Assessing Environmental Regulations Impacting Hypochlorous Acid

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hypochlorous Acid Regulatory Landscape

The regulatory landscape surrounding hypochlorous acid (HOCl) is complex and multifaceted, reflecting its diverse applications and potential environmental impacts. In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating HOCl under various statutes, including the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and the Clean Water Act (CWA).

Under FIFRA, HOCl is classified as a pesticide when used for antimicrobial purposes. This classification requires manufacturers to register their products with the EPA, providing extensive data on efficacy, safety, and environmental impact. The registration process involves rigorous testing and review, ensuring that HOCl-based products meet stringent safety standards before entering the market.

The Clean Water Act also impacts HOCl regulation, particularly in industrial and municipal settings. Facilities using or producing HOCl must adhere to effluent guidelines and obtain necessary permits under the National Pollutant Discharge Elimination System (NPDES). These regulations aim to control the release of chlorine-based compounds into water bodies, mitigating potential ecological harm.

Internationally, the regulatory approach to HOCl varies. The European Union, through its Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, requires manufacturers and importers to register HOCl and provide safety data. This process ensures a comprehensive assessment of HOCl's environmental and health impacts within the EU market.

In Asia, countries like Japan and South Korea have implemented their own chemical control laws, which include provisions for HOCl. These regulations often focus on labeling requirements, safety data sheets, and risk assessment procedures for chemical substances, including HOCl.

The World Health Organization (WHO) provides guidelines on the use of HOCl in drinking water treatment, influencing regulatory decisions in many countries. These guidelines establish acceptable levels of chlorine-based disinfectants in potable water, balancing microbial safety with potential health risks from disinfection by-products.

Emerging regulations are increasingly focusing on the environmental fate of HOCl and its by-products. Concerns about the formation of disinfection by-products, such as trihalomethanes and haloacetic acids, have led to more stringent monitoring requirements and treatment techniques in water management systems.

As environmental awareness grows, regulatory bodies are also considering the lifecycle impact of HOCl production and use. This includes assessing the energy consumption and carbon footprint associated with HOCl generation, as well as the environmental implications of its precursor materials, such as sodium chloride used in electrolytic production methods.

Under FIFRA, HOCl is classified as a pesticide when used for antimicrobial purposes. This classification requires manufacturers to register their products with the EPA, providing extensive data on efficacy, safety, and environmental impact. The registration process involves rigorous testing and review, ensuring that HOCl-based products meet stringent safety standards before entering the market.

The Clean Water Act also impacts HOCl regulation, particularly in industrial and municipal settings. Facilities using or producing HOCl must adhere to effluent guidelines and obtain necessary permits under the National Pollutant Discharge Elimination System (NPDES). These regulations aim to control the release of chlorine-based compounds into water bodies, mitigating potential ecological harm.

Internationally, the regulatory approach to HOCl varies. The European Union, through its Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, requires manufacturers and importers to register HOCl and provide safety data. This process ensures a comprehensive assessment of HOCl's environmental and health impacts within the EU market.

In Asia, countries like Japan and South Korea have implemented their own chemical control laws, which include provisions for HOCl. These regulations often focus on labeling requirements, safety data sheets, and risk assessment procedures for chemical substances, including HOCl.

The World Health Organization (WHO) provides guidelines on the use of HOCl in drinking water treatment, influencing regulatory decisions in many countries. These guidelines establish acceptable levels of chlorine-based disinfectants in potable water, balancing microbial safety with potential health risks from disinfection by-products.

Emerging regulations are increasingly focusing on the environmental fate of HOCl and its by-products. Concerns about the formation of disinfection by-products, such as trihalomethanes and haloacetic acids, have led to more stringent monitoring requirements and treatment techniques in water management systems.

As environmental awareness grows, regulatory bodies are also considering the lifecycle impact of HOCl production and use. This includes assessing the energy consumption and carbon footprint associated with HOCl generation, as well as the environmental implications of its precursor materials, such as sodium chloride used in electrolytic production methods.

Market Demand Analysis

The market demand for hypochlorous acid (HOCl) has been steadily increasing due to its versatile applications and growing awareness of its benefits. As a powerful yet safe disinfectant, HOCl has gained significant traction in various industries, particularly in healthcare, food processing, and water treatment sectors.

In the healthcare industry, the demand for HOCl has surged, driven by its effectiveness against a wide range of pathogens, including bacteria, viruses, and fungi. Hospitals, clinics, and other medical facilities are increasingly adopting HOCl-based solutions for surface disinfection, wound care, and sterilization purposes. The ongoing global health concerns have further accelerated this trend, with healthcare providers seeking safer and more efficient disinfection methods.

The food processing industry has also recognized the potential of HOCl as a food-safe sanitizer. Its ability to effectively eliminate foodborne pathogens without leaving harmful residues has made it an attractive alternative to traditional chemical sanitizers. As consumers become more health-conscious and demand cleaner food production processes, the market for HOCl in this sector is expected to grow substantially.

Water treatment applications represent another significant market for HOCl. Municipal water treatment facilities and industrial water systems are exploring HOCl as an environmentally friendly alternative to chlorine-based disinfectants. Its effectiveness in controlling biofilm formation and reducing the risk of waterborne diseases has positioned HOCl as a promising solution for sustainable water management.

The agriculture sector is emerging as a new frontier for HOCl applications. Farmers are increasingly using HOCl for crop protection, seed treatment, and post-harvest sanitation. The growing emphasis on organic farming and reduced chemical usage in agriculture is likely to drive further demand for HOCl-based products in this sector.

Consumer products featuring HOCl are also gaining popularity, particularly in personal care and household cleaning categories. The non-toxic nature of HOCl and its effectiveness against common household germs have led to the development of various spray disinfectants, hand sanitizers, and cleaning solutions for domestic use.

Despite the positive market outlook, the growth of HOCl demand is not without challenges. Environmental regulations play a crucial role in shaping the market landscape. While HOCl is generally considered environmentally friendly, its production methods and potential byproducts are subject to scrutiny. Manufacturers must navigate complex regulatory frameworks to ensure compliance with environmental standards, which can impact production costs and market accessibility.

As environmental regulations continue to evolve, the HOCl market is likely to see further innovations in production technologies and application methods. Companies investing in research and development to improve HOCl stability, reduce production costs, and expand its applications are poised to capture significant market share. The interplay between market demand and environmental regulations will be a key factor in determining the long-term growth trajectory of the HOCl industry.

In the healthcare industry, the demand for HOCl has surged, driven by its effectiveness against a wide range of pathogens, including bacteria, viruses, and fungi. Hospitals, clinics, and other medical facilities are increasingly adopting HOCl-based solutions for surface disinfection, wound care, and sterilization purposes. The ongoing global health concerns have further accelerated this trend, with healthcare providers seeking safer and more efficient disinfection methods.

The food processing industry has also recognized the potential of HOCl as a food-safe sanitizer. Its ability to effectively eliminate foodborne pathogens without leaving harmful residues has made it an attractive alternative to traditional chemical sanitizers. As consumers become more health-conscious and demand cleaner food production processes, the market for HOCl in this sector is expected to grow substantially.

Water treatment applications represent another significant market for HOCl. Municipal water treatment facilities and industrial water systems are exploring HOCl as an environmentally friendly alternative to chlorine-based disinfectants. Its effectiveness in controlling biofilm formation and reducing the risk of waterborne diseases has positioned HOCl as a promising solution for sustainable water management.

The agriculture sector is emerging as a new frontier for HOCl applications. Farmers are increasingly using HOCl for crop protection, seed treatment, and post-harvest sanitation. The growing emphasis on organic farming and reduced chemical usage in agriculture is likely to drive further demand for HOCl-based products in this sector.

Consumer products featuring HOCl are also gaining popularity, particularly in personal care and household cleaning categories. The non-toxic nature of HOCl and its effectiveness against common household germs have led to the development of various spray disinfectants, hand sanitizers, and cleaning solutions for domestic use.

Despite the positive market outlook, the growth of HOCl demand is not without challenges. Environmental regulations play a crucial role in shaping the market landscape. While HOCl is generally considered environmentally friendly, its production methods and potential byproducts are subject to scrutiny. Manufacturers must navigate complex regulatory frameworks to ensure compliance with environmental standards, which can impact production costs and market accessibility.

As environmental regulations continue to evolve, the HOCl market is likely to see further innovations in production technologies and application methods. Companies investing in research and development to improve HOCl stability, reduce production costs, and expand its applications are poised to capture significant market share. The interplay between market demand and environmental regulations will be a key factor in determining the long-term growth trajectory of the HOCl industry.

Environmental Impact Assessment

The environmental impact assessment of hypochlorous acid (HOCl) production and use is crucial for understanding its regulatory landscape. HOCl, a weak acid with powerful disinfectant properties, has gained prominence in various applications, particularly in water treatment, healthcare, and cleaning industries. However, its production and use are subject to stringent environmental regulations due to potential ecological and health concerns.

The primary environmental considerations for HOCl revolve around its production methods and disposal practices. The most common production method involves the electrolysis of salt water, which can have implications for energy consumption and brine disposal. Regulatory bodies, such as the Environmental Protection Agency (EPA) in the United States, have established guidelines for the safe production and handling of HOCl to minimize environmental impact.

Water quality is a significant concern in HOCl regulation. When used in water treatment, HOCl can form disinfection by-products (DBPs) such as trihalomethanes (THMs) and haloacetic acids (HAAs). These by-products are regulated under the Safe Drinking Water Act, with strict limits on their presence in drinking water due to potential health risks. Consequently, water treatment facilities must carefully monitor and control HOCl dosage to balance effective disinfection with DBP formation.

Air quality regulations also apply to HOCl production and use, particularly in industrial settings. The release of chlorine gas, a potential by-product of HOCl production, is regulated under the Clean Air Act. Facilities must implement proper ventilation systems and safety protocols to prevent accidental releases and protect worker health.

Waste management is another critical aspect of HOCl environmental regulation. The disposal of HOCl and its by-products must comply with hazardous waste regulations, including proper neutralization and treatment before release into the environment. The Resource Conservation and Recovery Act (RCRA) in the United States provides guidelines for the handling and disposal of HOCl-related waste.

Ecological impact assessments have shown that HOCl can be harmful to aquatic life if released in high concentrations. Regulatory bodies have established effluent limitations and monitoring requirements to protect sensitive ecosystems. These regulations often require facilities to implement advanced treatment technologies to reduce HOCl concentrations in wastewater before discharge.

The global regulatory landscape for HOCl varies, with some countries adopting more stringent measures than others. For instance, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes additional requirements on HOCl producers and users, including comprehensive safety data sheets and exposure scenarios.

As environmental concerns continue to grow, regulatory trends indicate a move towards more sustainable production methods for HOCl. This includes the development of on-site generation technologies that reduce transportation risks and promote more efficient use of resources. Future regulations may incentivize or mandate the adoption of these greener technologies to further mitigate environmental impacts.

The primary environmental considerations for HOCl revolve around its production methods and disposal practices. The most common production method involves the electrolysis of salt water, which can have implications for energy consumption and brine disposal. Regulatory bodies, such as the Environmental Protection Agency (EPA) in the United States, have established guidelines for the safe production and handling of HOCl to minimize environmental impact.

Water quality is a significant concern in HOCl regulation. When used in water treatment, HOCl can form disinfection by-products (DBPs) such as trihalomethanes (THMs) and haloacetic acids (HAAs). These by-products are regulated under the Safe Drinking Water Act, with strict limits on their presence in drinking water due to potential health risks. Consequently, water treatment facilities must carefully monitor and control HOCl dosage to balance effective disinfection with DBP formation.

Air quality regulations also apply to HOCl production and use, particularly in industrial settings. The release of chlorine gas, a potential by-product of HOCl production, is regulated under the Clean Air Act. Facilities must implement proper ventilation systems and safety protocols to prevent accidental releases and protect worker health.

Waste management is another critical aspect of HOCl environmental regulation. The disposal of HOCl and its by-products must comply with hazardous waste regulations, including proper neutralization and treatment before release into the environment. The Resource Conservation and Recovery Act (RCRA) in the United States provides guidelines for the handling and disposal of HOCl-related waste.

Ecological impact assessments have shown that HOCl can be harmful to aquatic life if released in high concentrations. Regulatory bodies have established effluent limitations and monitoring requirements to protect sensitive ecosystems. These regulations often require facilities to implement advanced treatment technologies to reduce HOCl concentrations in wastewater before discharge.

The global regulatory landscape for HOCl varies, with some countries adopting more stringent measures than others. For instance, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes additional requirements on HOCl producers and users, including comprehensive safety data sheets and exposure scenarios.

As environmental concerns continue to grow, regulatory trends indicate a move towards more sustainable production methods for HOCl. This includes the development of on-site generation technologies that reduce transportation risks and promote more efficient use of resources. Future regulations may incentivize or mandate the adoption of these greener technologies to further mitigate environmental impacts.

Current Compliance Solutions

01 Production methods of hypochlorous acid

Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and the use of specialized equipment for on-site generation. These methods aim to create stable and effective hypochlorous acid solutions for different applications.- Production methods of hypochlorous acid: Various methods are employed to produce hypochlorous acid, including electrolysis of salt solutions, chemical reactions involving chlorine and water, and controlled mixing of precursor chemicals. These production methods aim to create stable and effective hypochlorous acid solutions for different applications.

- Antimicrobial applications of hypochlorous acid: Hypochlorous acid is widely used as an antimicrobial agent in various fields, including healthcare, food processing, and water treatment. Its effectiveness against a broad spectrum of pathogens, combined with its low toxicity to humans, makes it a valuable disinfectant and sanitizer.

- Stabilization techniques for hypochlorous acid solutions: Researchers have developed various stabilization techniques to prolong the shelf life and maintain the efficacy of hypochlorous acid solutions. These methods may involve pH adjustment, addition of stabilizing agents, or specialized packaging to prevent degradation and ensure consistent performance over time.

- Medical and therapeutic uses of hypochlorous acid: Hypochlorous acid has found applications in various medical and therapeutic contexts, including wound care, eye care, and respiratory treatments. Its ability to effectively kill pathogens while being gentle on human tissues makes it a promising option for treating infections and promoting healing.

- Environmental and industrial applications of hypochlorous acid: Hypochlorous acid is utilized in various environmental and industrial applications, such as water treatment, agriculture, and surface disinfection. Its eco-friendly nature and effectiveness in removing contaminants make it a preferred choice for sustainable cleaning and sanitization processes.

02 Applications in disinfection and sterilization

Hypochlorous acid is widely used as a powerful disinfectant and sterilizing agent. It is effective against a broad spectrum of microorganisms, including bacteria, viruses, and fungi. Applications include water treatment, surface disinfection, and medical sterilization.Expand Specific Solutions03 Formulations and stability enhancement

Research focuses on developing stable formulations of hypochlorous acid to extend its shelf life and maintain its efficacy. This includes the use of stabilizers, pH adjustments, and packaging innovations to prevent degradation and ensure long-term stability of the solution.Expand Specific Solutions04 Medical and therapeutic applications

Hypochlorous acid is explored for various medical and therapeutic uses due to its antimicrobial properties and low toxicity. Applications include wound care, eye care, respiratory treatments, and dermatological therapies. Research focuses on optimizing concentrations and delivery methods for these applications.Expand Specific Solutions05 Environmental and industrial uses

Hypochlorous acid finds applications in environmental remediation and industrial processes. It is used in water treatment, agriculture for crop protection, food processing for sanitization, and in various industrial cleaning processes. Research focuses on developing eco-friendly and efficient applications in these sectors.Expand Specific Solutions

Key Stakeholders Analysis

The environmental regulations impacting hypochlorous acid are shaping a competitive landscape in an industry that is still in its growth phase. The market for hypochlorous acid is expanding, driven by increasing awareness of its eco-friendly and effective disinfection properties. Companies like WIAB WATER INNOVATION AB, Fluid Energy Group Ltd., and ANNIHILARE MEDICAL SYSTEMS, INC. are at the forefront of developing and commercializing hypochlorous acid technologies. The technical maturity of hypochlorous acid production varies, with established players like Industrie De Nora SpA offering advanced electrochemical solutions, while newer entrants focus on innovative applications and delivery systems. As regulations evolve, companies are investing in research and development to ensure compliance and maintain a competitive edge in this growing market.

Fluid Energy Group Ltd.

Technical Solution: Fluid Energy Group Ltd. has developed a unique approach to hypochlorous acid production that focuses on minimizing environmental impact. Their technology utilizes a proprietary electrolysis process that generates hypochlorous acid with significantly reduced byproducts compared to traditional methods[10]. The company has implemented advanced filtration and purification systems to ensure that their hypochlorous acid meets stringent environmental standards for discharge and use[11]. Fluid Energy Group has also invested in renewable energy sources to power their production facilities, further reducing the carbon footprint of their operations[12].

Strengths: Reduced byproduct generation; advanced purification systems; use of renewable energy in production. Weaknesses: Potentially higher production costs due to advanced technology; may require specialized equipment for large-scale production.

Industrie De Nora SpA

Technical Solution: Industrie De Nora SpA has developed advanced electrochemical technologies for the production of hypochlorous acid. Their approach involves using dimensionally stable anodes (DSA) in electrolysis cells to generate hypochlorous acid on-site[1]. This method allows for precise control of the concentration and pH of the produced solution, ensuring compliance with environmental regulations. The company has also implemented a closed-loop system that minimizes waste and reduces the environmental impact of the production process[2]. Additionally, De Nora has invested in research to optimize the energy efficiency of their electrolysis cells, resulting in a significant reduction in power consumption compared to traditional chlorine production methods[3].

Strengths: On-site generation reduces transportation and storage risks; precise control over product quality; energy-efficient process. Weaknesses: Initial setup costs may be high; requires specialized technical knowledge for operation and maintenance.

Innovative Regulatory Approaches

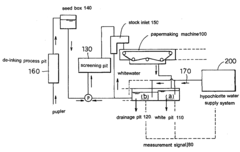

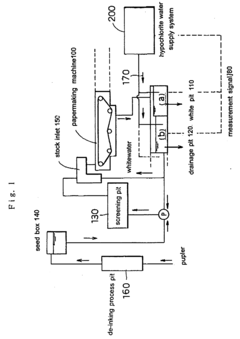

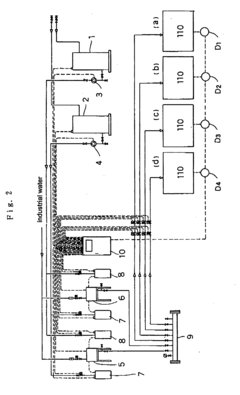

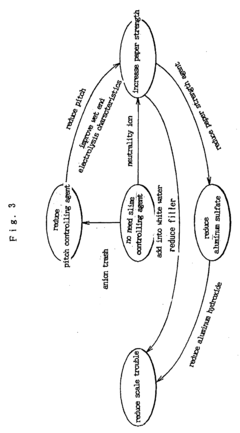

Method of Papermaking

PatentInactiveUS20090114353A1

Innovation

- The use of a chlorine series oxidizing agent, specifically acidic sodium hypochlorite aqueous solutions, is introduced to oxidize reductive materials, providing a strong bactericidal effect, controlling slime and pitch, and decomposing organic matter, thereby optimizing the papermaking environment and enabling the reuse of processed water.

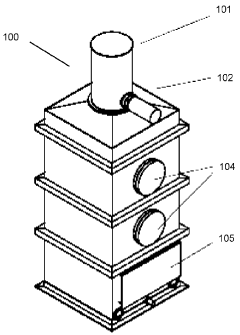

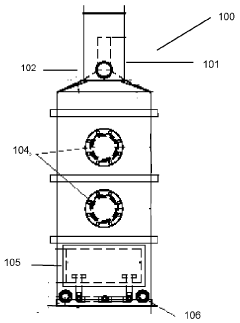

Improved method and system for treatment of PFAS contaminated wastewater and other contaminants utilizing NANO-aeration foam fractionation

PatentWO2024044860A1

Innovation

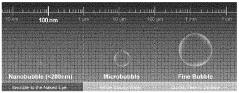

- The use of nanobubble technology in foam fractionation, which introduces nanobubbles with diameters less than 1000 nm to enhance the removal efficiency of PFAS contaminants by creating a foam fractionation process that concentrates and separates PFAS without the need for co-surfactants, achieving high removal rates of both short-chain and long-chain PFAS molecules.

Economic Implications

The economic implications of environmental regulations impacting hypochlorous acid (HOCl) production and use are multifaceted and far-reaching. These regulations, aimed at protecting human health and the environment, have significant effects on various industries and market dynamics.

Firstly, the implementation of stringent environmental regulations often leads to increased production costs for HOCl manufacturers. Companies may need to invest in new equipment, modify existing processes, or develop alternative production methods to comply with emission standards and waste management requirements. This can result in higher prices for HOCl products, potentially affecting downstream industries that rely on this chemical.

The agricultural sector, a major consumer of HOCl for disinfection and sanitation purposes, may experience increased operational costs due to these regulations. Farmers and food processors might need to adjust their practices or seek alternative solutions, potentially impacting food production costs and, ultimately, consumer prices.

On the other hand, environmental regulations can stimulate innovation and create new market opportunities. Companies that develop eco-friendly HOCl production methods or alternative disinfection technologies may gain a competitive advantage. This can lead to the emergence of new businesses and job creation in the green technology sector.

The healthcare industry, another significant user of HOCl, may face challenges in balancing regulatory compliance with the need for effective disinfection. Hospitals and medical facilities might need to invest in new equipment or training, potentially affecting healthcare costs. However, improved safety standards could lead to better health outcomes and reduced long-term healthcare expenses.

Environmental regulations can also impact international trade. Countries with stricter regulations may face challenges in competing with those with more lenient standards, potentially leading to shifts in global market shares for HOCl and related products. This could influence trade policies and international agreements related to chemical production and environmental protection.

The water treatment industry, which uses HOCl for disinfection, may need to adapt its processes to comply with new regulations. This could lead to increased costs for water utilities and, consequently, higher water bills for consumers. However, improved water quality standards could result in long-term public health benefits and reduced healthcare costs associated with waterborne diseases.

In conclusion, while environmental regulations on HOCl may initially pose economic challenges, they also drive innovation, create new market opportunities, and potentially lead to long-term economic benefits through improved public health and environmental quality. Balancing these factors is crucial for policymakers and industry stakeholders in navigating the complex landscape of environmental regulations and their economic implications.

Firstly, the implementation of stringent environmental regulations often leads to increased production costs for HOCl manufacturers. Companies may need to invest in new equipment, modify existing processes, or develop alternative production methods to comply with emission standards and waste management requirements. This can result in higher prices for HOCl products, potentially affecting downstream industries that rely on this chemical.

The agricultural sector, a major consumer of HOCl for disinfection and sanitation purposes, may experience increased operational costs due to these regulations. Farmers and food processors might need to adjust their practices or seek alternative solutions, potentially impacting food production costs and, ultimately, consumer prices.

On the other hand, environmental regulations can stimulate innovation and create new market opportunities. Companies that develop eco-friendly HOCl production methods or alternative disinfection technologies may gain a competitive advantage. This can lead to the emergence of new businesses and job creation in the green technology sector.

The healthcare industry, another significant user of HOCl, may face challenges in balancing regulatory compliance with the need for effective disinfection. Hospitals and medical facilities might need to invest in new equipment or training, potentially affecting healthcare costs. However, improved safety standards could lead to better health outcomes and reduced long-term healthcare expenses.

Environmental regulations can also impact international trade. Countries with stricter regulations may face challenges in competing with those with more lenient standards, potentially leading to shifts in global market shares for HOCl and related products. This could influence trade policies and international agreements related to chemical production and environmental protection.

The water treatment industry, which uses HOCl for disinfection, may need to adapt its processes to comply with new regulations. This could lead to increased costs for water utilities and, consequently, higher water bills for consumers. However, improved water quality standards could result in long-term public health benefits and reduced healthcare costs associated with waterborne diseases.

In conclusion, while environmental regulations on HOCl may initially pose economic challenges, they also drive innovation, create new market opportunities, and potentially lead to long-term economic benefits through improved public health and environmental quality. Balancing these factors is crucial for policymakers and industry stakeholders in navigating the complex landscape of environmental regulations and their economic implications.

International Regulatory Comparison

The international regulatory landscape for hypochlorous acid (HOCl) varies significantly across different regions, reflecting diverse approaches to environmental protection and chemical management. In the United States, the Environmental Protection Agency (EPA) regulates HOCl under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) as an antimicrobial pesticide. The EPA has established specific guidelines for its use in water treatment, food processing, and healthcare settings, with stringent requirements for product registration and labeling.

The European Union, through the European Chemicals Agency (ECHA), governs HOCl under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. REACH mandates comprehensive safety assessments and registration for chemicals produced or imported in quantities exceeding one tonne per year. Additionally, the EU's Biocidal Products Regulation (BPR) applies to HOCl when used as a disinfectant, imposing strict efficacy and safety standards.

In Japan, the Ministry of Health, Labour and Welfare oversees HOCl regulation, particularly in food safety applications. The Japanese regulatory framework emphasizes the importance of proper concentration levels and application methods to ensure safety and efficacy. The Japanese Industrial Standards (JIS) provide specific guidelines for HOCl production and quality control.

Australia's approach to HOCl regulation is managed by the Australian Pesticides and Veterinary Medicines Authority (APVMA). The APVMA requires thorough safety and efficacy data for HOCl products, especially those intended for agricultural or veterinary use. The National Industrial Chemicals Notification and Assessment Scheme (NICNAS) also plays a role in assessing the environmental impact of HOCl in industrial applications.

China's regulatory stance on HOCl is evolving, with the National Medical Products Administration (NMPA) overseeing its use in healthcare settings. The Ministry of Ecology and Environment is increasingly focusing on the environmental impact of chemical disinfectants, including HOCl, particularly in water treatment applications.

Globally, the World Health Organization (WHO) provides guidelines on the use of HOCl in drinking water treatment, influencing national policies worldwide. The Food and Agriculture Organization (FAO) also offers recommendations on HOCl use in food processing, which many countries incorporate into their regulatory frameworks.

These diverse regulatory approaches highlight the need for companies operating in the HOCl market to navigate a complex international landscape. Compliance with varying standards across different jurisdictions requires careful attention to product formulation, labeling, and application methods. As environmental concerns continue to shape regulatory policies, the HOCl industry must remain adaptable to evolving international standards and best practices.

The European Union, through the European Chemicals Agency (ECHA), governs HOCl under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. REACH mandates comprehensive safety assessments and registration for chemicals produced or imported in quantities exceeding one tonne per year. Additionally, the EU's Biocidal Products Regulation (BPR) applies to HOCl when used as a disinfectant, imposing strict efficacy and safety standards.

In Japan, the Ministry of Health, Labour and Welfare oversees HOCl regulation, particularly in food safety applications. The Japanese regulatory framework emphasizes the importance of proper concentration levels and application methods to ensure safety and efficacy. The Japanese Industrial Standards (JIS) provide specific guidelines for HOCl production and quality control.

Australia's approach to HOCl regulation is managed by the Australian Pesticides and Veterinary Medicines Authority (APVMA). The APVMA requires thorough safety and efficacy data for HOCl products, especially those intended for agricultural or veterinary use. The National Industrial Chemicals Notification and Assessment Scheme (NICNAS) also plays a role in assessing the environmental impact of HOCl in industrial applications.

China's regulatory stance on HOCl is evolving, with the National Medical Products Administration (NMPA) overseeing its use in healthcare settings. The Ministry of Ecology and Environment is increasingly focusing on the environmental impact of chemical disinfectants, including HOCl, particularly in water treatment applications.

Globally, the World Health Organization (WHO) provides guidelines on the use of HOCl in drinking water treatment, influencing national policies worldwide. The Food and Agriculture Organization (FAO) also offers recommendations on HOCl use in food processing, which many countries incorporate into their regulatory frameworks.

These diverse regulatory approaches highlight the need for companies operating in the HOCl market to navigate a complex international landscape. Compliance with varying standards across different jurisdictions requires careful attention to product formulation, labeling, and application methods. As environmental concerns continue to shape regulatory policies, the HOCl industry must remain adaptable to evolving international standards and best practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!