Predict Lithium Mine Resource Depletion Under Variable Extraction Scenarios

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Resource Depletion Prediction Background and Objectives

Lithium has emerged as a critical resource in the global transition towards sustainable energy systems, primarily due to its essential role in battery technology. The historical development of lithium extraction dates back to the 1920s, but has seen exponential growth since the early 2000s with the proliferation of portable electronics and, more recently, electric vehicles. This technological evolution has transformed lithium from a niche industrial material to a strategic resource of geopolitical significance.

The global lithium market has experienced unprecedented demand growth, with annual consumption increasing at a compound annual growth rate of approximately 8-10% over the past decade. Current projections suggest this growth trajectory will accelerate, potentially reaching 20-25% annually through 2030 as electric vehicle adoption and grid-scale energy storage deployments expand globally. This rapid demand escalation raises critical questions about resource sustainability and extraction capacity.

Current global lithium reserves are estimated at approximately 22 million tonnes, with resources potentially reaching 86 million tonnes. However, these figures represent static assessments that fail to account for the dynamic nature of extraction technologies, economic feasibility thresholds, and discovery rates. The geographical concentration of lithium resources—primarily in the "Lithium Triangle" of South America, Australia, and increasingly China—adds complexity to supply security considerations.

The technical objective of this research is to develop sophisticated predictive models that can accurately forecast lithium resource depletion under various extraction scenarios. These models must incorporate multiple variables including: technological advancements in extraction efficiency, recycling rates, substitution possibilities, demand elasticity, and the potential discovery of new deposits. The models should provide temporal projections with confidence intervals, allowing for strategic planning horizons of 10, 25, and 50 years.

Beyond pure resource quantification, this research aims to establish a framework for sustainable lithium management that balances economic imperatives with environmental and social considerations. This includes analyzing water usage in brine extraction operations, land disturbance in hard-rock mining, and impacts on indigenous communities in resource-rich regions. The ultimate goal is to provide decision-makers in industry and government with robust analytical tools to navigate the complex trade-offs inherent in lithium resource management.

By developing these predictive capabilities, stakeholders can better anticipate supply constraints, price volatility, and technological adaptation requirements. This foresight is essential for ensuring that the clean energy transition is not hampered by resource limitations in this critical mineral sector.

The global lithium market has experienced unprecedented demand growth, with annual consumption increasing at a compound annual growth rate of approximately 8-10% over the past decade. Current projections suggest this growth trajectory will accelerate, potentially reaching 20-25% annually through 2030 as electric vehicle adoption and grid-scale energy storage deployments expand globally. This rapid demand escalation raises critical questions about resource sustainability and extraction capacity.

Current global lithium reserves are estimated at approximately 22 million tonnes, with resources potentially reaching 86 million tonnes. However, these figures represent static assessments that fail to account for the dynamic nature of extraction technologies, economic feasibility thresholds, and discovery rates. The geographical concentration of lithium resources—primarily in the "Lithium Triangle" of South America, Australia, and increasingly China—adds complexity to supply security considerations.

The technical objective of this research is to develop sophisticated predictive models that can accurately forecast lithium resource depletion under various extraction scenarios. These models must incorporate multiple variables including: technological advancements in extraction efficiency, recycling rates, substitution possibilities, demand elasticity, and the potential discovery of new deposits. The models should provide temporal projections with confidence intervals, allowing for strategic planning horizons of 10, 25, and 50 years.

Beyond pure resource quantification, this research aims to establish a framework for sustainable lithium management that balances economic imperatives with environmental and social considerations. This includes analyzing water usage in brine extraction operations, land disturbance in hard-rock mining, and impacts on indigenous communities in resource-rich regions. The ultimate goal is to provide decision-makers in industry and government with robust analytical tools to navigate the complex trade-offs inherent in lithium resource management.

By developing these predictive capabilities, stakeholders can better anticipate supply constraints, price volatility, and technological adaptation requirements. This foresight is essential for ensuring that the clean energy transition is not hampered by resource limitations in this critical mineral sector.

Global Lithium Market Demand Analysis

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Annual demand for lithium has increased from approximately 200,000 metric tons of lithium carbonate equivalent (LCE) in 2016 to over 500,000 metric tons in 2022, representing a compound annual growth rate (CAGR) of 16.5% during this period.

The automotive sector currently accounts for the largest share of lithium demand, constituting nearly 80% of total consumption. This dominance is expected to intensify as major automotive manufacturers worldwide accelerate their EV production targets. For instance, several leading manufacturers have announced plans to achieve 100% electric vehicle production by 2030-2035, which will significantly amplify lithium demand.

Energy storage systems represent the second-largest demand segment, currently accounting for approximately 10% of global lithium consumption. As renewable energy integration increases and grid-scale storage becomes more prevalent, this segment is projected to grow at a CAGR of 27% through 2030, potentially reaching 200,000 metric tons LCE annually by that time.

Consumer electronics, traditionally a major driver of lithium demand, now represents a smaller but stable market segment at around 5% of total consumption. While growth in this sector has moderated compared to automotive applications, continuous innovation in portable devices maintains steady demand growth of 3-4% annually.

Regional analysis reveals that Asia-Pacific, particularly China, dominates global lithium consumption, accounting for approximately 65% of worldwide demand. This concentration stems from China's established battery manufacturing ecosystem and aggressive EV adoption policies. Europe follows with roughly 20% of global demand, while North America represents approximately 10%.

Future demand projections indicate potential supply constraints as extraction capabilities struggle to match accelerating consumption. Conservative estimates suggest global lithium demand will reach 1.5 million metric tons LCE by 2030, while aggressive forecasts predict up to 2.5 million metric tons, representing a 3-5x increase from current levels.

Price volatility has characterized the lithium market, with prices surging from $6,000 per metric ton in 2020 to peaks exceeding $70,000 in 2022, before moderating. This volatility underscores the critical importance of developing predictive models for lithium resource depletion under various extraction scenarios to ensure sustainable market development and appropriate investment in alternative technologies.

The automotive sector currently accounts for the largest share of lithium demand, constituting nearly 80% of total consumption. This dominance is expected to intensify as major automotive manufacturers worldwide accelerate their EV production targets. For instance, several leading manufacturers have announced plans to achieve 100% electric vehicle production by 2030-2035, which will significantly amplify lithium demand.

Energy storage systems represent the second-largest demand segment, currently accounting for approximately 10% of global lithium consumption. As renewable energy integration increases and grid-scale storage becomes more prevalent, this segment is projected to grow at a CAGR of 27% through 2030, potentially reaching 200,000 metric tons LCE annually by that time.

Consumer electronics, traditionally a major driver of lithium demand, now represents a smaller but stable market segment at around 5% of total consumption. While growth in this sector has moderated compared to automotive applications, continuous innovation in portable devices maintains steady demand growth of 3-4% annually.

Regional analysis reveals that Asia-Pacific, particularly China, dominates global lithium consumption, accounting for approximately 65% of worldwide demand. This concentration stems from China's established battery manufacturing ecosystem and aggressive EV adoption policies. Europe follows with roughly 20% of global demand, while North America represents approximately 10%.

Future demand projections indicate potential supply constraints as extraction capabilities struggle to match accelerating consumption. Conservative estimates suggest global lithium demand will reach 1.5 million metric tons LCE by 2030, while aggressive forecasts predict up to 2.5 million metric tons, representing a 3-5x increase from current levels.

Price volatility has characterized the lithium market, with prices surging from $6,000 per metric ton in 2020 to peaks exceeding $70,000 in 2022, before moderating. This volatility underscores the critical importance of developing predictive models for lithium resource depletion under various extraction scenarios to ensure sustainable market development and appropriate investment in alternative technologies.

Current Lithium Extraction Technologies and Limitations

Lithium extraction technologies have evolved significantly over the past decades, with three primary methods currently dominating the industry: conventional mining from hard rock deposits, extraction from brine resources, and emerging direct lithium extraction (DLE) technologies. Each method presents distinct advantages and limitations that impact resource depletion predictions.

Hard rock mining, predominantly focused on extracting lithium from spodumene, requires extensive energy inputs and generates significant waste material. The process involves crushing, heating to temperatures exceeding 1000°C, chemical processing, and precipitation. While offering high-grade lithium outputs (typically 6-7% lithium oxide), this method suffers from high production costs, substantial carbon footprint, and limited recovery rates typically between 50-70%.

Brine extraction, accounting for approximately 66% of global lithium production, involves pumping lithium-rich brine from underground reservoirs into large evaporation ponds. This process, while less energy-intensive than hard rock mining, requires 12-18 months for concentration and faces significant water loss through evaporation—approximately 500,000 gallons per ton of lithium produced. Recovery efficiencies remain suboptimal at 30-50%, and operations are highly vulnerable to climate variations.

Direct Lithium Extraction technologies represent the industry's most promising innovation, utilizing selective adsorption, ion exchange membranes, or solvent extraction to isolate lithium ions. These methods potentially reduce water consumption by 70%, decrease land footprint by 90%, and accelerate extraction timeframes from months to hours. However, DLE technologies remain largely experimental at commercial scale, with challenges in membrane fouling, high energy requirements, and process optimization.

Current extraction methodologies face several critical limitations affecting depletion modeling. Water consumption presents a significant constraint, particularly in arid regions where many lithium deposits are located. Processing inefficiencies result in substantial resource waste, with current technologies leaving 30-70% of available lithium unrecovered. Energy requirements remain prohibitively high, with hard rock mining consuming approximately 5,000-6,000 kWh per ton of lithium carbonate equivalent.

Environmental impacts further complicate extraction scenarios, with concerns regarding groundwater contamination, habitat disruption, and chemical waste management. Geographical constraints also limit extraction potential, as approximately 75% of known lithium resources are concentrated in the "Lithium Triangle" of Argentina, Bolivia, and Chile, creating geopolitical dependencies and supply chain vulnerabilities.

These technological limitations create significant uncertainty in depletion modeling, as extraction efficiency improvements could substantially extend resource availability timelines, while environmental restrictions might accelerate depletion scenarios through regulatory constraints.

Hard rock mining, predominantly focused on extracting lithium from spodumene, requires extensive energy inputs and generates significant waste material. The process involves crushing, heating to temperatures exceeding 1000°C, chemical processing, and precipitation. While offering high-grade lithium outputs (typically 6-7% lithium oxide), this method suffers from high production costs, substantial carbon footprint, and limited recovery rates typically between 50-70%.

Brine extraction, accounting for approximately 66% of global lithium production, involves pumping lithium-rich brine from underground reservoirs into large evaporation ponds. This process, while less energy-intensive than hard rock mining, requires 12-18 months for concentration and faces significant water loss through evaporation—approximately 500,000 gallons per ton of lithium produced. Recovery efficiencies remain suboptimal at 30-50%, and operations are highly vulnerable to climate variations.

Direct Lithium Extraction technologies represent the industry's most promising innovation, utilizing selective adsorption, ion exchange membranes, or solvent extraction to isolate lithium ions. These methods potentially reduce water consumption by 70%, decrease land footprint by 90%, and accelerate extraction timeframes from months to hours. However, DLE technologies remain largely experimental at commercial scale, with challenges in membrane fouling, high energy requirements, and process optimization.

Current extraction methodologies face several critical limitations affecting depletion modeling. Water consumption presents a significant constraint, particularly in arid regions where many lithium deposits are located. Processing inefficiencies result in substantial resource waste, with current technologies leaving 30-70% of available lithium unrecovered. Energy requirements remain prohibitively high, with hard rock mining consuming approximately 5,000-6,000 kWh per ton of lithium carbonate equivalent.

Environmental impacts further complicate extraction scenarios, with concerns regarding groundwater contamination, habitat disruption, and chemical waste management. Geographical constraints also limit extraction potential, as approximately 75% of known lithium resources are concentrated in the "Lithium Triangle" of Argentina, Bolivia, and Chile, creating geopolitical dependencies and supply chain vulnerabilities.

These technological limitations create significant uncertainty in depletion modeling, as extraction efficiency improvements could substantially extend resource availability timelines, while environmental restrictions might accelerate depletion scenarios through regulatory constraints.

Extraction Scenario Modeling Methodologies

01 Lithium resource management systems

Advanced systems for managing lithium resources utilize digital technologies to monitor extraction rates, resource levels, and consumption patterns. These systems help prevent depletion by optimizing mining operations and providing real-time data on resource availability. By implementing smart resource management, mining companies can extend the lifespan of lithium deposits and ensure more sustainable extraction practices.- Lithium resource management and monitoring systems: Advanced systems for monitoring and managing lithium resources to prevent depletion. These technologies include real-time tracking of extraction rates, resource utilization efficiency metrics, and predictive analytics to forecast resource availability. Such systems help mining companies optimize extraction processes while ensuring sustainable resource management, ultimately extending the lifespan of lithium deposits and reducing the risk of rapid depletion.

- Sustainable lithium extraction technologies: Innovative extraction methods designed to minimize environmental impact and maximize resource efficiency. These technologies focus on reducing water usage, decreasing chemical waste, and implementing closed-loop systems that recycle materials used in the extraction process. By improving extraction efficiency and reducing waste, these technologies help address concerns about lithium resource depletion while maintaining economic viability of mining operations.

- Resource allocation and optimization frameworks: Frameworks and methodologies for optimal allocation of lithium resources across various industries and applications. These systems prioritize critical applications, implement quota systems during scarcity, and develop alternative material strategies for less critical uses. By ensuring lithium is directed to its highest-value applications, these frameworks help mitigate the impacts of potential resource constraints while supporting continued technological development.

- Lithium recycling and circular economy solutions: Technologies and systems focused on recovering lithium from end-of-life products and manufacturing waste. These solutions include advanced battery recycling processes, material recovery systems, and circular economy business models that prioritize reuse of critical materials. By creating closed-loop systems for lithium use, these technologies reduce dependence on primary mining and extend the effective global supply of lithium resources.

- Network-based resource monitoring and distribution systems: Distributed network systems that coordinate lithium resource information across global supply chains. These technologies leverage cloud computing, IoT sensors, and distributed ledger technologies to create transparent tracking of lithium from mine to end product. By improving supply chain visibility and resource allocation efficiency, these systems help prevent localized depletion while optimizing global distribution of available lithium resources.

02 Recycling and recovery technologies

Technologies focused on recycling and recovering lithium from used batteries and other products help address resource depletion concerns. These innovations include chemical processes for extracting lithium from spent materials and reintroducing it into the supply chain. By implementing efficient recycling methods, the industry can reduce dependence on primary mining and extend the global availability of lithium resources.Expand Specific Solutions03 Alternative extraction methods

Novel extraction methods are being developed to access lithium from non-traditional sources, such as geothermal brines and seawater. These techniques aim to reduce environmental impact while tapping into previously unused lithium reserves. By diversifying extraction sources, these innovations help mitigate concerns about depletion of conventional lithium deposits and reduce pressure on existing mining operations.Expand Specific Solutions04 Resource monitoring and forecasting

Systems for monitoring lithium resources and forecasting future availability employ advanced analytics and modeling techniques. These technologies track global lithium reserves, consumption rates, and market demands to predict potential shortages. By providing accurate forecasts, these systems enable better planning for resource allocation and help prevent unexpected depletion scenarios in the lithium supply chain.Expand Specific Solutions05 Efficiency optimization in lithium processing

Innovations in lithium processing focus on increasing efficiency to maximize yield from existing resources. These technologies include improved extraction processes, reduced waste generation, and enhanced purification methods. By optimizing the processing of lithium ore and brines, these advancements help extend the lifespan of current lithium deposits and reduce the rate of resource depletion.Expand Specific Solutions

Major Lithium Mining Companies and Competitive Landscape

The lithium resource depletion prediction market is in its growth phase, characterized by increasing demand for accurate forecasting tools as global lithium consumption accelerates. The market size is expanding rapidly, driven by electric vehicle adoption and energy storage needs, with projections suggesting a multi-billion dollar valuation for lithium resource management technologies. Technologically, the field remains moderately mature, with companies like Schlumberger Technologies and Baker Hughes bringing advanced resource modeling expertise from the oil sector, while specialized players such as American Battery Technology Co. and Alpha ESS are developing lithium-specific extraction and resource assessment methodologies. Academic institutions including Beihang University and King Abdullah University of Science & Technology are contributing fundamental research, while State Grid Corp. of China and Saudi Arabian Oil Co. are investing in large-scale implementation of predictive technologies to secure strategic mineral supplies.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed "LithiumPulse," an advanced lithium resource depletion prediction system that builds upon the company's extensive experience in subsurface resource modeling. The platform integrates geological, hydrological, and extraction data to create comprehensive digital twins of lithium deposits. LithiumPulse employs proprietary algorithms that process multi-physics simulation data to predict resource behavior under different extraction scenarios with reported accuracy improvements of 35% compared to conventional methods. The system incorporates machine learning models trained on data from multiple global lithium operations to identify patterns in resource depletion rates across different geological formations. Schlumberger's approach includes detailed modeling of brine dynamics for lithium salt flat operations, accounting for seasonal variations, recharge rates, and extraction methodologies. Their platform features scenario planning tools that allow operators to model different extraction intensities, technological advancements, and market conditions to generate adaptive depletion forecasts with confidence intervals. The system includes real-time monitoring capabilities that continuously refine prediction models based on operational data, enabling dynamic resource management strategies.

Strengths: Builds on extensive subsurface modeling expertise; provides sophisticated simulation of brine dynamics for salt flat operations; features adaptive modeling capabilities that improve with operational data. Weaknesses: May have stronger focus on brine extraction methods than hard rock mining; requires significant implementation resources and expertise; relatively new application of technology to lithium specifically.

Baker Hughes Oilfield Operations LLC

Technical Solution: Baker Hughes has adapted its extensive oil field resource management expertise to develop "LithiumVision," a comprehensive lithium resource depletion prediction platform. The system leverages the company's deep experience in subsurface modeling and resource extraction optimization from the petroleum industry. LithiumVision employs advanced seismic imaging and geophysical analysis techniques to create detailed 3D models of lithium deposits with resolution capabilities down to 5-meter intervals. The platform incorporates a dynamic simulation engine that accounts for variable extraction rates, technological efficiency improvements, and market demand fluctuations to generate adaptive depletion forecasts. Baker Hughes' approach includes proprietary algorithms that model the impact of different extraction technologies, including traditional evaporation ponds, direct lithium extraction (DLE), and hard rock mining methods. Their system features real-time monitoring capabilities that continuously refine prediction models based on actual extraction data, allowing for adaptive resource management strategies. The platform includes economic modeling tools that help operators balance extraction rates with market conditions to optimize resource utilization over projected timeframes.

Strengths: Leverages extensive subsurface modeling expertise from oil and gas industry; provides comprehensive simulation capabilities for different extraction technologies; features adaptive modeling that improves with operational data. Weaknesses: May have stronger focus on brine extraction methods given company background; requires significant implementation resources; relatively new application of technology to lithium specifically.

Critical Resource Depletion Prediction Algorithms

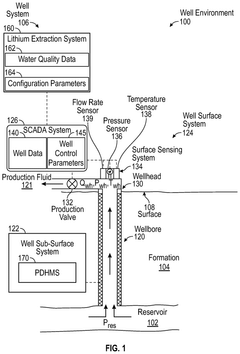

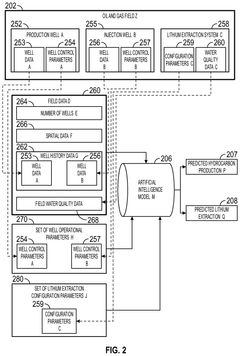

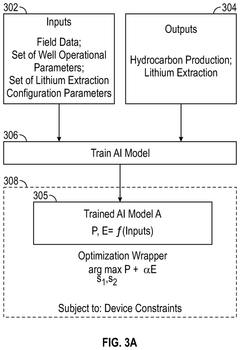

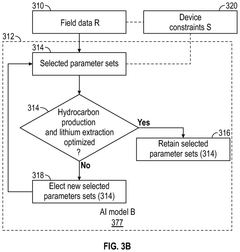

Artificial intelligence based framework for the optimization of lithium extraction in reservoir brine

PatentPendingUS20250223893A1

Innovation

- An artificial intelligence (AI) model is used to predict hydrocarbon production and lithium extraction based on well operational and lithium extraction configuration parameters, allowing for the automatic adjustment of these parameters in real-time to maximize both outputs simultaneously.

Brine concentrating process prediction system

PatentWO2024128656A1

Innovation

- A system comprising a data collection, pre-processing, and prediction unit that utilizes nonlinear regression analysis and machine learning to calculate the solubility of precipitate components, predict the final precipitation amount, and adjust operating conditions, thereby improving the reliability of predicting the composition and concentration of components in the brine, reducing lithium loss and optimizing the concentration process.

Environmental Impact Assessment of Extraction Scenarios

The environmental impact of lithium mining operations varies significantly across different extraction scenarios, with implications for both local ecosystems and global sustainability goals. Traditional open-pit mining methods typically result in substantial land disturbance, habitat fragmentation, and biodiversity loss. These operations often require the removal of large volumes of soil and rock, creating visible scars on landscapes that can persist for decades without proper reclamation efforts.

Water usage represents one of the most critical environmental concerns in lithium extraction, particularly in brine-based operations prevalent in South America's "Lithium Triangle." Under high-intensity extraction scenarios, these operations can deplete local aquifers at rates exceeding natural replenishment, leading to desertification and threatening both wildlife and indigenous communities that depend on these water sources. Models suggest that for every ton of lithium produced, approximately 500,000 gallons of water may be consumed in arid regions where water resources are already stressed.

Chemical contamination presents another significant environmental risk factor. The processing of lithium involves various chemicals including sulfuric acid, hydrochloric acid, and sodium carbonate, which can contaminate soil and water systems if not properly managed. Under accelerated extraction scenarios, the risk of accidental releases increases proportionally with production volume, potentially causing long-term damage to aquatic ecosystems and groundwater resources.

Carbon emissions associated with lithium extraction also vary considerably between scenarios. Energy-intensive processing methods can generate between 5-15 tons of CO2 per ton of lithium carbonate equivalent produced, depending on the energy sources utilized. Scenarios involving renewable energy integration in mining operations could potentially reduce these emissions by 30-60%, representing a significant opportunity for environmental impact mitigation.

Emerging direct lithium extraction (DLE) technologies present promising alternatives with potentially reduced environmental footprints. These methods can decrease water consumption by up to 70% compared to traditional evaporation techniques and require significantly less land disturbance. However, their energy requirements may be higher, creating a complex environmental trade-off that must be carefully evaluated in each specific implementation context.

Cumulative impacts across the lithium supply chain must also be considered when assessing different extraction scenarios. Life cycle assessments indicate that aggressive extraction timelines often result in corner-cutting regarding environmental safeguards, while more measured approaches allow for implementation of best practices and technological improvements that can substantially reduce overall environmental impact.

Water usage represents one of the most critical environmental concerns in lithium extraction, particularly in brine-based operations prevalent in South America's "Lithium Triangle." Under high-intensity extraction scenarios, these operations can deplete local aquifers at rates exceeding natural replenishment, leading to desertification and threatening both wildlife and indigenous communities that depend on these water sources. Models suggest that for every ton of lithium produced, approximately 500,000 gallons of water may be consumed in arid regions where water resources are already stressed.

Chemical contamination presents another significant environmental risk factor. The processing of lithium involves various chemicals including sulfuric acid, hydrochloric acid, and sodium carbonate, which can contaminate soil and water systems if not properly managed. Under accelerated extraction scenarios, the risk of accidental releases increases proportionally with production volume, potentially causing long-term damage to aquatic ecosystems and groundwater resources.

Carbon emissions associated with lithium extraction also vary considerably between scenarios. Energy-intensive processing methods can generate between 5-15 tons of CO2 per ton of lithium carbonate equivalent produced, depending on the energy sources utilized. Scenarios involving renewable energy integration in mining operations could potentially reduce these emissions by 30-60%, representing a significant opportunity for environmental impact mitigation.

Emerging direct lithium extraction (DLE) technologies present promising alternatives with potentially reduced environmental footprints. These methods can decrease water consumption by up to 70% compared to traditional evaporation techniques and require significantly less land disturbance. However, their energy requirements may be higher, creating a complex environmental trade-off that must be carefully evaluated in each specific implementation context.

Cumulative impacts across the lithium supply chain must also be considered when assessing different extraction scenarios. Life cycle assessments indicate that aggressive extraction timelines often result in corner-cutting regarding environmental safeguards, while more measured approaches allow for implementation of best practices and technological improvements that can substantially reduce overall environmental impact.

Policy Frameworks for Lithium Resource Management

Effective policy frameworks are essential for sustainable lithium resource management, especially when predicting depletion under variable extraction scenarios. These frameworks must balance economic development with environmental protection and social equity. Currently, major lithium-producing countries employ diverse regulatory approaches, from Chile's concession-based system to Australia's mining act framework, each with varying degrees of effectiveness in resource conservation.

International governance mechanisms are increasingly important as lithium becomes a critical material for global energy transition. The UN Resource Panel and International Energy Agency have developed guidelines for sustainable mineral extraction, while regional agreements like the EU's Critical Raw Materials Act establish frameworks for responsible sourcing and strategic reserves. These international frameworks provide valuable models for national policy development.

Resource taxation and royalty systems represent crucial economic instruments for managing lithium extraction rates. Progressive taxation models that increase rates as extraction intensifies can effectively moderate depletion speeds while generating revenue for sustainable development initiatives. Countries like Bolivia have implemented such systems to ensure national benefit from lithium resources while controlling extraction rates.

Permitting processes and extraction quotas serve as direct regulatory tools for controlling lithium mining activities. Best practices include comprehensive environmental impact assessments, mandatory rehabilitation plans, and extraction limits based on scientific depletion models. These regulatory mechanisms can be dynamically adjusted based on ongoing resource assessment and technological developments in extraction efficiency.

Stakeholder engagement policies are increasingly recognized as essential components of effective lithium resource management. Indigenous communities and local populations must be meaningfully involved in decision-making processes through formal consultation mechanisms, benefit-sharing agreements, and participatory monitoring programs. Such inclusive approaches not only improve social outcomes but also enhance the effectiveness of resource management policies.

Future policy directions point toward adaptive management frameworks that can respond to changing extraction technologies, market conditions, and environmental knowledge. Policies incorporating regular reassessment of reserves, technology-neutral performance standards, and international coordination mechanisms show promise for sustainable lithium resource management. The integration of predictive depletion modeling into regulatory frameworks represents a particularly important advancement for evidence-based policy development.

International governance mechanisms are increasingly important as lithium becomes a critical material for global energy transition. The UN Resource Panel and International Energy Agency have developed guidelines for sustainable mineral extraction, while regional agreements like the EU's Critical Raw Materials Act establish frameworks for responsible sourcing and strategic reserves. These international frameworks provide valuable models for national policy development.

Resource taxation and royalty systems represent crucial economic instruments for managing lithium extraction rates. Progressive taxation models that increase rates as extraction intensifies can effectively moderate depletion speeds while generating revenue for sustainable development initiatives. Countries like Bolivia have implemented such systems to ensure national benefit from lithium resources while controlling extraction rates.

Permitting processes and extraction quotas serve as direct regulatory tools for controlling lithium mining activities. Best practices include comprehensive environmental impact assessments, mandatory rehabilitation plans, and extraction limits based on scientific depletion models. These regulatory mechanisms can be dynamically adjusted based on ongoing resource assessment and technological developments in extraction efficiency.

Stakeholder engagement policies are increasingly recognized as essential components of effective lithium resource management. Indigenous communities and local populations must be meaningfully involved in decision-making processes through formal consultation mechanisms, benefit-sharing agreements, and participatory monitoring programs. Such inclusive approaches not only improve social outcomes but also enhance the effectiveness of resource management policies.

Future policy directions point toward adaptive management frameworks that can respond to changing extraction technologies, market conditions, and environmental knowledge. Policies incorporating regular reassessment of reserves, technology-neutral performance standards, and international coordination mechanisms show promise for sustainable lithium resource management. The integration of predictive depletion modeling into regulatory frameworks represents a particularly important advancement for evidence-based policy development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!