Environmental Aspects of Electroless Nickel Plating

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electroless Nickel Plating Evolution and Objectives

Electroless nickel plating has evolved significantly since its inception in the mid-20th century, transforming from a niche process to a critical surface treatment technology across multiple industries. The technique was first developed in 1944 by Abner Brenner and Grace Riddell at the National Bureau of Standards, who discovered that nickel could be deposited onto a substrate without using an external electrical current. This breakthrough laid the foundation for what would become an essential industrial process.

Throughout the 1950s and 1960s, the technology saw rapid advancement as researchers optimized bath compositions and operating parameters. The introduction of phosphorus co-deposition created varying deposit properties, expanding application possibilities. By the 1970s, electroless nickel plating had established itself in automotive, aerospace, and electronics industries due to its uniform coating capabilities regardless of part geometry.

The 1980s and 1990s marked a period of significant refinement, with the development of more stable bath formulations and improved additives that enhanced deposit characteristics. During this era, environmental concerns began to emerge as a consideration in process development, though they were not yet central to innovation efforts.

The early 2000s witnessed a paradigm shift as environmental regulations tightened globally. Traditional electroless nickel baths contained several problematic components, including nickel salts (carcinogenic), sodium hypophosphite (high BOD/COD values), complexing agents (non-biodegradable), and stabilizers (heavy metals). This regulatory pressure catalyzed research into more environmentally compatible alternatives.

Current technological evolution is primarily driven by sustainability objectives. The industry aims to develop processes that maintain or exceed traditional performance metrics while significantly reducing environmental impact. Key objectives include eliminating or reducing hazardous chemicals, decreasing water consumption, minimizing energy requirements, and developing closed-loop systems for chemical recovery.

Recent innovations focus on replacing conventional stabilizers with biodegradable alternatives, implementing more efficient filtration and recovery systems, and developing low-temperature processes to reduce energy consumption. Additionally, research into alternative reducing agents beyond sodium hypophosphite represents a frontier in making the process more environmentally sustainable.

The trajectory of electroless nickel plating technology is now firmly oriented toward achieving a balance between technical performance and environmental responsibility. Future objectives include the development of completely cadmium and lead-free processes, reduction of nickel exposure risks, implementation of zero-discharge systems, and integration with broader green manufacturing initiatives. These environmental aspects have transformed from peripheral concerns to central drivers of innovation in the field.

Throughout the 1950s and 1960s, the technology saw rapid advancement as researchers optimized bath compositions and operating parameters. The introduction of phosphorus co-deposition created varying deposit properties, expanding application possibilities. By the 1970s, electroless nickel plating had established itself in automotive, aerospace, and electronics industries due to its uniform coating capabilities regardless of part geometry.

The 1980s and 1990s marked a period of significant refinement, with the development of more stable bath formulations and improved additives that enhanced deposit characteristics. During this era, environmental concerns began to emerge as a consideration in process development, though they were not yet central to innovation efforts.

The early 2000s witnessed a paradigm shift as environmental regulations tightened globally. Traditional electroless nickel baths contained several problematic components, including nickel salts (carcinogenic), sodium hypophosphite (high BOD/COD values), complexing agents (non-biodegradable), and stabilizers (heavy metals). This regulatory pressure catalyzed research into more environmentally compatible alternatives.

Current technological evolution is primarily driven by sustainability objectives. The industry aims to develop processes that maintain or exceed traditional performance metrics while significantly reducing environmental impact. Key objectives include eliminating or reducing hazardous chemicals, decreasing water consumption, minimizing energy requirements, and developing closed-loop systems for chemical recovery.

Recent innovations focus on replacing conventional stabilizers with biodegradable alternatives, implementing more efficient filtration and recovery systems, and developing low-temperature processes to reduce energy consumption. Additionally, research into alternative reducing agents beyond sodium hypophosphite represents a frontier in making the process more environmentally sustainable.

The trajectory of electroless nickel plating technology is now firmly oriented toward achieving a balance between technical performance and environmental responsibility. Future objectives include the development of completely cadmium and lead-free processes, reduction of nickel exposure risks, implementation of zero-discharge systems, and integration with broader green manufacturing initiatives. These environmental aspects have transformed from peripheral concerns to central drivers of innovation in the field.

Market Demand for Eco-friendly Surface Finishing

The global market for eco-friendly surface finishing solutions has witnessed substantial growth in recent years, driven primarily by increasing environmental regulations and growing awareness about sustainable manufacturing practices. The electroless nickel plating industry, valued at approximately $1.8 billion in 2022, is experiencing significant pressure to adopt greener technologies due to the environmental concerns associated with traditional plating processes.

Environmental regulations such as the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives have created strong market demand for environmentally responsible surface finishing alternatives. These regulations have effectively limited the use of certain hazardous chemicals commonly found in traditional electroless nickel plating baths, including lead, cadmium, and hexavalent chromium compounds.

Consumer preferences are increasingly shifting toward products manufactured using sustainable processes. A recent industry survey revealed that 67% of industrial buyers now consider environmental impact when selecting surface finishing suppliers, compared to just 38% five years ago. This shift represents a significant market driver for eco-friendly electroless nickel plating solutions.

The automotive sector represents the largest market segment for environmentally friendly surface finishing, accounting for approximately 28% of the total demand. This is followed by electronics (22%), aerospace (17%), and industrial machinery (15%). These industries are particularly sensitive to environmental compliance due to their global supply chains and consumer-facing nature.

Regional analysis indicates that Europe leads in the adoption of eco-friendly surface finishing technologies, followed by North America and Asia-Pacific. However, the fastest growth is occurring in emerging economies, particularly in India and China, where environmental regulations are becoming increasingly stringent while manufacturing activities continue to expand.

The premium pricing model for eco-friendly electroless nickel plating solutions remains viable, with customers demonstrating willingness to pay 15-20% more for environmentally compliant alternatives. This price tolerance is supported by the long-term cost benefits associated with avoiding regulatory penalties and the marketing advantages of sustainable manufacturing credentials.

Market forecasts suggest that the eco-friendly segment of the electroless nickel plating market will grow at a CAGR of 7.8% through 2028, significantly outpacing the overall market growth rate of 4.2%. This accelerated growth trajectory underscores the strong market demand for sustainable surface finishing solutions and presents substantial opportunities for innovation in this space.

Environmental regulations such as the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives have created strong market demand for environmentally responsible surface finishing alternatives. These regulations have effectively limited the use of certain hazardous chemicals commonly found in traditional electroless nickel plating baths, including lead, cadmium, and hexavalent chromium compounds.

Consumer preferences are increasingly shifting toward products manufactured using sustainable processes. A recent industry survey revealed that 67% of industrial buyers now consider environmental impact when selecting surface finishing suppliers, compared to just 38% five years ago. This shift represents a significant market driver for eco-friendly electroless nickel plating solutions.

The automotive sector represents the largest market segment for environmentally friendly surface finishing, accounting for approximately 28% of the total demand. This is followed by electronics (22%), aerospace (17%), and industrial machinery (15%). These industries are particularly sensitive to environmental compliance due to their global supply chains and consumer-facing nature.

Regional analysis indicates that Europe leads in the adoption of eco-friendly surface finishing technologies, followed by North America and Asia-Pacific. However, the fastest growth is occurring in emerging economies, particularly in India and China, where environmental regulations are becoming increasingly stringent while manufacturing activities continue to expand.

The premium pricing model for eco-friendly electroless nickel plating solutions remains viable, with customers demonstrating willingness to pay 15-20% more for environmentally compliant alternatives. This price tolerance is supported by the long-term cost benefits associated with avoiding regulatory penalties and the marketing advantages of sustainable manufacturing credentials.

Market forecasts suggest that the eco-friendly segment of the electroless nickel plating market will grow at a CAGR of 7.8% through 2028, significantly outpacing the overall market growth rate of 4.2%. This accelerated growth trajectory underscores the strong market demand for sustainable surface finishing solutions and presents substantial opportunities for innovation in this space.

Environmental Challenges in Current Plating Processes

Electroless nickel plating processes, while offering significant technical advantages, present substantial environmental challenges that have become increasingly concerning for the industry. Traditional electroless nickel baths contain several environmentally problematic components, with nickel compounds themselves being classified as carcinogenic, mutagenic, and reprotoxic (CMR) substances. The European Chemicals Agency (ECHA) has placed nickel compounds under strict regulatory scrutiny, requiring comprehensive risk management measures during handling and disposal.

The reducing agents used in conventional processes, particularly sodium hypophosphite, create significant environmental burdens. These compounds contribute to high Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD) in wastewater, requiring extensive treatment before discharge. Industry data indicates that a typical electroless nickel plating facility can generate wastewater with COD values exceeding 15,000 mg/L, far above regulatory limits in most jurisdictions.

Complexing agents and stabilizers in plating baths present another environmental challenge. EDTA (ethylenediaminetetraacetic acid) and similar chelating agents persist in the environment, potentially mobilizing heavy metals in soil and water systems. These compounds resist conventional wastewater treatment methods, with removal efficiencies often below 30% in standard treatment facilities.

The energy intensity of electroless nickel processes further compounds environmental concerns. Maintaining baths at operating temperatures (typically 85-95°C) requires significant energy input, with estimates suggesting energy consumption of 5-8 kWh per square meter of plated surface. This contributes substantially to the carbon footprint of plating operations, particularly in regions dependent on fossil fuel energy sources.

Waste management represents perhaps the most pressing environmental challenge. Spent plating solutions contain not only nickel but also phosphorus compounds, organic contaminants, and various breakdown products. The disposal of these solutions often requires specialized treatment, with costs estimated at $500-1,000 per 1,000 liters of spent solution. Improper disposal has led to documented cases of soil and groundwater contamination at multiple industrial sites globally.

Air emissions from electroless nickel operations, though less discussed than liquid waste, also present environmental concerns. Hydrogen gas generated during the plating reaction creates explosion risks and ventilation requirements, while volatile organic compounds from certain bath additives contribute to air quality issues. Measurements at plating facilities have detected nickel particulates in workplace air at concentrations approaching occupational exposure limits.

Regulatory pressures continue to intensify globally, with the EU's REACH regulations, China's increasingly stringent environmental protection laws, and the US EPA's tightened effluent guidelines all targeting metal finishing operations. These evolving regulatory frameworks are forcing the industry to reconsider traditional electroless nickel processes and explore more environmentally sustainable alternatives.

The reducing agents used in conventional processes, particularly sodium hypophosphite, create significant environmental burdens. These compounds contribute to high Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD) in wastewater, requiring extensive treatment before discharge. Industry data indicates that a typical electroless nickel plating facility can generate wastewater with COD values exceeding 15,000 mg/L, far above regulatory limits in most jurisdictions.

Complexing agents and stabilizers in plating baths present another environmental challenge. EDTA (ethylenediaminetetraacetic acid) and similar chelating agents persist in the environment, potentially mobilizing heavy metals in soil and water systems. These compounds resist conventional wastewater treatment methods, with removal efficiencies often below 30% in standard treatment facilities.

The energy intensity of electroless nickel processes further compounds environmental concerns. Maintaining baths at operating temperatures (typically 85-95°C) requires significant energy input, with estimates suggesting energy consumption of 5-8 kWh per square meter of plated surface. This contributes substantially to the carbon footprint of plating operations, particularly in regions dependent on fossil fuel energy sources.

Waste management represents perhaps the most pressing environmental challenge. Spent plating solutions contain not only nickel but also phosphorus compounds, organic contaminants, and various breakdown products. The disposal of these solutions often requires specialized treatment, with costs estimated at $500-1,000 per 1,000 liters of spent solution. Improper disposal has led to documented cases of soil and groundwater contamination at multiple industrial sites globally.

Air emissions from electroless nickel operations, though less discussed than liquid waste, also present environmental concerns. Hydrogen gas generated during the plating reaction creates explosion risks and ventilation requirements, while volatile organic compounds from certain bath additives contribute to air quality issues. Measurements at plating facilities have detected nickel particulates in workplace air at concentrations approaching occupational exposure limits.

Regulatory pressures continue to intensify globally, with the EU's REACH regulations, China's increasingly stringent environmental protection laws, and the US EPA's tightened effluent guidelines all targeting metal finishing operations. These evolving regulatory frameworks are forcing the industry to reconsider traditional electroless nickel processes and explore more environmentally sustainable alternatives.

Current Eco-friendly Electroless Nickel Methodologies

01 Reduction of hazardous chemicals in electroless nickel plating

Efforts to reduce environmental impact focus on minimizing or eliminating hazardous chemicals in electroless nickel plating processes. This includes developing formulations with reduced heavy metal content, lower toxicity, and elimination of environmentally harmful substances like lead compounds. These environmentally friendly alternatives maintain plating quality while significantly reducing ecological risks and workplace hazards.- Reduction of toxic chemicals in electroless nickel plating: Efforts to reduce the environmental impact of electroless nickel plating focus on minimizing or eliminating toxic chemicals such as lead compounds and formaldehyde. Alternative reducing agents and stabilizers that are more environmentally friendly have been developed. These innovations help decrease hazardous waste generation and improve workplace safety while maintaining plating quality and performance.

- Waste treatment and recycling methods: Various waste treatment and recycling methods have been developed to address the environmental concerns of electroless nickel plating processes. These include recovery systems for nickel and other metals from spent plating baths, wastewater treatment technologies to remove heavy metals and other contaminants, and closed-loop systems that minimize discharge. Such approaches significantly reduce the environmental footprint of plating operations.

- Energy-efficient plating processes: Energy consumption is a significant environmental concern in electroless nickel plating. Innovations in this area include low-temperature plating processes, improved bath stability to extend solution life, and more efficient heating systems. These developments reduce the carbon footprint of plating operations while often providing economic benefits through reduced energy costs and increased production efficiency.

- Green chemistry approaches for electroless plating: Green chemistry principles are being applied to electroless nickel plating to develop more sustainable processes. This includes using bio-based or renewable materials as reducing agents or stabilizers, developing water-based systems with reduced volatile organic compounds, and creating plating baths with lower toxicity. These approaches aim to maintain or improve coating performance while reducing environmental impact throughout the product lifecycle.

- Regulatory compliance and environmental management systems: Electroless nickel plating facilities are implementing comprehensive environmental management systems to ensure regulatory compliance and minimize environmental impact. These systems include monitoring and controlling emissions, implementing best practices for chemical handling and storage, conducting lifecycle assessments, and obtaining environmental certifications. Such approaches help companies meet increasingly stringent environmental regulations while improving their sustainability profile.

02 Waste treatment and recycling solutions

Advanced waste treatment methods have been developed to address the environmental concerns of electroless nickel plating. These include specialized filtration systems, chemical precipitation techniques, and ion exchange processes to remove nickel and phosphorus compounds from wastewater. Recycling technologies enable the recovery and reuse of valuable metals from spent plating baths, significantly reducing waste discharge and resource consumption.Expand Specific Solutions03 Energy-efficient plating processes

Innovative approaches to electroless nickel plating focus on reducing energy consumption during the plating process. These include lower temperature plating baths, optimized chemical formulations that require less heating, and improved equipment design for better energy efficiency. These developments not only reduce the carbon footprint of the plating operation but also often result in cost savings and improved process stability.Expand Specific Solutions04 Sustainable alternatives to traditional plating chemicals

Research has led to the development of more sustainable alternatives to traditional electroless nickel plating chemicals. These include bio-based reducing agents, environmentally benign complexing agents, and stabilizers derived from renewable resources. Such alternatives reduce dependence on petroleum-based chemicals and decrease the environmental footprint of the plating process while maintaining or even enhancing coating performance.Expand Specific Solutions05 Regulatory compliance and environmental management systems

Implementation of comprehensive environmental management systems for electroless nickel plating operations ensures regulatory compliance and continuous improvement in environmental performance. This includes monitoring and controlling emissions, establishing proper chemical handling procedures, and developing emergency response protocols. Certification to international environmental standards provides a framework for systematically reducing environmental impacts while maintaining operational efficiency.Expand Specific Solutions

Leading Companies in Sustainable Plating Technologies

The electroless nickel plating industry is currently in a mature growth phase, characterized by established technologies and steady market expansion. The global market size is estimated to exceed $2 billion, driven by increasing applications in automotive, electronics, and aerospace sectors. From a technological maturity perspective, leading players like MacDermid Enthone and Atotech Deutschland have developed advanced environmentally-friendly solutions addressing traditional concerns with hazardous chemicals. Companies such as BYD and Surface Technologies are implementing sustainable practices, while research institutions like Empa and National Tsing-Hua University are pioneering new formulations with reduced environmental impact. IBM and Carbodeon are advancing the technology through nanomaterial integration, creating more efficient processes with lower environmental footprints. The competitive landscape shows a balance between established chemical companies and innovative technology developers focused on sustainability.

MacDermid, Inc.

Technical Solution: MacDermid has pioneered environmentally responsible electroless nickel plating with their ENOVA™ and VAND-ALOY™ systems. These systems utilize proprietary stabilizer technology that extends bath life up to 8 metal turnovers (MTO), significantly reducing waste generation[3]. Their formulations are free from lead compounds and other restricted substances, instead using alternative stabilizers that maintain performance while reducing environmental toxicity. MacDermid's process incorporates advanced filtration and ion exchange systems that continuously remove contaminants, extending solution life and reducing disposal frequency. Their technology includes precise dosing systems that optimize chemical consumption, reducing excess usage by up to 25% compared to conventional systems[4]. MacDermid has also developed low-temperature electroless nickel processes that operate effectively at 65-70°C instead of traditional 85-90°C, resulting in approximately 20% energy savings while reducing evaporation losses and associated emissions.

Strengths: Extended bath life significantly reduces waste generation and chemical consumption. Their systems offer excellent deposit uniformity even on complex geometries, with reduced energy requirements. Weaknesses: The processes may require more precise control parameters and can be more sensitive to contamination than traditional high-temperature systems, potentially requiring additional operator training and monitoring.

Atotech Deutschland GmbH & Co. KG

Technical Solution: Atotech has developed environmentally friendly electroless nickel plating solutions that significantly reduce environmental impact. Their ENIG (Electroless Nickel Immersion Gold) and ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) processes utilize nickel-phosphorus alloy deposition with reduced chemical consumption. Their innovative approach includes mid-phosphorus electroless nickel plating solutions that are free from lead, cadmium, and other heavy metals[1]. Atotech's systems incorporate closed-loop recovery systems that recycle and reuse process chemicals, reducing waste by up to 40%. Their advanced filtration technologies remove particulates down to submicron levels, extending bath life and reducing disposal frequency[2]. Additionally, they've implemented energy-efficient heating systems that reduce energy consumption by approximately 30% compared to conventional systems, while maintaining precise temperature control essential for quality plating results.

Strengths: Advanced recovery systems significantly reduce chemical waste and water consumption. Their formulations comply with RoHS and REACH regulations, making them suitable for global markets with strict environmental standards. Weaknesses: The initial implementation cost is higher than traditional systems, and the technology requires more sophisticated monitoring and control systems to maintain optimal performance.

Key Innovations in Low-impact Plating Chemistry

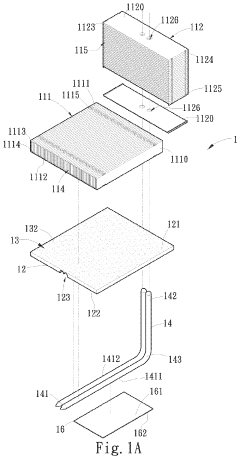

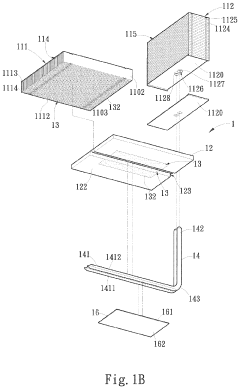

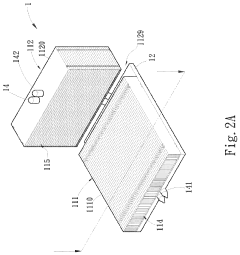

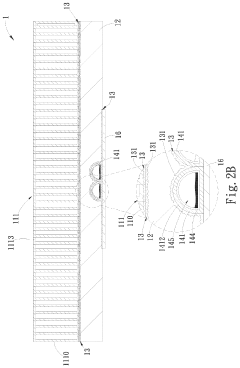

Thermal module structure

PatentActiveUS20230243608A1

Innovation

- A thermal module structure with copper embedding layers on an aluminum base and fin assemblies allows direct welding of copper and aluminum components without pre-surface modification, using copper embedding layers to enhance bonding and reduce manufacturing costs and environmental impact.

Environmentally friendly nickel electroplating compositions and methods

PatentActiveTW201905242A

Innovation

- An environmentally friendly nickel electroplating composition comprising nickel ions, carboxylate ions, and 2-phenyl-5-benzimidazole sulfonic acid or its salts, which enables bright, uniform, and ductile nickel deposits with good internal stress properties, suitable as an underlayer to prevent corrosion and pore formation in gold and gold alloys.

Regulatory Compliance Framework for Metal Finishing

The regulatory landscape for metal finishing operations, particularly electroless nickel plating, has evolved significantly in response to growing environmental concerns. At the international level, the Basel Convention regulates transboundary movements of hazardous wastes, while the Stockholm Convention addresses persistent organic pollutants that may be present in certain plating processes. The Rotterdam Convention further controls the international trade of hazardous chemicals used in metal finishing operations.

In the United States, the Environmental Protection Agency (EPA) enforces several key regulations affecting electroless nickel plating facilities. The Clean Water Act establishes the National Pollutant Discharge Elimination System (NPDES) permit program, which regulates point source discharges of pollutants into U.S. waters. Additionally, the Resource Conservation and Recovery Act (RCRA) governs the management of hazardous wastes generated during plating operations, including spent nickel solutions and treatment sludges.

The European Union implements the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which requires manufacturers and importers to register chemicals and demonstrate safe use. The EU's Restriction of Hazardous Substances (RoHS) Directive restricts the use of certain hazardous substances in electrical and electronic equipment, affecting nickel-plated components. Furthermore, the Industrial Emissions Directive (IED) establishes an integrated approach to controlling emissions from industrial activities.

In Asia, countries like China, Japan, and South Korea have developed their own regulatory frameworks. China's Environmental Protection Law and Measures for the Administration of Hazardous Waste Operation Permits impose strict requirements on metal finishing operations. Japan's Chemical Substances Control Law and Air Pollution Control Law establish comprehensive regulations for chemical management and emissions control.

Industry-specific standards complement these regulatory frameworks. The Metal Finishing Facility Report, developed under the EPA's Common Sense Initiative, provides guidance on environmental performance. ISO 14001 certification has become increasingly important for metal finishing operations seeking to demonstrate environmental management system implementation.

Compliance challenges for electroless nickel plating facilities include managing wastewater containing heavy metals, reducing air emissions of volatile organic compounds, and properly disposing of hazardous wastes. Many facilities are implementing pollution prevention strategies, such as bath life extension techniques and recovery technologies, to reduce environmental impacts while achieving regulatory compliance.

In the United States, the Environmental Protection Agency (EPA) enforces several key regulations affecting electroless nickel plating facilities. The Clean Water Act establishes the National Pollutant Discharge Elimination System (NPDES) permit program, which regulates point source discharges of pollutants into U.S. waters. Additionally, the Resource Conservation and Recovery Act (RCRA) governs the management of hazardous wastes generated during plating operations, including spent nickel solutions and treatment sludges.

The European Union implements the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which requires manufacturers and importers to register chemicals and demonstrate safe use. The EU's Restriction of Hazardous Substances (RoHS) Directive restricts the use of certain hazardous substances in electrical and electronic equipment, affecting nickel-plated components. Furthermore, the Industrial Emissions Directive (IED) establishes an integrated approach to controlling emissions from industrial activities.

In Asia, countries like China, Japan, and South Korea have developed their own regulatory frameworks. China's Environmental Protection Law and Measures for the Administration of Hazardous Waste Operation Permits impose strict requirements on metal finishing operations. Japan's Chemical Substances Control Law and Air Pollution Control Law establish comprehensive regulations for chemical management and emissions control.

Industry-specific standards complement these regulatory frameworks. The Metal Finishing Facility Report, developed under the EPA's Common Sense Initiative, provides guidance on environmental performance. ISO 14001 certification has become increasingly important for metal finishing operations seeking to demonstrate environmental management system implementation.

Compliance challenges for electroless nickel plating facilities include managing wastewater containing heavy metals, reducing air emissions of volatile organic compounds, and properly disposing of hazardous wastes. Many facilities are implementing pollution prevention strategies, such as bath life extension techniques and recovery technologies, to reduce environmental impacts while achieving regulatory compliance.

Life Cycle Assessment of Electroless Nickel Processes

Life Cycle Assessment (LCA) of electroless nickel plating processes provides a comprehensive framework for evaluating the environmental impacts throughout the entire lifecycle of these processes. This assessment begins with raw material extraction and continues through manufacturing, use, and end-of-life disposal or recycling. The analysis reveals that electroless nickel plating processes contribute significantly to environmental burdens across multiple categories.

The extraction and processing of nickel compounds, particularly nickel sulfate and nickel chloride, represent substantial environmental hotspots. Mining operations cause habitat destruction, soil erosion, and water contamination. Processing these raw materials requires considerable energy inputs, resulting in greenhouse gas emissions and resource depletion. Studies indicate that the production of 1 kg of nickel sulfate generates approximately 6-8 kg CO2 equivalent emissions.

Chemical manufacturing for plating baths presents another critical phase in the lifecycle. Reducing agents like sodium hypophosphite and complexing agents such as sodium citrate require energy-intensive production processes. These chemicals often have upstream environmental impacts related to petroleum extraction and refining. Additionally, stabilizers and brighteners used in bath formulations frequently contain compounds with high toxicity potential.

The operational phase of electroless nickel plating demonstrates significant environmental concerns. Energy consumption for bath heating (typically maintained at 85-95°C) represents a major contributor to the carbon footprint. Water usage is substantial, with rinse systems consuming 5-10 liters per square meter of plated surface. Chemical waste generation includes spent plating solutions containing heavy metals, reducing agents, and complexing agents that require specialized treatment.

End-of-life considerations reveal challenges in material recovery and waste management. While nickel-plated components can theoretically be recycled, the presence of phosphorus in the coating complicates separation processes. Waste treatment of spent solutions requires precipitation, filtration, and sometimes advanced oxidation processes to meet discharge regulations.

Comparative LCA studies show that electroless nickel processes generally have higher environmental impacts than electrolytic nickel plating across most impact categories, particularly in global warming potential, acidification, and human toxicity. However, electroless processes may perform better in terms of water eutrophication when properly managed. Recent innovations in bath chemistry, including lower-temperature formulations and recovery systems for nickel and reducing agents, demonstrate potential for reducing the overall environmental footprint of these processes.

The extraction and processing of nickel compounds, particularly nickel sulfate and nickel chloride, represent substantial environmental hotspots. Mining operations cause habitat destruction, soil erosion, and water contamination. Processing these raw materials requires considerable energy inputs, resulting in greenhouse gas emissions and resource depletion. Studies indicate that the production of 1 kg of nickel sulfate generates approximately 6-8 kg CO2 equivalent emissions.

Chemical manufacturing for plating baths presents another critical phase in the lifecycle. Reducing agents like sodium hypophosphite and complexing agents such as sodium citrate require energy-intensive production processes. These chemicals often have upstream environmental impacts related to petroleum extraction and refining. Additionally, stabilizers and brighteners used in bath formulations frequently contain compounds with high toxicity potential.

The operational phase of electroless nickel plating demonstrates significant environmental concerns. Energy consumption for bath heating (typically maintained at 85-95°C) represents a major contributor to the carbon footprint. Water usage is substantial, with rinse systems consuming 5-10 liters per square meter of plated surface. Chemical waste generation includes spent plating solutions containing heavy metals, reducing agents, and complexing agents that require specialized treatment.

End-of-life considerations reveal challenges in material recovery and waste management. While nickel-plated components can theoretically be recycled, the presence of phosphorus in the coating complicates separation processes. Waste treatment of spent solutions requires precipitation, filtration, and sometimes advanced oxidation processes to meet discharge regulations.

Comparative LCA studies show that electroless nickel processes generally have higher environmental impacts than electrolytic nickel plating across most impact categories, particularly in global warming potential, acidification, and human toxicity. However, electroless processes may perform better in terms of water eutrophication when properly managed. Recent innovations in bath chemistry, including lower-temperature formulations and recovery systems for nickel and reducing agents, demonstrate potential for reducing the overall environmental footprint of these processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!