Mechanical Properties of Ni P Coatings under Stress

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ni-P Coating Technology Background and Objectives

Nickel-phosphorus (Ni-P) coatings have emerged as a significant surface engineering solution over the past several decades, offering exceptional corrosion resistance, wear resistance, and unique mechanical properties. The evolution of these coatings dates back to the mid-20th century, with substantial advancements occurring in the 1960s and 1970s when electroless plating techniques were refined for industrial applications. Since then, the technology has continuously evolved to meet increasingly demanding performance requirements across various industries.

The development trajectory of Ni-P coating technology has been characterized by progressive improvements in deposition methods, composition control, and post-treatment processes. Early applications focused primarily on corrosion protection, but as understanding of the microstructural characteristics deepened, researchers began exploring the mechanical behavior of these coatings under various stress conditions. The relationship between phosphorus content, heat treatment, and resulting mechanical properties has become a central focus in recent research efforts.

Current technological trends indicate a growing interest in optimizing Ni-P coatings for specific stress environments, including cyclic loading, thermal cycling, and high-pressure applications. The industry is moving toward more sophisticated multi-layer and composite Ni-P coating systems that can withstand complex stress states while maintaining structural integrity. Additionally, there is increasing attention to environmentally friendly deposition processes that reduce or eliminate hazardous chemicals traditionally used in electroless plating.

The primary technical objectives of this research focus on comprehensively understanding the mechanical behavior of Ni-P coatings under various stress conditions. Specifically, we aim to investigate the relationship between phosphorus content (ranging from low to high percentages) and mechanical properties such as hardness, elastic modulus, yield strength, and fatigue resistance when subjected to different stress states. Furthermore, we seek to elucidate the microstructural evolution of these coatings during stress application and identify the dominant deformation mechanisms.

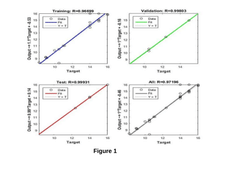

Another critical objective is to develop predictive models that can accurately forecast the mechanical response of Ni-P coatings under complex loading scenarios, enabling more effective coating design for specific applications. This includes understanding the influence of heat treatment protocols on stress resistance and establishing optimal processing parameters for enhanced mechanical performance. The ultimate goal is to establish design guidelines for Ni-P coating systems that can be tailored to specific stress environments, thereby extending component lifespans and improving reliability in critical applications.

The development trajectory of Ni-P coating technology has been characterized by progressive improvements in deposition methods, composition control, and post-treatment processes. Early applications focused primarily on corrosion protection, but as understanding of the microstructural characteristics deepened, researchers began exploring the mechanical behavior of these coatings under various stress conditions. The relationship between phosphorus content, heat treatment, and resulting mechanical properties has become a central focus in recent research efforts.

Current technological trends indicate a growing interest in optimizing Ni-P coatings for specific stress environments, including cyclic loading, thermal cycling, and high-pressure applications. The industry is moving toward more sophisticated multi-layer and composite Ni-P coating systems that can withstand complex stress states while maintaining structural integrity. Additionally, there is increasing attention to environmentally friendly deposition processes that reduce or eliminate hazardous chemicals traditionally used in electroless plating.

The primary technical objectives of this research focus on comprehensively understanding the mechanical behavior of Ni-P coatings under various stress conditions. Specifically, we aim to investigate the relationship between phosphorus content (ranging from low to high percentages) and mechanical properties such as hardness, elastic modulus, yield strength, and fatigue resistance when subjected to different stress states. Furthermore, we seek to elucidate the microstructural evolution of these coatings during stress application and identify the dominant deformation mechanisms.

Another critical objective is to develop predictive models that can accurately forecast the mechanical response of Ni-P coatings under complex loading scenarios, enabling more effective coating design for specific applications. This includes understanding the influence of heat treatment protocols on stress resistance and establishing optimal processing parameters for enhanced mechanical performance. The ultimate goal is to establish design guidelines for Ni-P coating systems that can be tailored to specific stress environments, thereby extending component lifespans and improving reliability in critical applications.

Market Applications and Demand Analysis for Ni-P Coatings

The global market for Ni-P coatings has experienced significant growth in recent years, driven primarily by increasing demand across multiple industrial sectors. The automotive industry represents one of the largest application areas, where Ni-P coatings are extensively used for components requiring superior wear resistance and corrosion protection under mechanical stress. This includes engine parts, fuel systems, and transmission components where the mechanical properties of these coatings directly impact vehicle performance and longevity.

The aerospace sector constitutes another major market segment, with stringent requirements for materials that can withstand extreme mechanical stress conditions. In this domain, Ni-P coatings are valued for their ability to maintain structural integrity under high-stress environments, particularly in landing gear components, turbine blades, and hydraulic systems. Market analysis indicates that this sector's demand is projected to grow steadily as aircraft production increases globally.

Electronics manufacturing represents a rapidly expanding application area, particularly in the production of printed circuit boards, connectors, and semiconductor components. Here, the demand focuses on Ni-P coatings that can provide reliable mechanical properties under thermal cycling and mechanical stress. The miniaturization trend in electronics has further intensified requirements for coatings that maintain performance integrity despite reduced dimensions.

The oil and gas industry utilizes Ni-P coatings extensively for downhole tools, valves, and pumping equipment operating under severe mechanical stress conditions. Market research indicates growing demand in this sector, particularly for coatings that can withstand both mechanical stress and corrosive environments simultaneously.

Chemical processing equipment manufacturers constitute another significant market segment, requiring coatings that maintain mechanical stability under both stress and chemical exposure. Applications include reactor vessels, heat exchangers, and fluid handling systems where material failure could lead to catastrophic consequences.

Regional market analysis reveals that Asia-Pacific currently dominates the global Ni-P coating market, with China, Japan, and South Korea being the primary contributors. This regional dominance is attributed to the high concentration of electronics manufacturing, automotive production, and industrial machinery sectors. North America and Europe follow as significant markets, with demand driven primarily by aerospace, defense, and high-precision engineering applications.

Market forecasts suggest that the global demand for Ni-P coatings with enhanced mechanical properties under stress conditions will continue to grow at a compound annual rate exceeding the general surface treatment market. This growth is further supported by emerging applications in renewable energy systems, medical devices, and advanced manufacturing technologies where mechanical performance under stress remains a critical requirement.

The aerospace sector constitutes another major market segment, with stringent requirements for materials that can withstand extreme mechanical stress conditions. In this domain, Ni-P coatings are valued for their ability to maintain structural integrity under high-stress environments, particularly in landing gear components, turbine blades, and hydraulic systems. Market analysis indicates that this sector's demand is projected to grow steadily as aircraft production increases globally.

Electronics manufacturing represents a rapidly expanding application area, particularly in the production of printed circuit boards, connectors, and semiconductor components. Here, the demand focuses on Ni-P coatings that can provide reliable mechanical properties under thermal cycling and mechanical stress. The miniaturization trend in electronics has further intensified requirements for coatings that maintain performance integrity despite reduced dimensions.

The oil and gas industry utilizes Ni-P coatings extensively for downhole tools, valves, and pumping equipment operating under severe mechanical stress conditions. Market research indicates growing demand in this sector, particularly for coatings that can withstand both mechanical stress and corrosive environments simultaneously.

Chemical processing equipment manufacturers constitute another significant market segment, requiring coatings that maintain mechanical stability under both stress and chemical exposure. Applications include reactor vessels, heat exchangers, and fluid handling systems where material failure could lead to catastrophic consequences.

Regional market analysis reveals that Asia-Pacific currently dominates the global Ni-P coating market, with China, Japan, and South Korea being the primary contributors. This regional dominance is attributed to the high concentration of electronics manufacturing, automotive production, and industrial machinery sectors. North America and Europe follow as significant markets, with demand driven primarily by aerospace, defense, and high-precision engineering applications.

Market forecasts suggest that the global demand for Ni-P coatings with enhanced mechanical properties under stress conditions will continue to grow at a compound annual rate exceeding the general surface treatment market. This growth is further supported by emerging applications in renewable energy systems, medical devices, and advanced manufacturing technologies where mechanical performance under stress remains a critical requirement.

Current State and Challenges in Ni-P Coating Mechanical Performance

Ni-P coatings have gained significant attention in various industrial applications due to their excellent corrosion resistance, wear resistance, and unique mechanical properties. Currently, these coatings are widely employed in aerospace, automotive, electronics, and chemical processing industries. The global research landscape shows concentrated efforts in Asia, particularly China and Japan, with substantial contributions from European research institutions and North American companies focusing on specialized applications.

The mechanical performance of Ni-P coatings under stress conditions presents several critical challenges. Phosphorus content significantly influences mechanical properties, with high-phosphorus coatings (>10% P) exhibiting amorphous structures that provide excellent corrosion resistance but reduced hardness, while low-phosphorus coatings (<5% P) demonstrate crystalline structures with superior hardness but decreased corrosion resistance. This fundamental trade-off remains a persistent challenge for researchers and engineers.

Heat treatment processes substantially alter the mechanical properties of Ni-P coatings. While heat treatment at temperatures between 300-400°C can increase hardness through the precipitation of Ni3P particles, excessive temperatures lead to grain coarsening and deterioration of mechanical properties. Optimizing heat treatment protocols for specific stress conditions without compromising other properties represents a significant technical hurdle.

Internal stress development during deposition and service conditions poses another major challenge. Residual stresses can lead to cracking, delamination, and premature failure, particularly under cyclic loading conditions. Current deposition techniques struggle to consistently produce low-stress coatings while maintaining other desirable properties. The relationship between deposition parameters and resultant stress profiles remains incompletely understood despite extensive research.

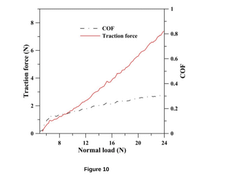

Wear resistance under varying stress conditions shows inconsistent performance across different applications. While Ni-P coatings generally exhibit good wear resistance, their performance deteriorates under high contact stresses or elevated temperatures. The mechanisms of wear and fatigue failure under complex stress states require further investigation to develop more resilient coating systems.

The integration of Ni-P coatings with substrate materials presents compatibility challenges, particularly with high-strength alloys where interfacial adhesion becomes critical under stress conditions. Differential thermal expansion between coating and substrate can induce additional stresses during thermal cycling, leading to premature failure.

Advanced characterization techniques for in-situ monitoring of mechanical properties under stress conditions remain limited, hampering real-time understanding of failure mechanisms and performance degradation pathways. This technological gap restricts the development of predictive models for coating behavior under complex stress states.

The mechanical performance of Ni-P coatings under stress conditions presents several critical challenges. Phosphorus content significantly influences mechanical properties, with high-phosphorus coatings (>10% P) exhibiting amorphous structures that provide excellent corrosion resistance but reduced hardness, while low-phosphorus coatings (<5% P) demonstrate crystalline structures with superior hardness but decreased corrosion resistance. This fundamental trade-off remains a persistent challenge for researchers and engineers.

Heat treatment processes substantially alter the mechanical properties of Ni-P coatings. While heat treatment at temperatures between 300-400°C can increase hardness through the precipitation of Ni3P particles, excessive temperatures lead to grain coarsening and deterioration of mechanical properties. Optimizing heat treatment protocols for specific stress conditions without compromising other properties represents a significant technical hurdle.

Internal stress development during deposition and service conditions poses another major challenge. Residual stresses can lead to cracking, delamination, and premature failure, particularly under cyclic loading conditions. Current deposition techniques struggle to consistently produce low-stress coatings while maintaining other desirable properties. The relationship between deposition parameters and resultant stress profiles remains incompletely understood despite extensive research.

Wear resistance under varying stress conditions shows inconsistent performance across different applications. While Ni-P coatings generally exhibit good wear resistance, their performance deteriorates under high contact stresses or elevated temperatures. The mechanisms of wear and fatigue failure under complex stress states require further investigation to develop more resilient coating systems.

The integration of Ni-P coatings with substrate materials presents compatibility challenges, particularly with high-strength alloys where interfacial adhesion becomes critical under stress conditions. Differential thermal expansion between coating and substrate can induce additional stresses during thermal cycling, leading to premature failure.

Advanced characterization techniques for in-situ monitoring of mechanical properties under stress conditions remain limited, hampering real-time understanding of failure mechanisms and performance degradation pathways. This technological gap restricts the development of predictive models for coating behavior under complex stress states.

Current Methodologies for Evaluating Ni-P Coating Mechanical Properties

01 Composition and structure of Ni-P coatings

Ni-P coatings can be formulated with varying phosphorus content which significantly affects their mechanical properties. Low phosphorus content (1-5%) typically results in crystalline structures with higher hardness, while medium (5-9%) and high phosphorus (>9%) contents produce semi-crystalline and amorphous structures respectively. The microstructure of these coatings directly influences their hardness, wear resistance, and other mechanical properties. Heat treatment can transform the amorphous structure to crystalline, further enhancing hardness through the precipitation of Ni3P particles.- Composition and structure of Ni-P coatings: The mechanical properties of Ni-P coatings are significantly influenced by their composition and microstructure. The phosphorus content in the coating affects hardness, wear resistance, and corrosion resistance. Low phosphorus content (1-5%) typically results in crystalline structures with higher hardness, while medium (5-9%) and high phosphorus content (>9%) leads to semi-amorphous or amorphous structures with different mechanical characteristics. The microstructure can be further modified through heat treatment to optimize specific mechanical properties.

- Heat treatment effects on Ni-P coatings: Heat treatment significantly enhances the mechanical properties of Ni-P coatings through precipitation hardening and crystallization processes. Annealing at specific temperatures (typically 300-400°C) transforms the amorphous structure into a crystalline one with Ni3P precipitates, substantially increasing hardness and wear resistance. The duration and temperature of heat treatment must be carefully controlled to achieve optimal mechanical properties without causing embrittlement or other undesirable effects.

- Co-deposition and alloying elements in Ni-P coatings: The incorporation of additional elements such as tungsten, cobalt, copper, or ceramic particles into Ni-P coatings creates composite or alloy coatings with enhanced mechanical properties. These additions can significantly improve hardness, wear resistance, and thermal stability compared to binary Ni-P coatings. Nano-particles or other reinforcing materials can be co-deposited to create nanocomposite coatings with superior mechanical performance, including increased hardness, better wear resistance, and improved load-bearing capacity.

- Deposition parameters affecting mechanical properties: The mechanical properties of Ni-P coatings are strongly influenced by the electroless or electroplating deposition parameters. Factors such as bath composition, pH, temperature, and deposition rate significantly affect the resulting coating's hardness, internal stress, adhesion strength, and wear resistance. Optimizing these parameters allows for tailored mechanical properties suited for specific applications. Pulse plating techniques can also be employed to control grain size and distribution, further enhancing mechanical properties.

- Surface preparation and post-treatment techniques: Surface preparation before coating and post-treatment processes significantly impact the mechanical properties of Ni-P coatings. Proper substrate preparation ensures good adhesion, which is crucial for the coating's mechanical performance under load. Post-treatments such as burnishing, shot peening, or laser surface modification can enhance surface hardness, reduce friction coefficient, and improve wear resistance. These treatments can also help relieve internal stresses in the coating, preventing cracking and delamination under mechanical loads.

02 Heat treatment effects on Ni-P coating properties

Heat treatment significantly enhances the mechanical properties of Ni-P coatings through microstructural changes. When heated at temperatures between 300-400°C, the amorphous structure crystallizes and forms Ni3P precipitates, which can increase hardness by up to 70%. The optimal heat treatment temperature and duration depend on the phosphorus content, with higher phosphorus coatings typically requiring higher temperatures. However, excessive heat treatment can cause grain coarsening and reduced hardness. Controlled heat treatment processes can achieve hardness values exceeding 1000 HV.Expand Specific Solutions03 Incorporation of nanoparticles and composite formation

The incorporation of nanoparticles into Ni-P coatings creates composite coatings with enhanced mechanical properties. Common additives include SiC, Al2O3, TiO2, diamond, and carbon nanotubes. These nanoparticles act as reinforcement agents, significantly improving hardness, wear resistance, and friction coefficient. The uniform distribution of these particles within the Ni-P matrix is crucial for optimal performance. Composite Ni-P coatings can achieve superior mechanical properties compared to conventional Ni-P coatings, with hardness values potentially exceeding 1200 HV and greatly improved wear resistance.Expand Specific Solutions04 Deposition parameters and their influence on mechanical properties

The deposition parameters significantly influence the mechanical properties of Ni-P coatings. Key parameters include bath composition, pH, temperature, current density (for electroplating), and deposition time. Higher current densities typically produce finer grain structures with improved hardness. Bath temperature affects phosphorus content and deposition rate, with lower temperatures generally favoring higher phosphorus incorporation. The pH value influences the phosphorus content and coating quality, with lower pH values typically resulting in higher phosphorus content. Optimizing these parameters allows for tailored mechanical properties suited to specific applications.Expand Specific Solutions05 Corrosion resistance and durability characteristics

Ni-P coatings offer excellent corrosion resistance in addition to their mechanical properties. High phosphorus content coatings typically provide superior corrosion protection due to their amorphous structure and passive film formation. The corrosion resistance complements mechanical properties, creating durable surfaces for harsh environments. Heat treatment can sometimes reduce corrosion resistance while improving hardness, requiring optimization for specific applications. The combination of high hardness, wear resistance, and corrosion protection makes Ni-P coatings particularly valuable for components exposed to both mechanical stress and corrosive environments.Expand Specific Solutions

Key Industry Players and Research Institutions in Ni-P Coating Field

The mechanical properties of Ni-P coatings under stress represent a maturing technological field with significant industrial applications. The market is characterized by moderate growth, estimated at $2-3 billion annually, driven by increasing demand in automotive, electronics, and aerospace sectors. The competitive landscape features established industrial players like Kobe Steel, Atotech Deutschland, and Mitsubishi Materials, who lead in commercial applications, alongside research-focused entities such as Toyota Central R&D Labs and Xi'an Jiaotong University advancing fundamental understanding. Technical maturity varies across application domains, with well-established processes for conventional applications but ongoing innovation in high-stress environments and specialized applications. Companies like Sumitomo Electric Industries and Hon Hai Precision are expanding capabilities in advanced coating technologies, while academic-industry collaborations are accelerating development of next-generation solutions with enhanced stress resistance properties.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed advanced electroless Ni-P coating technologies with precise control over phosphorus content to optimize mechanical properties under stress conditions. Their research focuses on creating multi-layered Ni-P coatings with varying phosphorus concentrations (low, medium, and high) to achieve optimal hardness-to-ductility ratios. Through proprietary heat treatment processes at temperatures between 300-400°C, they've achieved hardness values exceeding 1000 HV while maintaining good adhesion strength. Their coatings demonstrate superior wear resistance with wear rates reduced by approximately 40% compared to conventional coatings. Kobe Steel has also pioneered nano-composite Ni-P coatings incorporating ceramic particles that show enhanced stress resistance, with fatigue strength improvements of up to 30% under cyclic loading conditions.

Strengths: Superior control over phosphorus content distribution allows customization for specific stress applications; excellent wear resistance and hardness after heat treatment; innovative multi-layered approach provides balanced mechanical properties. Weaknesses: Heat treatment requirements add processing complexity and cost; potential for hydrogen embrittlement during deposition; thickness limitations for certain high-stress applications.

Atotech Deutschland GmbH & Co. KG

Technical Solution: Atotech has pioneered pulse-plating techniques for Ni-P coatings that significantly enhance mechanical properties under stress conditions. Their proprietary Ni-P formulations incorporate specialized organic additives that promote columnar grain structure formation, resulting in coatings with improved ductility while maintaining hardness values of 600-700 HV. Their research has demonstrated that controlled incorporation of nano-sized particles (SiC, Al2O3) at concentrations of 2-5% by volume creates composite coatings with enhanced load-bearing capacity and reduced crack propagation under stress. Atotech's coatings show approximately 25% higher fatigue resistance compared to standard electroless Ni-P deposits. Additionally, they've developed post-treatment processes involving controlled thermal cycling that relieves internal stresses while optimizing precipitation hardening, resulting in coatings that maintain structural integrity under thermal and mechanical cycling with less than 5% property degradation after 1000 cycles.

Strengths: Advanced pulse-plating technology creates optimized microstructures for stress resistance; nano-composite formulations provide superior fatigue performance; excellent thermal stability of mechanical properties. Weaknesses: Higher production costs compared to conventional electroless processes; requires specialized equipment for pulse plating; some formulations have limited corrosion resistance in certain aggressive environments.

Critical Patents and Research on Ni-P Coating Stress Resistance

A surface coating and method of preparation thereof using computational tools

PatentPendingIN202331079025A

Innovation

- A method using artificial neural networking to predict optimal bath parameters for an electroless Ni-Cu-Sn-B coating, eliminating lead and heavy metals, and achieving improved mechanical properties through a quaternary alloy composition optimized for specific surface requirements.

Environmental Impact and Sustainability of Ni-P Coating Processes

The environmental impact of Ni-P coating processes has become increasingly significant as industrial applications expand. Traditional electroplating methods for Ni-P coatings typically involve chemicals that pose substantial environmental concerns, including nickel compounds classified as carcinogenic and phosphorus-containing solutions that contribute to water pollution when improperly managed. These processes generate hazardous waste streams requiring specialized treatment and disposal protocols to prevent ecological damage.

Recent sustainability assessments reveal that electroless Ni-P coating processes consume considerable energy and water resources. The high temperature requirements (85-95°C) for bath operation translate to significant energy consumption, while water usage for rinsing and cleaning operations further increases the environmental footprint. Additionally, the relatively short lifespan of plating baths necessitates frequent disposal and replacement, exacerbating waste management challenges.

Regulatory frameworks worldwide have responded with increasingly stringent controls on nickel-containing waste streams. The European Union's REACH regulations and similar initiatives in North America and Asia have established strict guidelines for the handling, use, and disposal of nickel compounds, driving industry adaptation toward more sustainable practices.

Encouragingly, several sustainable innovations are emerging in the Ni-P coating sector. Low-temperature electroless plating processes have been developed, reducing energy requirements by operating at 60-70°C without compromising coating quality or mechanical properties under stress. Recovery systems for nickel and phosphorus from spent baths demonstrate promising reclamation rates exceeding 85%, substantially reducing raw material demands and waste generation.

Green chemistry approaches are transforming formulation practices, with biodegradable complexing agents replacing traditional chelators like EDTA. These alternatives maintain coating performance characteristics while significantly reducing environmental toxicity. Closed-loop systems that continuously filter and regenerate plating solutions extend bath life by up to 300%, dramatically reducing waste volumes and resource consumption.

Life cycle assessments comparing traditional and emerging Ni-P coating technologies indicate that advanced processes can reduce carbon footprints by 30-45% and water consumption by 25-40%. These improvements maintain or enhance the mechanical properties that make Ni-P coatings valuable, including hardness, wear resistance, and performance under stress conditions, demonstrating that environmental sustainability need not compromise technical performance.

Recent sustainability assessments reveal that electroless Ni-P coating processes consume considerable energy and water resources. The high temperature requirements (85-95°C) for bath operation translate to significant energy consumption, while water usage for rinsing and cleaning operations further increases the environmental footprint. Additionally, the relatively short lifespan of plating baths necessitates frequent disposal and replacement, exacerbating waste management challenges.

Regulatory frameworks worldwide have responded with increasingly stringent controls on nickel-containing waste streams. The European Union's REACH regulations and similar initiatives in North America and Asia have established strict guidelines for the handling, use, and disposal of nickel compounds, driving industry adaptation toward more sustainable practices.

Encouragingly, several sustainable innovations are emerging in the Ni-P coating sector. Low-temperature electroless plating processes have been developed, reducing energy requirements by operating at 60-70°C without compromising coating quality or mechanical properties under stress. Recovery systems for nickel and phosphorus from spent baths demonstrate promising reclamation rates exceeding 85%, substantially reducing raw material demands and waste generation.

Green chemistry approaches are transforming formulation practices, with biodegradable complexing agents replacing traditional chelators like EDTA. These alternatives maintain coating performance characteristics while significantly reducing environmental toxicity. Closed-loop systems that continuously filter and regenerate plating solutions extend bath life by up to 300%, dramatically reducing waste volumes and resource consumption.

Life cycle assessments comparing traditional and emerging Ni-P coating technologies indicate that advanced processes can reduce carbon footprints by 30-45% and water consumption by 25-40%. These improvements maintain or enhance the mechanical properties that make Ni-P coatings valuable, including hardness, wear resistance, and performance under stress conditions, demonstrating that environmental sustainability need not compromise technical performance.

Failure Analysis and Reliability Testing Standards for Ni-P Coatings

Reliability testing standards for Ni-P coatings have evolved significantly over the past decades to address the complex failure mechanisms observed in various industrial applications. The American Society for Testing and Materials (ASTM) has established several key standards specifically for evaluating Ni-P coating performance under stress conditions, including ASTM B578 for adhesion testing and ASTM B489 for measurement of coating thickness.

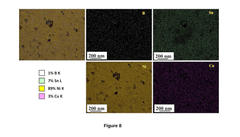

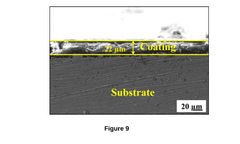

Failure analysis protocols for Ni-P coatings typically involve a systematic approach beginning with visual inspection, followed by more sophisticated analytical techniques. Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-ray Spectroscopy (EDS) has become the gold standard for identifying failure modes such as cracking, delamination, and corrosion products at the microscopic level.

The International Organization for Standardization (ISO) has contributed significantly with ISO 4527, which specifically addresses the testing requirements for autocatalytic nickel-phosphorus coatings. This standard outlines procedures for evaluating coating properties including hardness, wear resistance, and corrosion protection capabilities under various stress conditions.

Accelerated life testing represents a critical component of reliability assessment for Ni-P coatings. Salt spray testing (ASTM B117) remains widely utilized, though industry experts increasingly recognize its limitations in predicting real-world performance. More advanced cyclic corrosion tests that alternate between salt spray, humidity, and dry conditions provide more realistic evaluation of coating durability under combined stresses.

Mechanical property degradation testing standards focus on evaluating how Ni-P coatings respond to mechanical stresses over time. Nanoindentation techniques following ISO 14577 have become increasingly important for characterizing hardness and elastic modulus changes after exposure to various environmental conditions. These measurements provide critical data on how the coating's mechanical integrity evolves under stress.

Electrochemical Impedance Spectroscopy (EIS) has emerged as a powerful non-destructive testing method for evaluating coating degradation mechanisms. ASTM G106 provides guidelines for conducting EIS measurements, allowing researchers to monitor changes in coating resistance and capacitance as indicators of developing failure mechanisms before they become visually apparent.

Industry-specific standards have also been developed to address unique failure modes in particular applications. For example, the automotive industry employs specialized thermal cycling tests (following SAE J2334) that simulate the extreme temperature variations experienced by Ni-P coated components in vehicle systems, while the electronics industry has developed specific testing protocols for evaluating solderability and thermal shock resistance.

Failure analysis protocols for Ni-P coatings typically involve a systematic approach beginning with visual inspection, followed by more sophisticated analytical techniques. Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-ray Spectroscopy (EDS) has become the gold standard for identifying failure modes such as cracking, delamination, and corrosion products at the microscopic level.

The International Organization for Standardization (ISO) has contributed significantly with ISO 4527, which specifically addresses the testing requirements for autocatalytic nickel-phosphorus coatings. This standard outlines procedures for evaluating coating properties including hardness, wear resistance, and corrosion protection capabilities under various stress conditions.

Accelerated life testing represents a critical component of reliability assessment for Ni-P coatings. Salt spray testing (ASTM B117) remains widely utilized, though industry experts increasingly recognize its limitations in predicting real-world performance. More advanced cyclic corrosion tests that alternate between salt spray, humidity, and dry conditions provide more realistic evaluation of coating durability under combined stresses.

Mechanical property degradation testing standards focus on evaluating how Ni-P coatings respond to mechanical stresses over time. Nanoindentation techniques following ISO 14577 have become increasingly important for characterizing hardness and elastic modulus changes after exposure to various environmental conditions. These measurements provide critical data on how the coating's mechanical integrity evolves under stress.

Electrochemical Impedance Spectroscopy (EIS) has emerged as a powerful non-destructive testing method for evaluating coating degradation mechanisms. ASTM G106 provides guidelines for conducting EIS measurements, allowing researchers to monitor changes in coating resistance and capacitance as indicators of developing failure mechanisms before they become visually apparent.

Industry-specific standards have also been developed to address unique failure modes in particular applications. For example, the automotive industry employs specialized thermal cycling tests (following SAE J2334) that simulate the extreme temperature variations experienced by Ni-P coated components in vehicle systems, while the electronics industry has developed specific testing protocols for evaluating solderability and thermal shock resistance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!