Surface Roughness Control in Electroless Plating

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electroless Plating Surface Roughness Background and Objectives

Electroless plating, first discovered in the early 1940s by Brenner and Riddell, has evolved significantly over the past eight decades to become a critical process in various industries including electronics, automotive, aerospace, and medical devices. This chemical deposition method, which operates without external electrical current, offers unique advantages in terms of uniform coating thickness even on complex geometries and non-conductive substrates.

Surface roughness in electroless plating represents a critical quality parameter that directly impacts product performance characteristics including wear resistance, friction coefficient, optical properties, and adhesion strength. Historically, the focus of electroless plating development was primarily on achieving desired functional properties such as corrosion resistance and conductivity, with surface roughness being a secondary consideration.

The technological evolution in precision manufacturing and miniaturization across industries has dramatically shifted requirements toward tighter surface roughness specifications. Modern microelectronics, MEMS devices, and high-precision optical components demand exceptionally smooth surfaces with roughness values in the nanometer range. This transition has elevated surface roughness control from a peripheral concern to a central technical challenge in electroless plating processes.

Current industry benchmarks typically require average roughness (Ra) values between 0.05-0.5 μm for standard applications, while advanced applications may demand Ra values below 0.01 μm. The achievement of these specifications while maintaining other functional properties presents significant technical challenges that necessitate innovative approaches to bath chemistry, process parameters, and post-plating treatments.

The primary objective of this technical investigation is to comprehensively analyze the factors influencing surface roughness in electroless plating processes and identify effective control strategies. Specifically, we aim to establish correlations between bath composition variables (metal ion concentration, reducing agent type and concentration, complexing agents, stabilizers, and pH buffers) and resultant surface topography characteristics.

Additionally, this research seeks to evaluate the impact of process parameters including temperature, agitation methods, substrate preparation techniques, and post-plating treatments on surface roughness outcomes. The ultimate goal is to develop a systematic framework for surface roughness prediction and control that can be implemented across various electroless plating systems, particularly focusing on nickel, copper, and gold plating processes which represent the most commercially significant applications.

By establishing this technical foundation, we intend to enable more precise engineering of surface properties to meet increasingly stringent requirements across diverse industrial applications, while simultaneously improving process reliability and reducing rejection rates in high-precision manufacturing environments.

Surface roughness in electroless plating represents a critical quality parameter that directly impacts product performance characteristics including wear resistance, friction coefficient, optical properties, and adhesion strength. Historically, the focus of electroless plating development was primarily on achieving desired functional properties such as corrosion resistance and conductivity, with surface roughness being a secondary consideration.

The technological evolution in precision manufacturing and miniaturization across industries has dramatically shifted requirements toward tighter surface roughness specifications. Modern microelectronics, MEMS devices, and high-precision optical components demand exceptionally smooth surfaces with roughness values in the nanometer range. This transition has elevated surface roughness control from a peripheral concern to a central technical challenge in electroless plating processes.

Current industry benchmarks typically require average roughness (Ra) values between 0.05-0.5 μm for standard applications, while advanced applications may demand Ra values below 0.01 μm. The achievement of these specifications while maintaining other functional properties presents significant technical challenges that necessitate innovative approaches to bath chemistry, process parameters, and post-plating treatments.

The primary objective of this technical investigation is to comprehensively analyze the factors influencing surface roughness in electroless plating processes and identify effective control strategies. Specifically, we aim to establish correlations between bath composition variables (metal ion concentration, reducing agent type and concentration, complexing agents, stabilizers, and pH buffers) and resultant surface topography characteristics.

Additionally, this research seeks to evaluate the impact of process parameters including temperature, agitation methods, substrate preparation techniques, and post-plating treatments on surface roughness outcomes. The ultimate goal is to develop a systematic framework for surface roughness prediction and control that can be implemented across various electroless plating systems, particularly focusing on nickel, copper, and gold plating processes which represent the most commercially significant applications.

By establishing this technical foundation, we intend to enable more precise engineering of surface properties to meet increasingly stringent requirements across diverse industrial applications, while simultaneously improving process reliability and reducing rejection rates in high-precision manufacturing environments.

Market Demand Analysis for Smooth Electroless Plated Surfaces

The global market for electroless plating with controlled surface roughness has experienced significant growth in recent years, driven primarily by the electronics, automotive, and aerospace industries. The demand for smooth electroless plated surfaces has been particularly strong in the printed circuit board (PCB) manufacturing sector, where the miniaturization trend requires increasingly precise surface finishes to ensure reliable electrical connections and signal integrity.

Market research indicates that the electronics industry represents the largest consumer segment for smooth electroless plated surfaces, accounting for approximately 45% of the total market demand. This is primarily due to the increasing complexity of electronic devices and the growing need for high-density interconnects in advanced electronic packaging. The automotive sector follows with roughly 20% market share, driven by the rapid adoption of electronic components in modern vehicles and the need for reliable, corrosion-resistant connections in harsh operating environments.

Consumer preferences have shifted notably toward products with enhanced durability and aesthetic appeal, both of which are directly influenced by surface roughness control in electroless plating. Industry surveys reveal that manufacturers are willing to pay a premium of 15-30% for plating solutions that can consistently deliver surface roughness values below 0.5 μm Ra (roughness average), highlighting the significant market value placed on smooth finishes.

The geographical distribution of market demand shows Asia-Pacific leading with the highest consumption rate, particularly in countries like China, Japan, South Korea, and Taiwan, where electronics manufacturing is concentrated. North America and Europe follow, with growing demand in these regions primarily driven by aerospace, medical device, and premium automotive applications.

Market forecasts project a compound annual growth rate (CAGR) of 6.8% for smooth electroless plated surfaces through 2028, outpacing the overall electroless plating market growth of 5.2%. This differential underscores the increasing importance placed on surface quality control across industries.

Key market drivers include the ongoing miniaturization of electronic components, increasing reliability requirements in critical applications, and growing emphasis on product aesthetics in consumer electronics. Additionally, regulatory pressures regarding environmental compliance have created market opportunities for electroless plating processes that can achieve smooth surfaces while using more environmentally friendly chemistry.

Customer pain points identified through market research include consistency challenges in achieving uniform surface roughness across large production batches, difficulties in meeting increasingly stringent roughness specifications below 0.3 μm Ra, and the need for cost-effective solutions that don't compromise on quality or production throughput.

Market research indicates that the electronics industry represents the largest consumer segment for smooth electroless plated surfaces, accounting for approximately 45% of the total market demand. This is primarily due to the increasing complexity of electronic devices and the growing need for high-density interconnects in advanced electronic packaging. The automotive sector follows with roughly 20% market share, driven by the rapid adoption of electronic components in modern vehicles and the need for reliable, corrosion-resistant connections in harsh operating environments.

Consumer preferences have shifted notably toward products with enhanced durability and aesthetic appeal, both of which are directly influenced by surface roughness control in electroless plating. Industry surveys reveal that manufacturers are willing to pay a premium of 15-30% for plating solutions that can consistently deliver surface roughness values below 0.5 μm Ra (roughness average), highlighting the significant market value placed on smooth finishes.

The geographical distribution of market demand shows Asia-Pacific leading with the highest consumption rate, particularly in countries like China, Japan, South Korea, and Taiwan, where electronics manufacturing is concentrated. North America and Europe follow, with growing demand in these regions primarily driven by aerospace, medical device, and premium automotive applications.

Market forecasts project a compound annual growth rate (CAGR) of 6.8% for smooth electroless plated surfaces through 2028, outpacing the overall electroless plating market growth of 5.2%. This differential underscores the increasing importance placed on surface quality control across industries.

Key market drivers include the ongoing miniaturization of electronic components, increasing reliability requirements in critical applications, and growing emphasis on product aesthetics in consumer electronics. Additionally, regulatory pressures regarding environmental compliance have created market opportunities for electroless plating processes that can achieve smooth surfaces while using more environmentally friendly chemistry.

Customer pain points identified through market research include consistency challenges in achieving uniform surface roughness across large production batches, difficulties in meeting increasingly stringent roughness specifications below 0.3 μm Ra, and the need for cost-effective solutions that don't compromise on quality or production throughput.

Current Challenges in Surface Roughness Control

Despite significant advancements in electroless plating technology, surface roughness control remains one of the most challenging aspects of the process. The inherent complexity stems from the autocatalytic nature of electroless deposition, where chemical reduction occurs without external electrical current. This fundamental characteristic makes precise control of deposition kinetics and resultant surface morphology particularly difficult compared to electroplating processes.

A primary challenge is the sensitivity of surface roughness to bath composition fluctuations. Minor variations in reducing agent concentration, complexing agents, stabilizers, or pH can dramatically alter nucleation and growth mechanisms, leading to inconsistent surface finishes. This sensitivity increases with bath age, creating a moving target for process engineers attempting to maintain consistent quality over production runs.

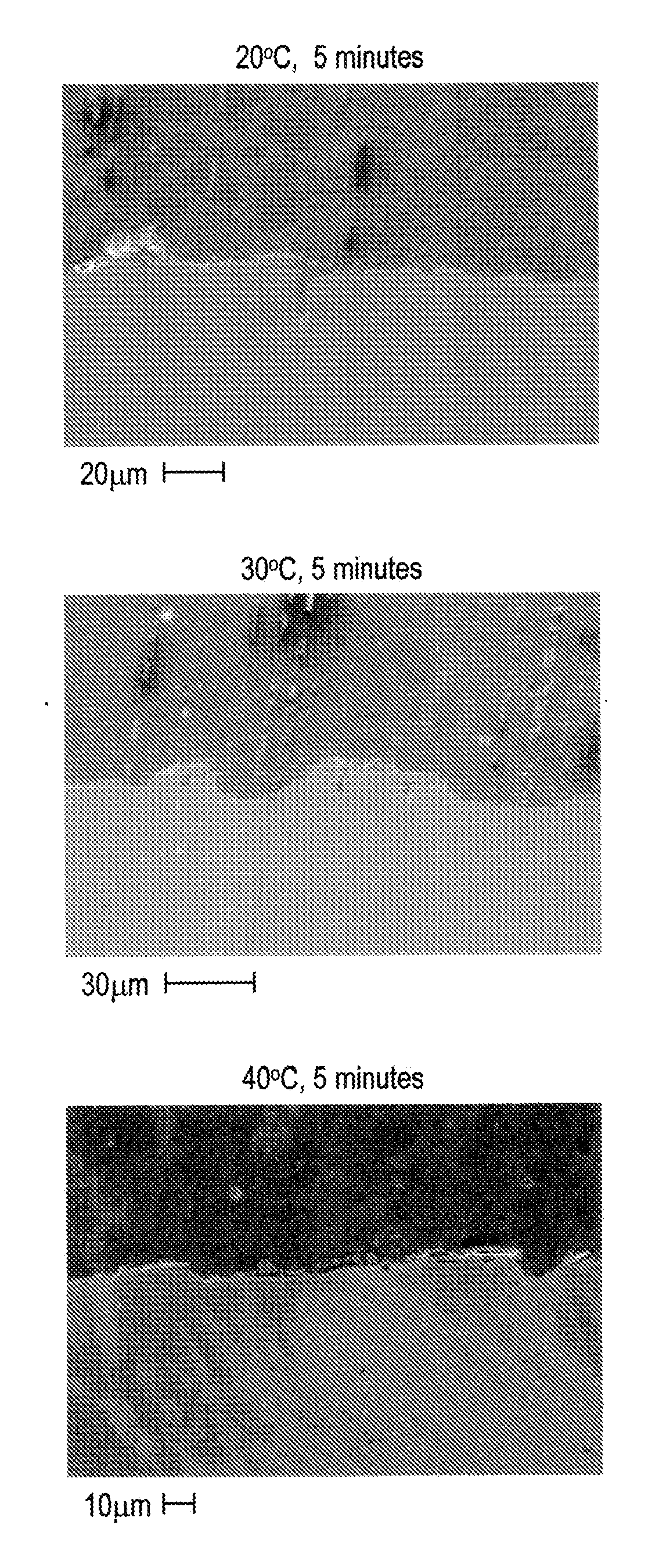

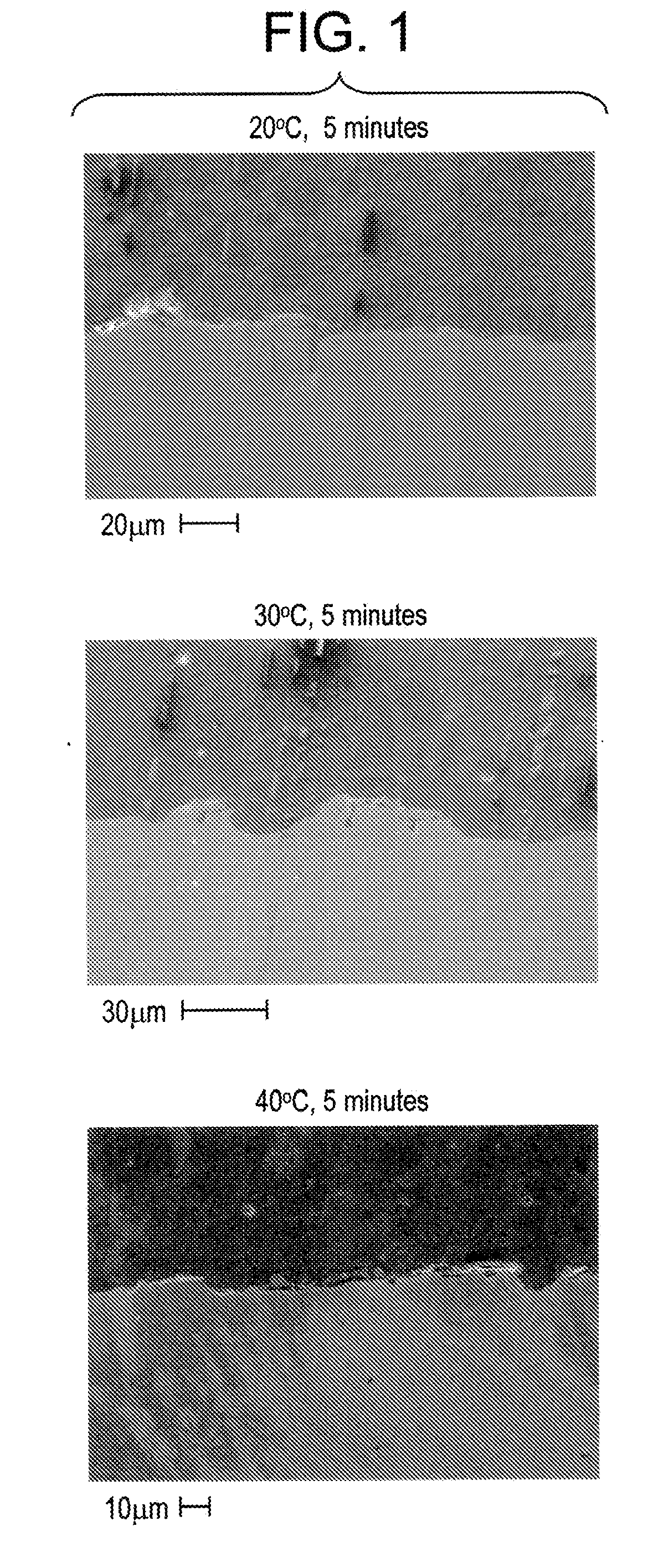

Temperature control presents another significant hurdle. Most electroless plating processes operate within narrow temperature windows, where even small deviations (±2°C) can substantially impact reaction kinetics and consequently surface roughness. Maintaining uniform temperature distribution throughout plating baths, especially in large-scale industrial applications, remains technically demanding and costly.

Substrate preparation inconsistencies contribute substantially to roughness control difficulties. Surface activation processes, essential for initiating electroless deposition, can introduce variability when not precisely controlled. Microscopic contaminants, oxide layers, or uneven catalyst distribution on substrate surfaces often lead to preferential deposition and roughness irregularities that propagate throughout the coating process.

The industry also faces challenges with bath stability over time. Electroless plating solutions undergo continuous composition changes during operation due to byproduct accumulation, additive depletion, and spontaneous decomposition reactions. These changes progressively alter deposition characteristics and surface finish quality, necessitating complex bath maintenance protocols that are difficult to optimize.

Advanced applications requiring ultra-smooth surfaces (Ra < 10nm) for electronics, optics, and precision engineering face particularly severe limitations. Current technologies struggle to achieve consistent nano-scale smoothness while maintaining other critical properties like adhesion, thickness uniformity, and internal stress characteristics.

Analytical and monitoring capabilities represent another significant gap. Real-time measurement of critical bath parameters affecting surface roughness remains limited, forcing many manufacturers to rely on periodic sampling and offline analysis. This reactive approach often results in quality variations being detected only after defective products have been produced.

The increasing demand for environmentally friendly plating processes further complicates roughness control, as traditional additives effective for smoothing (often containing heavy metals or persistent organic compounds) are being phased out due to regulatory restrictions, requiring development of new, often less effective alternatives.

A primary challenge is the sensitivity of surface roughness to bath composition fluctuations. Minor variations in reducing agent concentration, complexing agents, stabilizers, or pH can dramatically alter nucleation and growth mechanisms, leading to inconsistent surface finishes. This sensitivity increases with bath age, creating a moving target for process engineers attempting to maintain consistent quality over production runs.

Temperature control presents another significant hurdle. Most electroless plating processes operate within narrow temperature windows, where even small deviations (±2°C) can substantially impact reaction kinetics and consequently surface roughness. Maintaining uniform temperature distribution throughout plating baths, especially in large-scale industrial applications, remains technically demanding and costly.

Substrate preparation inconsistencies contribute substantially to roughness control difficulties. Surface activation processes, essential for initiating electroless deposition, can introduce variability when not precisely controlled. Microscopic contaminants, oxide layers, or uneven catalyst distribution on substrate surfaces often lead to preferential deposition and roughness irregularities that propagate throughout the coating process.

The industry also faces challenges with bath stability over time. Electroless plating solutions undergo continuous composition changes during operation due to byproduct accumulation, additive depletion, and spontaneous decomposition reactions. These changes progressively alter deposition characteristics and surface finish quality, necessitating complex bath maintenance protocols that are difficult to optimize.

Advanced applications requiring ultra-smooth surfaces (Ra < 10nm) for electronics, optics, and precision engineering face particularly severe limitations. Current technologies struggle to achieve consistent nano-scale smoothness while maintaining other critical properties like adhesion, thickness uniformity, and internal stress characteristics.

Analytical and monitoring capabilities represent another significant gap. Real-time measurement of critical bath parameters affecting surface roughness remains limited, forcing many manufacturers to rely on periodic sampling and offline analysis. This reactive approach often results in quality variations being detected only after defective products have been produced.

The increasing demand for environmentally friendly plating processes further complicates roughness control, as traditional additives effective for smoothing (often containing heavy metals or persistent organic compounds) are being phased out due to regulatory restrictions, requiring development of new, often less effective alternatives.

Current Surface Roughness Control Methodologies

01 Surface roughness control methods in electroless plating

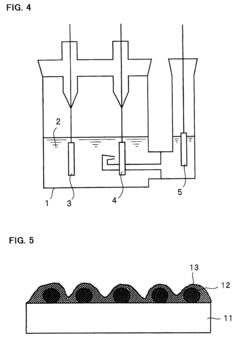

Various methods can be employed to control surface roughness during electroless plating processes. These include adjusting plating bath composition, controlling temperature and pH levels, and implementing specific pre-treatment procedures. By carefully managing these parameters, the resulting plated surface can achieve desired roughness characteristics, which is crucial for applications requiring specific friction properties or subsequent coating adhesion.- Surface roughness control methods in electroless plating: Various methods can be employed to control surface roughness during electroless plating processes. These include adjusting plating bath composition, controlling temperature and pH, using specific additives, and implementing pre-treatment processes. These methods help achieve desired surface characteristics by influencing the nucleation and growth of the metal deposits, resulting in smoother or rougher surfaces as required for specific applications.

- Substrate preparation techniques for improved surface finish: Proper substrate preparation is crucial for controlling surface roughness in electroless plating. Techniques such as mechanical polishing, chemical etching, ultrasonic cleaning, and surface activation can significantly impact the final surface roughness. These preparation methods remove contaminants, create uniform nucleation sites, and provide an optimal surface for metal deposition, resulting in improved adhesion and more consistent surface roughness.

- Bath composition effects on surface roughness: The composition of electroless plating baths significantly influences surface roughness. Key components include metal salts, reducing agents, complexing agents, stabilizers, and surfactants. By optimizing the concentration and ratio of these components, the plating process can be controlled to achieve specific surface roughness values. Certain additives can promote smoother deposits by modifying crystal growth patterns or inhibiting dendritic formation.

- Measurement and characterization of surface roughness: Various techniques are employed to measure and characterize surface roughness in electroless plated surfaces. These include profilometry, atomic force microscopy, scanning electron microscopy, and optical methods. These measurement techniques provide quantitative data on surface topography, allowing for precise control and optimization of the plating process to achieve desired roughness specifications for specific applications.

- Surface roughness optimization for specific applications: Surface roughness in electroless plating can be optimized for specific applications such as electronics, automotive components, and decorative finishes. For electronic applications, smoother surfaces may be required for better conductivity and solderability. In contrast, certain mechanical applications benefit from controlled roughness to improve adhesion, wear resistance, or fluid dynamics properties. Tailoring the plating process to achieve application-specific roughness enhances product performance and durability.

02 Additives for reducing surface roughness

Specific additives can be incorporated into electroless plating baths to reduce surface roughness of the deposited layer. These include surfactants, leveling agents, and brighteners that help to produce smoother, more uniform coatings. The additives work by modifying the deposition kinetics, promoting even growth of the metal layer, and preventing the formation of nodules or other surface irregularities that contribute to roughness.Expand Specific Solutions03 Surface preparation techniques for improved smoothness

Proper surface preparation before electroless plating significantly impacts the final surface roughness. Techniques such as mechanical polishing, chemical etching, and ultrasonic cleaning can be used to create an optimal substrate surface. These preparation methods remove contaminants, reduce initial surface irregularities, and create uniform nucleation sites for the plating process, resulting in smoother electroless deposits.Expand Specific Solutions04 Post-plating treatments for roughness modification

After electroless plating, various post-treatment methods can be applied to modify surface roughness. These include heat treatment, burnishing, and light mechanical finishing. Such treatments can help to reduce surface roughness by promoting recrystallization of the plated layer, relieving internal stresses, and physically smoothing any remaining surface irregularities, resulting in improved surface quality for specific applications.Expand Specific Solutions05 Roughness measurement and characterization techniques

Accurate measurement and characterization of surface roughness in electroless plated components is essential for quality control. Various techniques including profilometry, atomic force microscopy, scanning electron microscopy, and optical methods can be employed to quantify surface roughness parameters. These measurements provide critical feedback for process optimization and ensure that the plated surfaces meet the required specifications for their intended applications.Expand Specific Solutions

Key Industry Players in Electroless Plating Technology

The electroless plating surface roughness control market is currently in a growth phase, with increasing demand driven by electronics miniaturization and advanced manufacturing requirements. The global market size is estimated to exceed $2 billion, expanding at 6-8% CAGR. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include IBIDEN and Nitto Denko with advanced substrate plating technologies, Atotech Deutschland as a surface finishing specialist, RESONAC and Mitsui Kinzoku focusing on functional materials, and TOPPAN and Panasonic developing precision electronics applications. Japanese companies dominate this sector, with significant contributions from European and American enterprises developing proprietary roughness control methodologies for high-performance electronic components.

Mitsui Kinzoku Co., Ltd.

Technical Solution: Mitsui Kinzoku has developed an innovative electroless plating technology called MicroFine that specifically addresses surface roughness control through advanced bath chemistry and process optimization. Their approach utilizes proprietary organic brighteners that selectively adsorb onto high-energy sites during metal deposition, promoting lateral rather than vertical crystal growth. The company's process incorporates a unique two-stage plating sequence with different stabilizer concentrations that first establishes a uniform nucleation layer followed by controlled growth conditions. Their technology achieves remarkably consistent surface roughness with Ra values typically between 0.15-0.25μm across various substrate materials. Mitsui's system also features specialized pre-treatment processes that modify substrate surface energy distribution to ensure uniform initial nucleation density, which is critical for subsequent smooth film growth. Their latest innovation includes pulse-reverse techniques that periodically dissolve high-points in the deposit to further enhance smoothness.

Strengths: Exceptional nano-scale roughness control; excellent deposit uniformity across complex geometries; superior performance on difficult substrates like high-glass-transition temperature polymers. Weaknesses: Requires more sophisticated process control equipment; higher sensitivity to organic contamination; more complex waste treatment requirements due to specialized additives.

Rohm and Haas Electronic Materials, Inc.

Technical Solution: Rohm and Haas has developed a comprehensive electroless plating system called SmartFill that incorporates advanced leveling agents to control surface roughness. Their technology utilizes proprietary nitrogen-containing heterocyclic compounds that selectively inhibit growth on protruding features while allowing deposition in recessed areas, effectively planarizing the surface during deposition. The company's process includes a unique pre-plating conditioning step that normalizes surface energy across the substrate, ensuring uniform nucleation density. Their bath formulations incorporate nano-scale polymer additives that co-deposit with the metal and fill micro-voids, resulting in exceptionally smooth surfaces with Ra values consistently below 0.3μm. Rohm and Haas has also pioneered real-time spectroscopic monitoring systems that maintain optimal concentrations of roughness-controlling additives throughout the plating process.

Strengths: Superior performance in high-aspect-ratio applications; excellent throwing power while maintaining smoothness; formulations specifically designed for semiconductor and advanced packaging applications. Weaknesses: Higher chemical costs compared to standard formulations; more complex bath maintenance requirements; some solutions have narrower operating windows requiring precise control.

Critical Patents and Research in Electroless Plating Surface Control

Processes for texturing a surface prior to electroless plating

PatentInactiveUS20090302005A1

Innovation

- A process involving an aqueous solution of oxalic acid, sulfuric acid, and hydrogen peroxide is used to texture the surface, achieving an average roughness greater than 60 Ra, which improves adhesion of electroless nickel plating without damaging the substrate and minimizing residue formation.

Electrode for rechargeable lithium battery and rechargeable lithium battery

PatentInactiveUS7147971B2

Innovation

- A copper alloy current collector with a tensile strength of 400 N/mm² or higher, a proportional limit of 160 N/mm² or higher, and an elastic coefficient of 1.1 N/mm² or higher, along with a surface roughness of 0.01–1 μm, is used to prevent deformation and enhance adhesion, while Cu—Ni—Si or Cu—Cr—Zr alloys further improve tensile strength and prevent wrinkling, allowing for better stress relaxation and increased energy density.

Environmental Impact and Sustainability Considerations

Electroless plating processes traditionally involve the use of chemicals that pose significant environmental concerns. The baths typically contain heavy metals such as nickel, copper, and cobalt, along with reducing agents like formaldehyde, sodium hypophosphite, and complexing agents that can be environmentally harmful when discharged without proper treatment. Surface roughness control methods often exacerbate these issues by introducing additional chemical additives or requiring more frequent bath replacements.

Recent regulatory frameworks, including the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, have placed increasing pressure on the electroless plating industry to adopt more sustainable practices. Companies must now consider the entire lifecycle environmental impact of their plating operations, from raw material sourcing to waste disposal.

Significant progress has been made in developing environmentally friendly alternatives for surface roughness control. Green chemistry approaches include the replacement of formaldehyde with less toxic reducing agents such as glyoxylic acid or sodium borohydride. Additionally, biodegradable complexing agents derived from natural sources are being investigated as substitutes for conventional EDTA (Ethylenediaminetetraacetic acid) and similar chelating agents.

Water consumption represents another critical environmental concern in electroless plating operations. Traditional roughness control methods often require multiple rinsing steps, consuming substantial volumes of water. Closed-loop water recycling systems and cascade rinsing techniques have emerged as effective solutions, reducing water usage by up to 60% in some facilities while maintaining desired surface roughness specifications.

Energy efficiency improvements in electroless plating processes contribute significantly to sustainability goals. Optimized bath formulations that operate at lower temperatures reduce energy consumption while still achieving controlled surface roughness. Some innovative approaches utilize ultrasonic or electromagnetic assistance to enhance plating uniformity at reduced temperatures, further decreasing the carbon footprint of the process.

Waste minimization strategies specifically targeting surface roughness control include bath life extension through selective filtration and replenishment protocols. Advanced monitoring techniques using real-time sensors allow for precise chemical additions, preventing overdosing of additives used for roughness control and extending bath longevity from weeks to months in some applications.

Life cycle assessment (LCA) studies comparing traditional and emerging surface roughness control methods demonstrate that newer techniques can reduce environmental impact by 30-45% across multiple impact categories, including global warming potential, acidification, and ecotoxicity. These findings provide valuable guidance for industry practitioners seeking to balance technical performance requirements with environmental responsibility.

Recent regulatory frameworks, including the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, have placed increasing pressure on the electroless plating industry to adopt more sustainable practices. Companies must now consider the entire lifecycle environmental impact of their plating operations, from raw material sourcing to waste disposal.

Significant progress has been made in developing environmentally friendly alternatives for surface roughness control. Green chemistry approaches include the replacement of formaldehyde with less toxic reducing agents such as glyoxylic acid or sodium borohydride. Additionally, biodegradable complexing agents derived from natural sources are being investigated as substitutes for conventional EDTA (Ethylenediaminetetraacetic acid) and similar chelating agents.

Water consumption represents another critical environmental concern in electroless plating operations. Traditional roughness control methods often require multiple rinsing steps, consuming substantial volumes of water. Closed-loop water recycling systems and cascade rinsing techniques have emerged as effective solutions, reducing water usage by up to 60% in some facilities while maintaining desired surface roughness specifications.

Energy efficiency improvements in electroless plating processes contribute significantly to sustainability goals. Optimized bath formulations that operate at lower temperatures reduce energy consumption while still achieving controlled surface roughness. Some innovative approaches utilize ultrasonic or electromagnetic assistance to enhance plating uniformity at reduced temperatures, further decreasing the carbon footprint of the process.

Waste minimization strategies specifically targeting surface roughness control include bath life extension through selective filtration and replenishment protocols. Advanced monitoring techniques using real-time sensors allow for precise chemical additions, preventing overdosing of additives used for roughness control and extending bath longevity from weeks to months in some applications.

Life cycle assessment (LCA) studies comparing traditional and emerging surface roughness control methods demonstrate that newer techniques can reduce environmental impact by 30-45% across multiple impact categories, including global warming potential, acidification, and ecotoxicity. These findings provide valuable guidance for industry practitioners seeking to balance technical performance requirements with environmental responsibility.

Quality Assurance and Testing Standards for Surface Finish

Quality assurance in electroless plating surface finish requires comprehensive testing standards to ensure consistent roughness control. Industry standards such as ASTM B733, ISO 4527, and MIL-C-26074 provide specific parameters for surface roughness measurement and acceptance criteria in electroless plating applications. These standards define the acceptable Ra (arithmetic average roughness) values, typically ranging from 0.05 to 3.2 μm depending on the application requirements.

Surface profilometry represents the primary testing methodology, with contact profilometers and non-contact optical systems being the most widely utilized instruments. Contact profilometers offer high accuracy for micro-roughness measurement with resolution down to nanometer scale, while optical systems provide faster measurement without surface contact, preventing potential damage to delicate plated surfaces.

Statistical process control (SPC) methodologies have become increasingly important in electroless plating quality assurance. Implementation of SPC charts for surface roughness monitoring enables real-time detection of process drift before it results in non-conforming products. Industry best practices recommend measurement frequency based on batch size, with critical applications requiring 100% inspection protocols.

Correlation between surface roughness and functional performance necessitates application-specific testing standards. For electronic components, surface roughness directly impacts solderability and electrical contact resistance, requiring specialized testing protocols such as IPC-TM-650. Aerospace applications follow standards like AS9100, which mandates rigorous documentation of surface roughness measurements throughout the production process.

Advanced measurement technologies including atomic force microscopy (AFM) and white light interferometry are gaining prominence for high-precision applications. These technologies enable three-dimensional surface characterization beyond traditional two-dimensional parameters, providing Sa (area roughness) measurements that better represent the functional performance of plated surfaces.

Certification requirements vary by industry sector, with medical device manufacturing following ISO 13485 standards that mandate validated measurement systems with documented calibration procedures. Automotive applications typically adhere to IATF 16949 standards, requiring measurement system analysis (MSA) studies to verify the reliability of surface roughness testing equipment and procedures.

Digital documentation systems have revolutionized quality assurance in electroless plating operations, enabling complete traceability of surface roughness measurements. Modern quality management systems incorporate machine learning algorithms to predict potential surface defects based on process parameter trends, moving the industry toward predictive quality assurance rather than reactive inspection methodologies.

Surface profilometry represents the primary testing methodology, with contact profilometers and non-contact optical systems being the most widely utilized instruments. Contact profilometers offer high accuracy for micro-roughness measurement with resolution down to nanometer scale, while optical systems provide faster measurement without surface contact, preventing potential damage to delicate plated surfaces.

Statistical process control (SPC) methodologies have become increasingly important in electroless plating quality assurance. Implementation of SPC charts for surface roughness monitoring enables real-time detection of process drift before it results in non-conforming products. Industry best practices recommend measurement frequency based on batch size, with critical applications requiring 100% inspection protocols.

Correlation between surface roughness and functional performance necessitates application-specific testing standards. For electronic components, surface roughness directly impacts solderability and electrical contact resistance, requiring specialized testing protocols such as IPC-TM-650. Aerospace applications follow standards like AS9100, which mandates rigorous documentation of surface roughness measurements throughout the production process.

Advanced measurement technologies including atomic force microscopy (AFM) and white light interferometry are gaining prominence for high-precision applications. These technologies enable three-dimensional surface characterization beyond traditional two-dimensional parameters, providing Sa (area roughness) measurements that better represent the functional performance of plated surfaces.

Certification requirements vary by industry sector, with medical device manufacturing following ISO 13485 standards that mandate validated measurement systems with documented calibration procedures. Automotive applications typically adhere to IATF 16949 standards, requiring measurement system analysis (MSA) studies to verify the reliability of surface roughness testing equipment and procedures.

Digital documentation systems have revolutionized quality assurance in electroless plating operations, enabling complete traceability of surface roughness measurements. Modern quality management systems incorporate machine learning algorithms to predict potential surface defects based on process parameter trends, moving the industry toward predictive quality assurance rather than reactive inspection methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!