Bath Stability and pH Control in Electroless Nickel Processes

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electroless Nickel Plating Technology Evolution and Objectives

Electroless nickel plating emerged in the mid-20th century as a revolutionary surface finishing technology, offering unique properties such as uniform deposit thickness regardless of component geometry. The process evolved from the initial discoveries by Brenner and Riddell in the 1940s, who developed the first practical autocatalytic nickel deposition methods. This breakthrough laid the foundation for modern electroless nickel plating technologies that have become indispensable across multiple industries.

The evolution of electroless nickel plating has been marked by significant advancements in bath chemistry and process control. Early formulations relied on simple nickel-phosphorus systems with limited stability and short bath life. By the 1970s, researchers had developed more sophisticated bath compositions incorporating stabilizers and complexing agents that dramatically improved performance and reliability. The 1980s and 1990s saw further refinements with the introduction of environmentally friendlier alternatives to replace hazardous chemicals like lead-based stabilizers.

Bath stability and pH control have consistently remained critical challenges throughout this technological evolution. The autocatalytic nature of the process makes it inherently susceptible to spontaneous decomposition, requiring precise control mechanisms. Historical approaches to pH management relied heavily on manual adjustments and basic buffering systems, which proved inadequate for maintaining the narrow pH ranges required for optimal deposition.

Modern electroless nickel plating objectives focus on achieving unprecedented levels of bath stability while maintaining strict pH control parameters. The industry aims to develop systems capable of extended bath life exceeding 10 metal turnovers without compromising deposit quality or introducing environmental concerns. Additionally, there is growing emphasis on real-time monitoring and automated adjustment technologies to maintain optimal pH levels between 4.5-5.0 for standard nickel-phosphorus baths.

The technological trajectory points toward intelligent plating systems incorporating advanced sensors, predictive algorithms, and automated dosing mechanisms. These innovations seek to address the fundamental challenge of maintaining bath equilibrium despite the continuous consumption of reducing agents and generation of hydrogen ions during the plating process. Research is increasingly focused on developing novel stabilizer systems that can prevent bath decomposition without interfering with the catalytic deposition mechanism.

Current objectives also include the development of more robust buffering systems specifically designed for electroless nickel applications, capable of maintaining pH stability across varying production volumes and operating conditions. The industry is simultaneously pursuing more sustainable formulations with reduced environmental impact while maintaining or exceeding the performance standards established by traditional systems.

The evolution of electroless nickel plating has been marked by significant advancements in bath chemistry and process control. Early formulations relied on simple nickel-phosphorus systems with limited stability and short bath life. By the 1970s, researchers had developed more sophisticated bath compositions incorporating stabilizers and complexing agents that dramatically improved performance and reliability. The 1980s and 1990s saw further refinements with the introduction of environmentally friendlier alternatives to replace hazardous chemicals like lead-based stabilizers.

Bath stability and pH control have consistently remained critical challenges throughout this technological evolution. The autocatalytic nature of the process makes it inherently susceptible to spontaneous decomposition, requiring precise control mechanisms. Historical approaches to pH management relied heavily on manual adjustments and basic buffering systems, which proved inadequate for maintaining the narrow pH ranges required for optimal deposition.

Modern electroless nickel plating objectives focus on achieving unprecedented levels of bath stability while maintaining strict pH control parameters. The industry aims to develop systems capable of extended bath life exceeding 10 metal turnovers without compromising deposit quality or introducing environmental concerns. Additionally, there is growing emphasis on real-time monitoring and automated adjustment technologies to maintain optimal pH levels between 4.5-5.0 for standard nickel-phosphorus baths.

The technological trajectory points toward intelligent plating systems incorporating advanced sensors, predictive algorithms, and automated dosing mechanisms. These innovations seek to address the fundamental challenge of maintaining bath equilibrium despite the continuous consumption of reducing agents and generation of hydrogen ions during the plating process. Research is increasingly focused on developing novel stabilizer systems that can prevent bath decomposition without interfering with the catalytic deposition mechanism.

Current objectives also include the development of more robust buffering systems specifically designed for electroless nickel applications, capable of maintaining pH stability across varying production volumes and operating conditions. The industry is simultaneously pursuing more sustainable formulations with reduced environmental impact while maintaining or exceeding the performance standards established by traditional systems.

Market Analysis for Electroless Nickel Coating Applications

The electroless nickel coating market has demonstrated robust growth over recent years, driven by increasing demand across multiple industrial sectors. The global market value for electroless nickel plating reached approximately $1.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% through 2028. This growth trajectory is supported by expanding applications in automotive, electronics, aerospace, and chemical processing industries.

The automotive sector represents the largest market segment, accounting for nearly 30% of total electroless nickel consumption. This dominance stems from the coating's excellent wear resistance, uniform deposition capabilities, and corrosion protection properties, which are critical for engine components, fuel systems, and brake parts. The electronics industry follows closely, utilizing electroless nickel for printed circuit boards, connectors, and electromagnetic shielding applications.

Geographically, Asia-Pacific leads the market with approximately 40% share, driven by rapid industrialization in China, India, and Southeast Asian countries. North America and Europe collectively account for about 45% of the market, with established manufacturing bases in aerospace and precision engineering sectors.

A significant market trend is the increasing demand for environmentally compliant electroless nickel processes. Regulatory pressures, particularly in Europe and North America, are pushing the industry toward nickel baths with reduced environmental impact. This has created a premium market segment for processes featuring improved bath stability and pH control systems that minimize waste generation and chemical consumption.

The market for specialized bath stability additives and pH control systems has emerged as a high-growth niche, estimated at $250 million annually with 8-10% growth rates. Companies offering comprehensive solutions that extend bath life while maintaining consistent deposit quality command premium pricing, with customers willing to pay 15-20% more for systems that demonstrate measurable reductions in bath replacement frequency.

End-users increasingly prioritize total cost of ownership over initial implementation costs, creating market opportunities for advanced monitoring and control systems. Solutions that offer real-time bath stability monitoring and automated pH adjustment capabilities are experiencing particularly strong demand growth, especially among high-volume plating operations where bath stability directly impacts production economics and quality consistency.

The market also shows growing interest in digitalization and Industry 4.0 integration capabilities, with plating operations seeking bath management systems that can interface with broader manufacturing execution systems to optimize production scheduling based on bath condition forecasting.

The automotive sector represents the largest market segment, accounting for nearly 30% of total electroless nickel consumption. This dominance stems from the coating's excellent wear resistance, uniform deposition capabilities, and corrosion protection properties, which are critical for engine components, fuel systems, and brake parts. The electronics industry follows closely, utilizing electroless nickel for printed circuit boards, connectors, and electromagnetic shielding applications.

Geographically, Asia-Pacific leads the market with approximately 40% share, driven by rapid industrialization in China, India, and Southeast Asian countries. North America and Europe collectively account for about 45% of the market, with established manufacturing bases in aerospace and precision engineering sectors.

A significant market trend is the increasing demand for environmentally compliant electroless nickel processes. Regulatory pressures, particularly in Europe and North America, are pushing the industry toward nickel baths with reduced environmental impact. This has created a premium market segment for processes featuring improved bath stability and pH control systems that minimize waste generation and chemical consumption.

The market for specialized bath stability additives and pH control systems has emerged as a high-growth niche, estimated at $250 million annually with 8-10% growth rates. Companies offering comprehensive solutions that extend bath life while maintaining consistent deposit quality command premium pricing, with customers willing to pay 15-20% more for systems that demonstrate measurable reductions in bath replacement frequency.

End-users increasingly prioritize total cost of ownership over initial implementation costs, creating market opportunities for advanced monitoring and control systems. Solutions that offer real-time bath stability monitoring and automated pH adjustment capabilities are experiencing particularly strong demand growth, especially among high-volume plating operations where bath stability directly impacts production economics and quality consistency.

The market also shows growing interest in digitalization and Industry 4.0 integration capabilities, with plating operations seeking bath management systems that can interface with broader manufacturing execution systems to optimize production scheduling based on bath condition forecasting.

Bath Stability Challenges and Current Technical Limitations

Electroless nickel plating baths face significant stability challenges that limit process efficiency and product quality. The primary issue is the inherent thermodynamic instability of these solutions, which contain both reducing agents and metal ions in the same environment. This metastable condition can lead to spontaneous decomposition, resulting in random nickel precipitation throughout the solution rather than controlled deposition on the substrate surface.

pH fluctuation represents one of the most critical technical limitations in electroless nickel processes. The optimal pH range for most commercial baths is narrow (typically 4.5-5.0 for acid baths and 8.0-10.0 for alkaline formulations), and even minor deviations can dramatically affect deposition rates and coating properties. During operation, the reduction reactions naturally produce hydrogen ions that progressively acidify the bath, requiring continuous pH adjustment.

Temperature control presents another significant challenge, as electroless nickel baths operate near their decomposition threshold. Most commercial processes function at 85-95°C, where the reaction kinetics are favorable but the risk of bath instability increases exponentially. The technical difficulty lies in maintaining precise temperature control across the entire bath volume, as local hotspots can trigger catastrophic decomposition events.

Bath loading factors (the ratio of surface area being plated to solution volume) introduce additional complexity. Current technical limitations make it difficult to maintain consistent deposition rates across varying load conditions. When bath loading is low, excess reducing agent accumulates, increasing decomposition risk; conversely, high loading can rapidly deplete critical components, causing uneven coating properties.

Contaminant management remains an unresolved technical challenge. Metal ions like copper, lead, zinc, and cadmium, even at concentrations below 1 ppm, can catalyze unwanted reactions and accelerate bath decomposition. Current filtration and purification technologies cannot completely eliminate these trace contaminants during continuous operation.

Stabilizer systems, while necessary for bath longevity, introduce their own limitations. These compounds (typically sulfur, lead, or cadmium derivatives) function by temporarily poisoning active sites, but their effectiveness diminishes over time as they become incorporated into the deposit or break down. The technical challenge involves balancing sufficient stabilization against maintaining acceptable deposition rates.

Bath aging effects present perhaps the most complex limitation, as multiple chemical processes occur simultaneously: oxidation of reducing agents, accumulation of reaction byproducts, depletion of complexing agents, and gradual breakdown of stabilizers. Current analytical methods cannot comprehensively monitor all these parameters in real-time, making proactive bath maintenance difficult and often reactive.

pH fluctuation represents one of the most critical technical limitations in electroless nickel processes. The optimal pH range for most commercial baths is narrow (typically 4.5-5.0 for acid baths and 8.0-10.0 for alkaline formulations), and even minor deviations can dramatically affect deposition rates and coating properties. During operation, the reduction reactions naturally produce hydrogen ions that progressively acidify the bath, requiring continuous pH adjustment.

Temperature control presents another significant challenge, as electroless nickel baths operate near their decomposition threshold. Most commercial processes function at 85-95°C, where the reaction kinetics are favorable but the risk of bath instability increases exponentially. The technical difficulty lies in maintaining precise temperature control across the entire bath volume, as local hotspots can trigger catastrophic decomposition events.

Bath loading factors (the ratio of surface area being plated to solution volume) introduce additional complexity. Current technical limitations make it difficult to maintain consistent deposition rates across varying load conditions. When bath loading is low, excess reducing agent accumulates, increasing decomposition risk; conversely, high loading can rapidly deplete critical components, causing uneven coating properties.

Contaminant management remains an unresolved technical challenge. Metal ions like copper, lead, zinc, and cadmium, even at concentrations below 1 ppm, can catalyze unwanted reactions and accelerate bath decomposition. Current filtration and purification technologies cannot completely eliminate these trace contaminants during continuous operation.

Stabilizer systems, while necessary for bath longevity, introduce their own limitations. These compounds (typically sulfur, lead, or cadmium derivatives) function by temporarily poisoning active sites, but their effectiveness diminishes over time as they become incorporated into the deposit or break down. The technical challenge involves balancing sufficient stabilization against maintaining acceptable deposition rates.

Bath aging effects present perhaps the most complex limitation, as multiple chemical processes occur simultaneously: oxidation of reducing agents, accumulation of reaction byproducts, depletion of complexing agents, and gradual breakdown of stabilizers. Current analytical methods cannot comprehensively monitor all these parameters in real-time, making proactive bath maintenance difficult and often reactive.

Current Bath Stabilization and pH Regulation Techniques

01 pH Control Methods for Electroless Nickel Baths

Various methods are employed to control and maintain the pH of electroless nickel plating baths, which is crucial for bath stability. These methods include the use of buffer systems, automatic pH controllers, and specific pH adjusting agents. Maintaining the optimal pH range (typically 4.5-5.5 for acidic baths) ensures consistent deposition rates and prevents bath decomposition. Effective pH control systems continuously monitor and adjust the pH level to compensate for the natural pH decrease that occurs during the plating process due to hydrogen ion generation.- pH Control Mechanisms for Electroless Nickel Baths: Maintaining optimal pH levels is critical for electroless nickel plating bath stability. Various buffering agents and pH control mechanisms can be employed to prevent pH fluctuations during the plating process. These mechanisms include automatic pH controllers, specific buffer systems, and controlled addition of alkaline compounds to counteract the natural acidification that occurs during plating reactions. Proper pH control ensures consistent deposition rates and prevents bath decomposition.

- Stabilizing Additives for Bath Longevity: Specific additives can significantly enhance the stability of electroless nickel plating baths. These stabilizers prevent spontaneous decomposition of the bath by controlling the reduction reaction. Common stabilizers include sulfur compounds, heavy metal ions, and organic compounds that form complexes with nickel ions. The proper selection and concentration of stabilizers is essential for extending bath life while maintaining acceptable deposition rates and quality of the nickel coating.

- Complexing Agents for Bath Stability: Complexing agents play a crucial role in electroless nickel bath stability by forming stable complexes with nickel ions, preventing their premature precipitation. These agents control the concentration of free nickel ions available for deposition and help maintain bath stability across a wider pH range. Common complexing agents include organic acids, amines, and their salts. The proper selection and concentration of complexing agents significantly impacts bath stability, deposition rate, and coating properties.

- Monitoring and Replenishment Systems: Advanced monitoring and replenishment systems are essential for maintaining electroless nickel bath stability. These systems continuously track key parameters such as pH, nickel concentration, reducing agent levels, and bath temperature. Automated replenishment systems can add precise amounts of components as they are consumed, maintaining optimal bath chemistry. Regular analysis and adjustment of bath components prevent bath degradation and ensure consistent coating quality throughout the bath's operational life.

- Temperature Control for Bath Stability: Temperature control is critical for electroless nickel bath stability and pH maintenance. Fluctuations in temperature can accelerate bath decomposition, alter deposition rates, and affect pH stability. Precise temperature control systems, including heating/cooling mechanisms and thermal insulation, help maintain consistent bath conditions. The optimal operating temperature range depends on bath composition, with most electroless nickel baths operating between 80-95°C. Proper temperature management extends bath life and ensures uniform coating properties.

02 Stabilizing Agents for Bath Longevity

Stabilizing agents are critical components in electroless nickel baths that prevent spontaneous decomposition of the solution. These compounds, including sulfur-containing compounds, heavy metal ions, and organic stabilizers, control the autocatalytic reaction by moderating the reduction rate of nickel ions. The proper concentration of stabilizers is essential - too little leads to bath decomposition while excessive amounts inhibit the plating process. Modern formulations often use combinations of different stabilizers to achieve optimal bath performance and extended solution life without compromising deposition rate or coating quality.Expand Specific Solutions03 Complexing Agents for Bath Stability

Complexing agents form coordination compounds with nickel ions in electroless plating baths, preventing their precipitation as nickel hydroxide and maintaining bath stability. Common complexing agents include organic acids such as citric acid, lactic acid, and malic acid, as well as their salts. These agents buffer the solution against pH fluctuations and influence the plating rate and deposit properties. The type and concentration of complexing agents must be carefully balanced to ensure optimal bath performance, as they affect not only stability but also the phosphorus content and physical properties of the resulting nickel deposit.Expand Specific Solutions04 Replenishment Strategies for Bath Maintenance

Continuous or periodic replenishment of electroless nickel bath components is essential for maintaining bath stability and consistent coating quality during extended operation. Replenishment systems add nickel salts, reducing agents, complexing agents, and stabilizers to compensate for their consumption during the plating process. Advanced monitoring techniques, including chemical analysis and electrochemical methods, help determine the optimal timing and composition of replenishment additions. Proper replenishment strategies prevent bath imbalances that could lead to poor deposit quality or sudden bath decomposition, thereby extending bath life and ensuring consistent plating results.Expand Specific Solutions05 Temperature Control and Its Impact on Bath Stability

Temperature control is a critical factor in maintaining electroless nickel bath stability. Operating temperature affects reaction kinetics, with higher temperatures accelerating deposition rates but potentially reducing bath stability. Most electroless nickel baths operate between 80-95°C, and temperature fluctuations must be minimized to prevent spontaneous decomposition. Heating and cooling systems with precise temperature control capabilities are essential components of electroless plating equipment. The relationship between temperature, pH, and stabilizer concentration must be carefully balanced, as these parameters interact to determine overall bath stability and plating performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in EN Technology

The electroless nickel plating bath stability and pH control market is currently in a growth phase, with increasing demand driven by electronics, automotive, and aerospace applications. The global market size is estimated to exceed $1.5 billion, expanding at approximately 5-7% CAGR. Technology maturity varies across players, with established companies like MacDermid, Atotech Deutschland, and DuPont leading innovation through advanced formulations that enhance bath longevity and precision pH control. Asian manufacturers including Samsung Electro Mechanics and JCU Corp are rapidly advancing capabilities, while research institutions like South China University of Technology are developing next-generation solutions focusing on environmental sustainability and process efficiency. Competition is intensifying as companies invest in proprietary additives and automated monitoring systems to address the critical challenges of bath decomposition and pH fluctuation.

MacDermid, Inc.

Technical Solution: MacDermid has developed advanced bath stability systems for electroless nickel plating that incorporate proprietary pH buffer technologies. Their ENPLATE® series utilizes a multi-component stabilizer system that maintains optimal bath conditions through controlled release of stabilizing agents. The technology employs carboxylic acid derivatives as primary pH buffers combined with specialized chelating agents that prevent metal ion precipitation while allowing controlled deposition. MacDermid's system includes real-time monitoring capabilities with automatic dosing controllers that adjust stabilizer and pH modifier concentrations based on bath parameters. Their proprietary bath analysis software tracks multiple parameters simultaneously, predicting bath life and maintenance requirements. The company has also pioneered the use of organic sulfur compounds as secondary stabilizers that activate only when primary stabilizers are depleted, extending bath life significantly while maintaining consistent deposition rates.

Strengths: Superior bath longevity (up to 12 metal turnovers compared to industry standard 8-10), excellent deposit uniformity, and reduced waste treatment costs. Their system requires less frequent bath replacement, reducing downtime and chemical consumption. Weaknesses: Higher initial implementation cost, requires more sophisticated control equipment, and may need specialized operator training for optimal results.

Atotech Deutschland GmbH & Co. KG

Technical Solution: Atotech has developed the ENPLATE® NI BATH GUARDIAN system, an advanced solution for electroless nickel bath stability and pH control. This technology utilizes a combination of proprietary organic stabilizers and automated process control. The system incorporates real-time monitoring with ion-selective electrodes that continuously measure nickel concentration, hypophosphite levels, and pH values. Their patented stabilizer chemistry includes specialized nitrogen-containing heterocyclic compounds that form temporary complexes with nickel ions, preventing spontaneous decomposition while allowing controlled deposition on catalytic surfaces. The BATH GUARDIAN technology features adaptive dosing algorithms that adjust replenishment rates based on deposition history and bath age, maintaining optimal chemical balance throughout the bath life cycle. Atotech's system also employs a dual-buffer approach with primary fast-acting buffers for immediate pH correction and secondary slow-release buffers that provide long-term stability during production fluctuations.

Strengths: Exceptional bath stability with up to 15 metal turnovers in production environments, reduced chemical consumption by approximately 30% compared to conventional systems, and minimized waste treatment requirements. The automated control system reduces labor costs and human error. Weaknesses: Requires significant capital investment for full implementation, complex integration with existing plating lines, and proprietary chemistry creates vendor dependency for replenishment chemicals.

Key Patents and Innovations in EN Bath Chemistry

Method of electrolytically dissolving nickel into electroless nickel plating solutions

PatentWO2009114217A8

Innovation

- The method involves using an electrolytic cell with a nickel anode and a cation exchange membrane to dissolve nickel into the plating bath, maintaining nickel concentration without introducing anions and stabilizing pH through hydrogen ion transport, thereby extending bath life and reducing the need for pH corrections.

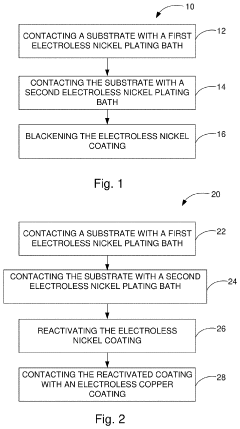

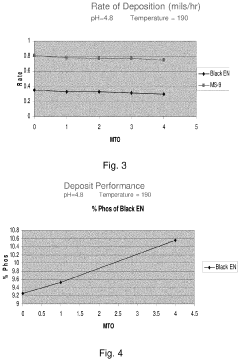

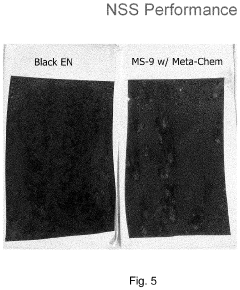

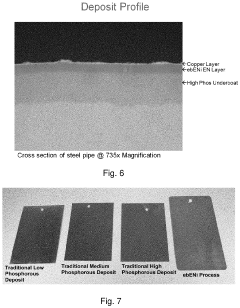

Electroless nickel coatings and compositions and methods for forming the coatings

PatentInactiveUS20220145469A1

Innovation

- An aqueous electroless nickel plating bath is developed without sulfur compounds, utilizing nickel, hypophosphorous reducing agents, zinc, and bismuth stabilizers, which allows for a stable and uniform black electroless nickel coating by maintaining specific pH and temperature conditions, enabling higher phosphorous content and improved corrosion resistance.

Environmental Impact and Waste Management Considerations

Electroless nickel plating processes generate significant environmental concerns due to the chemical composition of plating baths. These baths typically contain heavy metals such as nickel and various reducing agents like sodium hypophosphite, which can be harmful to aquatic ecosystems and human health if improperly managed. The waste streams from these processes are classified as hazardous materials in most jurisdictions, requiring specialized treatment before disposal.

The pH control chemicals used in electroless nickel baths, particularly ammonia-based compounds, contribute to air pollution through volatile emissions. Modern facilities are increasingly implementing closed-loop ventilation systems with scrubbers to capture these emissions, reducing workplace exposure and environmental release. Additionally, the stabilizers used to maintain bath performance often contain lead, cadmium, or other toxic compounds that persist in the environment and can bioaccumulate in living organisms.

Waste management strategies for electroless nickel operations have evolved significantly in recent years. Traditional end-of-pipe treatment is being supplemented or replaced by source reduction techniques. Bath life extension through careful pH monitoring and controlled additions of stabilizers not only improves process economics but also reduces waste generation. Advanced filtration systems, including membrane technologies, allow for selective removal of contaminants while retaining valuable bath components, enabling partial recycling of process chemicals.

Recovery technologies for nickel from spent baths have become economically viable as metal prices increase and disposal costs rise. Electrolytic recovery, ion exchange, and precipitation methods can reclaim up to 98% of nickel from waste streams. These recovered materials can be reintroduced into the manufacturing cycle, creating a more circular economy approach to plating operations.

Regulatory frameworks worldwide are becoming increasingly stringent regarding electroless nickel waste. The European Union's REACH regulations and similar legislation in North America and Asia have established strict limits on heavy metal discharge and chemical usage. Companies are now required to document their chemical management practices and demonstrate continuous improvement in waste reduction. This regulatory pressure has accelerated innovation in greener chemistry for electroless nickel processes.

Water consumption represents another significant environmental impact of electroless nickel operations. A typical plating line may use 5-10 liters of water per square meter of plated surface. Water recycling systems, including reverse osmosis and evaporation technologies, can reduce freshwater requirements by up to 80%, simultaneously decreasing the volume of waste requiring treatment and disposal.

The pH control chemicals used in electroless nickel baths, particularly ammonia-based compounds, contribute to air pollution through volatile emissions. Modern facilities are increasingly implementing closed-loop ventilation systems with scrubbers to capture these emissions, reducing workplace exposure and environmental release. Additionally, the stabilizers used to maintain bath performance often contain lead, cadmium, or other toxic compounds that persist in the environment and can bioaccumulate in living organisms.

Waste management strategies for electroless nickel operations have evolved significantly in recent years. Traditional end-of-pipe treatment is being supplemented or replaced by source reduction techniques. Bath life extension through careful pH monitoring and controlled additions of stabilizers not only improves process economics but also reduces waste generation. Advanced filtration systems, including membrane technologies, allow for selective removal of contaminants while retaining valuable bath components, enabling partial recycling of process chemicals.

Recovery technologies for nickel from spent baths have become economically viable as metal prices increase and disposal costs rise. Electrolytic recovery, ion exchange, and precipitation methods can reclaim up to 98% of nickel from waste streams. These recovered materials can be reintroduced into the manufacturing cycle, creating a more circular economy approach to plating operations.

Regulatory frameworks worldwide are becoming increasingly stringent regarding electroless nickel waste. The European Union's REACH regulations and similar legislation in North America and Asia have established strict limits on heavy metal discharge and chemical usage. Companies are now required to document their chemical management practices and demonstrate continuous improvement in waste reduction. This regulatory pressure has accelerated innovation in greener chemistry for electroless nickel processes.

Water consumption represents another significant environmental impact of electroless nickel operations. A typical plating line may use 5-10 liters of water per square meter of plated surface. Water recycling systems, including reverse osmosis and evaporation technologies, can reduce freshwater requirements by up to 80%, simultaneously decreasing the volume of waste requiring treatment and disposal.

Quality Assurance and Process Monitoring Systems

Quality assurance and process monitoring systems are critical components in electroless nickel plating operations, serving as the foundation for consistent bath stability and precise pH control. Modern electroless nickel facilities implement comprehensive monitoring frameworks that combine real-time data collection with advanced analytical capabilities to maintain optimal processing conditions.

Automated monitoring systems typically incorporate multiple sensor arrays that continuously track key bath parameters including pH levels, temperature, nickel concentration, reducing agent levels, and contaminant presence. These systems utilize specialized pH probes designed to withstand the harsh chemical environment while providing accurate readings within ±0.01 pH units, essential for processes where even minor pH fluctuations can significantly impact deposit quality.

Data acquisition systems collect and process information from these sensors at predetermined intervals, typically ranging from continuous monitoring to 15-minute sampling periods depending on bath sensitivity and production requirements. Advanced systems employ statistical process control (SPC) methodologies to establish control limits and identify trends before parameters drift beyond acceptable ranges, enabling proactive rather than reactive intervention.

Integration of spectrophotometric analysis provides real-time chemical composition monitoring, allowing for automated dosing systems that maintain precise chemical balance. These systems can detect subtle changes in bath composition that might precede instability issues, triggering corrective actions before quality problems emerge in the finished product.

Quality verification protocols complement continuous monitoring through scheduled analytical testing regimens. These include hull cell testing to evaluate deposit appearance and distribution, X-ray fluorescence (XRF) for coating thickness and composition analysis, and adhesion testing to verify mechanical properties. The correlation between these quality metrics and recorded bath parameters creates valuable historical data for process optimization.

Modern facilities increasingly implement machine learning algorithms that analyze historical process data to identify complex relationships between multiple parameters and plating outcomes. These predictive models can anticipate bath stability issues hours before conventional monitoring systems would detect problems, allowing for preventive maintenance and reducing costly production interruptions.

Documentation and traceability systems record all process parameters, chemical additions, and maintenance activities, creating comprehensive batch records that support quality certification and troubleshooting efforts. This historical database becomes increasingly valuable over time, enabling process engineers to refine control parameters and establish more precise operating windows for specific product requirements.

Automated monitoring systems typically incorporate multiple sensor arrays that continuously track key bath parameters including pH levels, temperature, nickel concentration, reducing agent levels, and contaminant presence. These systems utilize specialized pH probes designed to withstand the harsh chemical environment while providing accurate readings within ±0.01 pH units, essential for processes where even minor pH fluctuations can significantly impact deposit quality.

Data acquisition systems collect and process information from these sensors at predetermined intervals, typically ranging from continuous monitoring to 15-minute sampling periods depending on bath sensitivity and production requirements. Advanced systems employ statistical process control (SPC) methodologies to establish control limits and identify trends before parameters drift beyond acceptable ranges, enabling proactive rather than reactive intervention.

Integration of spectrophotometric analysis provides real-time chemical composition monitoring, allowing for automated dosing systems that maintain precise chemical balance. These systems can detect subtle changes in bath composition that might precede instability issues, triggering corrective actions before quality problems emerge in the finished product.

Quality verification protocols complement continuous monitoring through scheduled analytical testing regimens. These include hull cell testing to evaluate deposit appearance and distribution, X-ray fluorescence (XRF) for coating thickness and composition analysis, and adhesion testing to verify mechanical properties. The correlation between these quality metrics and recorded bath parameters creates valuable historical data for process optimization.

Modern facilities increasingly implement machine learning algorithms that analyze historical process data to identify complex relationships between multiple parameters and plating outcomes. These predictive models can anticipate bath stability issues hours before conventional monitoring systems would detect problems, allowing for preventive maintenance and reducing costly production interruptions.

Documentation and traceability systems record all process parameters, chemical additions, and maintenance activities, creating comprehensive batch records that support quality certification and troubleshooting efforts. This historical database becomes increasingly valuable over time, enabling process engineers to refine control parameters and establish more precise operating windows for specific product requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!