Quantify Lithium Mine Wastewater Salinity and Recovery Potential

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Wastewater Treatment Background and Objectives

Lithium extraction has emerged as a critical industry due to the exponential growth in demand for lithium-ion batteries, which power everything from smartphones to electric vehicles and grid-scale energy storage systems. This surge in lithium mining activities has led to significant environmental challenges, particularly regarding wastewater management. Lithium mining operations, especially those utilizing brine extraction methods, generate substantial volumes of highly saline wastewater containing valuable minerals and contaminants that require proper treatment and management.

The evolution of lithium extraction technologies has progressed from traditional evaporation pond methods to more advanced direct lithium extraction (DLE) techniques. While these newer methods have improved efficiency, they still generate considerable wastewater streams with complex chemical compositions. The industry has gradually recognized the dual imperative of environmental stewardship and resource recovery, driving innovation in wastewater treatment technologies.

Current trends indicate a shift toward closed-loop systems that minimize freshwater consumption and maximize resource recovery from wastewater streams. This approach aligns with circular economy principles and addresses growing regulatory pressures on mining operations worldwide. The quantification of salinity levels and recovery potential represents a crucial step in optimizing these systems and improving overall sustainability metrics.

The primary objectives of lithium wastewater treatment research focus on several interconnected goals. First, developing accurate and reliable methods to quantify the salinity levels in lithium mine wastewater across different operational contexts and geological settings. Second, identifying and evaluating the economic potential of recovering valuable minerals and compounds from these waste streams, including lithium, boron, potassium, and magnesium.

Additionally, research aims to establish standardized protocols for assessing the environmental impact of wastewater discharge and developing mitigation strategies. This includes understanding the effects of high-salinity discharge on local ecosystems and groundwater resources, particularly in water-stressed regions where many lithium operations are located.

The ultimate goal is to transform what is currently viewed as a waste management challenge into an opportunity for resource recovery and environmental protection. By quantifying both the salinity challenges and recovery potential, the industry can develop more sustainable practices that reduce freshwater consumption, minimize environmental footprint, and improve the economic viability of lithium production operations through the creation of valuable by-products from wastewater streams.

The evolution of lithium extraction technologies has progressed from traditional evaporation pond methods to more advanced direct lithium extraction (DLE) techniques. While these newer methods have improved efficiency, they still generate considerable wastewater streams with complex chemical compositions. The industry has gradually recognized the dual imperative of environmental stewardship and resource recovery, driving innovation in wastewater treatment technologies.

Current trends indicate a shift toward closed-loop systems that minimize freshwater consumption and maximize resource recovery from wastewater streams. This approach aligns with circular economy principles and addresses growing regulatory pressures on mining operations worldwide. The quantification of salinity levels and recovery potential represents a crucial step in optimizing these systems and improving overall sustainability metrics.

The primary objectives of lithium wastewater treatment research focus on several interconnected goals. First, developing accurate and reliable methods to quantify the salinity levels in lithium mine wastewater across different operational contexts and geological settings. Second, identifying and evaluating the economic potential of recovering valuable minerals and compounds from these waste streams, including lithium, boron, potassium, and magnesium.

Additionally, research aims to establish standardized protocols for assessing the environmental impact of wastewater discharge and developing mitigation strategies. This includes understanding the effects of high-salinity discharge on local ecosystems and groundwater resources, particularly in water-stressed regions where many lithium operations are located.

The ultimate goal is to transform what is currently viewed as a waste management challenge into an opportunity for resource recovery and environmental protection. By quantifying both the salinity challenges and recovery potential, the industry can develop more sustainable practices that reduce freshwater consumption, minimize environmental footprint, and improve the economic viability of lithium production operations through the creation of valuable by-products from wastewater streams.

Market Analysis for Lithium Recovery Technologies

The global lithium market has experienced unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market valuation reached approximately $7.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 12.3% through 2030. This remarkable growth trajectory creates significant economic incentives for developing and implementing efficient lithium recovery technologies from mine wastewater.

Traditional lithium extraction methods face increasing scrutiny due to their environmental impact and resource inefficiency. Conventional evaporation pond techniques typically recover only 50-60% of available lithium, leaving substantial value in wastewater streams. This inefficiency represents a market opportunity valued at nearly $3 billion annually in recoverable lithium that currently goes to waste.

The lithium recovery technology market is segmented into several categories: adsorption-based systems, membrane filtration technologies, electrochemical processes, and hybrid solutions. Among these, direct lithium extraction (DLE) technologies are gaining significant traction, with market adoption increasing by 35% in the past two years. Companies implementing advanced recovery systems report cost reductions of 30-40% compared to traditional extraction methods.

Regional analysis reveals that China dominates the lithium processing market with 60% of global capacity, while North America and Australia are rapidly expanding their technological capabilities to reduce dependency on foreign supply chains. Latin American countries, particularly within the "Lithium Triangle" (Argentina, Bolivia, and Chile), represent the most promising growth markets for wastewater recovery technologies due to their extensive brine operations.

End-user industries demonstrate varying levels of willingness to invest in recovery technologies. Battery manufacturers show the highest adoption rates, with 78% expressing interest in securing partnerships with technology providers that can guarantee consistent lithium quality from recovered sources. Energy storage system manufacturers follow at 65%, while consumer electronics producers show more conservative adoption at 42%.

Investment in lithium recovery technologies has surged, with venture capital funding reaching $1.2 billion in 2022, a 150% increase from 2020 levels. This investment surge indicates strong market confidence in the commercial viability of advanced recovery solutions. Government incentives further bolster market growth, with the European Union allocating €750 million to critical mineral recovery projects and the United States implementing tax credits worth up to 30% for qualifying lithium recycling investments.

Market barriers include high initial capital requirements, technical challenges in handling variable wastewater compositions, and regulatory uncertainties regarding waste classification. Despite these challenges, the economic case for lithium recovery technologies continues to strengthen as lithium prices maintain their upward trajectory and environmental regulations tighten globally.

Traditional lithium extraction methods face increasing scrutiny due to their environmental impact and resource inefficiency. Conventional evaporation pond techniques typically recover only 50-60% of available lithium, leaving substantial value in wastewater streams. This inefficiency represents a market opportunity valued at nearly $3 billion annually in recoverable lithium that currently goes to waste.

The lithium recovery technology market is segmented into several categories: adsorption-based systems, membrane filtration technologies, electrochemical processes, and hybrid solutions. Among these, direct lithium extraction (DLE) technologies are gaining significant traction, with market adoption increasing by 35% in the past two years. Companies implementing advanced recovery systems report cost reductions of 30-40% compared to traditional extraction methods.

Regional analysis reveals that China dominates the lithium processing market with 60% of global capacity, while North America and Australia are rapidly expanding their technological capabilities to reduce dependency on foreign supply chains. Latin American countries, particularly within the "Lithium Triangle" (Argentina, Bolivia, and Chile), represent the most promising growth markets for wastewater recovery technologies due to their extensive brine operations.

End-user industries demonstrate varying levels of willingness to invest in recovery technologies. Battery manufacturers show the highest adoption rates, with 78% expressing interest in securing partnerships with technology providers that can guarantee consistent lithium quality from recovered sources. Energy storage system manufacturers follow at 65%, while consumer electronics producers show more conservative adoption at 42%.

Investment in lithium recovery technologies has surged, with venture capital funding reaching $1.2 billion in 2022, a 150% increase from 2020 levels. This investment surge indicates strong market confidence in the commercial viability of advanced recovery solutions. Government incentives further bolster market growth, with the European Union allocating €750 million to critical mineral recovery projects and the United States implementing tax credits worth up to 30% for qualifying lithium recycling investments.

Market barriers include high initial capital requirements, technical challenges in handling variable wastewater compositions, and regulatory uncertainties regarding waste classification. Despite these challenges, the economic case for lithium recovery technologies continues to strengthen as lithium prices maintain their upward trajectory and environmental regulations tighten globally.

Current Challenges in Lithium Mine Wastewater Management

Lithium mining operations face significant challenges in wastewater management, with salinity control being one of the most pressing issues. The high concentration of dissolved salts in lithium mine wastewater creates environmental hazards and operational inefficiencies that demand innovative solutions. Current extraction methods, particularly in brine operations, generate substantial volumes of hypersaline wastewater that can contain 5-10 times the salt concentration of seawater.

Traditional wastewater management approaches have proven inadequate for handling the unique chemical composition of lithium mine effluent. The presence of multiple salt species including sodium, potassium, magnesium, and calcium compounds complicates treatment processes and limits the effectiveness of conventional desalination technologies. Furthermore, seasonal variations in evaporation rates and precipitation patterns create fluctuating wastewater volumes that challenge consistent treatment protocols.

Regulatory compliance presents another significant hurdle, as environmental standards for wastewater discharge are becoming increasingly stringent worldwide. Mining operations in water-stressed regions face particular scrutiny, with some jurisdictions implementing zero liquid discharge requirements that necessitate complete recovery of water and isolation of salt byproducts. The cost of compliance with these regulations has become a substantial operational expense for lithium producers.

Technical limitations in measurement and monitoring systems further complicate management efforts. Current salinity quantification methods often lack the precision needed for optimizing recovery processes, while real-time monitoring capabilities remain underdeveloped. This data gap hinders the implementation of adaptive management strategies that could improve both environmental outcomes and economic returns.

Water scarcity in many lithium-producing regions adds another layer of complexity, creating competition between mining operations and local communities for limited water resources. This has intensified the need for water recycling and recovery solutions that can minimize freshwater consumption while maintaining production efficiency. However, the high energy requirements of current desalination technologies often make comprehensive water recovery economically prohibitive.

The recovery potential of valuable minerals from wastewater streams represents an untapped opportunity that could transform waste management from a cost center to a revenue source. Current technologies can recover lithium from wastewater with varying degrees of efficiency, but the extraction of other valuable components such as boron, potassium, and magnesium remains technically challenging and often economically unfeasible at commercial scales.

Cross-contamination between different process streams further complicates recovery efforts, as the presence of organic contaminants, processing chemicals, and suspended solids can interfere with selective extraction of target compounds. This necessitates multi-stage treatment approaches that add complexity and cost to recovery operations.

Traditional wastewater management approaches have proven inadequate for handling the unique chemical composition of lithium mine effluent. The presence of multiple salt species including sodium, potassium, magnesium, and calcium compounds complicates treatment processes and limits the effectiveness of conventional desalination technologies. Furthermore, seasonal variations in evaporation rates and precipitation patterns create fluctuating wastewater volumes that challenge consistent treatment protocols.

Regulatory compliance presents another significant hurdle, as environmental standards for wastewater discharge are becoming increasingly stringent worldwide. Mining operations in water-stressed regions face particular scrutiny, with some jurisdictions implementing zero liquid discharge requirements that necessitate complete recovery of water and isolation of salt byproducts. The cost of compliance with these regulations has become a substantial operational expense for lithium producers.

Technical limitations in measurement and monitoring systems further complicate management efforts. Current salinity quantification methods often lack the precision needed for optimizing recovery processes, while real-time monitoring capabilities remain underdeveloped. This data gap hinders the implementation of adaptive management strategies that could improve both environmental outcomes and economic returns.

Water scarcity in many lithium-producing regions adds another layer of complexity, creating competition between mining operations and local communities for limited water resources. This has intensified the need for water recycling and recovery solutions that can minimize freshwater consumption while maintaining production efficiency. However, the high energy requirements of current desalination technologies often make comprehensive water recovery economically prohibitive.

The recovery potential of valuable minerals from wastewater streams represents an untapped opportunity that could transform waste management from a cost center to a revenue source. Current technologies can recover lithium from wastewater with varying degrees of efficiency, but the extraction of other valuable components such as boron, potassium, and magnesium remains technically challenging and often economically unfeasible at commercial scales.

Cross-contamination between different process streams further complicates recovery efforts, as the presence of organic contaminants, processing chemicals, and suspended solids can interfere with selective extraction of target compounds. This necessitates multi-stage treatment approaches that add complexity and cost to recovery operations.

Existing Salinity Quantification and Recovery Solutions

01 Membrane-based desalination technologies for lithium mine wastewater

Various membrane-based technologies can be employed to reduce salinity in lithium mine wastewater. These include reverse osmosis, nanofiltration, and electrodialysis systems specifically designed to handle the high salt content of lithium extraction waste streams. These technologies effectively separate salts from the wastewater, allowing for water reuse and potentially recovering valuable minerals in the process.- Membrane-based desalination technologies for lithium mine wastewater: Various membrane-based technologies are employed to reduce salinity in lithium mine wastewater. These include reverse osmosis, nanofiltration, and electrodialysis systems specifically designed to handle the high salt concentrations typical in lithium extraction operations. These technologies effectively separate salts from the wastewater, allowing for water reuse and potentially recovering valuable minerals in the process.

- Chemical precipitation methods for salinity reduction: Chemical precipitation techniques are used to reduce salinity in lithium mine wastewater by adding specific reagents that react with dissolved salts to form insoluble compounds. These precipitates can then be removed through sedimentation or filtration processes. This approach is particularly effective for removing specific ions like calcium, magnesium, and sulfates that contribute to high salinity levels in lithium mining effluents.

- Evaporation and crystallization systems: Evaporation ponds and crystallization systems are employed to manage high-salinity wastewater from lithium mining operations. These systems utilize solar energy or mechanical evaporators to concentrate the brine, allowing for salt crystallization and recovery. The process not only reduces wastewater volume but also enables the recovery of valuable minerals, including lithium compounds, while addressing salinity issues.

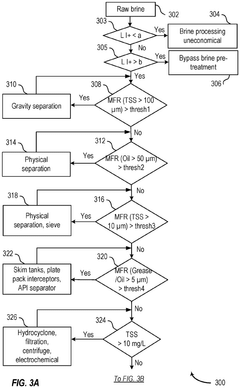

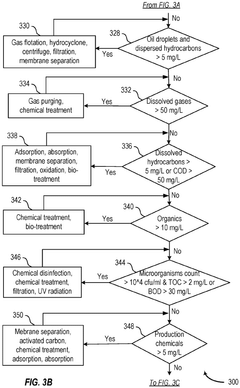

- Integrated multi-stage treatment processes: Comprehensive multi-stage treatment systems combine various technologies to effectively manage lithium mine wastewater salinity. These integrated approaches typically involve a sequence of treatments such as pre-filtration, chemical treatment, membrane separation, and final polishing steps. By combining multiple technologies, these systems can handle complex wastewater compositions and achieve higher water recovery rates while reducing overall salinity.

- Biological treatment methods for salinity management: Biological treatment approaches utilize specialized microorganisms or plant-based systems to help manage salinity in lithium mine wastewater. These methods include constructed wetlands, bioreactors with salt-tolerant bacteria, and phytoremediation techniques. Biological systems can complement physical and chemical treatments by removing specific contaminants, adjusting pH levels, and potentially reducing certain dissolved solids that contribute to salinity.

02 Evaporation and crystallization methods for salt recovery

Evaporation ponds and crystallization techniques are used to manage high-salinity wastewater from lithium mining operations. These methods concentrate the brine solution, allowing for the sequential precipitation of various salts. Advanced crystallization processes can selectively recover valuable compounds while reducing the overall salinity of the wastewater, making it more environmentally manageable.Expand Specific Solutions03 Chemical precipitation and ion exchange for salinity reduction

Chemical treatment methods involving precipitation agents and ion exchange resins can effectively reduce salinity in lithium mine wastewater. These processes selectively remove specific ions from the solution, allowing for targeted salinity reduction. Various reagents and resins can be optimized for the particular ionic composition of lithium mining effluents, improving treatment efficiency and potentially recovering valuable components.Expand Specific Solutions04 Integrated multi-stage treatment systems

Comprehensive treatment approaches combining multiple technologies in sequence can effectively address the complex salinity issues in lithium mine wastewater. These integrated systems typically involve pre-treatment, primary salt removal, and polishing stages to progressively reduce salinity to acceptable levels. Such multi-stage approaches allow for optimization at each step and can be tailored to specific wastewater characteristics.Expand Specific Solutions05 Biological treatment methods for saline wastewater

Specialized biological treatment processes using salt-tolerant microorganisms can help manage certain aspects of lithium mine wastewater. These biological systems can degrade organic contaminants even in high-salinity environments and may contribute to salinity reduction through bioaccumulation or transformation processes. Engineered wetlands and bioreactors with halophilic organisms represent emerging approaches for sustainable management of saline mining effluents.Expand Specific Solutions

Leading Companies in Lithium Wastewater Treatment

The lithium mine wastewater treatment and recovery market is in an early growth phase, characterized by increasing demand driven by the expanding lithium battery industry. The market is projected to grow significantly as lithium production increases globally to meet EV and energy storage demands. Technologically, the field shows varying maturity levels, with companies at different development stages. Leading players include Albemarle Corp. and POSCO Holdings focusing on commercial-scale solutions, while specialized firms like ADY Resources and Xi'an Lanshen New Material Technology are developing innovative extraction technologies. Academic-industry partnerships with institutions like Xi'an Jiaotong University and Pontificia Universidad Católica de Chile are advancing novel approaches. Asian companies, particularly from Japan, South Korea, and China, demonstrate strong presence in this emerging field, leveraging their expertise in materials processing and water treatment technologies.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has leveraged its extensive experience in oilfield brine management to develop a sophisticated lithium mine wastewater analysis and recovery system. Their technology integrates advanced downhole sensing equipment with surface processing facilities to provide comprehensive salinity quantification and recovery optimization. The system employs multi-parameter probes that simultaneously measure conductivity, density, temperature, and specific ion concentrations in real-time, creating detailed salinity profiles throughout the lithium extraction process. Schlumberger's LithiumComplete™ platform incorporates proprietary algorithms that analyze these measurements to calculate recovery potential based on thermodynamic models and historical performance data. Their process includes selective membrane filtration combined with electrochemical separation techniques that can process high-salinity brines (up to 350,000 mg/L TDS) while achieving lithium concentration factors of 15-20x from the original brine. The technology features automated control systems that continuously adjust operating parameters based on incoming brine composition, maximizing recovery efficiency while maintaining consistent product quality. Schlumberger's integrated approach enables lithium recovery rates exceeding 80% while reducing freshwater consumption by up to 65% through advanced water recycling processes.

Strengths: Unparalleled expertise in handling complex brine chemistries from decades of oilfield experience; comprehensive data acquisition and analysis capabilities; robust equipment designed for harsh mining environments. Weaknesses: Higher complexity and capital costs compared to conventional systems; requires significant technical expertise to operate effectively; energy-intensive for certain separation processes.

Korea Institute of Geoscience & Mineral Resources

Technical Solution: The Korea Institute of Geoscience & Mineral Resources (KIGAM) has developed an innovative lithium mine wastewater analysis and recovery system that combines advanced spectroscopic techniques with electrochemical extraction methods. Their technology employs a multi-sensor array incorporating ion-selective electrodes and Raman spectroscopy to provide comprehensive real-time analysis of brine composition, including detailed salinity profiles and lithium concentration measurements with precision of ±1.5%. KIGAM's system features a proprietary electrochemical cell design that selectively extracts lithium ions from high-salinity brines while minimizing energy consumption. Their integrated data management platform, LithBrine™, incorporates machine learning algorithms that analyze historical performance data to optimize recovery parameters based on specific brine characteristics. The technology can effectively process brines with TDS levels ranging from 20,000 to 200,000 mg/L, achieving lithium recovery rates of up to 92% in laboratory conditions and 78-85% in field implementations. KIGAM's process includes a novel membrane distillation component that enables water recovery exceeding 75%, significantly reducing the environmental footprint of lithium extraction operations while providing accurate quantification of recovery potential across varying brine compositions.

Strengths: Cutting-edge research capabilities with strong focus on sustainability; highly accurate analytical methods for precise salinity quantification; energy-efficient extraction technology compared to conventional methods. Weaknesses: Less commercial deployment experience compared to industry giants; technology still scaling from laboratory to industrial applications; requires specialized technical knowledge for optimal operation.

Key Technologies for Lithium Brine Analysis

Quantitative brine analysis for mineral extraction

PatentPendingEP4549602A1

Innovation

- A method for quantitative brine analysis that involves obtaining parameters of a sample brine, determining pretreatment, extraction, and post-extraction scores, and calculating a total score to assess the brine's quality and optimize mineral extraction processes.

Recovering method of lithium

PatentWO2025135716A1

Innovation

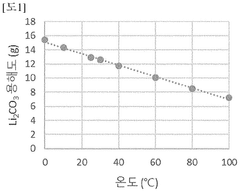

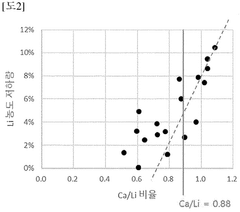

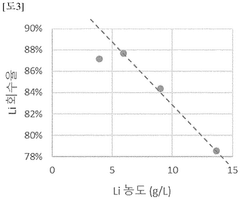

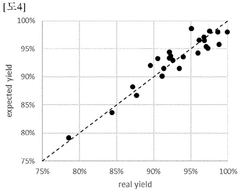

- A method for recovering lithium by quantifying process technology according to calcium concentration, involving preparing a lithium-containing solution, adding a calcium remover to precipitate calcium, and separating the precipitate to obtain a lithium-rich solution with reduced calcium content, using a recovery rate equation that considers temperature, lithium concentration, and calcium/lithium ratio.

Environmental Impact Assessment of Recovery Processes

The recovery processes for lithium from mine wastewater carry significant environmental implications that must be thoroughly assessed. Traditional extraction methods often involve extensive use of chemicals, high energy consumption, and produce substantial waste streams that can negatively impact surrounding ecosystems. Evaporation ponds, commonly used in lithium brine processing, require large land areas and can lead to soil contamination through leakage of saline water, potentially affecting groundwater quality and agricultural productivity in adjacent areas.

Direct lithium extraction (DLE) technologies present more environmentally favorable alternatives, with reduced land footprint requirements of up to 90% compared to conventional methods. However, these processes still generate concentrated brine streams that require proper management. Studies indicate that for every ton of lithium carbonate produced, approximately 500 cubic meters of wastewater containing elevated levels of manganese, zinc, and other heavy metals may be generated, necessitating additional treatment before discharge.

Energy consumption represents another critical environmental consideration. Membrane-based recovery systems typically require 10-15 kWh per cubic meter of processed brine, while adsorption-based technologies may consume 8-12 kWh. This energy demand translates to significant carbon emissions when powered by non-renewable sources, with estimates suggesting 5-7 tons of CO2 equivalent per ton of lithium carbonate produced.

Water usage efficiency varies considerably across recovery technologies. Advanced membrane processes achieve recovery rates of 85-90%, while selective adsorption methods typically recover 70-80% of water. The remaining highly concentrated brine presents disposal challenges, with potential for soil salinization if not properly managed. Recent pilot projects implementing zero liquid discharge (ZLD) systems have demonstrated promising results, reducing freshwater consumption by up to 65% compared to conventional operations.

Biodiversity impacts must also be considered, particularly in ecologically sensitive mining regions. Monitoring data from existing operations indicates that improper wastewater management can lead to elevated salinity levels in surrounding water bodies, potentially affecting aquatic ecosystems within a 5-10 kilometer radius of processing facilities. Studies have documented reduced species diversity in affected areas, with particularly notable impacts on amphibian populations and freshwater invertebrates.

Regulatory frameworks increasingly require comprehensive life cycle assessments of recovery processes. Recent analyses indicate that advanced recovery technologies can reduce the overall environmental footprint by 30-40% compared to traditional methods when considering combined impacts across water usage, land disturbance, and greenhouse gas emissions. These improvements represent significant progress toward more sustainable lithium production practices essential for meeting growing demand while minimizing environmental degradation.

Direct lithium extraction (DLE) technologies present more environmentally favorable alternatives, with reduced land footprint requirements of up to 90% compared to conventional methods. However, these processes still generate concentrated brine streams that require proper management. Studies indicate that for every ton of lithium carbonate produced, approximately 500 cubic meters of wastewater containing elevated levels of manganese, zinc, and other heavy metals may be generated, necessitating additional treatment before discharge.

Energy consumption represents another critical environmental consideration. Membrane-based recovery systems typically require 10-15 kWh per cubic meter of processed brine, while adsorption-based technologies may consume 8-12 kWh. This energy demand translates to significant carbon emissions when powered by non-renewable sources, with estimates suggesting 5-7 tons of CO2 equivalent per ton of lithium carbonate produced.

Water usage efficiency varies considerably across recovery technologies. Advanced membrane processes achieve recovery rates of 85-90%, while selective adsorption methods typically recover 70-80% of water. The remaining highly concentrated brine presents disposal challenges, with potential for soil salinization if not properly managed. Recent pilot projects implementing zero liquid discharge (ZLD) systems have demonstrated promising results, reducing freshwater consumption by up to 65% compared to conventional operations.

Biodiversity impacts must also be considered, particularly in ecologically sensitive mining regions. Monitoring data from existing operations indicates that improper wastewater management can lead to elevated salinity levels in surrounding water bodies, potentially affecting aquatic ecosystems within a 5-10 kilometer radius of processing facilities. Studies have documented reduced species diversity in affected areas, with particularly notable impacts on amphibian populations and freshwater invertebrates.

Regulatory frameworks increasingly require comprehensive life cycle assessments of recovery processes. Recent analyses indicate that advanced recovery technologies can reduce the overall environmental footprint by 30-40% compared to traditional methods when considering combined impacts across water usage, land disturbance, and greenhouse gas emissions. These improvements represent significant progress toward more sustainable lithium production practices essential for meeting growing demand while minimizing environmental degradation.

Economic Feasibility of Wastewater Recovery Systems

The economic feasibility of lithium mine wastewater recovery systems hinges on several interconnected factors that must be carefully evaluated. Initial capital expenditure represents a significant barrier, with advanced recovery technologies requiring investments ranging from $5-20 million depending on facility scale and technological sophistication. These systems typically incorporate membrane filtration, chemical precipitation, and evaporation technologies, each contributing substantially to upfront costs.

Operational expenses present another critical consideration, averaging between $3-7 per cubic meter of processed wastewater. Energy consumption constitutes approximately 40-60% of these operational costs, particularly for thermal evaporation and reverse osmosis processes. Chemical reagents and membrane replacement contribute an additional 20-30% to ongoing expenses, while maintenance and labor account for the remainder.

Return on investment calculations reveal promising potential, with payback periods typically ranging from 3-7 years depending on lithium market prices and recovery efficiency. Current lithium carbonate prices exceeding $20,000 per ton significantly enhance economic viability. Recovery systems capable of extracting 85-95% of lithium content from wastewater streams can generate substantial revenue streams that offset initial investments.

Environmental compliance costs must also factor into feasibility assessments. Regulatory requirements for wastewater discharge are becoming increasingly stringent worldwide, with non-compliance penalties ranging from $10,000-$100,000 per violation in major mining jurisdictions. Recovery systems that enable closed-loop operations can eliminate these compliance risks while simultaneously reducing freshwater procurement costs by 30-50%.

Scale economies play a decisive role in determining feasibility. Analysis indicates that operations processing at least 500 cubic meters of wastewater daily typically achieve optimal cost-efficiency. Smaller operations may benefit from modular systems that can be expanded incrementally as production volumes increase, though these generally command higher per-unit costs initially.

Geographic considerations significantly impact economic calculations. Remote mining operations face elevated costs for equipment transport and installation, sometimes increasing capital expenditures by 15-25%. Conversely, mines located in water-scarce regions derive additional value from water recovery, with freshwater procurement savings potentially reaching $2-4 per cubic meter in arid regions, substantially improving overall project economics.

Operational expenses present another critical consideration, averaging between $3-7 per cubic meter of processed wastewater. Energy consumption constitutes approximately 40-60% of these operational costs, particularly for thermal evaporation and reverse osmosis processes. Chemical reagents and membrane replacement contribute an additional 20-30% to ongoing expenses, while maintenance and labor account for the remainder.

Return on investment calculations reveal promising potential, with payback periods typically ranging from 3-7 years depending on lithium market prices and recovery efficiency. Current lithium carbonate prices exceeding $20,000 per ton significantly enhance economic viability. Recovery systems capable of extracting 85-95% of lithium content from wastewater streams can generate substantial revenue streams that offset initial investments.

Environmental compliance costs must also factor into feasibility assessments. Regulatory requirements for wastewater discharge are becoming increasingly stringent worldwide, with non-compliance penalties ranging from $10,000-$100,000 per violation in major mining jurisdictions. Recovery systems that enable closed-loop operations can eliminate these compliance risks while simultaneously reducing freshwater procurement costs by 30-50%.

Scale economies play a decisive role in determining feasibility. Analysis indicates that operations processing at least 500 cubic meters of wastewater daily typically achieve optimal cost-efficiency. Smaller operations may benefit from modular systems that can be expanded incrementally as production volumes increase, though these generally command higher per-unit costs initially.

Geographic considerations significantly impact economic calculations. Remote mining operations face elevated costs for equipment transport and installation, sometimes increasing capital expenditures by 15-25%. Conversely, mines located in water-scarce regions derive additional value from water recovery, with freshwater procurement savings potentially reaching $2-4 per cubic meter in arid regions, substantially improving overall project economics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!