Validate Lithium Mine Environmental Monitoring Systems for Data Integrity

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Mining Environmental Monitoring Background and Objectives

Environmental monitoring in lithium mining operations has evolved significantly over the past two decades, transitioning from basic manual sampling methods to sophisticated integrated sensor networks. This evolution has been driven by increasing regulatory requirements, growing environmental concerns, and technological advancements in sensor technology and data analytics. The primary objective of these monitoring systems is to ensure sustainable extraction practices while minimizing ecological impact on surrounding ecosystems, particularly water resources and biodiversity.

Lithium, as a critical component in battery technology, has experienced unprecedented demand growth, with global consumption increasing by approximately 25% annually since 2015. This surge has intensified mining activities in the "Lithium Triangle" of South America, Australia's hard rock deposits, and emerging sites in North America and Europe, necessitating robust environmental monitoring frameworks to prevent ecological degradation.

Current environmental monitoring systems in lithium operations typically track several key parameters: groundwater levels and quality, brine chemistry, soil contamination, air quality, and increasingly, biodiversity indicators. These systems generate massive volumes of data—often exceeding 500GB annually for a single mid-sized operation—creating significant challenges for data validation, integrity verification, and meaningful interpretation.

The integrity of this environmental data is paramount, as it informs regulatory compliance, operational decision-making, and corporate sustainability reporting. However, the harsh conditions of mining environments (extreme temperatures, high salinity, remote locations) frequently compromise sensor reliability and data accuracy. Industry reports indicate that up to 30% of environmental monitoring data may contain anomalies requiring validation or correction before use in compliance reporting.

Recent technological developments have introduced advanced validation methodologies, including machine learning algorithms for anomaly detection, blockchain-based data verification systems, and remote sensing integration for cross-validation. These innovations aim to establish unalterable audit trails for environmental data, ensuring transparency and accountability throughout the monitoring process.

The ultimate goal of validating lithium mine environmental monitoring systems is threefold: to ensure regulatory compliance with increasingly stringent environmental standards; to provide accurate, defensible data for operational optimization and impact mitigation; and to build stakeholder trust through transparent environmental performance reporting. This validation process must balance technical rigor with practical implementation considerations in challenging mining environments.

Lithium, as a critical component in battery technology, has experienced unprecedented demand growth, with global consumption increasing by approximately 25% annually since 2015. This surge has intensified mining activities in the "Lithium Triangle" of South America, Australia's hard rock deposits, and emerging sites in North America and Europe, necessitating robust environmental monitoring frameworks to prevent ecological degradation.

Current environmental monitoring systems in lithium operations typically track several key parameters: groundwater levels and quality, brine chemistry, soil contamination, air quality, and increasingly, biodiversity indicators. These systems generate massive volumes of data—often exceeding 500GB annually for a single mid-sized operation—creating significant challenges for data validation, integrity verification, and meaningful interpretation.

The integrity of this environmental data is paramount, as it informs regulatory compliance, operational decision-making, and corporate sustainability reporting. However, the harsh conditions of mining environments (extreme temperatures, high salinity, remote locations) frequently compromise sensor reliability and data accuracy. Industry reports indicate that up to 30% of environmental monitoring data may contain anomalies requiring validation or correction before use in compliance reporting.

Recent technological developments have introduced advanced validation methodologies, including machine learning algorithms for anomaly detection, blockchain-based data verification systems, and remote sensing integration for cross-validation. These innovations aim to establish unalterable audit trails for environmental data, ensuring transparency and accountability throughout the monitoring process.

The ultimate goal of validating lithium mine environmental monitoring systems is threefold: to ensure regulatory compliance with increasingly stringent environmental standards; to provide accurate, defensible data for operational optimization and impact mitigation; and to build stakeholder trust through transparent environmental performance reporting. This validation process must balance technical rigor with practical implementation considerations in challenging mining environments.

Market Demand for Reliable Environmental Monitoring in Mining

The lithium mining industry is experiencing unprecedented growth due to the global shift towards electric vehicles and renewable energy storage solutions. This surge has created a significant demand for reliable environmental monitoring systems that can ensure data integrity throughout mining operations. According to recent market analyses, the global lithium mining market is projected to reach $6.8 billion by 2027, with environmental monitoring systems representing an increasingly critical component of operational infrastructure.

Environmental regulatory frameworks across major lithium-producing regions have become progressively stringent, particularly in countries like Australia, Chile, Argentina, and China. These regulations mandate continuous monitoring of water usage, groundwater quality, dust emissions, and ecosystem impacts. Mining companies face potential fines exceeding $1 million for compliance failures, creating strong financial incentives for implementing robust monitoring solutions.

Stakeholder pressure has emerged as another significant market driver. Investors increasingly incorporate Environmental, Social, and Governance (ESG) metrics into their decision-making processes, with 72% of institutional investors now considering environmental performance data when evaluating mining companies. Additionally, downstream customers, particularly automotive manufacturers, demand verifiable environmental data as part of their supply chain due diligence.

The market for environmental monitoring systems in lithium mining operations has evolved from basic compliance tools to sophisticated data integrity solutions. Current market demand focuses on systems that can validate data authenticity, prevent tampering, and provide immutable audit trails. This shift reflects the industry's recognition that environmental data now represents both a compliance requirement and a business asset affecting financing terms, customer relationships, and community acceptance.

Insurance providers have also become influential market participants, with several major underwriters now offering premium reductions of up to 18% for mining operations that implement validated environmental monitoring systems. This financial incentive has accelerated adoption rates, particularly among mid-tier producers seeking operational cost advantages.

The geographical distribution of market demand shows notable regional variations. Latin American operations, particularly in the "Lithium Triangle" of Chile, Argentina, and Bolivia, demonstrate the highest growth rate for advanced monitoring systems at 24% annually. This trend reflects both regulatory pressures and the unique environmental sensitivities of brine extraction operations in these regions.

North American and Australian markets exhibit strong demand for integrated solutions that combine environmental monitoring with production efficiency metrics, creating comprehensive operational intelligence platforms. Asian markets, particularly in China, show increasing interest in monitoring systems that emphasize water conservation and remediation capabilities, reflecting regional resource constraints.

Environmental regulatory frameworks across major lithium-producing regions have become progressively stringent, particularly in countries like Australia, Chile, Argentina, and China. These regulations mandate continuous monitoring of water usage, groundwater quality, dust emissions, and ecosystem impacts. Mining companies face potential fines exceeding $1 million for compliance failures, creating strong financial incentives for implementing robust monitoring solutions.

Stakeholder pressure has emerged as another significant market driver. Investors increasingly incorporate Environmental, Social, and Governance (ESG) metrics into their decision-making processes, with 72% of institutional investors now considering environmental performance data when evaluating mining companies. Additionally, downstream customers, particularly automotive manufacturers, demand verifiable environmental data as part of their supply chain due diligence.

The market for environmental monitoring systems in lithium mining operations has evolved from basic compliance tools to sophisticated data integrity solutions. Current market demand focuses on systems that can validate data authenticity, prevent tampering, and provide immutable audit trails. This shift reflects the industry's recognition that environmental data now represents both a compliance requirement and a business asset affecting financing terms, customer relationships, and community acceptance.

Insurance providers have also become influential market participants, with several major underwriters now offering premium reductions of up to 18% for mining operations that implement validated environmental monitoring systems. This financial incentive has accelerated adoption rates, particularly among mid-tier producers seeking operational cost advantages.

The geographical distribution of market demand shows notable regional variations. Latin American operations, particularly in the "Lithium Triangle" of Chile, Argentina, and Bolivia, demonstrate the highest growth rate for advanced monitoring systems at 24% annually. This trend reflects both regulatory pressures and the unique environmental sensitivities of brine extraction operations in these regions.

North American and Australian markets exhibit strong demand for integrated solutions that combine environmental monitoring with production efficiency metrics, creating comprehensive operational intelligence platforms. Asian markets, particularly in China, show increasing interest in monitoring systems that emphasize water conservation and remediation capabilities, reflecting regional resource constraints.

Current Challenges in Lithium Mine Monitoring Systems

Environmental monitoring systems in lithium mining operations face significant challenges that compromise data integrity and reliability. The primary issue stems from the harsh operational conditions in mining environments, where extreme temperatures, dust, vibration, and humidity can cause sensor malfunctions and calibration drift. These conditions often lead to inaccurate readings or complete system failures, creating gaps in critical environmental data collection.

Connectivity issues represent another major challenge, particularly in remote mining locations where reliable internet or cellular networks are limited. This results in data transmission delays or losses, affecting real-time monitoring capabilities and regulatory compliance reporting. When monitoring systems cannot transmit data consistently, decision-making processes based on environmental parameters become compromised.

Power supply instability further exacerbates monitoring challenges. Many lithium mining operations rely on intermittent power sources or battery-powered systems that may fail without warning. These power fluctuations can cause monitoring equipment to reset, lose calibration settings, or fail to record during critical operational periods.

Data security vulnerabilities present increasing concerns as monitoring systems become more digitized and interconnected. Unauthorized access to environmental monitoring data could lead to data manipulation, either accidentally through improper handling or deliberately through malicious interference. The lack of robust encryption and access controls in many legacy systems creates significant data integrity risks.

Calibration and maintenance challenges persist across the industry. Many monitoring systems require regular calibration to maintain accuracy, but the remote nature of mining operations makes frequent expert maintenance visits impractical. This leads to extended periods of operation with potentially miscalibrated equipment, resulting in systematic data errors that may go undetected.

Integration difficulties between different monitoring systems and data platforms create additional complications. Lithium mining operations typically employ multiple environmental monitoring technologies from various vendors, each with proprietary data formats and communication protocols. The resulting data silos prevent comprehensive environmental analysis and make it difficult to establish a single source of truth for compliance reporting.

Human factors also contribute significantly to data integrity issues. Manual data entry, interpretation errors, and inconsistent sampling methodologies introduce variability that undermines the reliability of environmental monitoring data. Training deficiencies and high staff turnover rates in remote mining operations further compound these human-related data integrity challenges.

Connectivity issues represent another major challenge, particularly in remote mining locations where reliable internet or cellular networks are limited. This results in data transmission delays or losses, affecting real-time monitoring capabilities and regulatory compliance reporting. When monitoring systems cannot transmit data consistently, decision-making processes based on environmental parameters become compromised.

Power supply instability further exacerbates monitoring challenges. Many lithium mining operations rely on intermittent power sources or battery-powered systems that may fail without warning. These power fluctuations can cause monitoring equipment to reset, lose calibration settings, or fail to record during critical operational periods.

Data security vulnerabilities present increasing concerns as monitoring systems become more digitized and interconnected. Unauthorized access to environmental monitoring data could lead to data manipulation, either accidentally through improper handling or deliberately through malicious interference. The lack of robust encryption and access controls in many legacy systems creates significant data integrity risks.

Calibration and maintenance challenges persist across the industry. Many monitoring systems require regular calibration to maintain accuracy, but the remote nature of mining operations makes frequent expert maintenance visits impractical. This leads to extended periods of operation with potentially miscalibrated equipment, resulting in systematic data errors that may go undetected.

Integration difficulties between different monitoring systems and data platforms create additional complications. Lithium mining operations typically employ multiple environmental monitoring technologies from various vendors, each with proprietary data formats and communication protocols. The resulting data silos prevent comprehensive environmental analysis and make it difficult to establish a single source of truth for compliance reporting.

Human factors also contribute significantly to data integrity issues. Manual data entry, interpretation errors, and inconsistent sampling methodologies introduce variability that undermines the reliability of environmental monitoring data. Training deficiencies and high staff turnover rates in remote mining operations further compound these human-related data integrity challenges.

Data Validation Methodologies for Environmental Sensors

01 Blockchain-based data integrity solutions

Blockchain technology is utilized in environmental monitoring systems to ensure data integrity through immutable ledger systems. These solutions create tamper-proof records of environmental data, allowing for transparent verification and audit trails. The distributed nature of blockchain prevents single points of failure and unauthorized modifications, making it particularly valuable for regulatory compliance and cross-organizational data sharing in environmental monitoring applications.- Blockchain-based data integrity solutions: Blockchain technology is utilized in environmental monitoring systems to ensure data integrity through immutable distributed ledgers. These systems create tamper-proof records of environmental data, allowing for transparent verification while preventing unauthorized modifications. The decentralized nature of blockchain provides enhanced security and trust in environmental monitoring data, making it particularly valuable for regulatory compliance and cross-organizational data sharing.

- Secure data transmission and storage protocols: Environmental monitoring systems employ specialized protocols for secure data transmission and storage to maintain integrity throughout the data lifecycle. These protocols include encryption methods, secure communication channels, and tamper-evident storage solutions that protect data from unauthorized access or modification. Advanced authentication mechanisms ensure that only authorized personnel can access or modify environmental monitoring data, while audit trails track all data interactions.

- Automated data validation and verification systems: Automated systems for validating and verifying environmental monitoring data help maintain data integrity by detecting anomalies, inconsistencies, or potential tampering. These systems employ algorithms that check data against expected parameters, historical trends, and physical constraints. Real-time validation processes flag suspicious data points for further investigation, while verification mechanisms confirm data authenticity through cross-referencing multiple sensors or data sources.

- Integrated compliance and audit frameworks: Environmental monitoring systems incorporate compliance and audit frameworks that ensure data integrity meets regulatory requirements. These frameworks include automated documentation of calibration activities, system maintenance, and data handling procedures. Comprehensive audit trails capture all system interactions, providing evidence of data integrity for regulatory inspections. The frameworks also facilitate periodic system reviews and assessments to identify potential vulnerabilities in data integrity processes.

- Redundant monitoring and backup systems: Redundant monitoring and backup systems protect environmental data integrity through multiple layers of data collection, storage, and recovery mechanisms. These systems employ parallel sensors, distributed storage architectures, and automated backup procedures to prevent data loss or corruption. In case of system failures, data recovery protocols restore information from secure backups while maintaining chain of custody. Cross-validation between redundant systems helps identify and correct discrepancies, ensuring continuous data integrity.

02 Secure data transmission and encryption protocols

Environmental monitoring systems employ advanced encryption and secure transmission protocols to maintain data integrity from collection points to storage systems. These solutions include end-to-end encryption, secure authentication mechanisms, and cryptographic verification to prevent data tampering during transmission. Secure channels ensure that environmental data remains protected against interception or modification, particularly important for remote monitoring stations and wireless sensor networks.Expand Specific Solutions03 Automated validation and error detection systems

Advanced algorithms and validation systems are implemented to automatically detect anomalies, inconsistencies, or errors in environmental monitoring data. These systems employ statistical analysis, machine learning, and predefined validation rules to flag suspicious data points or system malfunctions. Real-time error detection enables immediate corrective actions, ensuring the reliability and accuracy of environmental measurements while maintaining continuous data integrity throughout the monitoring process.Expand Specific Solutions04 Integrated audit trail and compliance documentation

Environmental monitoring systems incorporate comprehensive audit trail capabilities that document all data transactions, modifications, and access events. These solutions automatically generate compliance documentation that meets regulatory requirements for environmental data integrity. The systems maintain detailed logs of user activities, system changes, and data processing steps, providing verifiable evidence for regulatory inspections and ensuring accountability throughout the data lifecycle.Expand Specific Solutions05 Redundant storage and backup systems

To ensure environmental data integrity, monitoring systems implement redundant storage architectures and automated backup protocols. These solutions include distributed data storage across multiple physical or cloud locations, regular data synchronization, and disaster recovery mechanisms. The redundancy prevents data loss from hardware failures or localized disasters, while versioning systems maintain historical records that can be used to verify data integrity or recover from corruption incidents.Expand Specific Solutions

Key Industry Players in Mining Monitoring Solutions

The lithium mine environmental monitoring systems market is in a growth phase, driven by increasing demand for lithium in electric vehicles and energy storage. The market size is expanding rapidly as regulatory requirements for environmental compliance in mining operations become more stringent. Technologically, the field shows varying maturity levels, with established industrial players like Siemens AG offering comprehensive monitoring solutions alongside specialized environmental technology providers. Companies such as Kemira Oyj, Blu Environmental Technology, and China ENFI Engineering Corp. are developing integrated systems for data integrity validation, while newer entrants like Utilidata are bringing AI-powered edge computing solutions. Siemens leads with advanced industrial automation capabilities, while regional players like Guangdong Greenway Technology and Shanghai Yuanjing Kechuang focus on lithium-specific environmental monitoring technologies tailored to local regulatory frameworks.

Siemens AG

Technical Solution: Siemens has developed a comprehensive Environmental Data Integrity Platform specifically for mining operations, including lithium extraction. Their system employs a multi-layered approach combining hardware sensors, edge computing, and cloud-based analytics. The platform utilizes their SIMATIC industrial automation controllers with redundant sensor arrays that implement cross-validation protocols to detect anomalies in real-time. Data integrity is ensured through blockchain-based verification mechanisms that create immutable records of all environmental measurements. Their system incorporates AI-driven predictive analytics to identify potential sensor drift or calibration issues before they affect data quality. Siemens' solution also features automated compliance reporting tools that generate regulatory documentation while maintaining complete data provenance trails.

Strengths: Robust integration with existing industrial control systems, strong cybersecurity protocols, and global service network for maintenance. Weaknesses: Higher implementation costs compared to specialized solutions, and complex deployment requiring significant technical expertise.

Kemira Oyj

Technical Solution: Kemira has developed KemConnect™ Environmental Monitoring System specifically adapted for lithium mining operations. Their solution combines advanced water quality monitoring with comprehensive data integrity protocols. The system employs redundant sensor arrays with automated cross-validation to detect measurement anomalies in real-time. Kemira's platform features their proprietary "ChemWatch" algorithms that analyze the chemical signature of water samples to identify potential contamination events or sensor drift. The system incorporates blockchain-based data verification that creates tamper-proof records of all environmental measurements. Their solution includes automated calibration management that schedules and documents all sensor maintenance activities. KemConnect™ generates regulatory compliance reports while maintaining complete data provenance trails that satisfy the most stringent audit requirements.

Strengths: Deep expertise in water chemistry and treatment processes relevant to lithium extraction, excellent integration with water management systems, and strong regulatory compliance features. Weaknesses: More focused on water quality monitoring than comprehensive environmental monitoring, and requires specialized knowledge for optimal configuration.

Critical Technologies for Ensuring Monitoring Data Integrity

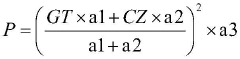

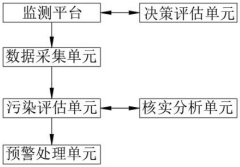

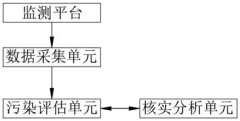

Mining environment pollution monitoring management system based on data analysis

PatentInactiveCN117522651A

Innovation

- Design a mining environmental pollution monitoring and management system based on data analysis, including a monitoring platform, data collection unit, decision-making assessment unit, pollution assessment unit, verification analysis unit and early warning processing unit, and analyze the environmental pollution of each monitoring sub-area from a small to large perspective. pollution degree, and verify monitoring results through information feedback to ensure data validity and reliability.

System for integrated measurement and management of sensing data for detection of collapse within mine pit

PatentWO2022045468A1

Innovation

- A sensing data integrated measurement management system is installed in mine environments, comprising collapse detection sensors, sensor nodes, gateways, and a management server that processes and standardizes data from various sensors, enabling real-time monitoring and alerting of preliminary collapse signs, allowing for immediate response to abnormal signals.

Regulatory Compliance Framework for Mining Operations

The regulatory landscape for lithium mining operations has evolved significantly in response to growing environmental concerns and data integrity requirements. Mining companies must navigate a complex web of international, national, and local regulations that govern environmental monitoring practices. The International Council on Mining and Metals (ICMM) has established global standards that many countries have adopted as baseline requirements, emphasizing transparent reporting and data validation protocols. These standards require continuous monitoring systems with specific calibration schedules and data verification procedures.

At the national level, countries with significant lithium resources have implemented specialized regulatory frameworks. Chile's Environmental Superintendency (SMA) mandates real-time data transmission from monitoring stations to government servers, with strict penalties for data manipulation or reporting failures. Australia's Environmental Protection Authority requires mining operations to implement ISO 14001-certified environmental management systems with independent third-party verification of monitoring data. The United States Bureau of Land Management has established specific guidelines for lithium brine operations that include groundwater monitoring requirements with chain-of-custody documentation for all samples.

Regulatory compliance for environmental monitoring systems typically involves three critical components: hardware certification, data management protocols, and reporting mechanisms. Monitoring equipment must meet industry standards such as those set by the International Organization for Standardization (ISO) or country-specific certifications. Data management systems must implement tamper-evident technologies, often utilizing blockchain or similar distributed ledger technologies to ensure data integrity from collection through reporting.

Penalties for non-compliance with environmental monitoring regulations can be severe, including operational shutdowns, significant financial penalties, and criminal prosecution of responsible executives. The European Union's Environmental Liability Directive has established a precedent for holding mining companies financially responsible for environmental remediation costs, creating strong incentives for accurate monitoring and reporting.

Recent regulatory trends indicate a move toward more stringent requirements for real-time monitoring with automated alerts for anomalous readings. Regulators increasingly require mining operations to implement redundant monitoring systems with cross-validation capabilities to ensure data accuracy. The integration of satellite monitoring as a verification layer for ground-based systems is becoming a standard expectation in many jurisdictions, particularly for water usage and contamination monitoring in lithium brine operations.

At the national level, countries with significant lithium resources have implemented specialized regulatory frameworks. Chile's Environmental Superintendency (SMA) mandates real-time data transmission from monitoring stations to government servers, with strict penalties for data manipulation or reporting failures. Australia's Environmental Protection Authority requires mining operations to implement ISO 14001-certified environmental management systems with independent third-party verification of monitoring data. The United States Bureau of Land Management has established specific guidelines for lithium brine operations that include groundwater monitoring requirements with chain-of-custody documentation for all samples.

Regulatory compliance for environmental monitoring systems typically involves three critical components: hardware certification, data management protocols, and reporting mechanisms. Monitoring equipment must meet industry standards such as those set by the International Organization for Standardization (ISO) or country-specific certifications. Data management systems must implement tamper-evident technologies, often utilizing blockchain or similar distributed ledger technologies to ensure data integrity from collection through reporting.

Penalties for non-compliance with environmental monitoring regulations can be severe, including operational shutdowns, significant financial penalties, and criminal prosecution of responsible executives. The European Union's Environmental Liability Directive has established a precedent for holding mining companies financially responsible for environmental remediation costs, creating strong incentives for accurate monitoring and reporting.

Recent regulatory trends indicate a move toward more stringent requirements for real-time monitoring with automated alerts for anomalous readings. Regulators increasingly require mining operations to implement redundant monitoring systems with cross-validation capabilities to ensure data accuracy. The integration of satellite monitoring as a verification layer for ground-based systems is becoming a standard expectation in many jurisdictions, particularly for water usage and contamination monitoring in lithium brine operations.

Environmental Impact Assessment Standards

Environmental impact assessment (EIA) standards for lithium mining operations have evolved significantly in response to growing concerns about the industry's ecological footprint. These standards now incorporate specific requirements for monitoring systems validation to ensure data integrity throughout the environmental assessment process. The International Association for Impact Assessment (IAIA) has established comprehensive guidelines that specifically address data collection methodologies, validation protocols, and reporting requirements for lithium extraction projects. These standards emphasize the importance of continuous monitoring with verified data integrity as a cornerstone of responsible mining practices.

Key regulatory frameworks such as ISO 14001 Environmental Management Systems and the Initiative for Responsible Mining Assurance (IRMA) Standard have integrated specific provisions for lithium operations. These frameworks mandate regular calibration of monitoring equipment, chain-of-custody documentation for environmental samples, and independent verification of monitoring data. The World Bank's Environmental and Social Framework also provides specific guidance for lithium projects, emphasizing the need for transparent data management systems with built-in validation mechanisms.

Regional standards have emerged to address location-specific concerns in major lithium producing regions. The Lithium Triangle countries (Argentina, Bolivia, and Chile) have developed the Puna High Plateau Environmental Standards, which include stringent requirements for water quality monitoring systems with mandatory data validation protocols. Similarly, Australia's National Environment Protection Measures (NEPM) incorporate specific provisions for lithium operations in sensitive ecological zones, requiring advanced monitoring technologies with demonstrable data integrity.

Industry-specific best practices have been codified by organizations like the International Council on Mining and Metals (ICMM), which has published detailed guidelines for environmental monitoring system validation in lithium operations. These guidelines recommend implementing automated data verification algorithms, regular third-party audits, and blockchain-based data storage solutions to maintain unalterable environmental records. The Global Reporting Initiative (GRI) Mining and Metals Sector Supplement provides standardized reporting frameworks that require verified environmental monitoring data.

Emerging standards are increasingly focusing on real-time monitoring capabilities with built-in validation mechanisms. The European Union's Best Available Techniques Reference Document for Management of Waste from Extractive Industries now includes specific sections on continuous environmental monitoring for lithium operations, with detailed requirements for data validation procedures. These standards are driving innovation in monitoring technologies, including AI-powered anomaly detection systems and satellite-based verification methods that can cross-reference ground-level measurements with remote sensing data.

Key regulatory frameworks such as ISO 14001 Environmental Management Systems and the Initiative for Responsible Mining Assurance (IRMA) Standard have integrated specific provisions for lithium operations. These frameworks mandate regular calibration of monitoring equipment, chain-of-custody documentation for environmental samples, and independent verification of monitoring data. The World Bank's Environmental and Social Framework also provides specific guidance for lithium projects, emphasizing the need for transparent data management systems with built-in validation mechanisms.

Regional standards have emerged to address location-specific concerns in major lithium producing regions. The Lithium Triangle countries (Argentina, Bolivia, and Chile) have developed the Puna High Plateau Environmental Standards, which include stringent requirements for water quality monitoring systems with mandatory data validation protocols. Similarly, Australia's National Environment Protection Measures (NEPM) incorporate specific provisions for lithium operations in sensitive ecological zones, requiring advanced monitoring technologies with demonstrable data integrity.

Industry-specific best practices have been codified by organizations like the International Council on Mining and Metals (ICMM), which has published detailed guidelines for environmental monitoring system validation in lithium operations. These guidelines recommend implementing automated data verification algorithms, regular third-party audits, and blockchain-based data storage solutions to maintain unalterable environmental records. The Global Reporting Initiative (GRI) Mining and Metals Sector Supplement provides standardized reporting frameworks that require verified environmental monitoring data.

Emerging standards are increasingly focusing on real-time monitoring capabilities with built-in validation mechanisms. The European Union's Best Available Techniques Reference Document for Management of Waste from Extractive Industries now includes specific sections on continuous environmental monitoring for lithium operations, with detailed requirements for data validation procedures. These standards are driving innovation in monitoring technologies, including AI-powered anomaly detection systems and satellite-based verification methods that can cross-reference ground-level measurements with remote sensing data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!