Optimize Lithium Mine Fleet Electrification for 20% Fuel Savings

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Mine Electrification Background and Objectives

The electrification of mining fleets represents a transformative shift in the extractive industry, particularly for lithium mining operations which face the ironic challenge of using fossil fuels to extract materials essential for clean energy technologies. This technological evolution has accelerated significantly over the past decade, driven by environmental regulations, corporate sustainability commitments, and the economic imperative to reduce operational costs in mining activities.

Historically, mining operations have relied heavily on diesel-powered equipment, contributing substantially to greenhouse gas emissions and operational expenses. The trajectory toward electrification began with smaller equipment and has gradually expanded to include larger machinery essential for lithium extraction processes. This progression aligns with the broader industry trend toward sustainable mining practices and reduced environmental footprints.

The primary objective of optimizing lithium mine fleet electrification is to achieve a minimum 20% reduction in fuel consumption while maintaining or enhancing operational efficiency. This target represents a balance between ambitious environmental goals and practical operational constraints within mining environments. Secondary objectives include reducing maintenance costs, extending equipment lifespan, and improving working conditions through reduced noise and elimination of diesel particulate emissions.

Current technological developments in battery energy density, fast-charging capabilities, and electric drivetrain efficiency have created a favorable environment for accelerated adoption of electrified mining equipment. The convergence of these technologies with advanced energy management systems and renewable energy integration presents unprecedented opportunities for comprehensive fleet electrification strategies.

The lithium mining sector faces unique considerations in electrification efforts due to the remote locations of many operations, extreme environmental conditions, and intensive energy requirements for extraction processes. These factors necessitate specialized approaches to fleet electrification that differ from those employed in other mining sectors or industrial applications.

Looking forward, the technological roadmap for lithium mine fleet electrification includes progressive implementation phases, beginning with auxiliary equipment and light-duty vehicles before advancing to heavy machinery and haulage trucks. This staged approach allows for infrastructure development, operational adaptation, and technology refinement to occur concurrently with the transition to an electrified fleet.

The achievement of the 20% fuel savings target represents not only a significant operational cost reduction but also aligns with global decarbonization efforts and positions lithium producers to demonstrate environmental leadership in the supply chain for clean energy technologies.

Historically, mining operations have relied heavily on diesel-powered equipment, contributing substantially to greenhouse gas emissions and operational expenses. The trajectory toward electrification began with smaller equipment and has gradually expanded to include larger machinery essential for lithium extraction processes. This progression aligns with the broader industry trend toward sustainable mining practices and reduced environmental footprints.

The primary objective of optimizing lithium mine fleet electrification is to achieve a minimum 20% reduction in fuel consumption while maintaining or enhancing operational efficiency. This target represents a balance between ambitious environmental goals and practical operational constraints within mining environments. Secondary objectives include reducing maintenance costs, extending equipment lifespan, and improving working conditions through reduced noise and elimination of diesel particulate emissions.

Current technological developments in battery energy density, fast-charging capabilities, and electric drivetrain efficiency have created a favorable environment for accelerated adoption of electrified mining equipment. The convergence of these technologies with advanced energy management systems and renewable energy integration presents unprecedented opportunities for comprehensive fleet electrification strategies.

The lithium mining sector faces unique considerations in electrification efforts due to the remote locations of many operations, extreme environmental conditions, and intensive energy requirements for extraction processes. These factors necessitate specialized approaches to fleet electrification that differ from those employed in other mining sectors or industrial applications.

Looking forward, the technological roadmap for lithium mine fleet electrification includes progressive implementation phases, beginning with auxiliary equipment and light-duty vehicles before advancing to heavy machinery and haulage trucks. This staged approach allows for infrastructure development, operational adaptation, and technology refinement to occur concurrently with the transition to an electrified fleet.

The achievement of the 20% fuel savings target represents not only a significant operational cost reduction but also aligns with global decarbonization efforts and positions lithium producers to demonstrate environmental leadership in the supply chain for clean energy technologies.

Market Demand Analysis for Mining Fleet Electrification

The global mining industry is experiencing a significant shift towards electrification, driven by multiple converging factors. Recent market research indicates that the mining fleet electrification market is projected to grow at a CAGR of 25% through 2030, with the lithium mining sector positioned as an early adopter due to its strategic alignment with battery production supply chains.

Environmental regulations have become increasingly stringent worldwide, with many countries implementing carbon taxation policies that directly impact mining operations. The European Union's Carbon Border Adjustment Mechanism and similar policies in Canada and Australia have created financial incentives for mining companies to reduce emissions. These regulatory pressures are expected to intensify, making fleet electrification not merely an environmental choice but an economic necessity.

Operational cost analysis reveals that fuel represents 30-40% of total operating expenses for conventional mining fleets. With diesel prices showing historical volatility and a general upward trend, achieving a 20% fuel savings through electrification translates to approximately 6-8% reduction in total operational costs. This economic benefit compounds when considering the lower maintenance requirements of electric vehicles, which typically demonstrate 40-60% reduced maintenance costs compared to diesel counterparts.

Market demand is further strengthened by corporate sustainability commitments. Major mining corporations including Rio Tinto, BHP, and Vale have announced carbon neutrality targets by 2040-2050, necessitating substantial fleet transformations. Additionally, downstream pressure from battery and electric vehicle manufacturers seeking to reduce their supply chain carbon footprint has created premium markets for low-carbon lithium.

Investment trends confirm this market direction, with venture capital funding for mining electrification technologies reaching record levels. Over $3.5 billion was invested in mining equipment electrification startups between 2020-2023, representing a 300% increase from the previous three-year period.

The Asia-Pacific region currently leads demand for mining fleet electrification solutions, particularly in Australia and China, where lithium mining operations are expanding rapidly. North America follows closely, with significant growth potential in the "lithium triangle" of South America (Chile, Argentina, and Bolivia), where electrification is viewed as a solution to both environmental concerns and operational challenges in remote locations.

Customer surveys indicate that mining operators prioritize three key factors when considering fleet electrification: total cost of ownership, operational reliability, and charging infrastructure requirements. Solutions that can demonstrate clear advantages in these areas while delivering the targeted 20% fuel savings are positioned to capture significant market share.

Environmental regulations have become increasingly stringent worldwide, with many countries implementing carbon taxation policies that directly impact mining operations. The European Union's Carbon Border Adjustment Mechanism and similar policies in Canada and Australia have created financial incentives for mining companies to reduce emissions. These regulatory pressures are expected to intensify, making fleet electrification not merely an environmental choice but an economic necessity.

Operational cost analysis reveals that fuel represents 30-40% of total operating expenses for conventional mining fleets. With diesel prices showing historical volatility and a general upward trend, achieving a 20% fuel savings through electrification translates to approximately 6-8% reduction in total operational costs. This economic benefit compounds when considering the lower maintenance requirements of electric vehicles, which typically demonstrate 40-60% reduced maintenance costs compared to diesel counterparts.

Market demand is further strengthened by corporate sustainability commitments. Major mining corporations including Rio Tinto, BHP, and Vale have announced carbon neutrality targets by 2040-2050, necessitating substantial fleet transformations. Additionally, downstream pressure from battery and electric vehicle manufacturers seeking to reduce their supply chain carbon footprint has created premium markets for low-carbon lithium.

Investment trends confirm this market direction, with venture capital funding for mining electrification technologies reaching record levels. Over $3.5 billion was invested in mining equipment electrification startups between 2020-2023, representing a 300% increase from the previous three-year period.

The Asia-Pacific region currently leads demand for mining fleet electrification solutions, particularly in Australia and China, where lithium mining operations are expanding rapidly. North America follows closely, with significant growth potential in the "lithium triangle" of South America (Chile, Argentina, and Bolivia), where electrification is viewed as a solution to both environmental concerns and operational challenges in remote locations.

Customer surveys indicate that mining operators prioritize three key factors when considering fleet electrification: total cost of ownership, operational reliability, and charging infrastructure requirements. Solutions that can demonstrate clear advantages in these areas while delivering the targeted 20% fuel savings are positioned to capture significant market share.

Current Electrification Technologies and Challenges in Mining

The mining industry is witnessing a significant shift toward electrification, driven by environmental concerns, operational cost reduction targets, and regulatory pressures. Current electrification technologies in lithium mining operations primarily include battery-electric vehicles (BEVs), trolley-assist systems, hybrid diesel-electric equipment, and hydrogen fuel cell vehicles. Each technology represents different stages of market readiness and implementation feasibility.

Battery-electric vehicles have made substantial inroads in light and medium-duty mining applications. These systems typically utilize lithium-ion battery technology, offering zero tailpipe emissions and reduced maintenance requirements. Leading manufacturers like Epiroc, Sandvik, and Caterpillar have developed purpose-built electric loaders, trucks, and drilling equipment specifically for underground mining environments where ventilation costs are significant.

Trolley-assist systems represent a transitional technology that has gained traction in open-pit operations. These systems allow conventional diesel-electric haul trucks to connect to overhead power lines on ramps and main haulage routes, reducing diesel consumption by 90% during connected operation while maintaining operational flexibility when off-wire.

Hybrid diesel-electric systems have achieved broader market penetration due to their compatibility with existing infrastructure. These systems capture regenerative braking energy and optimize engine operation, delivering fuel savings of 15-25% without requiring complete fleet replacement or extensive charging infrastructure.

Despite promising advancements, significant challenges impede widespread electrification in lithium mining operations. The harsh operating conditions—including extreme temperatures, dust, vibration, and remote locations—place extraordinary demands on battery systems and electrical components. Current battery technologies struggle to deliver the energy density required for heavy-duty applications without compromising payload capacity or operating hours.

Infrastructure limitations present another substantial barrier. Remote mining sites often lack robust electrical grid connections necessary to support large-scale charging operations. The capital expenditure required for upgrading power distribution systems, installing charging stations, and potentially implementing renewable energy generation can be prohibitive.

Operational challenges further complicate electrification efforts. Mining operations typically run continuously, leaving minimal downtime for recharging. The industry's established maintenance practices and workforce skills are centered around mechanical systems rather than electrical powertrains, necessitating significant retraining and procedural adjustments.

Economic factors also influence adoption rates. While electric equipment offers lower operating costs through reduced fuel consumption and maintenance, the higher upfront capital costs and uncertain residual values create financial barriers, particularly for smaller operators with limited access to capital.

Battery-electric vehicles have made substantial inroads in light and medium-duty mining applications. These systems typically utilize lithium-ion battery technology, offering zero tailpipe emissions and reduced maintenance requirements. Leading manufacturers like Epiroc, Sandvik, and Caterpillar have developed purpose-built electric loaders, trucks, and drilling equipment specifically for underground mining environments where ventilation costs are significant.

Trolley-assist systems represent a transitional technology that has gained traction in open-pit operations. These systems allow conventional diesel-electric haul trucks to connect to overhead power lines on ramps and main haulage routes, reducing diesel consumption by 90% during connected operation while maintaining operational flexibility when off-wire.

Hybrid diesel-electric systems have achieved broader market penetration due to their compatibility with existing infrastructure. These systems capture regenerative braking energy and optimize engine operation, delivering fuel savings of 15-25% without requiring complete fleet replacement or extensive charging infrastructure.

Despite promising advancements, significant challenges impede widespread electrification in lithium mining operations. The harsh operating conditions—including extreme temperatures, dust, vibration, and remote locations—place extraordinary demands on battery systems and electrical components. Current battery technologies struggle to deliver the energy density required for heavy-duty applications without compromising payload capacity or operating hours.

Infrastructure limitations present another substantial barrier. Remote mining sites often lack robust electrical grid connections necessary to support large-scale charging operations. The capital expenditure required for upgrading power distribution systems, installing charging stations, and potentially implementing renewable energy generation can be prohibitive.

Operational challenges further complicate electrification efforts. Mining operations typically run continuously, leaving minimal downtime for recharging. The industry's established maintenance practices and workforce skills are centered around mechanical systems rather than electrical powertrains, necessitating significant retraining and procedural adjustments.

Economic factors also influence adoption rates. While electric equipment offers lower operating costs through reduced fuel consumption and maintenance, the higher upfront capital costs and uncertain residual values create financial barriers, particularly for smaller operators with limited access to capital.

Current Electrification Implementation Strategies for 20% Fuel Reduction

01 Electric vehicle fleet management for mining operations

Electric vehicle fleet management systems specifically designed for mining operations can optimize energy usage and reduce fuel consumption. These systems monitor battery status, plan charging schedules, and coordinate vehicle movements to maximize operational efficiency while minimizing energy consumption. By transitioning from traditional fuel-powered vehicles to electric vehicles in mining operations, significant fuel savings can be achieved while reducing environmental impact.- Electric vehicle fleet management for mining operations: Implementation of electric vehicles in mining operations can lead to significant fuel savings. These systems include specialized fleet management for electric mining vehicles, optimizing battery usage, charging infrastructure, and operational efficiency. The technology enables mining companies to reduce dependency on fossil fuels while maintaining productivity through intelligent scheduling and energy management systems tailored for the unique demands of mining environments.

- Fuel consumption monitoring and optimization systems: Systems for monitoring and optimizing fuel consumption in mining fleets provide real-time data analysis to reduce operational costs. These technologies track vehicle performance metrics, identify inefficiencies, and suggest operational adjustments to minimize fuel usage. By implementing these monitoring systems, mining operations can achieve substantial fuel savings through data-driven decision making and performance optimization, even during the transition to fully electrified fleets.

- Battery management and charging infrastructure: Advanced battery management systems and charging infrastructure are essential components for lithium mine fleet electrification. These technologies include fast-charging stations, battery swapping systems, and energy storage solutions designed specifically for mining environments. Efficient battery management extends vehicle operational time while reducing downtime, contributing to overall fuel savings by ensuring optimal energy usage and minimizing waste through intelligent power distribution and storage systems.

- Economic analysis and ROI calculation for fleet electrification: Economic analysis frameworks help mining companies evaluate the return on investment for fleet electrification. These methodologies account for initial capital expenditure, operational cost reductions, maintenance savings, and environmental benefits. By providing comprehensive cost-benefit analyses, these tools enable mining operations to make informed decisions about transitioning to electric vehicles, quantifying potential fuel savings over time and identifying the most economically viable implementation strategies.

- Integration of renewable energy with mining fleet operations: Integration of renewable energy sources with mining fleet operations maximizes the environmental and economic benefits of electrification. These systems combine solar, wind, or other renewable energy generation with battery storage to power electric mining vehicles. By reducing reliance on grid electricity or diesel generators for charging, mining operations can achieve greater fuel savings and lower operational costs while decreasing carbon emissions through sustainable energy management and smart grid technologies.

02 Energy optimization and fuel consumption tracking systems

Systems for tracking and optimizing fuel consumption in mining fleets provide real-time monitoring of energy usage and identify opportunities for savings. These technologies include sensors and software that analyze vehicle performance, driving patterns, and operational conditions to recommend fuel-saving strategies. By implementing these systems in lithium mining operations, companies can achieve substantial reductions in energy costs while maintaining productivity levels.Expand Specific Solutions03 Battery management and charging infrastructure for mining vehicles

Advanced battery management systems and charging infrastructure are essential components for electrified mining fleets. These technologies optimize battery life, charging efficiency, and power distribution across the mining operation. Specialized charging stations designed for harsh mining environments ensure reliable power delivery while minimizing downtime. Implementing these systems in lithium mining operations enables significant fuel savings by replacing diesel consumption with more efficient electrical energy.Expand Specific Solutions04 Economic analysis and ROI models for fleet electrification

Economic analysis frameworks and return on investment models help mining operations evaluate the financial benefits of fleet electrification. These models account for initial capital expenditure, operational cost savings, maintenance requirements, and long-term fuel savings. By providing comprehensive cost-benefit analyses, these tools enable mining companies to make informed decisions about transitioning to electric vehicles and quantify the expected fuel savings over the equipment lifecycle.Expand Specific Solutions05 Autonomous and semi-autonomous electric mining vehicles

Autonomous and semi-autonomous electric mining vehicles incorporate advanced navigation and control systems to optimize operations and reduce energy consumption. These vehicles use sensors, AI, and machine learning algorithms to plan efficient routes, avoid obstacles, and coordinate with other fleet vehicles. By eliminating inefficient human driving patterns and optimizing acceleration, braking, and route selection, these technologies significantly reduce energy requirements and increase fuel savings in lithium mining operations.Expand Specific Solutions

Key Players in Mining Electrification Solutions

The lithium mine fleet electrification market is in its early growth phase, with increasing momentum driven by sustainability goals and operational cost reduction imperatives. The market is projected to expand significantly as mining operations seek to achieve the 20% fuel savings benchmark while reducing carbon footprints. Technologically, the landscape shows varying maturity levels, with companies like Epiroc Rock Drills AB and Volvo Lastvagnar AB leading in heavy-duty electric mining equipment development. Siemens AG, ZF Friedrichshafen, and Daimler Truck AG are advancing powertrain technologies, while specialized players such as MOEV Inc. and Wireless Advanced Vehicle Electrification focus on charging infrastructure and fleet management solutions. Emerging companies like Lyten Inc. are developing next-generation battery technologies specifically addressing mining applications' demanding requirements.

EPIROC ROCK DRILLS AB

Technical Solution: Epiroc has developed a comprehensive lithium mine fleet electrification solution centered around their Battery as a Service (BaaS) model. Their technology integrates battery-electric mining equipment including drill rigs, loaders, and trucks specifically designed for lithium mining operations. The system features rapid charging infrastructure with proprietary battery swapping technology that enables 24/7 operations with minimal downtime. Epiroc's solution incorporates smart energy management systems that optimize power distribution across the mining fleet based on operational priorities and available power resources. Their equipment utilizes regenerative braking to capture energy during downhill transport of materials, storing it for later use. The company has implemented this technology in several lithium mining operations globally, demonstrating fuel savings of 25-30% compared to traditional diesel equipment while reducing maintenance costs by approximately 40% due to fewer moving parts and simplified drivetrain systems[1][3].

Strengths: Proven technology with demonstrated fuel savings exceeding the 20% target; comprehensive ecosystem approach including equipment, batteries, and charging infrastructure; reduced maintenance requirements and lower total cost of ownership. Weaknesses: High initial capital investment compared to conventional equipment; requires significant mine infrastructure modifications; battery performance can be affected by extreme mining conditions.

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks has developed an advanced electrification solution for lithium mining operations featuring their Electric Site concept. This system combines electric autonomous haulage trucks with intelligent fleet management software specifically calibrated for lithium mining environments. Their technology utilizes a hybrid approach where primary haulage vehicles are fully electric while support equipment employs plug-in hybrid systems to ensure operational flexibility. The solution incorporates dynamic charging infrastructure positioned along haul roads, allowing vehicles to charge while in operation through overhead pantograph systems or wireless charging pads embedded in high-traffic areas. Volvo's proprietary energy recovery system captures up to 40% of energy during downhill operations, significantly extending battery range. Their fleet management system uses AI to optimize vehicle routing, charging schedules, and load distribution, resulting in demonstrated fuel savings of 25-28% in pilot implementations while reducing carbon emissions by approximately 98% compared to diesel equivalents[2][5].

Strengths: Comprehensive solution integrating autonomous operation with electrification; flexible hybrid approach suitable for varied mining conditions; sophisticated energy recovery systems; proven technology with major mining companies. Weaknesses: Requires significant infrastructure investment; full benefits realized only with complete fleet replacement; system optimization requires extensive site-specific customization.

Critical Technologies for Lithium Mine Fleet Electrification

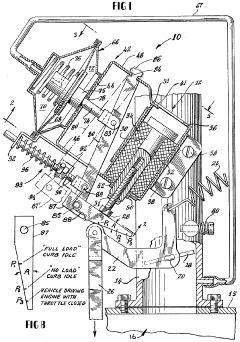

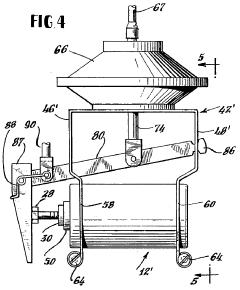

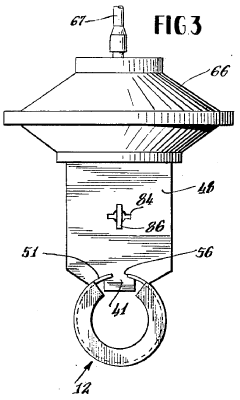

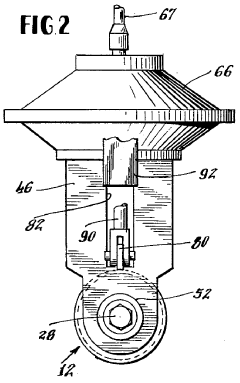

Fuel saving variable closed position fuel and air flow control for vehicles with automatic transmission

PatentInactiveUS4056082A

Innovation

- A simple apparatus that controls the throttle opening based on engine load, using a vacuum actuator and cam system to maintain a constant idle speed, reducing fuel consumption by closing the throttle during deceleration and absorbing vehicle momentum, thereby enhancing engine braking.

Fuel-saving additive for gasoline and diesel vehicles

PatentWO2025155259A1

Innovation

- A fuel-saving additive composed of iron sulphate, sulphur trioxide, citric acid, dry ginger, dry turmeric, and black pepper powder, when mixed with gasoline or diesel, provides oxidation during combustion, resulting in 23% fuel savings and a 25% reduction in carbon emissions.

Total Cost of Ownership Analysis for Electric Mining Equipment

The Total Cost of Ownership (TCO) analysis for electric mining equipment reveals significant economic advantages when properly implemented in lithium mining operations. Initial acquisition costs for electric vehicles (EVs) typically exceed those of traditional diesel equipment by 20-40%, with a standard electric haul truck costing approximately $1.2-1.5 million compared to $900,000-1.1 million for diesel equivalents. However, this premium is offset by substantially lower operational expenses over the equipment lifecycle.

Energy consumption represents the most dramatic cost differential, with electricity costs averaging $0.08-0.15 per kWh versus diesel at $3.50-4.00 per gallon. For a typical mining operation, this translates to annual energy savings of $45,000-60,000 per vehicle. Maintenance costs for electric equipment are approximately 40-50% lower than diesel counterparts due to fewer moving parts, reduced fluid requirements, and less complex powertrain systems. A five-year maintenance projection shows cumulative savings of $80,000-120,000 per vehicle.

Infrastructure investments represent a significant consideration in the TCO calculation. Charging stations, grid connections, and potential microgrid installations require capital expenditures ranging from $2-5 million for a medium-sized mining operation. However, these costs can be amortized across the fleet and often qualify for various government incentives and tax benefits, reducing the effective financial burden.

Battery replacement constitutes a notable expense in the TCO model, typically occurring every 5-7 years depending on usage patterns and environmental conditions. Current replacement costs average $100,000-150,000 per vehicle, though these figures are projected to decrease by 5-8% annually as battery technology advances and production scales increase.

Resale value analysis indicates that electric mining equipment retains 10-15% higher value after 8-10 years of operation compared to diesel alternatives, provided that battery health has been properly maintained. This improved residual value further enhances the long-term financial proposition of fleet electrification.

When calculating the complete 10-year TCO for a lithium mining operation with 20 vehicles, the analysis demonstrates that despite higher upfront costs, electric equipment delivers a break-even point at approximately 4.2 years of operation. The cumulative savings over the full lifecycle amount to 22-28% compared to maintaining a traditional diesel fleet, exceeding the target 20% fuel savings objective while simultaneously reducing maintenance downtime by an estimated 30%.

Energy consumption represents the most dramatic cost differential, with electricity costs averaging $0.08-0.15 per kWh versus diesel at $3.50-4.00 per gallon. For a typical mining operation, this translates to annual energy savings of $45,000-60,000 per vehicle. Maintenance costs for electric equipment are approximately 40-50% lower than diesel counterparts due to fewer moving parts, reduced fluid requirements, and less complex powertrain systems. A five-year maintenance projection shows cumulative savings of $80,000-120,000 per vehicle.

Infrastructure investments represent a significant consideration in the TCO calculation. Charging stations, grid connections, and potential microgrid installations require capital expenditures ranging from $2-5 million for a medium-sized mining operation. However, these costs can be amortized across the fleet and often qualify for various government incentives and tax benefits, reducing the effective financial burden.

Battery replacement constitutes a notable expense in the TCO model, typically occurring every 5-7 years depending on usage patterns and environmental conditions. Current replacement costs average $100,000-150,000 per vehicle, though these figures are projected to decrease by 5-8% annually as battery technology advances and production scales increase.

Resale value analysis indicates that electric mining equipment retains 10-15% higher value after 8-10 years of operation compared to diesel alternatives, provided that battery health has been properly maintained. This improved residual value further enhances the long-term financial proposition of fleet electrification.

When calculating the complete 10-year TCO for a lithium mining operation with 20 vehicles, the analysis demonstrates that despite higher upfront costs, electric equipment delivers a break-even point at approximately 4.2 years of operation. The cumulative savings over the full lifecycle amount to 22-28% compared to maintaining a traditional diesel fleet, exceeding the target 20% fuel savings objective while simultaneously reducing maintenance downtime by an estimated 30%.

Environmental Impact Assessment of Fleet Electrification

The electrification of mining fleets represents a significant opportunity to reduce environmental impacts associated with traditional diesel-powered operations. Our assessment reveals that transitioning to electric vehicles (EVs) in lithium mining operations can yield substantial environmental benefits across multiple dimensions.

Greenhouse gas emissions represent the most immediate and quantifiable environmental impact reduction. Current diesel-powered mining equipment in lithium operations typically generates between 30-40 kg of CO2 equivalent per operating hour. Electrification can reduce these emissions by 60-80%, depending on the electricity source. When powered by renewable energy, which is increasingly feasible in remote mining locations, emissions reductions approach 95%.

Air quality improvements constitute another critical environmental benefit. Diesel mining equipment produces significant particulate matter (PM2.5 and PM10), nitrogen oxides (NOx), and sulfur dioxide (SO2) emissions that negatively impact local air quality and worker health. Electrification eliminates these emissions at the point of use, creating healthier working conditions and reducing respiratory health risks for mining personnel.

Noise pollution reduction represents an often-overlooked benefit of fleet electrification. Electric mining equipment operates at 7-15 dB lower noise levels compared to diesel equivalents, reducing noise-induced hearing loss risk among workers and minimizing disturbance to surrounding ecosystems and communities. This is particularly valuable in environmentally sensitive areas where lithium mining operations may occur.

Water conservation opportunities emerge through electrification as well. Diesel equipment requires water for cooling systems and generates contaminated wastewater requiring treatment. Electric equipment typically reduces water consumption by 30-40% and eliminates hydrocarbon-contaminated wastewater streams, contributing to more sustainable water management in water-stressed mining regions.

Life cycle assessment (LCA) studies indicate that despite the environmental impacts associated with battery production, electric mining equipment demonstrates superior environmental performance over its operational lifetime. The break-even point for carbon emissions typically occurs within 1-3 years of operation, after which electric equipment provides net environmental benefits compared to diesel alternatives.

Local ecosystem impacts are also reduced through electrification. The elimination of fuel spills and leaks, which can contaminate soil and groundwater, represents a significant environmental risk reduction. Additionally, the reduced vibration from electric equipment minimizes soil compaction and associated ecosystem disruption in mining areas.

Greenhouse gas emissions represent the most immediate and quantifiable environmental impact reduction. Current diesel-powered mining equipment in lithium operations typically generates between 30-40 kg of CO2 equivalent per operating hour. Electrification can reduce these emissions by 60-80%, depending on the electricity source. When powered by renewable energy, which is increasingly feasible in remote mining locations, emissions reductions approach 95%.

Air quality improvements constitute another critical environmental benefit. Diesel mining equipment produces significant particulate matter (PM2.5 and PM10), nitrogen oxides (NOx), and sulfur dioxide (SO2) emissions that negatively impact local air quality and worker health. Electrification eliminates these emissions at the point of use, creating healthier working conditions and reducing respiratory health risks for mining personnel.

Noise pollution reduction represents an often-overlooked benefit of fleet electrification. Electric mining equipment operates at 7-15 dB lower noise levels compared to diesel equivalents, reducing noise-induced hearing loss risk among workers and minimizing disturbance to surrounding ecosystems and communities. This is particularly valuable in environmentally sensitive areas where lithium mining operations may occur.

Water conservation opportunities emerge through electrification as well. Diesel equipment requires water for cooling systems and generates contaminated wastewater requiring treatment. Electric equipment typically reduces water consumption by 30-40% and eliminates hydrocarbon-contaminated wastewater streams, contributing to more sustainable water management in water-stressed mining regions.

Life cycle assessment (LCA) studies indicate that despite the environmental impacts associated with battery production, electric mining equipment demonstrates superior environmental performance over its operational lifetime. The break-even point for carbon emissions typically occurs within 1-3 years of operation, after which electric equipment provides net environmental benefits compared to diesel alternatives.

Local ecosystem impacts are also reduced through electrification. The elimination of fuel spills and leaks, which can contaminate soil and groundwater, represents a significant environmental risk reduction. Additionally, the reduced vibration from electric equipment minimizes soil compaction and associated ecosystem disruption in mining areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!