Lithium Mine Open-Pit vs Underground Mining: Lifecycle Emissions Comparison

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Mining Emissions Background and Objectives

Lithium mining has emerged as a critical activity in the global transition to clean energy, with demand for this alkali metal surging due to its essential role in rechargeable batteries for electric vehicles and renewable energy storage systems. The evolution of lithium extraction technologies has progressed from traditional mining methods to more advanced techniques over the past several decades, with significant implications for environmental impact and sustainability.

Historically, lithium production has been dominated by two primary extraction methods: brine evaporation from salt flats (primarily in South America's "Lithium Triangle") and hard rock mining from lithium-bearing minerals such as spodumene. Within the hard rock mining category, both open-pit and underground mining approaches have been employed, each with distinct environmental footprints and lifecycle emissions profiles.

The technological trajectory in lithium mining has been driven by increasing demand, environmental concerns, and efficiency requirements. Early extraction methods focused primarily on production volume with limited consideration for environmental impacts. However, as climate change concerns have intensified and sustainability has become a corporate imperative, the industry has begun shifting toward more environmentally conscious extraction methodologies.

Current technical objectives in the lithium mining sector center on reducing the carbon footprint across the entire lifecycle of mining operations. This includes minimizing direct emissions from extraction equipment, processing facilities, and transportation, as well as addressing indirect emissions from energy consumption, land use changes, and chemical processes involved in refining lithium compounds.

The comparative analysis of lifecycle emissions between open-pit and underground lithium mining represents a crucial area of investigation, as the industry seeks to identify optimal extraction strategies that balance production efficiency with environmental sustainability. Open-pit mining typically involves larger-scale surface disturbance but may offer production efficiencies, while underground mining generally has a smaller surface footprint but potentially higher energy requirements for operation.

Looking forward, the technical goals for lithium mining emissions management include developing more energy-efficient extraction processes, implementing renewable energy sources for mining operations, reducing water consumption, minimizing chemical usage, and exploring innovative approaches to land reclamation and ecosystem restoration. These objectives align with broader industry trends toward responsible resource development and the growing recognition that environmental performance will be a key determinant of competitive advantage in the evolving global marketplace for critical minerals.

Historically, lithium production has been dominated by two primary extraction methods: brine evaporation from salt flats (primarily in South America's "Lithium Triangle") and hard rock mining from lithium-bearing minerals such as spodumene. Within the hard rock mining category, both open-pit and underground mining approaches have been employed, each with distinct environmental footprints and lifecycle emissions profiles.

The technological trajectory in lithium mining has been driven by increasing demand, environmental concerns, and efficiency requirements. Early extraction methods focused primarily on production volume with limited consideration for environmental impacts. However, as climate change concerns have intensified and sustainability has become a corporate imperative, the industry has begun shifting toward more environmentally conscious extraction methodologies.

Current technical objectives in the lithium mining sector center on reducing the carbon footprint across the entire lifecycle of mining operations. This includes minimizing direct emissions from extraction equipment, processing facilities, and transportation, as well as addressing indirect emissions from energy consumption, land use changes, and chemical processes involved in refining lithium compounds.

The comparative analysis of lifecycle emissions between open-pit and underground lithium mining represents a crucial area of investigation, as the industry seeks to identify optimal extraction strategies that balance production efficiency with environmental sustainability. Open-pit mining typically involves larger-scale surface disturbance but may offer production efficiencies, while underground mining generally has a smaller surface footprint but potentially higher energy requirements for operation.

Looking forward, the technical goals for lithium mining emissions management include developing more energy-efficient extraction processes, implementing renewable energy sources for mining operations, reducing water consumption, minimizing chemical usage, and exploring innovative approaches to land reclamation and ecosystem restoration. These objectives align with broader industry trends toward responsible resource development and the growing recognition that environmental performance will be a key determinant of competitive advantage in the evolving global marketplace for critical minerals.

Market Demand Analysis for Sustainable Lithium Production

The global lithium market is experiencing unprecedented growth driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current projections indicate the lithium market will grow from approximately $6.8 billion in 2022 to $18.9 billion by 2030, representing a compound annual growth rate of 13.5%. This surge in demand has intensified focus on sustainable lithium extraction methods, with particular attention to the environmental impacts of different mining approaches.

Consumer preferences are increasingly favoring products with demonstrably lower carbon footprints, creating market pressure for sustainably sourced lithium. Major automotive manufacturers including Tesla, Volkswagen, and BMW have publicly committed to reducing the environmental impact of their supply chains, with specific targets for battery material sourcing. These commitments translate directly to premium pricing potential for lithium produced with lower lifecycle emissions.

Regulatory frameworks worldwide are evolving to favor lower-emission production methods. The European Union's Battery Directive and proposed Carbon Border Adjustment Mechanism will effectively penalize high-emission lithium sources, while incentivizing those with smaller carbon footprints. Similarly, the United States' Inflation Reduction Act provides tax credits for domestically produced battery materials meeting specific sustainability criteria.

Market analysis reveals a growing price premium for sustainably produced lithium, with some buyers willing to pay 8-12% more for materials with verified lower environmental impacts. This premium is expected to increase as carbon pricing mechanisms become more widespread and stringent emissions reporting requirements take effect across major markets.

Investment patterns further confirm this trend, with venture capital and corporate investment increasingly flowing toward lithium extraction technologies promising reduced environmental footprints. Between 2020 and 2023, investment in sustainable lithium extraction technologies increased by 215%, reaching $1.2 billion annually.

The comparison between open-pit and underground lithium mining represents a critical decision point for producers entering or expanding in the market. While open-pit mining currently dominates production due to lower operational costs, market signals indicate growing demand for underground mining's potentially lower lifecycle emissions profile, particularly in environmentally sensitive regions or jurisdictions with strict emissions regulations.

End-user industries are increasingly incorporating lifecycle emissions data into procurement decisions, with battery manufacturers implementing supplier scorecards that heavily weight environmental performance. This trend is expected to accelerate as battery passport systems and material traceability technologies become standard industry practice by 2025.

Consumer preferences are increasingly favoring products with demonstrably lower carbon footprints, creating market pressure for sustainably sourced lithium. Major automotive manufacturers including Tesla, Volkswagen, and BMW have publicly committed to reducing the environmental impact of their supply chains, with specific targets for battery material sourcing. These commitments translate directly to premium pricing potential for lithium produced with lower lifecycle emissions.

Regulatory frameworks worldwide are evolving to favor lower-emission production methods. The European Union's Battery Directive and proposed Carbon Border Adjustment Mechanism will effectively penalize high-emission lithium sources, while incentivizing those with smaller carbon footprints. Similarly, the United States' Inflation Reduction Act provides tax credits for domestically produced battery materials meeting specific sustainability criteria.

Market analysis reveals a growing price premium for sustainably produced lithium, with some buyers willing to pay 8-12% more for materials with verified lower environmental impacts. This premium is expected to increase as carbon pricing mechanisms become more widespread and stringent emissions reporting requirements take effect across major markets.

Investment patterns further confirm this trend, with venture capital and corporate investment increasingly flowing toward lithium extraction technologies promising reduced environmental footprints. Between 2020 and 2023, investment in sustainable lithium extraction technologies increased by 215%, reaching $1.2 billion annually.

The comparison between open-pit and underground lithium mining represents a critical decision point for producers entering or expanding in the market. While open-pit mining currently dominates production due to lower operational costs, market signals indicate growing demand for underground mining's potentially lower lifecycle emissions profile, particularly in environmentally sensitive regions or jurisdictions with strict emissions regulations.

End-user industries are increasingly incorporating lifecycle emissions data into procurement decisions, with battery manufacturers implementing supplier scorecards that heavily weight environmental performance. This trend is expected to accelerate as battery passport systems and material traceability technologies become standard industry practice by 2025.

Current Emissions Status and Technical Challenges

The current emissions landscape of lithium mining operations reveals significant disparities between open-pit and underground extraction methods. Open-pit mining, which accounts for approximately 87% of global lithium production, generates substantially higher greenhouse gas (GHG) emissions compared to underground operations. Recent life cycle assessment (LCA) studies indicate that open-pit mining produces 15-20 tonnes of CO2 equivalent per tonne of lithium carbonate equivalent (LCE), while underground mining methods typically generate 9-12 tonnes CO2e/tonne LCE.

The primary emission sources in open-pit operations include diesel-powered heavy machinery for overburden removal, ore extraction, and transportation, collectively contributing to approximately 45-55% of total emissions. Additional significant sources include dust generation (15-20%), water management systems (10-15%), and on-site processing facilities (20-25%). The extensive land disturbance in open-pit mining also reduces carbon sequestration capacity, creating an often-overlooked indirect emissions impact.

Underground lithium mining, while less emissions-intensive, faces its own set of technical challenges. Ventilation systems necessary for worker safety consume substantial electricity, accounting for 30-40% of underground mining emissions. The deeper the mine extends, the greater the energy requirements for both ventilation and material transport, creating a non-linear emissions growth curve as depth increases.

A critical technical challenge for both mining methods is the energy transition paradox: the extraction of materials essential for clean energy technologies currently relies heavily on fossil fuel-powered equipment. The industry faces significant hurdles in electrifying heavy mining equipment, particularly for open-pit operations where the power requirements and operational conditions are more demanding. Battery technology limitations regarding energy density, charging infrastructure, and durability in harsh mining environments remain substantial barriers.

Water management presents another major emissions challenge, especially in water-scarce regions where lithium brine operations are common. Energy-intensive desalination and pumping systems contribute significantly to the carbon footprint. Furthermore, the processing of lithium ore to battery-grade materials involves multiple energy-intensive steps including crushing, grinding, chemical processing, and purification, collectively representing 35-45% of lifecycle emissions.

Regulatory frameworks across different mining jurisdictions show considerable variation in emissions reporting requirements and carbon pricing mechanisms, creating inconsistent incentives for emissions reduction technologies. This regulatory fragmentation, combined with the technical challenges of accurate emissions measurement in dynamic mining environments, complicates industry-wide progress toward standardized emissions accounting and mitigation strategies.

The primary emission sources in open-pit operations include diesel-powered heavy machinery for overburden removal, ore extraction, and transportation, collectively contributing to approximately 45-55% of total emissions. Additional significant sources include dust generation (15-20%), water management systems (10-15%), and on-site processing facilities (20-25%). The extensive land disturbance in open-pit mining also reduces carbon sequestration capacity, creating an often-overlooked indirect emissions impact.

Underground lithium mining, while less emissions-intensive, faces its own set of technical challenges. Ventilation systems necessary for worker safety consume substantial electricity, accounting for 30-40% of underground mining emissions. The deeper the mine extends, the greater the energy requirements for both ventilation and material transport, creating a non-linear emissions growth curve as depth increases.

A critical technical challenge for both mining methods is the energy transition paradox: the extraction of materials essential for clean energy technologies currently relies heavily on fossil fuel-powered equipment. The industry faces significant hurdles in electrifying heavy mining equipment, particularly for open-pit operations where the power requirements and operational conditions are more demanding. Battery technology limitations regarding energy density, charging infrastructure, and durability in harsh mining environments remain substantial barriers.

Water management presents another major emissions challenge, especially in water-scarce regions where lithium brine operations are common. Energy-intensive desalination and pumping systems contribute significantly to the carbon footprint. Furthermore, the processing of lithium ore to battery-grade materials involves multiple energy-intensive steps including crushing, grinding, chemical processing, and purification, collectively representing 35-45% of lifecycle emissions.

Regulatory frameworks across different mining jurisdictions show considerable variation in emissions reporting requirements and carbon pricing mechanisms, creating inconsistent incentives for emissions reduction technologies. This regulatory fragmentation, combined with the technical challenges of accurate emissions measurement in dynamic mining environments, complicates industry-wide progress toward standardized emissions accounting and mitigation strategies.

Current Emissions Measurement and Reduction Solutions

01 Environmental impact assessment of lithium mining operations

Methods and systems for assessing the environmental impact of lithium mining operations throughout their lifecycle. These approaches involve measuring and analyzing emissions generated during extraction, processing, and transportation phases. The assessment includes quantification of greenhouse gases, water usage, land disturbance, and other environmental factors to provide a comprehensive evaluation of the ecological footprint of lithium production activities.- Environmental impact assessment of lithium mining operations: Methods and systems for assessing the environmental impact of lithium mining operations throughout their lifecycle. These approaches involve measuring and analyzing greenhouse gas emissions, water usage, land disturbance, and other environmental factors associated with lithium extraction processes. The assessment tools help in quantifying the carbon footprint of different mining techniques and identifying opportunities for reducing emissions across the mining lifecycle.

- Sustainable lithium extraction technologies: Innovative technologies designed to reduce emissions in lithium extraction processes. These include advanced direct lithium extraction methods, closed-loop systems, and energy-efficient processing techniques that minimize environmental impact. The technologies focus on reducing water consumption, decreasing chemical usage, and lowering energy requirements compared to traditional lithium mining methods, resulting in significantly lower lifecycle emissions.

- Lifecycle analysis frameworks for battery materials: Comprehensive frameworks for analyzing the complete lifecycle emissions of lithium and other battery materials from extraction through processing, use, and disposal. These methodologies enable standardized assessment of environmental impacts across different mining operations and processing techniques. The frameworks incorporate data collection protocols, emission calculation models, and comparative analysis tools to evaluate the sustainability of lithium supply chains.

- Carbon reduction strategies in lithium processing: Specific strategies and methods for reducing carbon emissions in lithium processing operations. These include the integration of renewable energy sources into mining operations, optimization of chemical processes, implementation of energy recovery systems, and development of low-emission transportation solutions for raw materials. The approaches focus on minimizing the carbon footprint of lithium production while maintaining economic viability.

- Monitoring and reporting systems for emissions management: Digital systems and methodologies for monitoring, tracking, and reporting emissions throughout the lithium mining lifecycle. These solutions incorporate sensors, data analytics, and reporting tools to provide real-time insights into environmental performance. The systems enable mining operations to identify emission hotspots, implement targeted reduction measures, and demonstrate compliance with environmental regulations and sustainability standards.

02 Emission reduction technologies in lithium extraction processes

Innovative technologies designed to reduce emissions during lithium extraction processes. These include advanced extraction methods that minimize energy consumption, reduce water usage, and decrease chemical waste. The technologies incorporate sustainable practices such as closed-loop systems, renewable energy integration, and process optimizations that significantly lower the carbon footprint associated with lithium mining operations.Expand Specific Solutions03 Lifecycle analysis frameworks for battery materials

Comprehensive frameworks for conducting lifecycle analyses of battery materials, with specific focus on lithium mining and processing. These frameworks enable systematic evaluation of emissions from raw material extraction through manufacturing, use, and end-of-life management. The methodologies incorporate data collection protocols, standardized metrics, and analytical tools to quantify environmental impacts across the entire value chain of lithium-based energy storage systems.Expand Specific Solutions04 Carbon footprint monitoring and reporting systems

Systems and methods for monitoring, calculating, and reporting the carbon footprint associated with lithium mining operations. These solutions include sensor networks, data analytics platforms, and reporting tools that track emissions throughout the mining lifecycle. The systems provide real-time monitoring capabilities, predictive modeling, and standardized reporting formats to support regulatory compliance and sustainability initiatives in the lithium extraction industry.Expand Specific Solutions05 Sustainable lithium production management systems

Integrated management systems designed to optimize lithium production processes while minimizing environmental impacts. These systems incorporate sustainable practices, resource efficiency measures, and emissions control strategies throughout the mining lifecycle. The approaches include advanced planning tools, operational controls, and continuous improvement methodologies that balance production requirements with environmental sustainability goals in lithium extraction operations.Expand Specific Solutions

Key Industry Players in Lithium Mining Sector

The lithium mining industry is currently in a growth phase, with the global market expected to reach $6.62 billion by 2028, driven by increasing demand for lithium-ion batteries in electric vehicles and energy storage systems. The competition landscape features established mining companies alongside innovative startups developing more sustainable extraction technologies. Companies like Novalith Technologies are pioneering CO2-based extraction methods, while Redwood Materials and Lyten focus on circular supply chains and advanced battery materials. Academic institutions including Tsinghua University, University of Manchester, and Michigan Tech are contributing significant research on lifecycle emissions comparison between open-pit and underground mining methods. The industry is moving toward greater environmental consciousness, with companies like Pure Lithium and Ampcera developing technologies that could reduce the ecological footprint of lithium production.

Lyten, Inc.

Technical Solution: Lyten has pioneered an innovative approach to lithium battery technology through their Lyten 3D Graphene platform, which directly addresses lifecycle emissions in lithium battery production. Rather than focusing solely on mining methods, Lyten's technology enables the creation of lithium-sulfur batteries that require significantly less lithium per kWh of energy storage compared to conventional lithium-ion batteries. This reduction in lithium content (up to 80% less) dramatically decreases the demand for mined lithium, regardless of extraction method. Their process synthesizes graphene from methane, potentially using biogas or captured methane that would otherwise contribute to greenhouse gas emissions. The company's lifecycle analysis indicates that their lithium-sulfur batteries produce approximately 60% lower carbon emissions across the entire lifecycle compared to conventional lithium-ion batteries. By reducing the lithium intensity of batteries, Lyten's approach indirectly mitigates the emissions difference between open-pit and underground mining by simply requiring less mined material overall, while still delivering comparable or superior energy density.

Strengths: Dramatically reduces lithium requirements, minimizing mining impact regardless of method; utilizes methane as a carbon source, potentially creating carbon-negative materials; eliminates need for cobalt and nickel, avoiding associated mining impacts; higher energy density reduces material needs per kWh. Weaknesses: Technology is relatively new and still scaling to commercial production; methane sourcing must be carefully managed to ensure emissions benefits; requires changes to battery manufacturing infrastructure; performance characteristics differ from traditional lithium-ion, requiring adaptation.

Redwood Materials, Inc.

Technical Solution: Redwood Materials has developed a closed-loop lithium battery recycling ecosystem that significantly reduces lifecycle emissions compared to traditional mining methods. Their approach focuses on recovering lithium and other critical materials from end-of-life batteries and manufacturing scrap, effectively creating a circular economy for battery materials. Their technology enables the extraction of lithium, nickel, cobalt, and copper with over 95% efficiency, which can then be refined into battery-grade materials ready for reuse in new batteries. This approach eliminates the need for new mining operations, whether open-pit or underground, thereby avoiding the associated emissions from extraction, processing, and transportation. Redwood's process uses hydrometallurgical techniques that operate at lower temperatures than traditional pyrometallurgical methods, resulting in an estimated 80% reduction in CO2 emissions compared to mining new materials. Their lifecycle assessment shows that battery materials produced through their recycling process have approximately one-third the carbon footprint of those produced from newly mined resources.

Strengths: Eliminates direct mining emissions by creating a circular materials economy; reduces energy consumption by up to 80% compared to primary production; avoids land disturbance associated with both mining methods; scalable technology that can be deployed globally. Weaknesses: Currently limited by the availability of end-of-life batteries; requires efficient collection infrastructure; initial processing facilities still have carbon footprint; dependent on the chemistry of input batteries which may vary.

Critical Technologies for Lifecycle Assessment

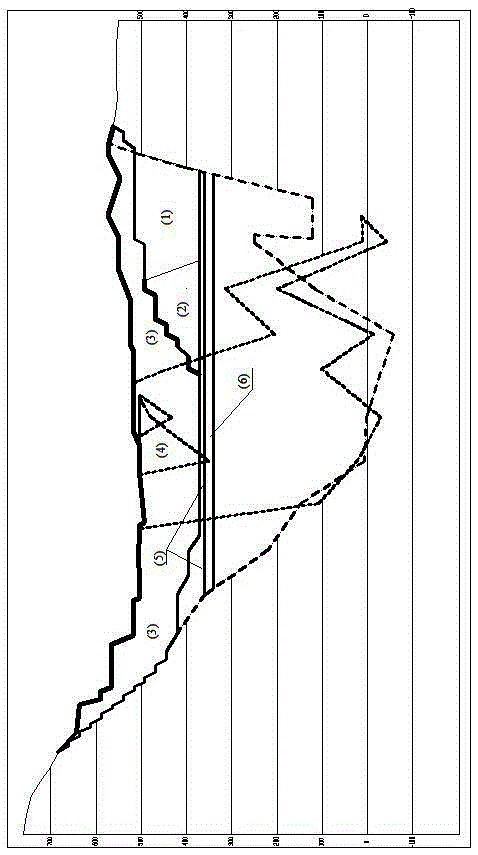

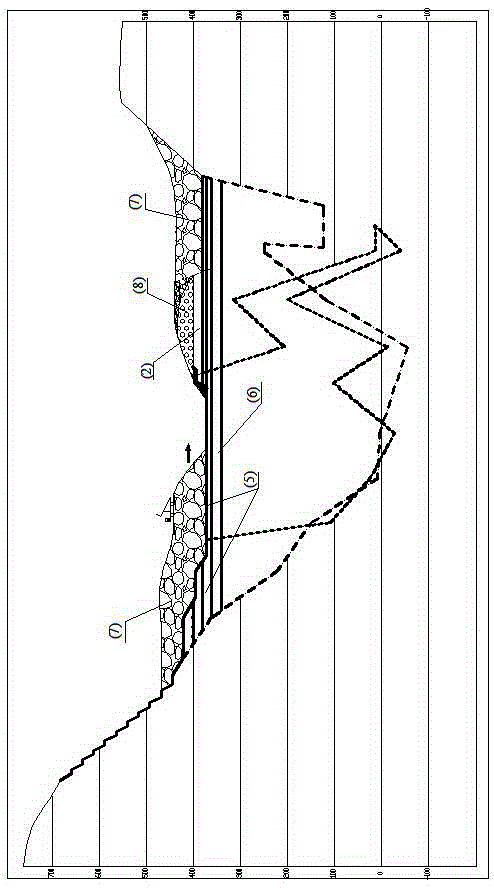

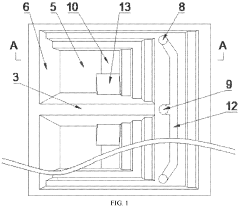

Recovery of long thick ore body hanging side ore and mining method in the transition period from open pit to underground

PatentInactiveCN104314570B

Innovation

- In the process of open-pit mining, the transitional underground mining area, open-pit mining area and isolated ore pillars are divided into zones. The caving method and the leveling tunnel tunnel method are used to jointly develop the segmented open field method for mining of the hanging gang mines, and the overlay is formed through waste rock backfilling. , gradually realize the recovery of the hanging ore body and the formation of the overburden.

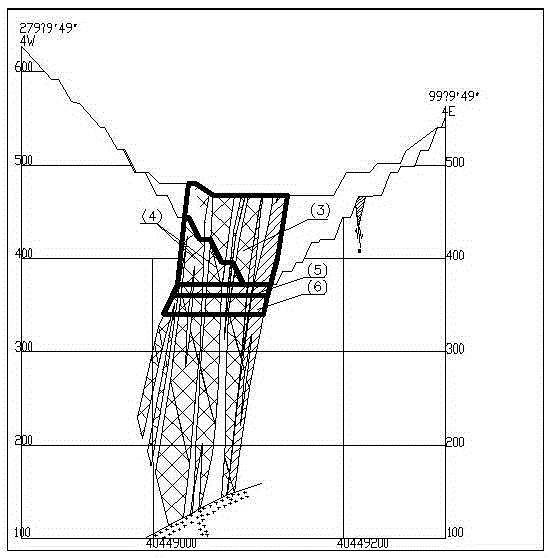

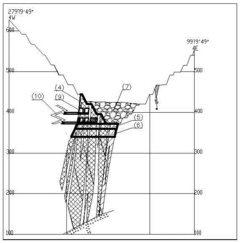

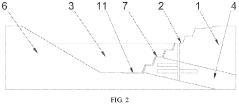

Underground mining method for unexploited coal in boundary open-pit mine

PatentActiveUS11821314B2

Innovation

- An underground mining method involving shaft construction, intermediate bridges, sealing of slopes, digging of auxiliary and main inclined shafts, constructing a water-sealed pit bottom, and laying water purification slopes to facilitate efficient coal extraction while maintaining slope stability and reducing air leakage.

Environmental Impact Assessment Methodologies

Environmental Impact Assessment Methodologies for comparing lifecycle emissions between open-pit and underground lithium mining require robust frameworks that capture the full spectrum of environmental effects. These methodologies typically employ Life Cycle Assessment (LCA) as the primary analytical tool, following ISO 14040 and 14044 standards to ensure comprehensive evaluation of emissions from raw material extraction through processing, transportation, and site rehabilitation.

The system boundary definition is crucial in these assessments, with most comprehensive studies adopting a "cradle-to-gate" approach that encompasses all mining operations, processing activities, and transportation to refineries. Some advanced methodologies extend to "cradle-to-grave" analyses, incorporating end-of-life considerations for mining equipment and infrastructure.

Inventory analysis methodologies differ significantly between open-pit and underground mining assessments. For open-pit operations, methodologies must account for extensive land clearing, overburden removal, and higher diesel consumption by heavy machinery. Underground mining assessments focus on electricity consumption for ventilation, water pumping, and specialized equipment operation, with particular attention to methane emissions in confined spaces.

Impact assessment frameworks typically categorize emissions into direct (Scope 1), energy-related indirect (Scope 2), and value chain (Scope 3) emissions. The Global Warming Potential (GWP) metric is commonly used to normalize different greenhouse gases to CO2-equivalent values, with most studies using 100-year time horizons (GWP100) as recommended by the IPCC.

Methodological challenges include allocation procedures for co-products in multi-metal deposits, which can significantly affect the attributed emissions of lithium extraction. The cut-off criteria for including or excluding processes also vary across studies, potentially leading to inconsistent results when comparing different mining methods.

Sensitivity and uncertainty analyses are increasingly incorporated into these methodologies to address data limitations and variability in operational conditions. Monte Carlo simulations and scenario analyses help quantify the range of potential emissions outcomes under different technological, geological, and operational assumptions.

Recent methodological advancements include the integration of spatial analysis using Geographic Information Systems (GIS) to account for site-specific factors that influence emissions profiles, such as local grid electricity composition, transportation distances, and regional climate conditions that affect energy requirements for processing.

The system boundary definition is crucial in these assessments, with most comprehensive studies adopting a "cradle-to-gate" approach that encompasses all mining operations, processing activities, and transportation to refineries. Some advanced methodologies extend to "cradle-to-grave" analyses, incorporating end-of-life considerations for mining equipment and infrastructure.

Inventory analysis methodologies differ significantly between open-pit and underground mining assessments. For open-pit operations, methodologies must account for extensive land clearing, overburden removal, and higher diesel consumption by heavy machinery. Underground mining assessments focus on electricity consumption for ventilation, water pumping, and specialized equipment operation, with particular attention to methane emissions in confined spaces.

Impact assessment frameworks typically categorize emissions into direct (Scope 1), energy-related indirect (Scope 2), and value chain (Scope 3) emissions. The Global Warming Potential (GWP) metric is commonly used to normalize different greenhouse gases to CO2-equivalent values, with most studies using 100-year time horizons (GWP100) as recommended by the IPCC.

Methodological challenges include allocation procedures for co-products in multi-metal deposits, which can significantly affect the attributed emissions of lithium extraction. The cut-off criteria for including or excluding processes also vary across studies, potentially leading to inconsistent results when comparing different mining methods.

Sensitivity and uncertainty analyses are increasingly incorporated into these methodologies to address data limitations and variability in operational conditions. Monte Carlo simulations and scenario analyses help quantify the range of potential emissions outcomes under different technological, geological, and operational assumptions.

Recent methodological advancements include the integration of spatial analysis using Geographic Information Systems (GIS) to account for site-specific factors that influence emissions profiles, such as local grid electricity composition, transportation distances, and regional climate conditions that affect energy requirements for processing.

Regulatory Frameworks for Mining Emissions

The regulatory landscape governing mining emissions varies significantly across jurisdictions, creating a complex framework that mining operations must navigate. For lithium mining specifically, both open-pit and underground methods face distinct regulatory challenges that impact their lifecycle emissions profiles and operational viability.

At the international level, the Paris Agreement provides an overarching framework that indirectly influences mining emissions through nationally determined contributions (NDCs). Countries with significant lithium reserves such as Chile, Australia, and Argentina have established varying degrees of regulatory stringency regarding emissions from extraction activities.

The European Union has implemented the most comprehensive regulatory approach through its Emissions Trading System (ETS) and the recent Carbon Border Adjustment Mechanism (CBAM), which will increasingly affect imported lithium based on its carbon footprint. This creates market pressure favoring lower-emission extraction methods, potentially benefiting underground mining operations that typically generate fewer scope 1 and 2 emissions.

In North America, regulations differ substantially between the United States and Canada. The U.S. Environmental Protection Agency regulates mining emissions through the Clean Air Act and New Source Performance Standards, while Canada employs both federal frameworks and provincial regulations that often include carbon pricing mechanisms. These differences create regional variations in compliance costs that mining companies must factor into operational decisions.

Emerging economies with lithium reserves typically have less stringent emissions regulations, creating potential "carbon leakage" where higher-emission extraction methods might concentrate in regions with fewer regulatory constraints. This regulatory arbitrage presents challenges for global emissions reduction efforts in the mining sector.

Regulatory frameworks increasingly incorporate lifecycle assessment (LCA) approaches, moving beyond point-source emissions to consider the entire value chain. This shift particularly impacts the comparative assessment of open-pit versus underground lithium mining, as regulations begin to account for land use changes, water consumption, and waste management practices that differ significantly between these extraction methods.

Industry-led initiatives and voluntary standards are filling regulatory gaps, with frameworks like the Initiative for Responsible Mining Assurance (IRMA) and the Mining Association of Canada's Towards Sustainable Mining program establishing best practices for emissions management that often exceed regulatory requirements.

Looking forward, regulatory convergence is anticipated as countries align mining emissions frameworks with climate commitments, potentially narrowing the current regulatory disparities between jurisdictions and creating more uniform expectations for lifecycle emissions performance across different lithium extraction methods.

At the international level, the Paris Agreement provides an overarching framework that indirectly influences mining emissions through nationally determined contributions (NDCs). Countries with significant lithium reserves such as Chile, Australia, and Argentina have established varying degrees of regulatory stringency regarding emissions from extraction activities.

The European Union has implemented the most comprehensive regulatory approach through its Emissions Trading System (ETS) and the recent Carbon Border Adjustment Mechanism (CBAM), which will increasingly affect imported lithium based on its carbon footprint. This creates market pressure favoring lower-emission extraction methods, potentially benefiting underground mining operations that typically generate fewer scope 1 and 2 emissions.

In North America, regulations differ substantially between the United States and Canada. The U.S. Environmental Protection Agency regulates mining emissions through the Clean Air Act and New Source Performance Standards, while Canada employs both federal frameworks and provincial regulations that often include carbon pricing mechanisms. These differences create regional variations in compliance costs that mining companies must factor into operational decisions.

Emerging economies with lithium reserves typically have less stringent emissions regulations, creating potential "carbon leakage" where higher-emission extraction methods might concentrate in regions with fewer regulatory constraints. This regulatory arbitrage presents challenges for global emissions reduction efforts in the mining sector.

Regulatory frameworks increasingly incorporate lifecycle assessment (LCA) approaches, moving beyond point-source emissions to consider the entire value chain. This shift particularly impacts the comparative assessment of open-pit versus underground lithium mining, as regulations begin to account for land use changes, water consumption, and waste management practices that differ significantly between these extraction methods.

Industry-led initiatives and voluntary standards are filling regulatory gaps, with frameworks like the Initiative for Responsible Mining Assurance (IRMA) and the Mining Association of Canada's Towards Sustainable Mining program establishing best practices for emissions management that often exceed regulatory requirements.

Looking forward, regulatory convergence is anticipated as countries align mining emissions frameworks with climate commitments, potentially narrowing the current regulatory disparities between jurisdictions and creating more uniform expectations for lifecycle emissions performance across different lithium extraction methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!