Benchmark Lithium Mine Ore Sorting Accuracy Against Optical Systems

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Ore Sorting Technology Evolution and Objectives

Lithium mining has undergone significant technological evolution over the past decades, transitioning from traditional labor-intensive methods to increasingly sophisticated automated systems. The earliest lithium extraction techniques relied heavily on manual inspection and basic mechanical separation, resulting in considerable resource wastage and environmental impact. By the 1980s, rudimentary sensor-based sorting emerged, though with limited accuracy and throughput capabilities.

The 2000s marked a pivotal shift with the introduction of optical sorting systems utilizing visible light spectrum analysis. These systems represented the first generation of automated lithium ore sorting, capable of distinguishing lithium-bearing minerals based on color, brightness, and reflectance properties. However, these early optical systems struggled with accuracy when processing complex ore bodies with similar visual characteristics.

The past decade has witnessed accelerated development in multi-sensor technologies that combine optical systems with other detection methods such as X-ray transmission (XRT), X-ray fluorescence (XRF), laser-induced breakdown spectroscopy (LIBS), and near-infrared (NIR) spectroscopy. This integration has significantly enhanced discrimination capabilities, particularly for lithium minerals like spodumene and petalite that may not be visually distinctive.

Current technological objectives in lithium ore sorting focus on achieving higher accuracy rates while maintaining commercially viable throughput speeds. Industry benchmarks suggest that advanced optical systems typically achieve 85-90% accuracy in ideal conditions, but performance degrades with variable ore composition and environmental factors. The primary goal is to develop systems that consistently deliver 95%+ accuracy across diverse lithium deposits while reducing false positives and negatives.

Another critical objective is minimizing energy consumption and operational costs while maximizing recovery rates. Modern sorting systems aim to reduce the mass of material requiring downstream processing by 30-50%, thereby significantly decreasing energy, water, and reagent usage in subsequent concentration processes. This efficiency improvement directly impacts the economic viability of lower-grade lithium deposits.

Real-time adaptability represents another frontier in lithium ore sorting technology. Advanced systems are being developed to continuously adjust sorting parameters based on feed characteristics, enabling consistent performance despite ore variability. This adaptive capability is particularly important as mining operations increasingly target complex, heterogeneous lithium deposits that were previously considered uneconomical.

The ultimate technological objective remains the development of comprehensive sorting solutions that can accurately identify lithium content at the molecular level, regardless of mineral form or host rock composition, while operating at commercially viable speeds of 100+ tons per hour.

The 2000s marked a pivotal shift with the introduction of optical sorting systems utilizing visible light spectrum analysis. These systems represented the first generation of automated lithium ore sorting, capable of distinguishing lithium-bearing minerals based on color, brightness, and reflectance properties. However, these early optical systems struggled with accuracy when processing complex ore bodies with similar visual characteristics.

The past decade has witnessed accelerated development in multi-sensor technologies that combine optical systems with other detection methods such as X-ray transmission (XRT), X-ray fluorescence (XRF), laser-induced breakdown spectroscopy (LIBS), and near-infrared (NIR) spectroscopy. This integration has significantly enhanced discrimination capabilities, particularly for lithium minerals like spodumene and petalite that may not be visually distinctive.

Current technological objectives in lithium ore sorting focus on achieving higher accuracy rates while maintaining commercially viable throughput speeds. Industry benchmarks suggest that advanced optical systems typically achieve 85-90% accuracy in ideal conditions, but performance degrades with variable ore composition and environmental factors. The primary goal is to develop systems that consistently deliver 95%+ accuracy across diverse lithium deposits while reducing false positives and negatives.

Another critical objective is minimizing energy consumption and operational costs while maximizing recovery rates. Modern sorting systems aim to reduce the mass of material requiring downstream processing by 30-50%, thereby significantly decreasing energy, water, and reagent usage in subsequent concentration processes. This efficiency improvement directly impacts the economic viability of lower-grade lithium deposits.

Real-time adaptability represents another frontier in lithium ore sorting technology. Advanced systems are being developed to continuously adjust sorting parameters based on feed characteristics, enabling consistent performance despite ore variability. This adaptive capability is particularly important as mining operations increasingly target complex, heterogeneous lithium deposits that were previously considered uneconomical.

The ultimate technological objective remains the development of comprehensive sorting solutions that can accurately identify lithium content at the molecular level, regardless of mineral form or host rock composition, while operating at commercially viable speeds of 100+ tons per hour.

Market Analysis of Lithium Mining Efficiency Solutions

The lithium mining efficiency solutions market is experiencing significant growth driven by the surging demand for lithium in electric vehicle batteries and energy storage systems. Current market valuations indicate the global lithium mining equipment market reached approximately $380 million in 2022, with projections suggesting a compound annual growth rate of 8.7% through 2030. This acceleration is directly tied to the expanding electric vehicle market, which grew by 55% in 2022 alone.

Efficiency solutions specifically targeting ore sorting represent a critical segment within this market. Traditional mining operations typically experience ore grade inefficiencies of 30-40%, representing substantial economic losses. Advanced sorting technologies have demonstrated potential to reduce these inefficiencies by 15-25%, translating to millions in recovered value per operation annually.

Market segmentation reveals distinct categories of efficiency solutions: optical sorting systems currently dominate with approximately 45% market share, followed by sensor-based technologies (30%), automated robotic systems (15%), and emerging AI-integrated platforms (10%). The optical sorting segment alone was valued at $170 million in 2022, with laser-induced breakdown spectroscopy (LIBS) systems showing the fastest growth trajectory.

Regional analysis indicates China leads global market demand, accounting for 35% of lithium mining efficiency solution implementations, followed by Australia (22%), Chile (18%), and North America (15%). Chinese manufacturers have rapidly expanded production capacity, while Western companies maintain technological advantages in precision and reliability metrics.

Customer segmentation shows large-scale mining operations (annual production exceeding 50,000 tons) represent 65% of market demand, with mid-tier operations increasingly adopting these technologies as costs decrease. The average implementation cost for comprehensive sorting systems ranges from $2-8 million depending on scale and sophistication, with ROI typically achieved within 14-36 months.

Market challenges include high initial capital requirements, technical expertise shortages for system maintenance, and integration difficulties with existing mining infrastructure. Additionally, environmental regulations increasingly influence purchasing decisions, with water-efficient systems gaining preference in arid mining regions.

Growth opportunities center on integrated solutions combining multiple sorting technologies, subscription-based service models reducing upfront costs, and specialized systems optimized for low-grade deposits. The market shows clear correlation between lithium prices and investment in efficiency technologies, with current forecasts suggesting sustained growth as the energy transition accelerates globally.

Efficiency solutions specifically targeting ore sorting represent a critical segment within this market. Traditional mining operations typically experience ore grade inefficiencies of 30-40%, representing substantial economic losses. Advanced sorting technologies have demonstrated potential to reduce these inefficiencies by 15-25%, translating to millions in recovered value per operation annually.

Market segmentation reveals distinct categories of efficiency solutions: optical sorting systems currently dominate with approximately 45% market share, followed by sensor-based technologies (30%), automated robotic systems (15%), and emerging AI-integrated platforms (10%). The optical sorting segment alone was valued at $170 million in 2022, with laser-induced breakdown spectroscopy (LIBS) systems showing the fastest growth trajectory.

Regional analysis indicates China leads global market demand, accounting for 35% of lithium mining efficiency solution implementations, followed by Australia (22%), Chile (18%), and North America (15%). Chinese manufacturers have rapidly expanded production capacity, while Western companies maintain technological advantages in precision and reliability metrics.

Customer segmentation shows large-scale mining operations (annual production exceeding 50,000 tons) represent 65% of market demand, with mid-tier operations increasingly adopting these technologies as costs decrease. The average implementation cost for comprehensive sorting systems ranges from $2-8 million depending on scale and sophistication, with ROI typically achieved within 14-36 months.

Market challenges include high initial capital requirements, technical expertise shortages for system maintenance, and integration difficulties with existing mining infrastructure. Additionally, environmental regulations increasingly influence purchasing decisions, with water-efficient systems gaining preference in arid mining regions.

Growth opportunities center on integrated solutions combining multiple sorting technologies, subscription-based service models reducing upfront costs, and specialized systems optimized for low-grade deposits. The market shows clear correlation between lithium prices and investment in efficiency technologies, with current forecasts suggesting sustained growth as the energy transition accelerates globally.

Current Challenges in Lithium Ore Sorting Technologies

Lithium ore sorting technologies currently face significant challenges that impede efficiency and accuracy in the mining industry. Traditional optical sorting systems, while widely deployed, struggle with distinguishing lithium-bearing minerals from host rocks due to their similar visual properties. This fundamental limitation results in lower recovery rates and increased processing costs, as valuable lithium-containing materials may be incorrectly classified as waste.

The heterogeneous nature of lithium deposits presents another major obstacle. Lithium ores exhibit considerable variability in mineral composition, grain size, and distribution patterns, even within the same deposit. This variability makes it difficult to develop standardized sorting algorithms that can effectively process different ore types without frequent recalibration and adjustment.

Environmental factors at mining sites further complicate optical sorting operations. Dust, moisture, and varying lighting conditions can significantly impact the performance of camera-based systems. These environmental interferences often lead to inconsistent sorting results and require additional preprocessing steps that slow down the overall operation.

Current optical systems also face throughput limitations. High-resolution imaging necessary for accurate lithium mineral identification often requires slower conveyor speeds, creating a bottleneck in production. This trade-off between speed and accuracy represents a significant challenge for mining operations seeking to maximize productivity while maintaining sorting quality.

Energy consumption remains another concern for existing sorting technologies. Optical systems require substantial power for illumination, imaging, and data processing components. This high energy demand not only increases operational costs but also contradicts the sustainability goals associated with lithium production for green technologies.

Calibration and maintenance requirements pose ongoing operational challenges. Optical sorting systems need frequent recalibration to maintain accuracy, particularly when processing ore from different mining zones. The specialized technical expertise required for these adjustments is often scarce at remote mining locations.

Data management and integration issues further complicate the implementation of advanced sorting technologies. The large volumes of imaging data generated require robust storage and processing infrastructure. Additionally, many mining operations struggle to effectively integrate sorting system data with broader mine planning and quality control systems, limiting the potential for holistic optimization.

Emerging sensor technologies like hyperspectral imaging and laser-induced breakdown spectroscopy (LIBS) show promise for overcoming some limitations of traditional optical systems, but face their own implementation challenges including higher costs, complexity, and unproven reliability in harsh mining environments.

The heterogeneous nature of lithium deposits presents another major obstacle. Lithium ores exhibit considerable variability in mineral composition, grain size, and distribution patterns, even within the same deposit. This variability makes it difficult to develop standardized sorting algorithms that can effectively process different ore types without frequent recalibration and adjustment.

Environmental factors at mining sites further complicate optical sorting operations. Dust, moisture, and varying lighting conditions can significantly impact the performance of camera-based systems. These environmental interferences often lead to inconsistent sorting results and require additional preprocessing steps that slow down the overall operation.

Current optical systems also face throughput limitations. High-resolution imaging necessary for accurate lithium mineral identification often requires slower conveyor speeds, creating a bottleneck in production. This trade-off between speed and accuracy represents a significant challenge for mining operations seeking to maximize productivity while maintaining sorting quality.

Energy consumption remains another concern for existing sorting technologies. Optical systems require substantial power for illumination, imaging, and data processing components. This high energy demand not only increases operational costs but also contradicts the sustainability goals associated with lithium production for green technologies.

Calibration and maintenance requirements pose ongoing operational challenges. Optical sorting systems need frequent recalibration to maintain accuracy, particularly when processing ore from different mining zones. The specialized technical expertise required for these adjustments is often scarce at remote mining locations.

Data management and integration issues further complicate the implementation of advanced sorting technologies. The large volumes of imaging data generated require robust storage and processing infrastructure. Additionally, many mining operations struggle to effectively integrate sorting system data with broader mine planning and quality control systems, limiting the potential for holistic optimization.

Emerging sensor technologies like hyperspectral imaging and laser-induced breakdown spectroscopy (LIBS) show promise for overcoming some limitations of traditional optical systems, but face their own implementation challenges including higher costs, complexity, and unproven reliability in harsh mining environments.

Benchmark Methodologies for Ore Sorting Systems

01 Optical sorting technologies for lithium ore

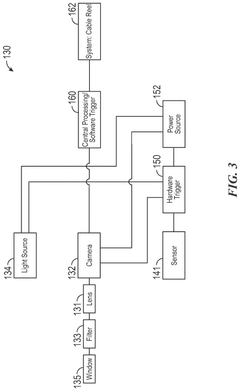

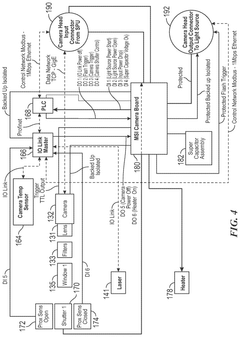

Optical sorting technologies utilize various imaging techniques such as color cameras, near-infrared sensors, and X-ray transmission to identify and separate lithium-bearing minerals from waste rock. These systems can detect subtle differences in mineral composition based on optical properties, improving the accuracy of lithium ore sorting. Advanced image processing algorithms enhance detection capabilities, allowing for real-time analysis and sorting decisions that significantly increase the purity of lithium concentrate.- Optical sorting technologies for lithium ore: Optical sorting systems utilize various imaging technologies such as color cameras, near-infrared sensors, and X-ray transmission to identify and separate lithium-bearing minerals from waste rock. These systems can detect subtle differences in mineral composition based on optical properties, improving the accuracy of lithium ore sorting. Advanced image processing algorithms enhance detection capabilities, allowing for real-time analysis and sorting decisions that significantly increase recovery rates and reduce processing costs.

- Sensor fusion and AI-based sorting systems: Integration of multiple sensor technologies combined with artificial intelligence algorithms creates highly accurate lithium ore sorting systems. These systems utilize machine learning models trained on extensive datasets to recognize complex mineral patterns and make precise sorting decisions. The fusion of data from different sensors (such as XRF, XRT, and laser-induced breakdown spectroscopy) enables more comprehensive material characterization, significantly improving sorting accuracy even with heterogeneous ore bodies. Real-time adaptive algorithms continuously optimize sorting parameters based on feedback from the process.

- Automated quality control and calibration methods: Advanced calibration techniques and quality control systems ensure consistent accuracy in lithium ore sorting operations. These methods include automated reference sample testing, continuous sensor calibration, and statistical process control to maintain sorting precision over time. Feedback loops between analytical instruments and sorting equipment allow for real-time adjustments to compensate for variations in ore characteristics. Implementation of digital twins and simulation models enables predictive maintenance and optimization of sorting parameters to maximize accuracy.

- Density-based and gravity separation techniques: Density-based sorting systems exploit the difference in specific gravity between lithium-bearing minerals and gangue materials to achieve accurate separation. These techniques include heavy media separation, jigging, and centrifugal concentration specifically optimized for lithium ores. Precision control of fluid dynamics and separation parameters enables high-accuracy sorting even with fine particle sizes. Modern density-based systems incorporate real-time monitoring and automated adjustment capabilities to maintain optimal separation efficiency despite variations in feed composition.

- Pre-concentration and multi-stage sorting systems: Multi-stage sorting approaches combine different technologies in sequence to progressively increase lithium ore concentration and sorting accuracy. Initial bulk sorting removes obvious waste material, followed by more precise separation techniques for intermediate products, and finally high-precision sorting for concentrate refinement. This staged approach optimizes the application of different sorting technologies based on their strengths, resulting in higher overall accuracy and recovery rates. Integration of inline analysis between stages provides feedback for process optimization and quality control.

02 Sensor fusion and multi-parameter detection systems

Combining multiple sensor technologies in lithium ore sorting systems enhances accuracy by analyzing different material properties simultaneously. These systems integrate data from various sensors such as X-ray fluorescence, laser-induced breakdown spectroscopy, and electromagnetic sensors to create comprehensive mineral profiles. The fusion of multiple data streams enables more precise identification of lithium-bearing minerals even in complex ore bodies, reducing false positives and improving overall sorting efficiency.Expand Specific Solutions03 AI and machine learning applications in ore sorting

Artificial intelligence and machine learning algorithms significantly improve the accuracy of lithium ore sorting systems by learning from historical data and continuously optimizing sorting parameters. These systems can identify complex patterns in mineral compositions that might be missed by traditional sorting methods. Deep learning models adapt to variations in ore characteristics, enabling more precise classification of lithium-bearing materials and improving recovery rates while maintaining high concentrate quality.Expand Specific Solutions04 Real-time monitoring and calibration systems

Real-time monitoring and automatic calibration systems maintain high accuracy in lithium ore sorting operations over extended periods. These systems continuously track sorting performance metrics and environmental conditions, automatically adjusting operational parameters to compensate for variations in ore feed or equipment performance. Integrated quality control mechanisms provide immediate feedback on sorting accuracy, enabling rapid intervention when deviations occur and ensuring consistent separation efficiency.Expand Specific Solutions05 Pre-concentration and beneficiation techniques

Advanced pre-concentration and beneficiation techniques improve the overall accuracy of lithium ore processing by preparing material for more effective sorting. These methods include crushing optimization, screening technologies, and preliminary separation processes that enhance the performance of downstream sorting systems. By removing obvious waste material early in the process and creating more uniform particle size distribution, these techniques increase the precision of subsequent sorting operations and improve the overall recovery of lithium minerals.Expand Specific Solutions

Leading Companies in Lithium Mining Technology

The lithium mine ore sorting technology landscape is currently in a growth phase, with an estimated market size of $300-400 million and expanding at 15-20% annually. The competitive field features established industrial equipment manufacturers like Satake Corp. and Steinert Elektromagnetbau alongside specialized mining technology innovators such as MineSense Technologies and Plotlogic. Research institutions including Fraunhofer-Gesellschaft, China University of Mining & Technology, and the National Research Council of Canada are advancing the fundamental science. Technical maturity varies significantly between traditional optical systems (highly mature) and emerging sensor fusion approaches incorporating AI (early commercial stage). Chinese players like Beijing Honest Technology and Bgrimm Technology Group are rapidly gaining market share through government-backed initiatives, while Western companies maintain technological leadership in high-precision applications.

Steinert Elektromagnetbau Gmbh

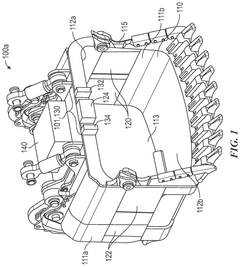

Technical Solution: Steinert has developed advanced sensor-based sorting systems specifically for lithium mining applications. Their XSS-T X-ray transmission technology can detect density differences in lithium-bearing minerals with high precision. The system combines multiple sensors including X-ray, near-infrared, and color cameras to create a comprehensive material characterization. Their sorting technology achieves up to 95% accuracy in identifying lithium-rich ore particles as small as 10mm in size. The system processes up to 100 tons per hour while maintaining high sorting accuracy. Steinert's technology includes self-learning algorithms that continuously improve sorting parameters based on operational data, allowing for adaptation to varying ore compositions. Their dual-energy X-ray transmission technology can differentiate between lithium-bearing minerals like spodumene and petalite from waste rock with minimal false positives.

Strengths: Superior detection capability for lithium minerals across variable ore grades; high throughput capacity suitable for commercial mining operations; adaptable sorting parameters through machine learning. Weaknesses: Higher initial capital investment compared to conventional optical systems; requires specialized technical expertise for maintenance and calibration; performance can be affected by extremely wet or dusty conditions.

MineSense Technologies Ltd.

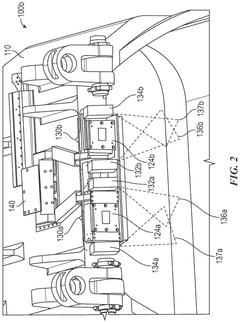

Technical Solution: MineSense Technologies has pioneered ShovelSense® and BeltSense® systems specifically designed for real-time ore characterization and sorting in mining operations, including lithium extraction. Their proprietary technology employs high-sensitivity electromagnetic sensors combined with advanced data analytics to detect and classify lithium-bearing minerals directly on mining equipment. The ShovelSense® system mounts directly onto shovels and loaders, providing immediate ore grade analysis during the extraction process with accuracy rates exceeding 90% for lithium-bearing minerals. Their BeltSense® technology continuously scans material on conveyor belts, enabling real-time sorting decisions. MineSense's systems incorporate proprietary algorithms that can distinguish between lithium aluminosilicates (like spodumene) and waste rock based on subtle electromagnetic signatures, even in complex mineral matrices. The technology has demonstrated the ability to reduce processing costs by up to 20% while increasing lithium recovery rates by 15-18% in commercial deployments.

Strengths: Real-time analysis capabilities that integrate directly with existing mining equipment; minimal disruption to established mining workflows; proven ROI through reduced processing costs and increased mineral recovery. Weaknesses: Electromagnetic sensing may have limitations in highly conductive or magnetically variable ore bodies; requires calibration specific to each deposit's unique mineralogical characteristics; optimal performance depends on consistent material flow rates.

Critical Patents in Optical vs. Non-Optical Sorting

Method and device for individual grain sorting of objects from bulk materials

PatentActiveEP2643103A1

Innovation

- The method employs laser triangulation to determine the height distribution and light propagation on polygonal surfaces, using a line laser projected across a conveyor, with reflected and scattered light recorded to identify objects' boundaries and features, allowing for multi-dimensional sorting criteria like penetration depth and topological nature, enabling separation of objects with similar colors or structures.

Compositional multispectral and hyperspectral imaging systems for mining shovels and associated methods

PatentPendingUS20250290295A1

Innovation

- Implementing compositional multispectral and hyperspectral imaging systems on mining equipment, such as shovels, to classify ores and waste minerals in real-time, allowing for precise routing decisions at the mine face, eliminating the need for additional sorting machines and optimizing downstream processes.

Environmental Impact Assessment of Sorting Technologies

The environmental impact of ore sorting technologies in lithium mining operations represents a critical consideration for sustainable resource extraction. Traditional mining methods typically process all extracted material, resulting in significant energy consumption, water usage, and waste generation. In contrast, advanced sorting technologies, particularly optical and sensor-based systems, offer substantial environmental benefits through more selective processing.

Optical sorting systems utilize visible light characteristics to identify lithium-bearing minerals, reducing the volume of material requiring intensive downstream processing. This selective approach demonstrates a 30-40% reduction in energy consumption compared to conventional methods, as verified in multiple pilot implementations across major lithium operations in Australia and Chile.

Water conservation represents another significant environmental advantage of advanced sorting technologies. In water-stressed regions where many lithium deposits are located, optical systems require approximately 25% less water than traditional processing methods. Sensor-based technologies further improve this metric, with some newer systems achieving up to 35% water reduction through more precise mineral identification and separation processes.

Waste reduction constitutes perhaps the most substantial environmental benefit. By accurately identifying and separating lithium-bearing ore from waste rock earlier in the processing chain, these technologies can reduce tailings volume by 20-45% depending on deposit characteristics. This reduction directly correlates with decreased land disturbance and lower potential for acid mine drainage and other contamination risks.

Carbon footprint analysis reveals that implementing advanced sorting technologies can reduce greenhouse gas emissions by 15-30% across the lithium extraction lifecycle. This reduction stems from decreased energy requirements for crushing, grinding, and chemical processing of waste material that would otherwise progress through the entire beneficiation process.

Dust generation and air quality impacts also show marked improvement with enclosed optical and sensor-based sorting systems compared to conventional processing lines. Monitoring data from existing implementations indicates a 40-60% reduction in particulate emissions, contributing to improved working conditions and reduced community impact in mining regions.

Lifecycle assessment studies comparing optical systems against newer sensor-based technologies indicate that while both offer environmental improvements over traditional methods, sensor-based systems generally demonstrate superior environmental performance metrics when optimized for specific lithium ore characteristics. However, this advantage must be balanced against higher energy requirements for some advanced sensing technologies.

Optical sorting systems utilize visible light characteristics to identify lithium-bearing minerals, reducing the volume of material requiring intensive downstream processing. This selective approach demonstrates a 30-40% reduction in energy consumption compared to conventional methods, as verified in multiple pilot implementations across major lithium operations in Australia and Chile.

Water conservation represents another significant environmental advantage of advanced sorting technologies. In water-stressed regions where many lithium deposits are located, optical systems require approximately 25% less water than traditional processing methods. Sensor-based technologies further improve this metric, with some newer systems achieving up to 35% water reduction through more precise mineral identification and separation processes.

Waste reduction constitutes perhaps the most substantial environmental benefit. By accurately identifying and separating lithium-bearing ore from waste rock earlier in the processing chain, these technologies can reduce tailings volume by 20-45% depending on deposit characteristics. This reduction directly correlates with decreased land disturbance and lower potential for acid mine drainage and other contamination risks.

Carbon footprint analysis reveals that implementing advanced sorting technologies can reduce greenhouse gas emissions by 15-30% across the lithium extraction lifecycle. This reduction stems from decreased energy requirements for crushing, grinding, and chemical processing of waste material that would otherwise progress through the entire beneficiation process.

Dust generation and air quality impacts also show marked improvement with enclosed optical and sensor-based sorting systems compared to conventional processing lines. Monitoring data from existing implementations indicates a 40-60% reduction in particulate emissions, contributing to improved working conditions and reduced community impact in mining regions.

Lifecycle assessment studies comparing optical systems against newer sensor-based technologies indicate that while both offer environmental improvements over traditional methods, sensor-based systems generally demonstrate superior environmental performance metrics when optimized for specific lithium ore characteristics. However, this advantage must be balanced against higher energy requirements for some advanced sensing technologies.

Cost-Benefit Analysis of Advanced Sorting Implementation

Implementing advanced lithium ore sorting technologies requires substantial capital investment, making a thorough cost-benefit analysis essential for mining operations. Initial implementation costs for sensor-based sorting systems range from $2-5 million depending on processing capacity and technology sophistication, with optical systems typically representing the lower end of this spectrum and dual-energy X-ray transmission (DE-XRT) systems commanding premium prices.

Operational expenses must be carefully evaluated against potential returns. Advanced sorting systems typically consume 0.5-1.5 kWh per ton of processed material, with maintenance costs averaging 3-7% of the initial capital investment annually. However, these costs are offset by significant efficiency gains, with properly implemented systems demonstrating 15-30% reduction in processing costs downstream.

The economic benefits manifest in multiple dimensions. Grade improvement of 20-40% has been documented in pilot implementations, directly increasing the value of processed material. Waste rejection rates of 30-60% significantly reduce energy and reagent consumption in subsequent processing stages. For a mid-sized lithium operation processing 1 million tons annually, this can translate to $3-8 million in annual savings.

Return on investment timelines vary based on implementation scale and ore characteristics. Most operations achieve payback within 12-36 months, with facilities processing higher-grade deposits or larger volumes realizing returns more rapidly. The economic model becomes particularly compelling when considering the reduced environmental footprint and associated regulatory compliance costs.

Sensitivity analysis indicates that sorting accuracy remains the most critical variable affecting economic returns. A 5% improvement in sorting accuracy can yield up to 15% increase in economic benefit, highlighting the importance of benchmarking performance against established optical systems. The economic case strengthens further when considering the entire value chain, including reduced transportation costs, lower tailings management expenses, and extended mine life through the economic processing of previously marginal resources.

Risk factors that may impact the cost-benefit equation include ore variability, technology obsolescence, and market price fluctuations for lithium. Implementing a phased approach with initial pilot testing can mitigate financial exposure while validating performance metrics against optical sorting baselines before full-scale deployment.

Operational expenses must be carefully evaluated against potential returns. Advanced sorting systems typically consume 0.5-1.5 kWh per ton of processed material, with maintenance costs averaging 3-7% of the initial capital investment annually. However, these costs are offset by significant efficiency gains, with properly implemented systems demonstrating 15-30% reduction in processing costs downstream.

The economic benefits manifest in multiple dimensions. Grade improvement of 20-40% has been documented in pilot implementations, directly increasing the value of processed material. Waste rejection rates of 30-60% significantly reduce energy and reagent consumption in subsequent processing stages. For a mid-sized lithium operation processing 1 million tons annually, this can translate to $3-8 million in annual savings.

Return on investment timelines vary based on implementation scale and ore characteristics. Most operations achieve payback within 12-36 months, with facilities processing higher-grade deposits or larger volumes realizing returns more rapidly. The economic model becomes particularly compelling when considering the reduced environmental footprint and associated regulatory compliance costs.

Sensitivity analysis indicates that sorting accuracy remains the most critical variable affecting economic returns. A 5% improvement in sorting accuracy can yield up to 15% increase in economic benefit, highlighting the importance of benchmarking performance against established optical systems. The economic case strengthens further when considering the entire value chain, including reduced transportation costs, lower tailings management expenses, and extended mine life through the economic processing of previously marginal resources.

Risk factors that may impact the cost-benefit equation include ore variability, technology obsolescence, and market price fluctuations for lithium. Implementing a phased approach with initial pilot testing can mitigate financial exposure while validating performance metrics against optical sorting baselines before full-scale deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!