Assessing Magnetron Life Cycle: Cost Analysis Methods

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Technology Background and Lifecycle Goals

Magnetrons have evolved significantly since their invention in the early 20th century, transforming from experimental devices into critical components in various applications ranging from radar systems to household microwave ovens. The technology was first developed during World War II for military radar applications, where its ability to generate microwave radiation proved invaluable for detection systems. Since then, magnetron technology has undergone continuous refinement to enhance efficiency, reliability, and cost-effectiveness.

The evolution of magnetron technology has been characterized by several key trends, including miniaturization, increased power output, improved frequency stability, and extended operational lifespan. Modern magnetrons incorporate advanced materials and manufacturing techniques that have substantially improved their performance characteristics while reducing production costs. These improvements have enabled the widespread adoption of magnetrons across diverse industries, including telecommunications, medical equipment, and industrial heating applications.

Current lifecycle goals for magnetron technology focus on several critical aspects. First, extending operational lifespan remains a primary objective, as longer-lasting magnetrons reduce replacement frequency and overall lifecycle costs. Second, improving energy efficiency is crucial, particularly as energy costs rise and environmental considerations become more prominent in technology development. Third, enhancing reliability under varying operational conditions ensures consistent performance across applications.

Cost analysis methods for magnetrons have become increasingly sophisticated, moving beyond simple purchase price considerations to comprehensive lifecycle assessments. These methods now incorporate factors such as energy consumption, maintenance requirements, replacement schedules, and end-of-life disposal costs. Understanding the total cost of ownership has become essential for organizations deploying magnetron technology at scale.

The technical objectives for magnetron lifecycle assessment include developing standardized testing protocols to accurately predict lifespan under various operational conditions, creating more precise models for calculating total cost of ownership, and establishing industry benchmarks for performance and efficiency. These objectives support the broader goal of optimizing magnetron selection and utilization across different applications.

Recent technological innovations have introduced new possibilities for magnetron lifecycle management, including real-time monitoring systems that can predict failure before it occurs, adaptive power management to extend operational life, and modular designs that facilitate easier maintenance and component replacement. These innovations represent promising directions for further reducing lifecycle costs while improving overall system reliability.

As magnetron technology continues to evolve, future development will likely focus on addressing emerging challenges such as resource scarcity, environmental regulations, and increasing performance demands. The integration of digital technologies for lifecycle monitoring and management represents a particularly promising frontier for optimizing magnetron cost-effectiveness across their operational lifespan.

The evolution of magnetron technology has been characterized by several key trends, including miniaturization, increased power output, improved frequency stability, and extended operational lifespan. Modern magnetrons incorporate advanced materials and manufacturing techniques that have substantially improved their performance characteristics while reducing production costs. These improvements have enabled the widespread adoption of magnetrons across diverse industries, including telecommunications, medical equipment, and industrial heating applications.

Current lifecycle goals for magnetron technology focus on several critical aspects. First, extending operational lifespan remains a primary objective, as longer-lasting magnetrons reduce replacement frequency and overall lifecycle costs. Second, improving energy efficiency is crucial, particularly as energy costs rise and environmental considerations become more prominent in technology development. Third, enhancing reliability under varying operational conditions ensures consistent performance across applications.

Cost analysis methods for magnetrons have become increasingly sophisticated, moving beyond simple purchase price considerations to comprehensive lifecycle assessments. These methods now incorporate factors such as energy consumption, maintenance requirements, replacement schedules, and end-of-life disposal costs. Understanding the total cost of ownership has become essential for organizations deploying magnetron technology at scale.

The technical objectives for magnetron lifecycle assessment include developing standardized testing protocols to accurately predict lifespan under various operational conditions, creating more precise models for calculating total cost of ownership, and establishing industry benchmarks for performance and efficiency. These objectives support the broader goal of optimizing magnetron selection and utilization across different applications.

Recent technological innovations have introduced new possibilities for magnetron lifecycle management, including real-time monitoring systems that can predict failure before it occurs, adaptive power management to extend operational life, and modular designs that facilitate easier maintenance and component replacement. These innovations represent promising directions for further reducing lifecycle costs while improving overall system reliability.

As magnetron technology continues to evolve, future development will likely focus on addressing emerging challenges such as resource scarcity, environmental regulations, and increasing performance demands. The integration of digital technologies for lifecycle monitoring and management represents a particularly promising frontier for optimizing magnetron cost-effectiveness across their operational lifespan.

Market Demand Analysis for Magnetron Applications

The global magnetron market has witnessed substantial growth in recent years, driven primarily by the increasing adoption of microwave ovens in residential and commercial sectors. Market research indicates that the global magnetron market was valued at approximately 5.8 billion USD in 2022 and is projected to reach 7.9 billion USD by 2028, growing at a CAGR of 5.2% during the forecast period. This growth trajectory underscores the robust demand for magnetron applications across various industries.

The household appliance sector represents the largest market segment for magnetrons, with microwave ovens being the primary application. The penetration rate of microwave ovens in developed economies exceeds 90%, while emerging markets show accelerating adoption rates of 15-20% annually. This widespread adoption is fueled by changing lifestyle patterns, increasing urbanization, and the growing preference for convenient cooking solutions.

Beyond consumer applications, industrial magnetrons are experiencing significant demand growth in sectors such as food processing, chemical processing, and materials science. The food processing industry, in particular, has embraced magnetron technology for rapid heating, drying, and sterilization processes, contributing to approximately 18% of the total magnetron market value.

The healthcare sector presents an emerging application area for magnetrons, particularly in medical equipment such as diathermy machines and cancer treatment devices. Market analysis suggests that medical applications of magnetrons are growing at 7.3% annually, outpacing the overall market growth rate.

Regional analysis reveals that Asia-Pacific dominates the magnetron market, accounting for approximately 42% of global demand, followed by North America (27%) and Europe (21%). China and Japan are the largest manufacturers, while India and Southeast Asian countries represent the fastest-growing markets with annual growth rates exceeding 8%.

A critical factor influencing market dynamics is the increasing focus on energy efficiency and sustainability. Consumers and industries alike are demanding magnetrons with higher energy conversion efficiency, longer operational lifespans, and reduced environmental impact. This trend has spurred innovation in magnetron design, with manufacturers investing in R&D to develop eco-friendly alternatives.

Cost considerations remain paramount in market adoption decisions. The total cost of ownership, including initial acquisition costs, operational expenses, and replacement costs, significantly influences purchasing decisions across all market segments. Consequently, life cycle cost analysis has become an essential tool for both manufacturers and end-users in evaluating magnetron technologies.

The household appliance sector represents the largest market segment for magnetrons, with microwave ovens being the primary application. The penetration rate of microwave ovens in developed economies exceeds 90%, while emerging markets show accelerating adoption rates of 15-20% annually. This widespread adoption is fueled by changing lifestyle patterns, increasing urbanization, and the growing preference for convenient cooking solutions.

Beyond consumer applications, industrial magnetrons are experiencing significant demand growth in sectors such as food processing, chemical processing, and materials science. The food processing industry, in particular, has embraced magnetron technology for rapid heating, drying, and sterilization processes, contributing to approximately 18% of the total magnetron market value.

The healthcare sector presents an emerging application area for magnetrons, particularly in medical equipment such as diathermy machines and cancer treatment devices. Market analysis suggests that medical applications of magnetrons are growing at 7.3% annually, outpacing the overall market growth rate.

Regional analysis reveals that Asia-Pacific dominates the magnetron market, accounting for approximately 42% of global demand, followed by North America (27%) and Europe (21%). China and Japan are the largest manufacturers, while India and Southeast Asian countries represent the fastest-growing markets with annual growth rates exceeding 8%.

A critical factor influencing market dynamics is the increasing focus on energy efficiency and sustainability. Consumers and industries alike are demanding magnetrons with higher energy conversion efficiency, longer operational lifespans, and reduced environmental impact. This trend has spurred innovation in magnetron design, with manufacturers investing in R&D to develop eco-friendly alternatives.

Cost considerations remain paramount in market adoption decisions. The total cost of ownership, including initial acquisition costs, operational expenses, and replacement costs, significantly influences purchasing decisions across all market segments. Consequently, life cycle cost analysis has become an essential tool for both manufacturers and end-users in evaluating magnetron technologies.

Current Challenges in Magnetron Lifecycle Assessment

The lifecycle assessment of magnetrons presents significant challenges that impede accurate cost analysis and performance evaluation. Current methodologies often fail to capture the complex interplay between operational parameters, environmental conditions, and material degradation mechanisms. Traditional cost models typically focus on initial acquisition costs while underestimating the substantial operational and maintenance expenses that accumulate throughout the magnetron's service life.

One primary challenge is the lack of standardized testing protocols for predicting magnetron longevity across diverse applications. Industrial microwave systems, radar equipment, and medical devices all impose different operational stresses on magnetrons, yet current assessment frameworks rarely account for these application-specific variables. This results in significant discrepancies between theoretical lifecycle projections and actual field performance.

Data collection represents another substantial hurdle. Real-time monitoring of magnetron performance parameters remains limited in many installations, creating blind spots in degradation pattern analysis. Without comprehensive performance data, organizations struggle to develop accurate predictive maintenance schedules or implement condition-based replacement strategies. This information gap leads to either premature replacements that increase costs or delayed replacements that risk catastrophic failures and extended downtime.

Environmental factors further complicate lifecycle assessments. Variations in ambient temperature, humidity, power supply stability, and cooling system efficiency all significantly impact magnetron longevity. Current models inadequately incorporate these environmental variables, resulting in lifecycle projections that may be valid under laboratory conditions but fail to reflect real-world operational environments.

The economic evaluation of end-of-life options presents additional challenges. Recycling technologies for magnetron components remain underdeveloped, and disposal costs are often excluded from lifecycle cost calculations. Furthermore, the environmental impact of magnetron disposal is rarely quantified in monetary terms, leading to incomplete cost assessments that fail to account for regulatory compliance expenses and potential environmental liabilities.

Technological evolution also complicates lifecycle assessment. As newer magnetron designs enter the market with improved efficiency and reliability characteristics, comparative analysis between generations becomes increasingly difficult. Organizations struggle to determine the optimal replacement timing when weighing the continued operation of existing units against the potential benefits of upgrading to newer technology with different lifecycle parameters.

Finally, supply chain uncertainties introduce significant variability into lifecycle cost projections. Fluctuations in raw material prices, particularly for rare earth elements and specialized metals used in magnetron construction, can dramatically alter replacement costs over time. Current assessment methodologies typically employ static pricing models that fail to account for these market dynamics.

One primary challenge is the lack of standardized testing protocols for predicting magnetron longevity across diverse applications. Industrial microwave systems, radar equipment, and medical devices all impose different operational stresses on magnetrons, yet current assessment frameworks rarely account for these application-specific variables. This results in significant discrepancies between theoretical lifecycle projections and actual field performance.

Data collection represents another substantial hurdle. Real-time monitoring of magnetron performance parameters remains limited in many installations, creating blind spots in degradation pattern analysis. Without comprehensive performance data, organizations struggle to develop accurate predictive maintenance schedules or implement condition-based replacement strategies. This information gap leads to either premature replacements that increase costs or delayed replacements that risk catastrophic failures and extended downtime.

Environmental factors further complicate lifecycle assessments. Variations in ambient temperature, humidity, power supply stability, and cooling system efficiency all significantly impact magnetron longevity. Current models inadequately incorporate these environmental variables, resulting in lifecycle projections that may be valid under laboratory conditions but fail to reflect real-world operational environments.

The economic evaluation of end-of-life options presents additional challenges. Recycling technologies for magnetron components remain underdeveloped, and disposal costs are often excluded from lifecycle cost calculations. Furthermore, the environmental impact of magnetron disposal is rarely quantified in monetary terms, leading to incomplete cost assessments that fail to account for regulatory compliance expenses and potential environmental liabilities.

Technological evolution also complicates lifecycle assessment. As newer magnetron designs enter the market with improved efficiency and reliability characteristics, comparative analysis between generations becomes increasingly difficult. Organizations struggle to determine the optimal replacement timing when weighing the continued operation of existing units against the potential benefits of upgrading to newer technology with different lifecycle parameters.

Finally, supply chain uncertainties introduce significant variability into lifecycle cost projections. Fluctuations in raw material prices, particularly for rare earth elements and specialized metals used in magnetron construction, can dramatically alter replacement costs over time. Current assessment methodologies typically employ static pricing models that fail to account for these market dynamics.

Current Cost Analysis Methodologies for Magnetrons

01 Cost reduction through manufacturing process improvements

Various manufacturing process improvements can significantly reduce the cost of magnetron production. These include optimized sputtering techniques, improved assembly methods, and streamlined production workflows. By enhancing the efficiency of the manufacturing process, manufacturers can lower production costs while maintaining or even improving the quality and performance of magnetrons.- Cost reduction through manufacturing process improvements: Various manufacturing process improvements can significantly reduce the cost of magnetron production. These include optimized sputtering techniques, improved assembly methods, and streamlined production workflows. By enhancing the efficiency of the manufacturing process, manufacturers can lower production costs while maintaining or even improving the quality of magnetrons.

- Cost-effective magnetron designs: Innovative magnetron designs can lead to cost savings in both production and operation. These designs may feature simplified structures, reduced component counts, or alternative materials that are less expensive but still meet performance requirements. Such design optimizations help to decrease the overall cost of magnetrons without compromising their functionality.

- Energy efficiency improvements to reduce operational costs: Enhancing the energy efficiency of magnetrons can significantly reduce their operational costs over their lifetime. This includes improvements in power conversion efficiency, reduced heat generation, and optimized power consumption. These advancements not only lower the cost of operation but also extend the service life of the magnetrons, providing additional cost benefits.

- Material selection for cost optimization: The selection of materials plays a crucial role in determining the cost of magnetrons. Using alternative materials that are less expensive but still provide the necessary performance characteristics can significantly reduce production costs. This includes using different cathode materials, alternative magnets, or more cost-effective structural components while maintaining the required electromagnetic properties.

- Mass production techniques for cost reduction: Implementing mass production techniques can substantially lower the unit cost of magnetrons. These techniques include automated assembly processes, standardized component designs, and economies of scale in material procurement. By producing magnetrons in larger quantities with consistent quality, manufacturers can achieve significant cost reductions per unit.

02 Cost-effective magnetron designs

Innovative magnetron designs can lead to cost savings in both production and operation. These designs may feature simplified structures, reduced component counts, or alternative materials that are less expensive but still meet performance requirements. Some designs focus on improving the durability and lifespan of magnetrons, which reduces the total cost of ownership over time.Expand Specific Solutions03 Energy efficiency improvements to reduce operational costs

Enhancing the energy efficiency of magnetrons can significantly reduce their operational costs. This includes improvements in power supply design, better cooling systems, and optimized electromagnetic field configurations. Energy-efficient magnetrons consume less power while maintaining the same output performance, resulting in lower electricity costs during operation.Expand Specific Solutions04 Material selection for cost optimization

The choice of materials used in magnetron construction has a significant impact on overall costs. Research focuses on identifying alternative materials that offer similar performance characteristics at lower prices. This includes using different cathode materials, alternative magnets, or more economical structural components that can withstand the operating conditions while reducing the total material cost.Expand Specific Solutions05 Mass production techniques for cost reduction

Implementing mass production techniques can substantially reduce the per-unit cost of magnetrons. These techniques include automated assembly lines, standardized components, and economies of scale in material procurement. Mass production approaches also involve quality control systems that minimize waste and rework, further contributing to cost efficiency in magnetron manufacturing.Expand Specific Solutions

Key Industry Players in Magnetron Manufacturing

The magnetron life cycle cost analysis market is currently in a growth phase, with increasing demand for cost-effective assessment methods across industrial and commercial applications. The market is estimated to reach approximately $3-4 billion by 2025, driven by the expanding microwave technology sector. From a technological maturity perspective, established players like Tokyo Electron, LG Electronics, and Midea Group have developed advanced cost analysis frameworks, while Applied Materials and Guangdong Galanz lead in magnetron lifecycle optimization technologies. Emerging competitors such as NAURA Microelectronics and Evatec AG are introducing innovative assessment methodologies, creating a competitive landscape divided between traditional manufacturers and specialized technology providers. The market shows regional concentration in Asia-Pacific, with growing adoption in North American and European industrial sectors.

Tokyo Electron Ltd.

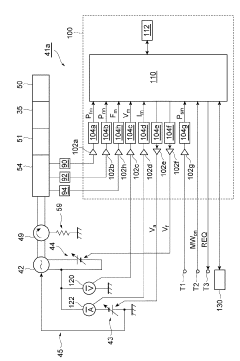

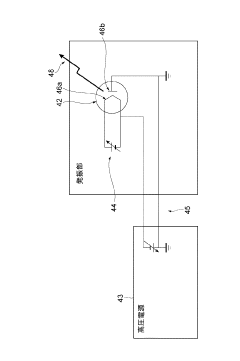

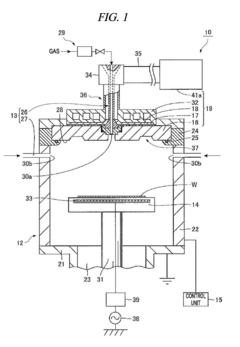

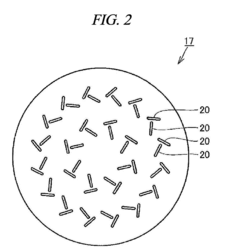

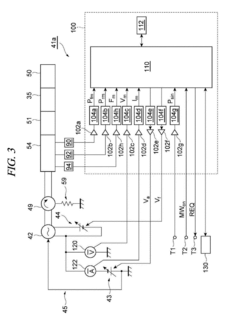

Technical Solution: Tokyo Electron has developed a comprehensive Magnetron Life Cycle Cost Analysis (MLCCA) framework that integrates real-time monitoring systems with predictive maintenance algorithms. Their approach utilizes IoT sensors embedded within semiconductor manufacturing equipment to continuously monitor magnetron performance parameters including RF power efficiency, target erosion patterns, and thermal profiles. The collected data feeds into their proprietary TEL-MLCCA software platform which employs machine learning algorithms to predict remaining useful life and optimize replacement schedules. Their system calculates total cost of ownership by factoring in initial acquisition costs, operational energy consumption, maintenance labor, downtime costs, and end-of-life disposal expenses. Tokyo Electron's methodology also incorporates environmental impact assessments, quantifying carbon footprint across the entire magnetron lifecycle.

Strengths: Industry-leading predictive analytics capabilities that reduce unplanned downtime by up to 35%; comprehensive data integration across multiple parameters for high-accuracy forecasting. Weaknesses: High implementation costs for the full monitoring system; requires significant historical data for accurate predictions in new installation environments.

Beijing NAURA Microelectronics Equipment Co., Ltd.

Technical Solution: NAURA has pioneered a dual-track approach to magnetron lifecycle cost analysis that combines traditional financial modeling with advanced reliability engineering. Their NMLA (NAURA Magnetron Lifecycle Assessment) platform incorporates both deterministic and probabilistic cost models to account for the inherent uncertainties in magnetron performance degradation. The system employs accelerated life testing methodologies to establish baseline performance curves, which are then calibrated using field data from their extensive installation base across China's semiconductor manufacturing sector. NAURA's approach particularly excels in quantifying the economic impact of different operating conditions on magnetron longevity, enabling customers to optimize process parameters for extended service life. Their cost analysis framework incorporates regional factors such as local energy costs, labor rates, and supply chain considerations to provide geographically relevant total cost of ownership projections.

Strengths: Highly adaptable cost models that can be customized for different manufacturing environments and regional economic conditions; strong integration with process optimization tools. Weaknesses: Less sophisticated predictive maintenance capabilities compared to Western competitors; models heavily weighted toward Chinese manufacturing contexts which may limit global applicability.

Critical Patents and Research in Lifecycle Costing

Method for inspecting magnetron

PatentInactiveJP2016081908A

Innovation

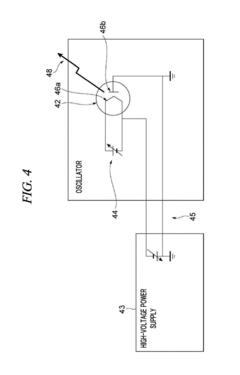

- A method for inspecting magnetrons by generating radio frequency power, detecting measurements after a predetermined time, ensuring the power of the reflected wave is zero and the traveling wave power matches the set power, and using corrected parameters to determine the magnetron's life based on comparisons with initial parameters.

Method for inspecting magnetron

PatentActiveUS20160109502A1

Innovation

- A method that involves starting high-frequency power generation, detecting specific measurement values, and waiting for a predetermined duration to ensure stability before comparing current and initial parameters to determine the magnetron's life, using correction values and offset calculations to assess the magnetron's status accurately.

Environmental Impact of Magnetron Manufacturing

The manufacturing of magnetrons presents significant environmental challenges throughout their production lifecycle. Raw material extraction, particularly for rare earth elements and metals like copper and nickel, involves energy-intensive mining operations that contribute to habitat destruction, soil erosion, and water pollution. These processes release substantial amounts of greenhouse gases and often generate toxic waste streams that require careful management.

During the manufacturing phase, magnetron production consumes considerable energy for precision machining, vacuum processing, and high-temperature operations. The fabrication of magnetron components involves various chemical processes including metal plating, etching, and cleaning that utilize hazardous substances such as solvents, acids, and heavy metals. These chemicals pose risks of air emissions and wastewater contamination if not properly controlled through advanced treatment systems.

Electronic waste (e-waste) represents a growing environmental concern as magnetrons reach end-of-life. The complex composition of magnetrons, containing valuable metals alongside potentially harmful substances, creates challenges for recycling and disposal. Without proper management, discarded magnetrons may release beryllium oxide and other toxic materials into the environment, posing serious health risks and contributing to soil and groundwater contamination.

Carbon footprint assessments of magnetron manufacturing reveal that the production phase accounts for approximately 60-70% of lifecycle emissions. Energy consumption during manufacturing contributes significantly to this environmental burden, with specialized processes like vacuum sealing and precision alignment requiring substantial power inputs. The transportation of components and finished products across global supply chains further adds to the carbon footprint through fuel consumption and associated emissions.

Recent industry initiatives have focused on developing more sustainable manufacturing approaches. These include implementing closed-loop water systems to minimize wastewater discharge, adopting energy-efficient equipment, and exploring alternative materials with reduced environmental impact. Some manufacturers have begun utilizing renewable energy sources to power production facilities, potentially reducing carbon emissions by 30-40% compared to conventional energy sources.

Life cycle assessment (LCA) studies indicate that extending magnetron lifespan through improved design and materials can significantly reduce environmental impact per unit of service delivered. Additionally, designing magnetrons for easier disassembly and component recovery facilitates more effective recycling and material reclamation at end-of-life, supporting circular economy principles and reducing demand for virgin material extraction.

During the manufacturing phase, magnetron production consumes considerable energy for precision machining, vacuum processing, and high-temperature operations. The fabrication of magnetron components involves various chemical processes including metal plating, etching, and cleaning that utilize hazardous substances such as solvents, acids, and heavy metals. These chemicals pose risks of air emissions and wastewater contamination if not properly controlled through advanced treatment systems.

Electronic waste (e-waste) represents a growing environmental concern as magnetrons reach end-of-life. The complex composition of magnetrons, containing valuable metals alongside potentially harmful substances, creates challenges for recycling and disposal. Without proper management, discarded magnetrons may release beryllium oxide and other toxic materials into the environment, posing serious health risks and contributing to soil and groundwater contamination.

Carbon footprint assessments of magnetron manufacturing reveal that the production phase accounts for approximately 60-70% of lifecycle emissions. Energy consumption during manufacturing contributes significantly to this environmental burden, with specialized processes like vacuum sealing and precision alignment requiring substantial power inputs. The transportation of components and finished products across global supply chains further adds to the carbon footprint through fuel consumption and associated emissions.

Recent industry initiatives have focused on developing more sustainable manufacturing approaches. These include implementing closed-loop water systems to minimize wastewater discharge, adopting energy-efficient equipment, and exploring alternative materials with reduced environmental impact. Some manufacturers have begun utilizing renewable energy sources to power production facilities, potentially reducing carbon emissions by 30-40% compared to conventional energy sources.

Life cycle assessment (LCA) studies indicate that extending magnetron lifespan through improved design and materials can significantly reduce environmental impact per unit of service delivered. Additionally, designing magnetrons for easier disassembly and component recovery facilitates more effective recycling and material reclamation at end-of-life, supporting circular economy principles and reducing demand for virgin material extraction.

Total Cost of Ownership Framework for Magnetrons

The Total Cost of Ownership (TCO) framework provides a comprehensive approach for evaluating the complete economic impact of magnetron acquisition and operation throughout its lifecycle. This framework extends beyond the initial purchase price to encompass all direct and indirect costs associated with magnetron ownership, offering organizations a holistic view of their investment.

The TCO framework for magnetrons consists of several key cost categories. Initial acquisition costs include not only the purchase price but also shipping, handling, and installation expenses. These upfront costs typically represent only 20-30% of the total lifecycle expenditure, highlighting the importance of considering long-term operational factors.

Operational costs form a significant portion of the TCO, encompassing energy consumption, cooling requirements, and regular maintenance. Magnetrons, particularly in industrial applications, can consume substantial electrical power, with energy costs often exceeding the initial purchase price within the first year of operation. The framework accounts for varying electricity rates and usage patterns to provide accurate operational cost projections.

Maintenance and service costs include scheduled preventive maintenance, unexpected repairs, and associated labor expenses. The framework incorporates mean time between failures (MTBF) data and service contract costs to estimate these expenditures over the magnetron's lifespan. For critical applications, redundancy costs may also be factored in to prevent production downtime.

Replacement part costs represent another crucial component, particularly for magnetron components with shorter lifespans than the overall system. The framework tracks the frequency and cost of replacing filaments, RF windows, and other wear items that deteriorate during normal operation.

End-of-life considerations include decommissioning expenses, disposal costs (particularly for models containing hazardous materials), and potential salvage value. These factors, often overlooked in simplified cost analyses, can significantly impact the overall TCO calculation.

The framework also incorporates opportunity costs associated with downtime, productivity losses during maintenance periods, and potential revenue impacts. For industrial applications where magnetrons support critical processes, these indirect costs can substantially influence the TCO calculation and equipment selection decisions.

By applying this comprehensive TCO framework, organizations can make more informed decisions regarding magnetron selection, maintenance strategies, and replacement timing. The model enables accurate comparison between different magnetron technologies, manufacturers, and operational approaches, ultimately optimizing long-term economic performance.

The TCO framework for magnetrons consists of several key cost categories. Initial acquisition costs include not only the purchase price but also shipping, handling, and installation expenses. These upfront costs typically represent only 20-30% of the total lifecycle expenditure, highlighting the importance of considering long-term operational factors.

Operational costs form a significant portion of the TCO, encompassing energy consumption, cooling requirements, and regular maintenance. Magnetrons, particularly in industrial applications, can consume substantial electrical power, with energy costs often exceeding the initial purchase price within the first year of operation. The framework accounts for varying electricity rates and usage patterns to provide accurate operational cost projections.

Maintenance and service costs include scheduled preventive maintenance, unexpected repairs, and associated labor expenses. The framework incorporates mean time between failures (MTBF) data and service contract costs to estimate these expenditures over the magnetron's lifespan. For critical applications, redundancy costs may also be factored in to prevent production downtime.

Replacement part costs represent another crucial component, particularly for magnetron components with shorter lifespans than the overall system. The framework tracks the frequency and cost of replacing filaments, RF windows, and other wear items that deteriorate during normal operation.

End-of-life considerations include decommissioning expenses, disposal costs (particularly for models containing hazardous materials), and potential salvage value. These factors, often overlooked in simplified cost analyses, can significantly impact the overall TCO calculation.

The framework also incorporates opportunity costs associated with downtime, productivity losses during maintenance periods, and potential revenue impacts. For industrial applications where magnetrons support critical processes, these indirect costs can substantially influence the TCO calculation and equipment selection decisions.

By applying this comprehensive TCO framework, organizations can make more informed decisions regarding magnetron selection, maintenance strategies, and replacement timing. The model enables accurate comparison between different magnetron technologies, manufacturers, and operational approaches, ultimately optimizing long-term economic performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!