Electroless Nickel Coatings for Aerospace Applications

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Electroless Nickel Coating Background and Objectives

Electroless nickel coating technology has evolved significantly since its inception in the 1940s, transforming from a niche process to a critical surface treatment technology in aerospace applications. The development trajectory has been characterized by continuous improvements in coating formulations, process parameters, and performance characteristics to meet the increasingly demanding requirements of modern aircraft and spacecraft components.

The aerospace industry has been a primary driver for advancements in electroless nickel coating technology, particularly due to its unique requirements for corrosion resistance, wear protection, and dimensional precision in extreme operating environments. Historical milestones include the introduction of phosphorus-content variations in the 1960s, which enabled tailored coating properties, and the development of composite electroless nickel coatings incorporating particles like silicon carbide and diamond in the 1980s for enhanced wear resistance.

Recent technological trends show a clear shift toward environmentally friendly electroless nickel processes, addressing concerns about traditional formulations containing lead, cadmium, and other toxic substances. Additionally, there is growing interest in nano-structured electroless nickel coatings that offer superior performance characteristics while using less material, aligning with the aerospace industry's push for lightweight components.

The primary technical objectives for electroless nickel coatings in aerospace applications include achieving exceptional corrosion resistance in diverse environments (from atmospheric exposure to fuel system contact), maintaining dimensional stability under thermal cycling conditions, and ensuring uniform coating thickness on complex geometries. These objectives are particularly critical for components such as landing gear parts, hydraulic actuators, engine components, and fasteners.

Further objectives include enhancing the coating's high-temperature performance, as modern aircraft engines operate at increasingly elevated temperatures, and improving adhesion to various substrate materials, including advanced aluminum alloys, titanium, and composite materials that are becoming more prevalent in aerospace construction.

The development of electroless nickel coating technology also aims to address specific aerospace challenges such as hydrogen embrittlement prevention, fatigue resistance enhancement, and compatibility with subsequent surface treatments or assembly processes. The industry is particularly focused on coatings that can maintain their protective properties throughout the extended service life of aerospace components, which may span several decades.

As the aerospace industry continues to evolve with trends toward electric propulsion, unmanned aerial vehicles, and space exploration, electroless nickel coating technology must adapt to new substrate materials, more extreme operating conditions, and stricter environmental regulations, driving continuous innovation in this field.

The aerospace industry has been a primary driver for advancements in electroless nickel coating technology, particularly due to its unique requirements for corrosion resistance, wear protection, and dimensional precision in extreme operating environments. Historical milestones include the introduction of phosphorus-content variations in the 1960s, which enabled tailored coating properties, and the development of composite electroless nickel coatings incorporating particles like silicon carbide and diamond in the 1980s for enhanced wear resistance.

Recent technological trends show a clear shift toward environmentally friendly electroless nickel processes, addressing concerns about traditional formulations containing lead, cadmium, and other toxic substances. Additionally, there is growing interest in nano-structured electroless nickel coatings that offer superior performance characteristics while using less material, aligning with the aerospace industry's push for lightweight components.

The primary technical objectives for electroless nickel coatings in aerospace applications include achieving exceptional corrosion resistance in diverse environments (from atmospheric exposure to fuel system contact), maintaining dimensional stability under thermal cycling conditions, and ensuring uniform coating thickness on complex geometries. These objectives are particularly critical for components such as landing gear parts, hydraulic actuators, engine components, and fasteners.

Further objectives include enhancing the coating's high-temperature performance, as modern aircraft engines operate at increasingly elevated temperatures, and improving adhesion to various substrate materials, including advanced aluminum alloys, titanium, and composite materials that are becoming more prevalent in aerospace construction.

The development of electroless nickel coating technology also aims to address specific aerospace challenges such as hydrogen embrittlement prevention, fatigue resistance enhancement, and compatibility with subsequent surface treatments or assembly processes. The industry is particularly focused on coatings that can maintain their protective properties throughout the extended service life of aerospace components, which may span several decades.

As the aerospace industry continues to evolve with trends toward electric propulsion, unmanned aerial vehicles, and space exploration, electroless nickel coating technology must adapt to new substrate materials, more extreme operating conditions, and stricter environmental regulations, driving continuous innovation in this field.

Aerospace Industry Demand Analysis for Electroless Nickel Coatings

The aerospace industry represents one of the most demanding sectors for advanced material solutions, with electroless nickel coatings emerging as a critical technology addressing multiple operational challenges. Current market analysis indicates that the global aerospace electroless nickel coating market is experiencing steady growth, driven primarily by increasing aircraft production rates and the expanding commercial aviation sector.

The demand for electroless nickel coatings in aerospace applications stems from several industry-specific requirements. First, the need for superior corrosion resistance in aircraft components exposed to extreme environmental conditions, including high-altitude operations, temperature fluctuations, and exposure to various chemicals and fuels. Second, the industry's push toward weight reduction while maintaining structural integrity creates demand for coatings that can provide surface hardness and wear resistance without adding significant mass to components.

Commercial aviation represents the largest market segment for these coatings, with applications spanning landing gear components, hydraulic systems, engine parts, and fasteners. Military aerospace applications follow closely, with additional requirements for stealth capabilities and resistance to specialized operational environments. The space segment, though smaller in volume, demands the highest performance specifications for coatings that must withstand the vacuum of space and extreme temperature variations.

Regional demand analysis shows North America leading the market due to its concentrated aerospace manufacturing base, followed by Europe and the rapidly growing Asia-Pacific region. China's expanding aerospace industry has become a significant driver of new demand, with annual growth rates exceeding the global average.

The aftermarket segment presents substantial opportunities, as maintenance, repair, and overhaul (MRO) operations increasingly utilize electroless nickel coatings to extend component life and improve performance of existing aircraft. This segment is projected to grow as global commercial fleets age and require more frequent maintenance interventions.

Industry surveys indicate that aerospace manufacturers prioritize three key performance attributes in electroless nickel coatings: uniform deposition on complex geometries, consistent performance under extreme conditions, and compatibility with aerospace-grade substrate materials. Cost considerations remain secondary to performance reliability, reflecting the safety-critical nature of aerospace applications.

Regulatory factors significantly influence market demand patterns, with environmental regulations driving interest in more sustainable coating processes that reduce or eliminate hazardous chemicals. The industry's shift toward more environmentally responsible manufacturing processes has accelerated research into alternative formulations that maintain performance while reducing environmental impact.

The demand for electroless nickel coatings in aerospace applications stems from several industry-specific requirements. First, the need for superior corrosion resistance in aircraft components exposed to extreme environmental conditions, including high-altitude operations, temperature fluctuations, and exposure to various chemicals and fuels. Second, the industry's push toward weight reduction while maintaining structural integrity creates demand for coatings that can provide surface hardness and wear resistance without adding significant mass to components.

Commercial aviation represents the largest market segment for these coatings, with applications spanning landing gear components, hydraulic systems, engine parts, and fasteners. Military aerospace applications follow closely, with additional requirements for stealth capabilities and resistance to specialized operational environments. The space segment, though smaller in volume, demands the highest performance specifications for coatings that must withstand the vacuum of space and extreme temperature variations.

Regional demand analysis shows North America leading the market due to its concentrated aerospace manufacturing base, followed by Europe and the rapidly growing Asia-Pacific region. China's expanding aerospace industry has become a significant driver of new demand, with annual growth rates exceeding the global average.

The aftermarket segment presents substantial opportunities, as maintenance, repair, and overhaul (MRO) operations increasingly utilize electroless nickel coatings to extend component life and improve performance of existing aircraft. This segment is projected to grow as global commercial fleets age and require more frequent maintenance interventions.

Industry surveys indicate that aerospace manufacturers prioritize three key performance attributes in electroless nickel coatings: uniform deposition on complex geometries, consistent performance under extreme conditions, and compatibility with aerospace-grade substrate materials. Cost considerations remain secondary to performance reliability, reflecting the safety-critical nature of aerospace applications.

Regulatory factors significantly influence market demand patterns, with environmental regulations driving interest in more sustainable coating processes that reduce or eliminate hazardous chemicals. The industry's shift toward more environmentally responsible manufacturing processes has accelerated research into alternative formulations that maintain performance while reducing environmental impact.

Global Electroless Nickel Technology Status and Challenges

The global landscape of electroless nickel (EN) coating technology presents a complex picture of advancement and challenges. Currently, the technology has reached maturity in many industrial applications, but aerospace requirements demand higher performance standards that push the boundaries of existing capabilities. The United States, Japan, and Western European countries maintain technological leadership in high-performance EN coatings, with significant research centers concentrated in these regions.

The primary technical challenges facing electroless nickel coatings in aerospace applications revolve around several critical factors. Durability under extreme conditions remains problematic, as aerospace components experience wide temperature fluctuations (-65°C to 650°C) and high mechanical stress that can compromise coating integrity. Current EN formulations struggle to maintain consistent performance across this operational spectrum.

Adhesion strength between the coating and various aerospace substrate materials presents another significant hurdle. While EN coatings adhere well to many metals, achieving reliable bonding with advanced aerospace alloys and composites requires specialized surface preparation techniques that are not yet standardized across the industry.

Environmental concerns have also emerged as a major constraint. Traditional EN baths contain chemicals like nickel sulfate and sodium hypophosphite that pose environmental and health risks. Regulatory pressures in North America, Europe, and increasingly in Asia are driving the need for more environmentally friendly formulations without sacrificing performance characteristics critical for aerospace applications.

Thickness uniformity represents another technical limitation, particularly for components with complex geometries common in aerospace designs. Current technology struggles to deliver consistent coating thickness on intricate parts with deep recesses, sharp edges, and varying surface areas, leading to performance inconsistencies.

Scalability challenges persist in manufacturing processes. While laboratory results show promising performance for specialized aerospace EN coatings, translating these into cost-effective, high-volume production remains difficult. The precision required for aerospace applications often conflicts with manufacturing efficiency.

Geographically, research efforts are distributed unevenly. North America and Europe lead in developing environmentally compliant formulations, while Asian research centers, particularly in Japan and China, focus on enhancing coating durability and corrosion resistance. This regional specialization creates both opportunities for collaboration and challenges in technology standardization.

Recent advancements in nanotechnology have begun addressing some of these limitations, with nano-composite EN coatings showing improved wear resistance and thermal stability. However, these solutions remain largely experimental and have not yet achieved widespread commercial implementation in aerospace applications.

The primary technical challenges facing electroless nickel coatings in aerospace applications revolve around several critical factors. Durability under extreme conditions remains problematic, as aerospace components experience wide temperature fluctuations (-65°C to 650°C) and high mechanical stress that can compromise coating integrity. Current EN formulations struggle to maintain consistent performance across this operational spectrum.

Adhesion strength between the coating and various aerospace substrate materials presents another significant hurdle. While EN coatings adhere well to many metals, achieving reliable bonding with advanced aerospace alloys and composites requires specialized surface preparation techniques that are not yet standardized across the industry.

Environmental concerns have also emerged as a major constraint. Traditional EN baths contain chemicals like nickel sulfate and sodium hypophosphite that pose environmental and health risks. Regulatory pressures in North America, Europe, and increasingly in Asia are driving the need for more environmentally friendly formulations without sacrificing performance characteristics critical for aerospace applications.

Thickness uniformity represents another technical limitation, particularly for components with complex geometries common in aerospace designs. Current technology struggles to deliver consistent coating thickness on intricate parts with deep recesses, sharp edges, and varying surface areas, leading to performance inconsistencies.

Scalability challenges persist in manufacturing processes. While laboratory results show promising performance for specialized aerospace EN coatings, translating these into cost-effective, high-volume production remains difficult. The precision required for aerospace applications often conflicts with manufacturing efficiency.

Geographically, research efforts are distributed unevenly. North America and Europe lead in developing environmentally compliant formulations, while Asian research centers, particularly in Japan and China, focus on enhancing coating durability and corrosion resistance. This regional specialization creates both opportunities for collaboration and challenges in technology standardization.

Recent advancements in nanotechnology have begun addressing some of these limitations, with nano-composite EN coatings showing improved wear resistance and thermal stability. However, these solutions remain largely experimental and have not yet achieved widespread commercial implementation in aerospace applications.

Current Electroless Nickel Coating Solutions for Aerospace Components

01 Composition of electroless nickel plating baths

Electroless nickel plating baths typically contain nickel salts, reducing agents, complexing agents, stabilizers, and pH adjusters. The composition of these baths significantly affects the properties of the resulting coating. Various formulations have been developed to optimize deposition rate, coating thickness, and uniformity. These baths can be tailored for specific applications by adjusting the concentration of components or introducing additives to enhance particular properties.- Composition and formulation of electroless nickel plating baths: Electroless nickel plating baths typically contain nickel salts, reducing agents, complexing agents, stabilizers, and pH adjusters. The composition can be optimized to achieve specific coating properties such as hardness, corrosion resistance, and uniformity. Different formulations may include hypophosphite-based solutions, borohydride-based solutions, or specialized additives to enhance deposition rate and coating quality.

- Surface preparation and pretreatment methods: Proper surface preparation is crucial for successful electroless nickel coating adhesion. This includes cleaning, degreasing, etching, and activation steps to ensure uniform deposition. Pretreatment methods may involve acid pickling, alkaline cleaning, mechanical abrasion, or specialized activation processes depending on the substrate material. These steps remove contaminants, oxides, and create an active surface for nucleation of the nickel deposit.

- Nickel-phosphorus and nickel-boron coating compositions: Electroless nickel coatings are commonly alloyed with phosphorus or boron to enhance specific properties. Nickel-phosphorus coatings can be classified as low, medium, or high phosphorus based on phosphorus content, each offering different characteristics. Nickel-boron coatings typically provide superior hardness and wear resistance. The composition can be controlled through bath formulation and operating parameters to achieve desired properties for specific applications.

- Post-treatment and heat treatment processes: Post-deposition treatments can significantly enhance the properties of electroless nickel coatings. Heat treatment at various temperatures can increase hardness, wear resistance, and adhesion strength. Other post-treatments include passivation, sealing, or application of topcoats to improve corrosion resistance or specific functional properties. The temperature and duration of heat treatment can be optimized based on the desired coating characteristics and substrate material.

- Specialized applications and composite coatings: Electroless nickel coatings can be modified for specialized applications by incorporating particles or creating composite structures. These include nickel-phosphorus-based composite coatings with embedded particles such as silicon carbide, diamond, or PTFE for enhanced wear resistance or lubricity. Other specialized applications include coatings for electronics, automotive components, aerospace parts, and chemical processing equipment, each requiring specific formulations and properties.

02 Nickel-phosphorus alloy coatings

Nickel-phosphorus alloy coatings are commonly produced through electroless deposition processes. The phosphorus content in these coatings can be controlled to achieve specific properties such as hardness, corrosion resistance, and wear resistance. Low phosphorus coatings (1-5%) offer higher hardness and magnetic properties, medium phosphorus coatings (6-9%) provide balanced properties, while high phosphorus coatings (10-13%) offer superior corrosion resistance and non-magnetic characteristics. Heat treatment can further enhance the mechanical properties of these coatings.Expand Specific Solutions03 Composite electroless nickel coatings

Composite electroless nickel coatings incorporate particles such as silicon carbide, diamond, PTFE, or other materials into the nickel matrix during deposition. These particles enhance specific properties of the coating, including wear resistance, lubricity, and hardness. The co-deposition process can be controlled by adjusting bath parameters such as particle concentration, agitation, and deposition conditions. These composite coatings find applications in industries requiring enhanced surface properties beyond what standard electroless nickel coatings can provide.Expand Specific Solutions04 Pre-treatment and post-treatment processes

Proper surface preparation and post-treatment are crucial for high-quality electroless nickel coatings. Pre-treatment processes include cleaning, etching, and activation of the substrate surface to ensure good adhesion and uniform coating. Post-treatment processes such as heat treatment can significantly improve the hardness, wear resistance, and other mechanical properties of the coating. The temperature and duration of heat treatment affect the crystallization of the nickel-phosphorus matrix and the formation of nickel phosphide phases.Expand Specific Solutions05 Applications in electronics and semiconductor industries

Electroless nickel coatings are widely used in electronics and semiconductor industries due to their uniform thickness, excellent solderability, and corrosion resistance. These coatings serve as diffusion barriers, wire bonding surfaces, and electromagnetic interference shields. The non-magnetic properties of high-phosphorus electroless nickel coatings make them suitable for electronic components. Additionally, the ability to coat complex geometries uniformly without electricity makes electroless nickel plating ideal for semiconductor packaging and interconnect applications.Expand Specific Solutions

Leading Aerospace Coating Manufacturers and Suppliers Analysis

The electroless nickel coating market for aerospace applications is in a growth phase, driven by increasing demand for corrosion-resistant and lightweight materials in aircraft components. The global market size is expanding steadily, with projections indicating significant growth as aerospace manufacturing recovers post-pandemic. Technologically, the field is moderately mature but continues to evolve, with key players driving innovation in nanolaminated coatings and environmentally friendly processes. Leading companies include United Technologies Corp. and its subsidiaries (Pratt & Whitney, Hamilton Sundstrand), specialized coating developers like Modumetal and Integran Technologies, and established surface treatment providers such as MacDermid Enthone and Atotech. Research institutions including University of Science & Technology Beijing and Harbin Institute of Technology are contributing to technological advancements, particularly in nanostructured coatings with enhanced performance characteristics.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed advanced electroless nickel coating systems specifically engineered for aerospace components subjected to extreme operating conditions. Their proprietary EN process incorporates phosphorus content optimization (8-12%) to achieve superior corrosion resistance while maintaining excellent wear properties. UTC's technology employs specialized pre-treatment protocols that enhance coating adhesion on aerospace alloys including titanium and high-strength aluminum. Their multi-layer approach combines an initial high-phosphorus layer for corrosion protection with a subsequent mid-phosphorus layer optimized for wear resistance. UTC has also pioneered the incorporation of nano-ceramic particles into their EN matrix, creating composite coatings that demonstrate up to 40% improved hardness after heat treatment while maintaining excellent ductility necessary for aerospace applications.

Strengths: Exceptional corrosion resistance in salt-spray environments exceeding 1000 hours, superior adhesion to difficult aerospace substrates, and excellent thickness uniformity even on complex geometries. Weaknesses: Higher processing costs compared to conventional plating, longer processing times required for thick deposits, and potential hydrogen embrittlement concerns with certain high-strength steel substrates.

Atotech Deutschland GmbH & Co. KG

Technical Solution: Atotech has developed the Teccor® aerospace-grade electroless nickel system specifically engineered to meet the demanding requirements of the aerospace industry. Their technology features a unique dual-catalyst activation process that ensures exceptional adhesion to a wide range of aerospace alloys including high-strength aluminum, titanium, and specialty steels. The company's proprietary bath formulation incorporates advanced stabilizers that extend solution life while maintaining consistent deposition rates (15-20 μm/hour). Atotech's process delivers precisely controlled phosphorus content (10-12%) to achieve optimal corrosion protection, with salt spray resistance exceeding 1,000 hours per ASTM B117 standards. Their technology includes specialized additives that reduce internal stress in the deposit, critical for preventing delamination during thermal cycling experienced in aerospace applications. Atotech has also pioneered environmentally compliant formulations that meet strict REACH and aerospace environmental regulations while maintaining performance properties.

Strengths: Exceptional bath stability allowing for consistent results over extended production runs, superior corrosion protection particularly in marine environments, and excellent thickness distribution even on complex geometries. Weaknesses: Relatively slower deposition rates compared to some competing technologies, higher sensitivity to metallic contamination requiring stringent bath maintenance, and more complex waste treatment requirements.

Key Patents and Innovations in Aerospace-Grade Electroless Nickel

Electroless nickel alloy plating baths, a method for deposition of nickel alloys, nickel alloy deposits and uses of such formed nickel alloy deposits

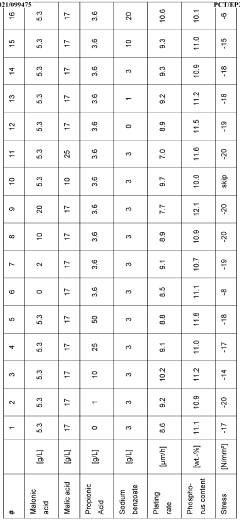

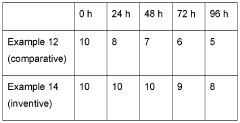

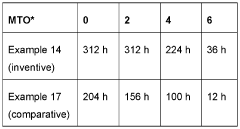

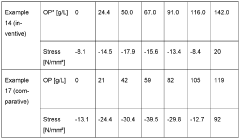

PatentWO2021099475A1

Innovation

- An electroless nickel alloy plating bath comprising nickel ions, molybdenum or copper ions, and hypophosphite as reducing agents, along with specific complexing agents like malonic acid, tartaric acid, and benzoic acid, which stabilize the bath and enhance deposition properties.

Environmental and Regulatory Compliance for Aerospace Coatings

The aerospace industry faces increasingly stringent environmental regulations regarding surface treatments and coatings. Electroless nickel coatings, while technically advantageous, must comply with complex regulatory frameworks that vary globally. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation has significantly impacted aerospace coating processes by restricting certain chemicals commonly used in electroless nickel baths, particularly those containing hexavalent chromium compounds and certain perfluorinated substances.

In the United States, the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA) impose strict guidelines on chemical handling, waste disposal, and worker exposure limits for electroless nickel processes. The Clean Air Act and Clean Water Act specifically regulate emissions and effluents from metal finishing operations, requiring sophisticated filtration and treatment systems for aerospace manufacturing facilities.

Aerospace manufacturers must also adhere to industry-specific standards such as NADCAP (National Aerospace and Defense Contractors Accreditation Program) requirements for special processes, which include detailed protocols for electroless nickel plating. These standards ensure consistency and quality while promoting environmentally responsible practices.

Recent developments in green chemistry have led to more environmentally friendly electroless nickel formulations. Low-phosphorus electroless nickel baths with reduced toxicity are gaining acceptance, though they must still meet the rigorous performance requirements of aerospace applications. Several manufacturers have developed proprietary systems that eliminate or reduce hazardous air pollutants (HAPs) while maintaining coating integrity under extreme conditions.

Waste management represents another critical compliance area. Spent electroless nickel solutions contain heavy metals and reducing agents that require specialized treatment before disposal. Closed-loop recovery systems and ion exchange technologies have become standard in modern aerospace plating facilities to minimize environmental impact and reduce operational costs through chemical recovery.

Carbon footprint considerations are increasingly important as aerospace companies commit to sustainability goals. Life cycle assessment (LCA) studies indicate that while electroless nickel processes consume significant energy, their contribution to extending component lifespan often results in net environmental benefits when evaluated across the full product lifecycle.

Looking forward, regulatory trends suggest further restrictions on nickel compounds themselves, classified as potential carcinogens in some jurisdictions. This drives ongoing research into alternative coating technologies that maintain the unique properties of electroless nickel while reducing environmental and health risks, positioning regulatory compliance as a key driver of innovation in aerospace surface treatment technologies.

In the United States, the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA) impose strict guidelines on chemical handling, waste disposal, and worker exposure limits for electroless nickel processes. The Clean Air Act and Clean Water Act specifically regulate emissions and effluents from metal finishing operations, requiring sophisticated filtration and treatment systems for aerospace manufacturing facilities.

Aerospace manufacturers must also adhere to industry-specific standards such as NADCAP (National Aerospace and Defense Contractors Accreditation Program) requirements for special processes, which include detailed protocols for electroless nickel plating. These standards ensure consistency and quality while promoting environmentally responsible practices.

Recent developments in green chemistry have led to more environmentally friendly electroless nickel formulations. Low-phosphorus electroless nickel baths with reduced toxicity are gaining acceptance, though they must still meet the rigorous performance requirements of aerospace applications. Several manufacturers have developed proprietary systems that eliminate or reduce hazardous air pollutants (HAPs) while maintaining coating integrity under extreme conditions.

Waste management represents another critical compliance area. Spent electroless nickel solutions contain heavy metals and reducing agents that require specialized treatment before disposal. Closed-loop recovery systems and ion exchange technologies have become standard in modern aerospace plating facilities to minimize environmental impact and reduce operational costs through chemical recovery.

Carbon footprint considerations are increasingly important as aerospace companies commit to sustainability goals. Life cycle assessment (LCA) studies indicate that while electroless nickel processes consume significant energy, their contribution to extending component lifespan often results in net environmental benefits when evaluated across the full product lifecycle.

Looking forward, regulatory trends suggest further restrictions on nickel compounds themselves, classified as potential carcinogens in some jurisdictions. This drives ongoing research into alternative coating technologies that maintain the unique properties of electroless nickel while reducing environmental and health risks, positioning regulatory compliance as a key driver of innovation in aerospace surface treatment technologies.

Corrosion Resistance and Durability Testing Methodologies

Corrosion resistance and durability are critical factors in evaluating electroless nickel coatings for aerospace applications. The testing methodologies employed must accurately simulate the harsh environmental conditions these coatings will encounter during service life. Standard testing protocols include salt spray testing (ASTM B117), which exposes coated specimens to a continuous salt fog atmosphere to assess corrosion resistance over time. This test is particularly relevant for aerospace components that may be exposed to marine environments or de-icing chemicals.

Cyclic corrosion testing provides a more realistic assessment by alternating between different environmental conditions such as salt spray, humidity, and drying cycles. This methodology better simulates the actual service conditions of aerospace components that experience varying environmental exposures during operation. The ASTM G85 standard outlines several variations of cyclic corrosion tests that are applicable to electroless nickel coatings.

Electrochemical impedance spectroscopy (EIS) offers a non-destructive approach to evaluate coating integrity and corrosion resistance. By applying a small amplitude alternating potential and measuring the current response, EIS can detect subtle changes in coating properties before visible corrosion occurs. This technique is particularly valuable for monitoring coating degradation over time and understanding corrosion mechanisms at the molecular level.

Adhesion testing, conducted according to ASTM D3359 (tape test) or ASTM D4541 (pull-off test), evaluates the bond strength between the electroless nickel coating and the substrate. Poor adhesion can lead to coating delamination and subsequent corrosion of the underlying material, making this a critical parameter for aerospace applications where thermal cycling and mechanical stress are common.

Wear resistance testing methodologies include pin-on-disk tests (ASTM G99) and Taber abrasion tests (ASTM D4060), which quantify the coating's ability to withstand mechanical wear. These tests are essential for components subject to friction and abrasion during service, such as landing gear components and actuator mechanisms.

High-temperature exposure testing evaluates coating stability at elevated temperatures typical of aerospace environments. This includes thermal cycling tests that simulate the temperature variations experienced during flight cycles, from sub-zero at high altitudes to elevated temperatures near engine components. Coating properties such as hardness, adhesion, and microstructure are evaluated before and after thermal exposure to assess degradation.

Hydrogen embrittlement testing is particularly important for high-strength steel components coated with electroless nickel, as the coating process can introduce hydrogen into the substrate. ASTM F519 provides standardized methods for evaluating susceptibility to hydrogen embrittlement, which is critical for safety-critical aerospace components.

Cyclic corrosion testing provides a more realistic assessment by alternating between different environmental conditions such as salt spray, humidity, and drying cycles. This methodology better simulates the actual service conditions of aerospace components that experience varying environmental exposures during operation. The ASTM G85 standard outlines several variations of cyclic corrosion tests that are applicable to electroless nickel coatings.

Electrochemical impedance spectroscopy (EIS) offers a non-destructive approach to evaluate coating integrity and corrosion resistance. By applying a small amplitude alternating potential and measuring the current response, EIS can detect subtle changes in coating properties before visible corrosion occurs. This technique is particularly valuable for monitoring coating degradation over time and understanding corrosion mechanisms at the molecular level.

Adhesion testing, conducted according to ASTM D3359 (tape test) or ASTM D4541 (pull-off test), evaluates the bond strength between the electroless nickel coating and the substrate. Poor adhesion can lead to coating delamination and subsequent corrosion of the underlying material, making this a critical parameter for aerospace applications where thermal cycling and mechanical stress are common.

Wear resistance testing methodologies include pin-on-disk tests (ASTM G99) and Taber abrasion tests (ASTM D4060), which quantify the coating's ability to withstand mechanical wear. These tests are essential for components subject to friction and abrasion during service, such as landing gear components and actuator mechanisms.

High-temperature exposure testing evaluates coating stability at elevated temperatures typical of aerospace environments. This includes thermal cycling tests that simulate the temperature variations experienced during flight cycles, from sub-zero at high altitudes to elevated temperatures near engine components. Coating properties such as hardness, adhesion, and microstructure are evaluated before and after thermal exposure to assess degradation.

Hydrogen embrittlement testing is particularly important for high-strength steel components coated with electroless nickel, as the coating process can introduce hydrogen into the substrate. ASTM F519 provides standardized methods for evaluating susceptibility to hydrogen embrittlement, which is critical for safety-critical aerospace components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!