Lithium Mine Brine vs Ore Extraction: Energy Efficiency Comparison

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Background and Objectives

Lithium extraction has evolved significantly over the past century, transitioning from a niche industrial process to a critical component of the global energy transition. Initially discovered in 1817 by Johan August Arfwedson, lithium remained primarily of academic interest until the early 20th century when its commercial applications began to emerge. The 1950s marked the beginning of industrial-scale lithium production, primarily focused on ceramic and glass manufacturing applications.

The technological landscape transformed dramatically in the 1990s with the commercialization of lithium-ion batteries, creating unprecedented demand for this alkali metal. This shift has accelerated exponentially in the 21st century, driven by electric vehicle adoption and renewable energy storage requirements, positioning lithium as a strategic resource in the global energy transition.

Currently, two primary extraction methodologies dominate the industry: traditional hard rock mining (ore extraction) and brine evaporation. Hard rock mining involves extracting lithium-bearing minerals such as spodumene from pegmatite deposits, followed by energy-intensive crushing, heating, and chemical processing. Conversely, brine extraction pumps lithium-rich saltwater from underground reservoirs into evaporation ponds, where solar concentration occurs before chemical processing.

The energy efficiency comparison between these extraction methods represents a critical technological challenge with significant environmental and economic implications. While brine operations typically consume less energy per unit of lithium produced, they require extensive land use and water consumption. Hard rock mining, though more energy-intensive, offers higher recovery rates and operates independently of climate conditions.

Recent technological innovations are reshaping this landscape, with direct lithium extraction (DLE) technologies emerging as potential game-changers. These processes aim to extract lithium directly from brines without evaporation ponds, potentially reducing both energy requirements and environmental footprint. Similarly, advances in hydrometallurgical processing for hard rock are improving energy efficiency in traditional mining operations.

The primary objective of this technical research is to conduct a comprehensive energy efficiency comparison between brine and ore extraction methodologies, accounting for the entire production lifecycle from extraction to battery-grade lithium compounds. This analysis aims to identify optimal extraction strategies for different geological contexts, quantify energy consumption differentials, and evaluate emerging technologies that may bridge the efficiency gap between these approaches.

Additionally, this research seeks to establish standardized metrics for energy efficiency in lithium extraction, enabling meaningful comparisons across different production methods and geographical locations, ultimately supporting strategic decision-making for sustainable lithium production in the rapidly expanding battery materials sector.

The technological landscape transformed dramatically in the 1990s with the commercialization of lithium-ion batteries, creating unprecedented demand for this alkali metal. This shift has accelerated exponentially in the 21st century, driven by electric vehicle adoption and renewable energy storage requirements, positioning lithium as a strategic resource in the global energy transition.

Currently, two primary extraction methodologies dominate the industry: traditional hard rock mining (ore extraction) and brine evaporation. Hard rock mining involves extracting lithium-bearing minerals such as spodumene from pegmatite deposits, followed by energy-intensive crushing, heating, and chemical processing. Conversely, brine extraction pumps lithium-rich saltwater from underground reservoirs into evaporation ponds, where solar concentration occurs before chemical processing.

The energy efficiency comparison between these extraction methods represents a critical technological challenge with significant environmental and economic implications. While brine operations typically consume less energy per unit of lithium produced, they require extensive land use and water consumption. Hard rock mining, though more energy-intensive, offers higher recovery rates and operates independently of climate conditions.

Recent technological innovations are reshaping this landscape, with direct lithium extraction (DLE) technologies emerging as potential game-changers. These processes aim to extract lithium directly from brines without evaporation ponds, potentially reducing both energy requirements and environmental footprint. Similarly, advances in hydrometallurgical processing for hard rock are improving energy efficiency in traditional mining operations.

The primary objective of this technical research is to conduct a comprehensive energy efficiency comparison between brine and ore extraction methodologies, accounting for the entire production lifecycle from extraction to battery-grade lithium compounds. This analysis aims to identify optimal extraction strategies for different geological contexts, quantify energy consumption differentials, and evaluate emerging technologies that may bridge the efficiency gap between these approaches.

Additionally, this research seeks to establish standardized metrics for energy efficiency in lithium extraction, enabling meaningful comparisons across different production methods and geographical locations, ultimately supporting strategic decision-making for sustainable lithium production in the rapidly expanding battery materials sector.

Global Market Demand for Lithium Resources

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Annual demand for lithium reached approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021, with projections indicating a potential increase to over 1.5 million metric tons by 2030. This represents a compound annual growth rate (CAGR) of nearly 20%, significantly outpacing the growth of many other industrial metals and minerals.

The EV sector currently accounts for over 70% of lithium demand, with consumer electronics comprising about 14%, and energy storage systems representing around 9%. The remaining demand comes from various industrial applications including ceramics, glass, and lubricants. As battery technology continues to evolve, the intensity of lithium use per vehicle is also changing, with some newer battery chemistries requiring up to 20% more lithium than previous generations.

Geographically, demand is concentrated in regions with advanced manufacturing capabilities and aggressive electrification policies. China leads global consumption, accounting for approximately 39% of worldwide lithium demand, followed by Japan and South Korea at 18% and 15% respectively. European markets collectively represent about 17% of global demand, while North America accounts for roughly 10%.

Supply constraints have created significant market imbalances, with lithium prices experiencing volatility. Spot prices for battery-grade lithium carbonate increased by over 400% between January 2021 and December 2022, before moderating somewhat in 2023. These price fluctuations have accelerated investment in both traditional extraction methods and alternative technologies.

The market structure is evolving from a relatively concentrated supply base toward greater diversification. While Australia, Chile, and China currently dominate production, new projects are being developed in Argentina, Bolivia, the United States, and several African nations. This geographical diversification reflects both the strategic importance of lithium resources and concerns about supply chain resilience.

Long-term demand forecasts remain robust despite short-term market adjustments. The International Energy Agency projects that achieving net-zero emissions scenarios would require lithium production to increase by over 40 times by 2040 compared to 2020 levels. This growth trajectory has significant implications for extraction methodologies, as the industry must balance increasing production volumes with environmental sustainability and energy efficiency considerations.

The comparison between brine and ore extraction methods has become increasingly relevant as manufacturers seek to secure environmentally responsible supply chains with lower carbon footprints. This market dynamic is creating competitive advantages for extraction processes that can demonstrate superior energy efficiency metrics.

The EV sector currently accounts for over 70% of lithium demand, with consumer electronics comprising about 14%, and energy storage systems representing around 9%. The remaining demand comes from various industrial applications including ceramics, glass, and lubricants. As battery technology continues to evolve, the intensity of lithium use per vehicle is also changing, with some newer battery chemistries requiring up to 20% more lithium than previous generations.

Geographically, demand is concentrated in regions with advanced manufacturing capabilities and aggressive electrification policies. China leads global consumption, accounting for approximately 39% of worldwide lithium demand, followed by Japan and South Korea at 18% and 15% respectively. European markets collectively represent about 17% of global demand, while North America accounts for roughly 10%.

Supply constraints have created significant market imbalances, with lithium prices experiencing volatility. Spot prices for battery-grade lithium carbonate increased by over 400% between January 2021 and December 2022, before moderating somewhat in 2023. These price fluctuations have accelerated investment in both traditional extraction methods and alternative technologies.

The market structure is evolving from a relatively concentrated supply base toward greater diversification. While Australia, Chile, and China currently dominate production, new projects are being developed in Argentina, Bolivia, the United States, and several African nations. This geographical diversification reflects both the strategic importance of lithium resources and concerns about supply chain resilience.

Long-term demand forecasts remain robust despite short-term market adjustments. The International Energy Agency projects that achieving net-zero emissions scenarios would require lithium production to increase by over 40 times by 2040 compared to 2020 levels. This growth trajectory has significant implications for extraction methodologies, as the industry must balance increasing production volumes with environmental sustainability and energy efficiency considerations.

The comparison between brine and ore extraction methods has become increasingly relevant as manufacturers seek to secure environmentally responsible supply chains with lower carbon footprints. This market dynamic is creating competitive advantages for extraction processes that can demonstrate superior energy efficiency metrics.

Current Extraction Technologies and Challenges

Lithium extraction technologies have evolved significantly over the past decades, with two primary methods dominating the industry: brine extraction and hard rock mining. Brine extraction involves pumping lithium-rich saltwater from underground reservoirs into large evaporation ponds, where solar evaporation concentrates the lithium over 12-18 months before chemical processing. This method is prevalent in the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia), which holds approximately 58% of the world's lithium resources.

Hard rock mining, predominantly from spodumene deposits, requires conventional mining techniques followed by crushing, heating to 1,100°C (calcination), cooling, additional heating with sulfuric acid, and multiple chemical processes to produce lithium carbonate. Australia leads global production using this method, with significant operations also in China and Zimbabwe.

The energy efficiency comparison between these methods reveals substantial differences. Brine extraction typically consumes 200-300 kWh per ton of lithium carbonate equivalent (LCE), while hard rock mining requires 5,000-6,000 kWh per ton. This significant disparity makes brine extraction approximately 20 times more energy-efficient, though actual figures vary based on specific site conditions and processing technologies.

Water consumption presents another critical challenge, with brine operations using 469-1,782 cubic meters of water per ton of LCE, primarily through evaporation losses. Hard rock mining consumes less water (170-315 cubic meters per ton) but generates more solid waste and has a larger land footprint.

Current technological challenges for brine extraction include lengthy processing times, weather dependency affecting evaporation rates, and declining lithium concentration in many reservoirs. Additionally, increasing concerns about water usage in arid regions where most brine operations exist have prompted regulatory scrutiny and community opposition.

For hard rock mining, the primary challenges include high energy costs, significant CO2 emissions (approximately 15 tons CO2 per ton of LCE), and complex waste management issues. The energy-intensive calcination process and acid leaching steps contribute substantially to both operational costs and environmental impact.

Emerging technologies attempting to address these challenges include direct lithium extraction (DLE) methods, which promise to reduce processing time from months to hours while decreasing water consumption by up to 70%. However, these technologies remain largely unproven at commercial scale, with questions about their economic viability and long-term environmental impacts still unanswered.

Hard rock mining, predominantly from spodumene deposits, requires conventional mining techniques followed by crushing, heating to 1,100°C (calcination), cooling, additional heating with sulfuric acid, and multiple chemical processes to produce lithium carbonate. Australia leads global production using this method, with significant operations also in China and Zimbabwe.

The energy efficiency comparison between these methods reveals substantial differences. Brine extraction typically consumes 200-300 kWh per ton of lithium carbonate equivalent (LCE), while hard rock mining requires 5,000-6,000 kWh per ton. This significant disparity makes brine extraction approximately 20 times more energy-efficient, though actual figures vary based on specific site conditions and processing technologies.

Water consumption presents another critical challenge, with brine operations using 469-1,782 cubic meters of water per ton of LCE, primarily through evaporation losses. Hard rock mining consumes less water (170-315 cubic meters per ton) but generates more solid waste and has a larger land footprint.

Current technological challenges for brine extraction include lengthy processing times, weather dependency affecting evaporation rates, and declining lithium concentration in many reservoirs. Additionally, increasing concerns about water usage in arid regions where most brine operations exist have prompted regulatory scrutiny and community opposition.

For hard rock mining, the primary challenges include high energy costs, significant CO2 emissions (approximately 15 tons CO2 per ton of LCE), and complex waste management issues. The energy-intensive calcination process and acid leaching steps contribute substantially to both operational costs and environmental impact.

Emerging technologies attempting to address these challenges include direct lithium extraction (DLE) methods, which promise to reduce processing time from months to hours while decreasing water consumption by up to 70%. However, these technologies remain largely unproven at commercial scale, with questions about their economic viability and long-term environmental impacts still unanswered.

Comparative Analysis of Brine vs Ore Extraction Processes

01 Direct lithium extraction (DLE) technologies

Direct lithium extraction technologies offer more energy-efficient alternatives to traditional evaporation methods. These processes use selective adsorption materials or ion exchange resins to extract lithium from brines with reduced processing time and environmental footprint. DLE methods can operate at ambient temperatures, significantly reducing energy requirements compared to conventional evaporation ponds that rely on solar energy over many months.- Direct lithium extraction (DLE) technologies: Direct lithium extraction technologies offer more energy-efficient alternatives to traditional evaporation methods. These processes use selective adsorption materials or ion exchange resins to extract lithium from brines with reduced processing time and environmental footprint. DLE methods can operate at ambient temperatures, significantly reducing energy requirements compared to conventional techniques while achieving higher recovery rates and purity levels.

- Electrochemical extraction methods: Electrochemical processes for lithium extraction utilize electrical energy to selectively recover lithium ions from various sources. These methods include electrochemical cells, electrodialysis, and capacitive deionization systems that can operate with lower energy consumption than thermal evaporation techniques. By optimizing electrode materials and operating parameters, these systems can achieve energy-efficient lithium recovery while minimizing waste generation and environmental impact.

- Solar-powered extraction systems: Solar energy integration with lithium extraction processes significantly improves energy efficiency and sustainability. These systems utilize photovoltaic panels or solar thermal collectors to power extraction operations, reducing dependence on fossil fuels. Some innovative approaches combine solar evaporation with selective recovery techniques, creating hybrid systems that optimize energy usage while maintaining high lithium recovery rates from brines and other sources.

- Heat recovery and thermal optimization: Advanced thermal management systems improve energy efficiency in lithium extraction by recovering and reusing waste heat from various process stages. These technologies incorporate heat exchangers, thermal storage solutions, and process integration techniques to minimize energy losses. By optimizing thermal gradients and implementing cascading energy use strategies, these systems can significantly reduce the overall energy footprint of lithium recovery operations while maintaining extraction performance.

- Membrane and filtration-based extraction: Membrane technologies offer energy-efficient approaches to lithium extraction by utilizing selective filtration processes that operate at lower pressures and temperatures than conventional methods. These systems employ nanofiltration, forward osmosis, or specialized membrane materials that selectively separate lithium ions from other components. The reduced energy requirements for pumping and minimal need for thermal inputs make membrane-based extraction particularly advantageous for energy efficiency while achieving high lithium recovery rates.

02 Electrochemical extraction methods

Electrochemical processes for lithium extraction utilize electrical energy to selectively recover lithium ions from various sources. These methods include electrochemical cells, electrodialysis, and capacitive deionization systems that can be optimized for energy efficiency. By controlling voltage and current parameters, these systems can achieve high lithium recovery rates while minimizing energy consumption, especially when coupled with renewable energy sources.Expand Specific Solutions03 Heat management and energy recovery systems

Advanced heat management and energy recovery systems improve the overall energy efficiency of lithium extraction processes. These innovations include waste heat recovery, thermal energy storage, and process integration techniques that capture and reuse thermal energy. By implementing heat exchangers and thermal integration strategies, extraction facilities can significantly reduce their energy footprint and operating costs.Expand Specific Solutions04 Renewable energy integration

Integration of renewable energy sources with lithium extraction processes enhances energy efficiency and sustainability. Solar, wind, and geothermal energy can power extraction operations, reducing dependence on fossil fuels. Some systems are specifically designed to operate with variable renewable energy inputs, optimizing extraction rates based on available power and minimizing the carbon footprint of lithium production.Expand Specific Solutions05 Process optimization and automation

Advanced process control and automation systems optimize energy consumption in lithium extraction operations. These technologies include AI-driven control algorithms, real-time monitoring, and predictive maintenance systems that adjust operational parameters to maximize efficiency. By optimizing flow rates, pressure, temperature, and chemical dosing, these systems minimize energy waste while maintaining high lithium recovery rates and product quality.Expand Specific Solutions

Major Industry Players in Lithium Extraction

The lithium extraction market is currently in a growth phase, with increasing demand driven by electric vehicle battery production. Brine extraction dominates due to its lower energy requirements compared to hard rock mining, though both methods continue to evolve. The market is projected to reach $6-8 billion by 2025, with a CAGR of approximately 8-10%. Companies like Vulcan Energy Resources and Novalith Technologies are pioneering carbon-neutral extraction processes, while Energy Exploration Technologies and International Battery Metals focus on advanced direct lithium extraction technologies for brines. Traditional mining companies are being challenged by these technology-focused entrants. Academic institutions such as Central South University and The University of Manchester are contributing significant research to improve extraction efficiency and sustainability across both methods.

Novalith Technologies Pty Ltd.

Technical Solution: Novalith Technologies has developed a proprietary CO2 leaching process for lithium extraction from ore that significantly reduces energy consumption compared to traditional methods. Their LiCAL™ technology uses carbon dioxide as a reagent to selectively leach lithium from spodumene concentrate, eliminating the need for high-temperature calcination (which typically requires temperatures of 1000-1100°C). The process operates at ambient temperature and pressure conditions, reducing energy requirements by up to 70% compared to conventional ore processing methods[1]. Additionally, the technology captures and recycles CO2 during the extraction process, creating a carbon-negative lithium production pathway. The system also minimizes water usage and eliminates the need for strong acids, sulfates, and extensive waste neutralization steps that are common in traditional ore processing[2].

Strengths: Significantly lower energy consumption than traditional ore processing; carbon-negative potential through CO2 utilization; reduced water consumption; elimination of high-temperature calcination steps; lower chemical reagent requirements. Weaknesses: Technology is still scaling to commercial production levels; may have limitations with certain ore compositions; requires consistent ore quality for optimal performance.

Vulcan Energie Ressourcen GmbH

Technical Solution: Vulcan Energy has pioneered a Zero Carbon Lithium™ extraction process focused on geothermal brine resources in the Upper Rhine Valley of Germany. Their integrated approach combines geothermal energy production with direct lithium extraction (DLE) from the same brine source. The process utilizes renewable geothermal energy to power the lithium extraction operations, creating a self-sustaining system with minimal external energy requirements. Their DLE technology employs specialized adsorbents that selectively capture lithium ions from brine at temperatures of 160-180°C without requiring prior cooling of the geothermal fluid[3]. After lithium adsorption, the brine is reinjected into the reservoir, maintaining hydraulic balance and minimizing environmental impact. The extracted lithium is then processed into battery-grade lithium hydroxide or carbonate using the excess geothermal energy from their plants. This integrated approach results in an estimated 60-90% lower carbon footprint compared to conventional lithium production methods[4].

Strengths: Near-zero carbon footprint through integration with renewable geothermal energy; closed-loop system with brine reinjection; minimal land and water usage compared to evaporative methods; production of both energy and lithium from the same resource. Weaknesses: Limited to regions with suitable geothermal brine resources; higher initial capital expenditure requirements; technology still scaling to full commercial production; dependent on specific brine chemistry and temperature conditions.

Energy Efficiency Innovations in Lithium Extraction

Lithium extraction method

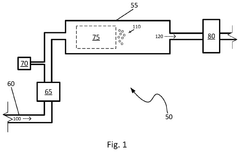

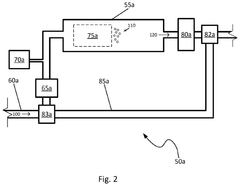

PatentWO2025129489A1

Innovation

- A process combining separation technologies such as lithium adsorbents, nanofiltration, and reverse osmosis to selectively extract lithium from brine solutions with reduced energy consumption and improved water utilization.

Lithium recovery from brine

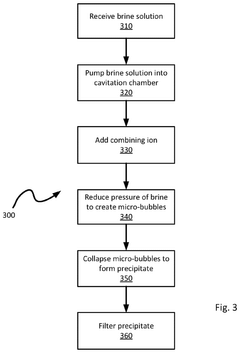

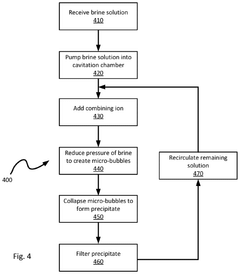

PatentPendingUS20250101544A1

Innovation

- The application of hydrodynamic cavitation to accelerate chemical reactions in lithium extraction from brine solutions by creating micro-bubbles that collapse and release high localized energy, enhancing mass transfer and precipitation rates, allowing for efficient removal of lithium and waste elements without extensive land use or water wastage.

Environmental Impact Assessment of Extraction Methods

The environmental impact of lithium extraction methods varies significantly between brine and ore-based processes, with each presenting distinct ecological challenges. Brine extraction, predominantly utilized in salt flats of South America's "Lithium Triangle," consumes substantial water resources in water-scarce regions. In Chile's Atacama Desert, for instance, lithium operations withdraw approximately 21 million liters of water daily, causing measurable groundwater depletion and threatening local ecosystems and indigenous communities' water access.

The evaporation ponds characteristic of brine operations modify local landscapes extensively, covering up to 50 square kilometers per facility. These artificial saline environments disrupt natural habitats and migration patterns of native species, particularly affecting flamingo populations that depend on these previously balanced ecosystems.

Conversely, hard-rock mining operations present different environmental challenges. Open-pit mining for lithium-bearing minerals like spodumene results in significant land disturbance, with typical operations excavating areas of 400-600 hectares. This process generates substantial waste rock, with a typical ratio of 10:1 waste-to-ore, creating long-term management challenges for tailings and overburden.

Air quality degradation represents another significant concern in ore extraction, with particulate matter emissions from blasting, crushing, and transportation activities. Studies indicate PM2.5 concentrations can reach 150-200 μg/m³ near active mining sites, far exceeding WHO air quality guidelines of 10 μg/m³ annual mean.

Chemical processing of ore introduces additional environmental risks through acid leaching processes that utilize sulfuric acid and other reagents. These processes generate acidic waste streams requiring neutralization and careful management to prevent soil and water contamination. Documented cases of containment failures have resulted in localized ecological damage at several lithium processing facilities.

Carbon footprint assessments reveal meaningful differences between extraction methods. Life cycle analyses indicate that hard-rock lithium production generates approximately 15-20 tonnes of CO2 equivalent per tonne of lithium carbonate equivalent (LCE), while brine operations typically produce 3-4 tonnes CO2e/tonne LCE. This disparity primarily stems from the energy-intensive crushing, grinding, and thermal processing required for ore extraction.

Biodiversity impacts also differ substantially between methods. Brine operations affect specialized salt flat ecosystems with high endemism rates but relatively low species diversity. In contrast, hard-rock mining impacts more diverse terrestrial ecosystems, potentially affecting greater numbers of species but typically in ecosystems with lower endemism rates and greater resilience.

The evaporation ponds characteristic of brine operations modify local landscapes extensively, covering up to 50 square kilometers per facility. These artificial saline environments disrupt natural habitats and migration patterns of native species, particularly affecting flamingo populations that depend on these previously balanced ecosystems.

Conversely, hard-rock mining operations present different environmental challenges. Open-pit mining for lithium-bearing minerals like spodumene results in significant land disturbance, with typical operations excavating areas of 400-600 hectares. This process generates substantial waste rock, with a typical ratio of 10:1 waste-to-ore, creating long-term management challenges for tailings and overburden.

Air quality degradation represents another significant concern in ore extraction, with particulate matter emissions from blasting, crushing, and transportation activities. Studies indicate PM2.5 concentrations can reach 150-200 μg/m³ near active mining sites, far exceeding WHO air quality guidelines of 10 μg/m³ annual mean.

Chemical processing of ore introduces additional environmental risks through acid leaching processes that utilize sulfuric acid and other reagents. These processes generate acidic waste streams requiring neutralization and careful management to prevent soil and water contamination. Documented cases of containment failures have resulted in localized ecological damage at several lithium processing facilities.

Carbon footprint assessments reveal meaningful differences between extraction methods. Life cycle analyses indicate that hard-rock lithium production generates approximately 15-20 tonnes of CO2 equivalent per tonne of lithium carbonate equivalent (LCE), while brine operations typically produce 3-4 tonnes CO2e/tonne LCE. This disparity primarily stems from the energy-intensive crushing, grinding, and thermal processing required for ore extraction.

Biodiversity impacts also differ substantially between methods. Brine operations affect specialized salt flat ecosystems with high endemism rates but relatively low species diversity. In contrast, hard-rock mining impacts more diverse terrestrial ecosystems, potentially affecting greater numbers of species but typically in ecosystems with lower endemism rates and greater resilience.

Water Resource Management in Lithium Production

Water resource management represents a critical aspect of lithium production processes, with significant variations between brine and ore extraction methods. Brine-based lithium extraction typically requires substantial water resources, with estimates suggesting between 500,000 to 2 million gallons of water per ton of lithium carbonate produced. This water-intensive process occurs in regions often characterized by arid conditions, creating potential conflicts with local communities and ecosystems.

The water footprint of brine operations manifests primarily through evaporation processes, where lithium-rich brines are pumped into large evaporation ponds and exposed to solar radiation for 12-18 months. This method, while energy-efficient, results in significant water loss through evaporation, with some operations reporting evaporation rates exceeding 95% of extracted brine volume.

In contrast, hard-rock lithium mining operations present different water management challenges. While generally less water-intensive per unit of lithium produced, these operations require water for ore processing, dust suppression, and various beneficiation processes. The water quality requirements also differ, with ore extraction typically utilizing freshwater resources rather than the saline water employed in brine operations.

Recent technological innovations have emerged to address water consumption concerns. Advanced membrane technologies, direct lithium extraction (DLE) methods, and closed-loop water systems have demonstrated potential to reduce freshwater consumption by 30-50% in pilot projects. These technologies aim to minimize environmental impact while maintaining economic viability.

Regulatory frameworks governing water usage in lithium production vary significantly across jurisdictions. Chile's Atacama region, home to substantial lithium reserves, has implemented water extraction quotas and mandatory monitoring systems. Similarly, Australia has established comprehensive water management requirements for hard-rock operations, including mandatory recycling targets and discharge limitations.

The economic implications of water management strategies cannot be overlooked. Water-efficient technologies typically require higher capital expenditure but may offer long-term operational savings and reduced environmental liabilities. Companies implementing advanced water management systems report reduced regulatory compliance costs and improved stakeholder relations, particularly in water-stressed regions.

Future sustainability in lithium production will likely depend on integrated water management approaches that consider regional water availability, competing demands, and climate change projections. Industry leaders are increasingly adopting watershed-level planning approaches that account for cumulative impacts across multiple operations and stakeholders.

The water footprint of brine operations manifests primarily through evaporation processes, where lithium-rich brines are pumped into large evaporation ponds and exposed to solar radiation for 12-18 months. This method, while energy-efficient, results in significant water loss through evaporation, with some operations reporting evaporation rates exceeding 95% of extracted brine volume.

In contrast, hard-rock lithium mining operations present different water management challenges. While generally less water-intensive per unit of lithium produced, these operations require water for ore processing, dust suppression, and various beneficiation processes. The water quality requirements also differ, with ore extraction typically utilizing freshwater resources rather than the saline water employed in brine operations.

Recent technological innovations have emerged to address water consumption concerns. Advanced membrane technologies, direct lithium extraction (DLE) methods, and closed-loop water systems have demonstrated potential to reduce freshwater consumption by 30-50% in pilot projects. These technologies aim to minimize environmental impact while maintaining economic viability.

Regulatory frameworks governing water usage in lithium production vary significantly across jurisdictions. Chile's Atacama region, home to substantial lithium reserves, has implemented water extraction quotas and mandatory monitoring systems. Similarly, Australia has established comprehensive water management requirements for hard-rock operations, including mandatory recycling targets and discharge limitations.

The economic implications of water management strategies cannot be overlooked. Water-efficient technologies typically require higher capital expenditure but may offer long-term operational savings and reduced environmental liabilities. Companies implementing advanced water management systems report reduced regulatory compliance costs and improved stakeholder relations, particularly in water-stressed regions.

Future sustainability in lithium production will likely depend on integrated water management approaches that consider regional water availability, competing demands, and climate change projections. Industry leaders are increasingly adopting watershed-level planning approaches that account for cumulative impacts across multiple operations and stakeholders.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!