate a multifaceted regulatory framework that varies significantly by region. In major lithium-producing countries like Chile, Australia, and China, regulations are evolving to address carbon emissions specifically from mining operations, with carbon taxation mechanisms being implemented or considered in several jurisdictions.

Environmental, Social, and Governance (ESG) considerations have become paramount for lithium producers, with investors increasingly demanding transparent carbon footprint reporting. The EU's Carbon Border Adjustment Mechanism (CBAM) and similar policies emerging globally are creating financial incentives for lower-carbon extraction methods. Companies utilizing high-carbon-intensity processes face growing regulatory risks, including potential carbon taxes, trade barriers, and restricted market access.

Voluntary carbon disclosure frameworks such as the Task Force on Climate-related Financial Disclosures (TCFD) and the Carbon Disclosure Project (CDP) are gaining prominence in the lithium sector. Leading producers are increasingly participating in these initiatives, with those demonstrating lower carbon intensity gaining competitive advantages in both capital markets and customer relationships.

Lithium extraction projects now routinely require comprehensive Environmental Impact Assessments (EIAs) that specifically address carbon emissions alongside traditional environmental concerns. The approval process for new projects increasingly scrutinizes projected lifetime carbon intensity, with permitting authorities showing preference for lower-emission extraction technologies.

Indigenous rights and community consent represent another critical dimension of ESG compliance, particularly relevant for lithium operations in South America's "Lithium Triangle." Companies must demonstrate not only environmental stewardship regarding carbon emissions but also positive community engagement and benefit-sharing arrangements.

The emergence of lithium battery passport initiatives and supply chain traceability requirements is creating unprecedented transparency demands. Downstream manufacturers, particularly in the electric vehicle sector, are implementing supplier codes of conduct that explicitly include carbon intensity thresholds, driving upstream pressure for cleaner extraction methods.

Looking forward, regulatory convergence is anticipated, with international standards for carbon accounting in lithium extraction likely to emerge. Companies investing in low-carbon extraction technologies today may gain significant competitive advantages as regulatory requirements tighten and carbon pricing becomes more widespread across global markets.

Environmental, Social, and Governance (ESG) considerations have become paramount for lithium producers, with investors increasingly demanding transparent carbon footprint reporting. The EU's Carbon Border Adjustment Mechanism (CBAM) and similar policies emerging globally are creating financial incentives for lower-carbon extraction methods. Companies utilizing high-carbon-intensity processes face growing regulatory risks, including potential carbon taxes, trade barriers, and restricted market access.

Voluntary carbon disclosure frameworks such as the Task Force on Climate-related Financial Disclosures (TCFD) and the Carbon Disclosure Project (CDP) are gaining prominence in the lithium sector. Leading producers are increasingly participating in these initiatives, with those demonstrating lower carbon intensity gaining competitive advantages in both capital markets and customer relationships.

Lithium extraction projects now routinely require comprehensive Environmental Impact Assessments (EIAs) that specifically address carbon emissions alongside traditional environmental concerns. The approval process for new projects increasingly scrutinizes projected lifetime carbon intensity, with permitting authorities showing preference for lower-emission extraction technologies.

Indigenous rights and community consent represent another critical dimension of ESG compliance, particularly relevant for lithium operations in South America's "Lithium Triangle." Companies must demonstrate not only environmental stewardship regarding carbon emissions but also positive community engagement and benefit-sharing arrangements.

The emergence of lithium battery passport initiatives and supply chain traceability requirements is creating unprecedented transparency demands. Downstream manufacturers, particularly in the electric vehicle sector, are implementing supplier codes of conduct that explicitly include carbon intensity thresholds, driving upstream pressure for cleaner extraction methods.

Looking forward, regulatory convergence is anticipated, with international standards for carbon accounting in lithium extraction likely to emerge. Companies investing in low-carbon extraction technologies today may gain significant competitive advantages as regulatory requirements tighten and carbon pricing becomes more widespread across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!