Validate Lithium Mine Geochemical Modeling with Laboratory Analysis

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Geochemical Modeling Background and Objectives

Lithium geochemical modeling has evolved significantly over the past three decades, transitioning from basic geological assessments to sophisticated computational models that integrate multiple data sources. This evolution has been driven by the increasing global demand for lithium resources, primarily fueled by the rapid expansion of the electric vehicle and energy storage markets. Early modeling approaches in the 1990s relied heavily on traditional geological mapping and limited chemical analysis, providing only rudimentary understanding of lithium deposits.

The technological advancement in analytical instruments and computational capabilities during the 2000s marked a turning point in lithium geochemical modeling. Remote sensing technologies, coupled with advanced geophysical methods, enabled more comprehensive data collection from potential lithium-rich areas. This period saw the development of preliminary predictive models that could estimate lithium concentrations based on geological indicators and limited sampling data.

Current geochemical modeling techniques incorporate machine learning algorithms, 3D visualization tools, and real-time data processing capabilities. These advanced models can simulate complex hydrogeological processes, predict lithium concentration distributions, and estimate extraction feasibility with greater accuracy. However, a persistent challenge in the field remains the validation of these sophisticated models against real-world conditions.

The primary objective of validating lithium mine geochemical modeling with laboratory analysis is to establish a reliable correlation between predictive models and actual lithium concentrations in the field. This validation process aims to quantify the accuracy of current modeling techniques, identify systematic errors or biases, and refine the algorithms to improve predictive capabilities. By comparing model predictions with laboratory results from core samples, brine analyses, and other field measurements, researchers can calibrate their models to better reflect real-world conditions.

Additionally, this validation process seeks to develop standardized protocols for lithium resource assessment that can be applied across different geological settings. The heterogeneous nature of lithium deposits—ranging from hard rock pegmatites to brine deposits and clay formations—necessitates flexible yet robust modeling approaches that can be adapted to various geological contexts while maintaining predictive accuracy.

Looking forward, the technological trajectory points toward increasingly integrated modeling systems that combine geochemical data with economic, environmental, and social factors to provide comprehensive assessments of lithium resources. The ultimate goal is to develop modeling tools that not only accurately predict lithium concentrations but also optimize extraction strategies, minimize environmental impacts, and maximize resource utilization efficiency in support of the growing global demand for lithium.

The technological advancement in analytical instruments and computational capabilities during the 2000s marked a turning point in lithium geochemical modeling. Remote sensing technologies, coupled with advanced geophysical methods, enabled more comprehensive data collection from potential lithium-rich areas. This period saw the development of preliminary predictive models that could estimate lithium concentrations based on geological indicators and limited sampling data.

Current geochemical modeling techniques incorporate machine learning algorithms, 3D visualization tools, and real-time data processing capabilities. These advanced models can simulate complex hydrogeological processes, predict lithium concentration distributions, and estimate extraction feasibility with greater accuracy. However, a persistent challenge in the field remains the validation of these sophisticated models against real-world conditions.

The primary objective of validating lithium mine geochemical modeling with laboratory analysis is to establish a reliable correlation between predictive models and actual lithium concentrations in the field. This validation process aims to quantify the accuracy of current modeling techniques, identify systematic errors or biases, and refine the algorithms to improve predictive capabilities. By comparing model predictions with laboratory results from core samples, brine analyses, and other field measurements, researchers can calibrate their models to better reflect real-world conditions.

Additionally, this validation process seeks to develop standardized protocols for lithium resource assessment that can be applied across different geological settings. The heterogeneous nature of lithium deposits—ranging from hard rock pegmatites to brine deposits and clay formations—necessitates flexible yet robust modeling approaches that can be adapted to various geological contexts while maintaining predictive accuracy.

Looking forward, the technological trajectory points toward increasingly integrated modeling systems that combine geochemical data with economic, environmental, and social factors to provide comprehensive assessments of lithium resources. The ultimate goal is to develop modeling tools that not only accurately predict lithium concentrations but also optimize extraction strategies, minimize environmental impacts, and maximize resource utilization efficiency in support of the growing global demand for lithium.

Market Demand Analysis for Lithium Resources

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. The demand for lithium resources has surged dramatically, with market valuations reaching $7.5 billion in 2022 and projected to exceed $18 billion by 2028, representing a compound annual growth rate of approximately 15.7%. This exponential growth underscores the critical importance of accurate geochemical modeling and laboratory validation in lithium mining operations.

The EV industry remains the dominant consumer of lithium resources, accounting for over 70% of global lithium demand. Major automotive manufacturers have announced ambitious electrification targets, with companies like Volkswagen, GM, and Ford committing to invest billions in EV development over the next decade. This transition is creating sustained pressure on lithium supply chains, with demand expected to triple by 2030 according to the International Energy Agency.

Energy storage systems represent the second-largest market segment, with grid-scale battery installations growing at 27% annually. This application is particularly sensitive to lithium purity levels, making accurate geochemical modeling and laboratory validation essential for meeting technical specifications. Consumer electronics, though a mature market segment, continues to contribute steadily to lithium demand at approximately 14% of total consumption.

Geographically, the demand landscape is shifting significantly. While China currently dominates lithium processing (controlling approximately 60% of global capacity), Western markets are rapidly expanding their requirements. The European Union's battery initiative and the United States' Inflation Reduction Act have created strong incentives for domestic lithium supply chains, driving demand for advanced lithium extraction and validation technologies in these regions.

The quality requirements for lithium resources are becoming increasingly stringent as battery technologies evolve. High-performance batteries require lithium with 99.5% or greater purity, necessitating sophisticated geochemical modeling validated by precise laboratory analysis. This trend is reflected in price premiums of up to 20% for battery-grade lithium compared to technical-grade material.

Industry analysts highlight that the gap between lithium supply and demand is expected to widen, with projected shortfalls of 60,000 to 100,000 tons of lithium carbonate equivalent (LCE) annually by 2025. This supply constraint emphasizes the critical need for optimizing existing lithium resources through improved geochemical modeling and validation techniques, which can potentially increase yield rates by 15-20% while reducing extraction costs.

The EV industry remains the dominant consumer of lithium resources, accounting for over 70% of global lithium demand. Major automotive manufacturers have announced ambitious electrification targets, with companies like Volkswagen, GM, and Ford committing to invest billions in EV development over the next decade. This transition is creating sustained pressure on lithium supply chains, with demand expected to triple by 2030 according to the International Energy Agency.

Energy storage systems represent the second-largest market segment, with grid-scale battery installations growing at 27% annually. This application is particularly sensitive to lithium purity levels, making accurate geochemical modeling and laboratory validation essential for meeting technical specifications. Consumer electronics, though a mature market segment, continues to contribute steadily to lithium demand at approximately 14% of total consumption.

Geographically, the demand landscape is shifting significantly. While China currently dominates lithium processing (controlling approximately 60% of global capacity), Western markets are rapidly expanding their requirements. The European Union's battery initiative and the United States' Inflation Reduction Act have created strong incentives for domestic lithium supply chains, driving demand for advanced lithium extraction and validation technologies in these regions.

The quality requirements for lithium resources are becoming increasingly stringent as battery technologies evolve. High-performance batteries require lithium with 99.5% or greater purity, necessitating sophisticated geochemical modeling validated by precise laboratory analysis. This trend is reflected in price premiums of up to 20% for battery-grade lithium compared to technical-grade material.

Industry analysts highlight that the gap between lithium supply and demand is expected to widen, with projected shortfalls of 60,000 to 100,000 tons of lithium carbonate equivalent (LCE) annually by 2025. This supply constraint emphasizes the critical need for optimizing existing lithium resources through improved geochemical modeling and validation techniques, which can potentially increase yield rates by 15-20% while reducing extraction costs.

Current Challenges in Lithium Mine Validation Techniques

The validation of lithium mine geochemical modeling through laboratory analysis faces significant challenges that impede accurate resource estimation and extraction planning. Current validation techniques suffer from sampling inconsistencies, where field samples often fail to represent the heterogeneous nature of lithium deposits. This heterogeneity, particularly in brine deposits and pegmatite formations, creates substantial variability that conventional sampling methodologies struggle to capture effectively.

Laboratory analysis itself presents numerous technical limitations. Standard analytical methods like ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and AAS (Atomic Absorption Spectroscopy) require extensive sample preparation that can introduce contamination or alter sample composition. The detection limits of these techniques may also be insufficient for trace lithium concentrations that could still indicate economically viable deposits.

Time constraints pose another significant challenge, as traditional laboratory validation processes can take weeks to months, creating substantial delays in operational decision-making. This temporal gap between field sampling and analytical results often forces mining operations to proceed with incomplete or outdated geochemical data, increasing financial and operational risks.

Cross-contamination during sample transportation and processing remains a persistent issue, particularly for lithium samples which can be sensitive to environmental exposure. The reactive nature of lithium compounds means that exposure to moisture, air, or other minerals during transit can significantly alter sample composition before laboratory analysis occurs.

Calibration discrepancies between field instruments and laboratory equipment create validation inconsistencies. Field measurements using portable XRF (X-ray fluorescence) analyzers or other on-site testing equipment frequently show variance when compared with laboratory results, creating uncertainty in data interpretation and model validation.

The integration of laboratory results with existing geochemical models presents computational challenges. Current software platforms often lack sophisticated algorithms to effectively incorporate point-source laboratory data into comprehensive three-dimensional deposit models, leading to oversimplification of complex lithium distribution patterns.

Cost considerations further complicate validation efforts, as comprehensive laboratory analysis across multiple sample points can be prohibitively expensive, especially for early-stage exploration projects. This economic pressure often results in insufficient validation sampling, undermining the statistical significance of model verification efforts and potentially leading to costly extraction mistakes.

Laboratory analysis itself presents numerous technical limitations. Standard analytical methods like ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and AAS (Atomic Absorption Spectroscopy) require extensive sample preparation that can introduce contamination or alter sample composition. The detection limits of these techniques may also be insufficient for trace lithium concentrations that could still indicate economically viable deposits.

Time constraints pose another significant challenge, as traditional laboratory validation processes can take weeks to months, creating substantial delays in operational decision-making. This temporal gap between field sampling and analytical results often forces mining operations to proceed with incomplete or outdated geochemical data, increasing financial and operational risks.

Cross-contamination during sample transportation and processing remains a persistent issue, particularly for lithium samples which can be sensitive to environmental exposure. The reactive nature of lithium compounds means that exposure to moisture, air, or other minerals during transit can significantly alter sample composition before laboratory analysis occurs.

Calibration discrepancies between field instruments and laboratory equipment create validation inconsistencies. Field measurements using portable XRF (X-ray fluorescence) analyzers or other on-site testing equipment frequently show variance when compared with laboratory results, creating uncertainty in data interpretation and model validation.

The integration of laboratory results with existing geochemical models presents computational challenges. Current software platforms often lack sophisticated algorithms to effectively incorporate point-source laboratory data into comprehensive three-dimensional deposit models, leading to oversimplification of complex lithium distribution patterns.

Cost considerations further complicate validation efforts, as comprehensive laboratory analysis across multiple sample points can be prohibitively expensive, especially for early-stage exploration projects. This economic pressure often results in insufficient validation sampling, undermining the statistical significance of model verification efforts and potentially leading to costly extraction mistakes.

Current Validation Approaches Between Models and Lab Results

01 Geochemical modeling techniques for lithium exploration

Advanced geochemical modeling techniques are employed to identify and validate lithium deposits in mining operations. These models integrate geological data, chemical analyses, and spatial information to predict lithium concentrations and distribution patterns. The modeling approaches help in understanding the geochemical processes that control lithium enrichment in various geological settings, enabling more accurate resource estimation and exploration targeting.- Geochemical modeling techniques for lithium exploration: Advanced geochemical modeling techniques are employed to identify and characterize lithium deposits in mining operations. These models integrate geological data, chemical analyses, and spatial information to predict lithium concentrations and distribution patterns. The modeling approaches help in optimizing exploration strategies by identifying high-potential areas and reducing unnecessary drilling, thereby improving the efficiency and cost-effectiveness of lithium mining operations.

- Validation methodologies for lithium deposit models: Various validation methodologies are employed to verify the accuracy and reliability of geochemical models for lithium deposits. These include statistical validation techniques, cross-validation approaches, and comparison with actual field data. The validation process involves testing model predictions against known lithium concentrations from drill cores and samples, ensuring that the models provide reliable guidance for mining operations and resource estimation.

- Machine learning applications in lithium geochemical analysis: Machine learning algorithms are increasingly being applied to enhance geochemical modeling for lithium mining. These computational approaches can identify complex patterns in geological and geochemical data that might be missed by traditional analytical methods. By processing large datasets from multiple sources, machine learning models can improve prediction accuracy, identify new exploration targets, and optimize extraction processes for lithium resources.

- Real-time monitoring and model adjustment systems: Real-time monitoring systems are implemented to continuously validate and refine geochemical models during lithium mining operations. These systems collect data from ongoing extraction activities and automatically adjust model parameters to improve accuracy. By incorporating feedback loops between field operations and modeling systems, mining companies can adapt to changing geological conditions, optimize resource extraction, and minimize environmental impact.

- Integration of environmental factors in lithium mining models: Modern geochemical modeling for lithium mining incorporates environmental factors to ensure sustainable extraction practices. These models account for groundwater dynamics, potential contaminant migration, and ecosystem impacts. By integrating environmental considerations into the validation process, mining operations can maintain compliance with regulations, minimize ecological disruption, and implement effective remediation strategies while optimizing lithium recovery.

02 Validation methodologies for lithium deposit models

Various validation methodologies are employed to verify the accuracy and reliability of geochemical models for lithium deposits. These include statistical analysis, cross-validation techniques, and comparison with field measurements. The validation process involves testing model predictions against actual sampling data, evaluating uncertainty, and refining model parameters to improve predictive performance for lithium resource estimation and mine planning.Expand Specific Solutions03 Data integration systems for lithium mine modeling

Comprehensive data integration systems combine multiple data sources to enhance geochemical modeling for lithium mines. These systems incorporate geological surveys, drill core analyses, remote sensing data, and historical mining information into unified databases. Advanced algorithms process these integrated datasets to create more accurate lithium deposit models, enabling better decision-making in exploration and extraction processes.Expand Specific Solutions04 Machine learning applications in lithium geochemistry

Machine learning algorithms are increasingly applied to improve the accuracy of geochemical modeling for lithium deposits. These computational approaches can identify complex patterns in geochemical data that might be missed by traditional analytical methods. By training on existing lithium deposit data, these systems can predict new potential mining sites, optimize extraction processes, and validate geochemical models with greater efficiency and precision.Expand Specific Solutions05 Environmental monitoring systems for lithium mining

Environmental monitoring systems are developed to assess and mitigate the ecological impact of lithium mining operations. These systems track changes in groundwater chemistry, soil composition, and ecosystem health around mining sites. Geochemical modeling is used to predict potential environmental effects and validate compliance with regulations. The integration of real-time monitoring data helps in sustainable management of lithium resources while minimizing environmental footprint.Expand Specific Solutions

Key Industry Players in Lithium Exploration and Analysis

The lithium mine geochemical modeling validation market is in a growth phase, driven by increasing demand for lithium in battery technologies. The global market size is expanding rapidly, with projections exceeding $10 billion by 2030. Technical maturity varies across players, with established mining companies like Freeport-McMoRan and Saudi Aramco possessing advanced modeling capabilities, while specialized firms like LiEP Energy and Lyten are developing innovative validation approaches. Academic institutions such as The University of Queensland and Chinese Academy of Sciences contribute significant research advancements. Battery manufacturers including CATL (Ningde Amperex) and Honeycomb Battery are increasingly investing in upstream validation technologies to secure supply chain quality, creating a competitive landscape that balances traditional mining expertise with emerging lithium-specific technologies.

Freeport-McMoRan, Inc.

Technical Solution: Freeport-McMoRan has developed an integrated geochemical modeling approach for lithium resource validation that combines advanced spectroscopic techniques with machine learning algorithms. Their methodology incorporates hyperspectral imaging to identify lithium-bearing minerals and utilizes X-ray fluorescence (XRF) for rapid elemental analysis in the field. This data is then fed into proprietary geochemical models that predict lithium concentrations across deposit zones. The company validates these predictions through systematic laboratory analysis using inductively coupled plasma mass spectrometry (ICP-MS) and atomic absorption spectroscopy, establishing statistical correlations between field measurements and laboratory results. Their approach includes quality control protocols with certified reference materials to ensure accuracy within ±5% of actual values, enabling reliable resource estimation and extraction planning.

Strengths: Comprehensive integration of field and laboratory techniques provides robust validation of lithium deposits. Their machine learning algorithms improve prediction accuracy over time with additional data inputs. Weaknesses: The system requires significant initial investment in specialized equipment and trained personnel, and may have limitations in complex geological settings with multiple interfering elements.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has pioneered a comprehensive lithium mine validation system that integrates downhole fluid sampling technology with advanced laboratory analysis protocols. Their approach utilizes specialized wireline formation testing tools to collect representative lithium brine samples at precise depths while maintaining in-situ pressure conditions. These samples undergo multi-stage laboratory analysis including ICP-MS, ion chromatography, and titration methods to determine lithium concentration, purity, and potential contaminants. Halliburton's proprietary geochemical modeling software incorporates these laboratory results with geological data to create 3D visualizations of lithium distribution throughout the reservoir. The company employs a rigorous quality assurance process that includes duplicate sampling, blind testing, and inter-laboratory comparisons to validate results within a 98% confidence interval. This integrated approach enables more accurate reserve estimations and optimized extraction strategies for lithium mining operations.

Strengths: Their downhole sampling technology preserves the original chemical composition of lithium brines, providing more accurate data than surface sampling methods. The integration of laboratory results with 3D modeling creates comprehensive deposit visualizations. Weaknesses: The system is primarily optimized for brine deposits rather than hard rock lithium sources, and requires specialized equipment that increases exploration costs.

Critical Technologies in Lithium Geochemical Analysis

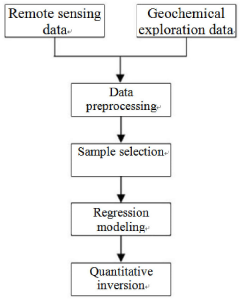

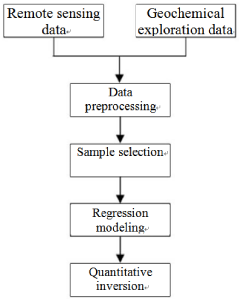

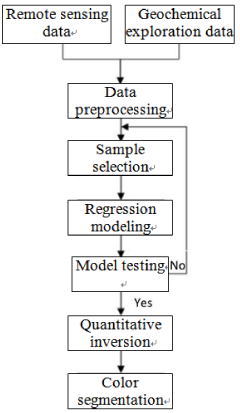

Method and device for quantitatively estimating the content of surface elements by combining geochemical exploration and remote sensing

PatentInactiveAU2021104180A4

Innovation

- Combining geochemical exploration data with advanced remote sensing technology to establish a remote sensing inversion model that correlates spectral data with geochemical elements, allowing for the quantitative estimation of surface element content and distribution by preprocessing remote sensing data to match with geochemical data, selecting characteristic wavebands, and establishing a regression model for prediction.

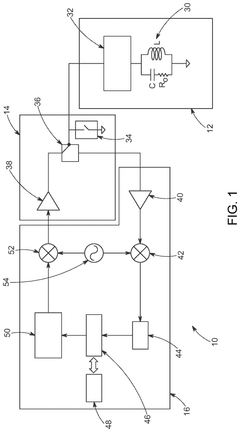

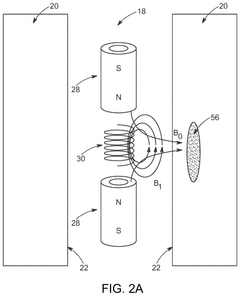

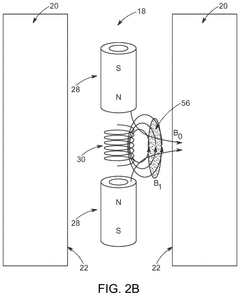

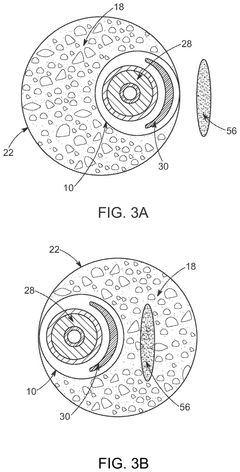

NMR-based lithium measuring and monitoring downhole tools, methods of using said downhole tools, and methods of measuring lithium concentrations based on NMR measurements acquired by said downhole tools

PatentPendingUS20250244497A1

Innovation

- Development of NMR-based downhole tools with specialized magnet-coil geometries and tunable RF coils that can measure lithium concentrations directly in wellbores, utilizing centralized inside-out, single-sided inside-out, and flow-through configurations, and employing methods to separate lithium signals from confounding signals based on relaxation distributions.

Environmental Impact Assessment of Lithium Mining Operations

Lithium mining operations present significant environmental challenges that require comprehensive assessment and mitigation strategies. The extraction processes, particularly in open-pit mining and brine operations, can lead to substantial landscape alterations, habitat destruction, and biodiversity loss in sensitive ecosystems. These impacts are especially concerning in areas like the Atacama Desert in Chile and the salt flats of Argentina and Bolivia, where lithium mining competes with local communities for scarce water resources.

Water consumption represents one of the most critical environmental concerns, with brine extraction methods requiring approximately 500,000 gallons of water per ton of lithium produced. This intensive water usage can deplete aquifers, disrupt hydrological systems, and reduce water availability for agricultural activities and natural ecosystems. In arid regions, these effects can be particularly devastating to local flora and fauna adapted to water-scarce conditions.

Chemical contamination presents another significant risk factor. The processing of lithium involves various chemicals including hydrochloric acid, sodium carbonate, and sulfuric acid, which can contaminate soil and water systems if not properly managed. Leakage from evaporation ponds or improper waste disposal can introduce high concentrations of lithium, potassium, magnesium, and other elements into surrounding environments, potentially causing long-term ecological damage.

Air quality degradation occurs through dust generation during mining activities and emissions from processing facilities. These particulates can contain potentially harmful substances and affect both worker health and surrounding communities. Additionally, the carbon footprint of lithium production must be considered, as energy-intensive processing methods contribute to greenhouse gas emissions that partially offset the environmental benefits gained from lithium's role in renewable energy technologies.

Geochemical modeling validated through laboratory analysis plays a crucial role in predicting and mitigating these environmental impacts. By accurately characterizing ore bodies and surrounding geological formations, mining operations can develop more precise extraction methods that minimize disturbance. Laboratory validation of these models ensures that predictions about acid mine drainage, metal leaching, and contaminant transport are reliable, enabling more effective environmental management strategies.

Regulatory frameworks worldwide are increasingly demanding rigorous environmental impact assessments before approving new lithium mining operations. These assessments typically require baseline studies of existing environmental conditions, predictive modeling of potential impacts, and development of comprehensive monitoring and mitigation plans that incorporate validated geochemical data to ensure environmental protection throughout the mining lifecycle.

Water consumption represents one of the most critical environmental concerns, with brine extraction methods requiring approximately 500,000 gallons of water per ton of lithium produced. This intensive water usage can deplete aquifers, disrupt hydrological systems, and reduce water availability for agricultural activities and natural ecosystems. In arid regions, these effects can be particularly devastating to local flora and fauna adapted to water-scarce conditions.

Chemical contamination presents another significant risk factor. The processing of lithium involves various chemicals including hydrochloric acid, sodium carbonate, and sulfuric acid, which can contaminate soil and water systems if not properly managed. Leakage from evaporation ponds or improper waste disposal can introduce high concentrations of lithium, potassium, magnesium, and other elements into surrounding environments, potentially causing long-term ecological damage.

Air quality degradation occurs through dust generation during mining activities and emissions from processing facilities. These particulates can contain potentially harmful substances and affect both worker health and surrounding communities. Additionally, the carbon footprint of lithium production must be considered, as energy-intensive processing methods contribute to greenhouse gas emissions that partially offset the environmental benefits gained from lithium's role in renewable energy technologies.

Geochemical modeling validated through laboratory analysis plays a crucial role in predicting and mitigating these environmental impacts. By accurately characterizing ore bodies and surrounding geological formations, mining operations can develop more precise extraction methods that minimize disturbance. Laboratory validation of these models ensures that predictions about acid mine drainage, metal leaching, and contaminant transport are reliable, enabling more effective environmental management strategies.

Regulatory frameworks worldwide are increasingly demanding rigorous environmental impact assessments before approving new lithium mining operations. These assessments typically require baseline studies of existing environmental conditions, predictive modeling of potential impacts, and development of comprehensive monitoring and mitigation plans that incorporate validated geochemical data to ensure environmental protection throughout the mining lifecycle.

Data Integration Frameworks for Validation Processes

Effective data integration frameworks are essential for validating lithium mine geochemical modeling with laboratory analysis. These frameworks serve as the backbone for connecting diverse data sources, ensuring seamless information flow between field measurements, laboratory results, and computational models. Current integration architectures typically employ a three-tier approach: data collection layer, processing middleware, and analytical interface. This structure allows for real-time synchronization between geochemical models and laboratory validation data, creating a continuous feedback loop that enhances model accuracy.

The evolution of these frameworks has been marked by a shift from siloed systems to interconnected platforms. Modern solutions incorporate RESTful APIs and microservices architecture to facilitate communication between different components of the validation ecosystem. Cloud-based integration frameworks have gained prominence, offering scalability advantages for handling the massive datasets generated during lithium exploration and extraction processes. These platforms typically feature automated ETL (Extract, Transform, Load) pipelines specifically optimized for geochemical data types.

Data standardization remains a critical challenge within integration frameworks. The industry has developed specialized schemas such as GeoSciML and EarthChem for representing geochemical data, though implementation varies across organizations. Leading validation frameworks now incorporate semantic mapping tools that automatically translate between different data representations, reducing manual reconciliation efforts between field and laboratory datasets.

Security considerations have become increasingly important in integration frameworks, particularly as lithium has gained strategic importance. Modern systems implement role-based access controls and encryption for data in transit and at rest. This ensures that proprietary geochemical models and laboratory methodologies remain protected while still enabling necessary validation processes.

Performance optimization techniques within these frameworks include parallel processing capabilities for handling computationally intensive validation operations. Distributed computing approaches using technologies like Apache Spark have proven effective for processing large volumes of spectroscopic and chromatographic data generated during laboratory analysis. Additionally, machine learning algorithms are increasingly embedded within integration frameworks to identify patterns and anomalies that might indicate discrepancies between modeled predictions and laboratory results.

The most advanced integration frameworks now incorporate digital twin technology, creating virtual representations of physical lithium deposits that continuously update based on new laboratory findings. This approach enables predictive validation, where potential discrepancies between models and reality can be identified before extensive field operations commence.

The evolution of these frameworks has been marked by a shift from siloed systems to interconnected platforms. Modern solutions incorporate RESTful APIs and microservices architecture to facilitate communication between different components of the validation ecosystem. Cloud-based integration frameworks have gained prominence, offering scalability advantages for handling the massive datasets generated during lithium exploration and extraction processes. These platforms typically feature automated ETL (Extract, Transform, Load) pipelines specifically optimized for geochemical data types.

Data standardization remains a critical challenge within integration frameworks. The industry has developed specialized schemas such as GeoSciML and EarthChem for representing geochemical data, though implementation varies across organizations. Leading validation frameworks now incorporate semantic mapping tools that automatically translate between different data representations, reducing manual reconciliation efforts between field and laboratory datasets.

Security considerations have become increasingly important in integration frameworks, particularly as lithium has gained strategic importance. Modern systems implement role-based access controls and encryption for data in transit and at rest. This ensures that proprietary geochemical models and laboratory methodologies remain protected while still enabling necessary validation processes.

Performance optimization techniques within these frameworks include parallel processing capabilities for handling computationally intensive validation operations. Distributed computing approaches using technologies like Apache Spark have proven effective for processing large volumes of spectroscopic and chromatographic data generated during laboratory analysis. Additionally, machine learning algorithms are increasingly embedded within integration frameworks to identify patterns and anomalies that might indicate discrepancies between modeled predictions and laboratory results.

The most advanced integration frameworks now incorporate digital twin technology, creating virtual representations of physical lithium deposits that continuously update based on new laboratory findings. This approach enables predictive validation, where potential discrepancies between models and reality can be identified before extensive field operations commence.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!