Phosphorus Content Effects in Electroless Nickel Coatings

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electroless Nickel Phosphorus Coating Background and Objectives

Electroless nickel phosphorus (ENP) coating technology has evolved significantly since its inception in the mid-20th century. Initially developed as an alternative to electrolytic nickel plating, this autocatalytic deposition process has gained substantial traction across various industries due to its ability to provide uniform coating thickness regardless of substrate geometry. The evolution of ENP technology has been characterized by continuous refinement of bath formulations, process parameters, and an enhanced understanding of the relationship between phosphorus content and coating properties.

The phosphorus content in ENP coatings has emerged as a critical parameter that fundamentally influences the microstructure, physical properties, and performance characteristics of the deposited layer. Historically, ENP coatings have been classified into three categories based on phosphorus content: low (1-5%), medium (5-9%), and high (>9%). Each category exhibits distinct properties that make them suitable for specific applications, driving specialized research and development efforts in each domain.

Recent technological advancements have focused on optimizing phosphorus distribution within the coating matrix to achieve enhanced performance characteristics. The industry has witnessed a shift from conventional ENP processes toward more environmentally friendly alternatives, addressing concerns related to traditional formulations containing lead, cadmium, and other hazardous substances. This transition aligns with global sustainability initiatives and increasingly stringent environmental regulations.

The global market for ENP coatings has expanded considerably, with applications spanning automotive components, aerospace parts, electronics, oil and gas equipment, and chemical processing facilities. This market growth has been propelled by the unique combination of corrosion resistance, wear resistance, and solderability that ENP coatings offer, particularly in harsh operating environments where traditional coatings fail to deliver adequate protection.

The primary technical objectives for ENP coating development center on establishing precise control mechanisms for phosphorus content during deposition, understanding the fundamental relationships between phosphorus distribution and coating performance, and developing novel bath formulations that enable tailored phosphorus content for specific application requirements. Additionally, there is growing interest in exploring the synergistic effects of incorporating secondary elements or nanoparticles alongside phosphorus to create composite coatings with enhanced properties.

Future research directions are expected to focus on developing advanced characterization techniques for real-time monitoring of phosphorus content during deposition, computational modeling of phosphorus incorporation mechanisms, and establishing standardized testing protocols for evaluating the performance of ENP coatings with varying phosphorus contents across different application scenarios. These efforts aim to bridge existing knowledge gaps and enable more predictable, consistent coating outcomes in industrial applications.

The phosphorus content in ENP coatings has emerged as a critical parameter that fundamentally influences the microstructure, physical properties, and performance characteristics of the deposited layer. Historically, ENP coatings have been classified into three categories based on phosphorus content: low (1-5%), medium (5-9%), and high (>9%). Each category exhibits distinct properties that make them suitable for specific applications, driving specialized research and development efforts in each domain.

Recent technological advancements have focused on optimizing phosphorus distribution within the coating matrix to achieve enhanced performance characteristics. The industry has witnessed a shift from conventional ENP processes toward more environmentally friendly alternatives, addressing concerns related to traditional formulations containing lead, cadmium, and other hazardous substances. This transition aligns with global sustainability initiatives and increasingly stringent environmental regulations.

The global market for ENP coatings has expanded considerably, with applications spanning automotive components, aerospace parts, electronics, oil and gas equipment, and chemical processing facilities. This market growth has been propelled by the unique combination of corrosion resistance, wear resistance, and solderability that ENP coatings offer, particularly in harsh operating environments where traditional coatings fail to deliver adequate protection.

The primary technical objectives for ENP coating development center on establishing precise control mechanisms for phosphorus content during deposition, understanding the fundamental relationships between phosphorus distribution and coating performance, and developing novel bath formulations that enable tailored phosphorus content for specific application requirements. Additionally, there is growing interest in exploring the synergistic effects of incorporating secondary elements or nanoparticles alongside phosphorus to create composite coatings with enhanced properties.

Future research directions are expected to focus on developing advanced characterization techniques for real-time monitoring of phosphorus content during deposition, computational modeling of phosphorus incorporation mechanisms, and establishing standardized testing protocols for evaluating the performance of ENP coatings with varying phosphorus contents across different application scenarios. These efforts aim to bridge existing knowledge gaps and enable more predictable, consistent coating outcomes in industrial applications.

Market Applications and Demand Analysis for EN-P Coatings

The global market for Electroless Nickel-Phosphorus (EN-P) coatings has experienced significant growth, driven by increasing demand across multiple industries. The automotive sector represents one of the largest markets for EN-P coatings, utilizing these materials for components requiring superior wear resistance and corrosion protection. Engine parts, fuel systems, and brake components particularly benefit from different phosphorus content variations, with high-phosphorus formulations preferred for corrosion-resistant applications and medium-phosphorus variants chosen for balanced performance characteristics.

The aerospace industry constitutes another critical market segment, where EN-P coatings are applied to landing gear components, hydraulic systems, and engine parts. This sector typically demands high-phosphorus content coatings (10-13% P) due to their exceptional corrosion resistance in extreme environments. Market analysis indicates that aerospace applications will continue expanding at a compound annual growth rate exceeding the industry average through 2028.

Electronics manufacturing represents a rapidly growing application area, particularly for high-phosphorus EN-P coatings used in printed circuit boards, connectors, and electromagnetic shielding. The miniaturization trend in electronics has intensified demand for uniform, thin coatings that low-phosphorus EN-P formulations can provide. Market research shows that electronics applications now account for approximately one-fifth of global EN-P coating consumption.

The oil and gas industry presents substantial demand for EN-P coatings with varying phosphorus contents, depending on specific operational environments. Offshore platforms and subsea equipment typically utilize high-phosphorus variants for superior corrosion resistance in saltwater environments, while drilling equipment often employs medium-phosphorus formulations balancing hardness and wear resistance.

Chemical processing equipment manufacturers constitute another significant market segment, requiring coatings that can withstand aggressive chemical environments. High-phosphorus EN-P coatings dominate this sector due to their superior chemical resistance properties.

Regional market analysis reveals that Asia-Pacific currently leads global demand, driven by rapid industrialization in China and India. North America and Europe maintain substantial market shares, with growth primarily in high-technology applications requiring specialized phosphorus content formulations.

Market forecasts indicate that demand for medium-phosphorus content coatings (6-9% P) will experience the fastest growth rate among all variants, as these formulations offer an optimal balance of hardness, wear resistance, and corrosion protection suitable for diverse industrial applications. The overall EN-P coatings market is projected to expand steadily, with particular growth in applications requiring precise control of phosphorus content to achieve specific performance characteristics.

The aerospace industry constitutes another critical market segment, where EN-P coatings are applied to landing gear components, hydraulic systems, and engine parts. This sector typically demands high-phosphorus content coatings (10-13% P) due to their exceptional corrosion resistance in extreme environments. Market analysis indicates that aerospace applications will continue expanding at a compound annual growth rate exceeding the industry average through 2028.

Electronics manufacturing represents a rapidly growing application area, particularly for high-phosphorus EN-P coatings used in printed circuit boards, connectors, and electromagnetic shielding. The miniaturization trend in electronics has intensified demand for uniform, thin coatings that low-phosphorus EN-P formulations can provide. Market research shows that electronics applications now account for approximately one-fifth of global EN-P coating consumption.

The oil and gas industry presents substantial demand for EN-P coatings with varying phosphorus contents, depending on specific operational environments. Offshore platforms and subsea equipment typically utilize high-phosphorus variants for superior corrosion resistance in saltwater environments, while drilling equipment often employs medium-phosphorus formulations balancing hardness and wear resistance.

Chemical processing equipment manufacturers constitute another significant market segment, requiring coatings that can withstand aggressive chemical environments. High-phosphorus EN-P coatings dominate this sector due to their superior chemical resistance properties.

Regional market analysis reveals that Asia-Pacific currently leads global demand, driven by rapid industrialization in China and India. North America and Europe maintain substantial market shares, with growth primarily in high-technology applications requiring specialized phosphorus content formulations.

Market forecasts indicate that demand for medium-phosphorus content coatings (6-9% P) will experience the fastest growth rate among all variants, as these formulations offer an optimal balance of hardness, wear resistance, and corrosion protection suitable for diverse industrial applications. The overall EN-P coatings market is projected to expand steadily, with particular growth in applications requiring precise control of phosphorus content to achieve specific performance characteristics.

Current Technical Challenges in Phosphorus Content Control

Despite significant advancements in electroless nickel plating technology, controlling phosphorus content remains one of the most challenging aspects of the process. The phosphorus content directly influences critical coating properties including hardness, corrosion resistance, magnetic properties, and wear resistance. Currently, manufacturers struggle to achieve precise and consistent phosphorus levels across production batches, leading to quality variations that impact product performance and reliability.

A primary technical challenge lies in the bath chemistry stability. Electroless nickel baths are complex chemical systems where multiple reactions occur simultaneously. The hypophosphite reducing agent concentration, which directly affects phosphorus co-deposition, changes continuously during the plating process. This dynamic nature makes maintaining consistent phosphorus content difficult, especially in production environments where baths are used for extended periods.

Temperature control presents another significant hurdle. Research has established that even minor temperature fluctuations (±2°C) can cause phosphorus content variations of up to 1-2%. Most industrial setups lack the sophisticated temperature control systems needed for ultra-precise regulation, particularly in large production tanks where thermal gradients naturally occur.

pH stability also critically affects phosphorus incorporation. The relationship between pH and phosphorus content follows a non-linear pattern, making precise control essential. Current pH monitoring and adjustment systems often operate on feedback mechanisms that introduce inherent delays, causing phosphorus content to fluctuate between adjustments.

Bath loading effects further complicate phosphorus control. The surface area-to-volume ratio influences deposition kinetics and consequently phosphorus incorporation. When processing parts with varying geometries and sizes, maintaining consistent phosphorus levels becomes exceptionally difficult without sophisticated compensation mechanisms.

Aging effects in plating baths represent another unresolved challenge. As baths age, organic breakdown products accumulate and bath components deplete at different rates, altering the deposition mechanism and phosphorus co-deposition. Current replenishment strategies often fail to fully address these complex aging dynamics.

Analytical limitations also hinder progress in this field. Real-time monitoring of phosphorus content remains elusive, with most manufacturers relying on post-process testing. This creates a significant lag between production and quality verification, making proactive process adjustments impossible.

The industry also faces challenges in developing standardized models that accurately predict phosphorus content based on multiple process variables. Existing models typically account for only a few parameters and fail to capture the complex interrelationships between factors affecting phosphorus incorporation.

A primary technical challenge lies in the bath chemistry stability. Electroless nickel baths are complex chemical systems where multiple reactions occur simultaneously. The hypophosphite reducing agent concentration, which directly affects phosphorus co-deposition, changes continuously during the plating process. This dynamic nature makes maintaining consistent phosphorus content difficult, especially in production environments where baths are used for extended periods.

Temperature control presents another significant hurdle. Research has established that even minor temperature fluctuations (±2°C) can cause phosphorus content variations of up to 1-2%. Most industrial setups lack the sophisticated temperature control systems needed for ultra-precise regulation, particularly in large production tanks where thermal gradients naturally occur.

pH stability also critically affects phosphorus incorporation. The relationship between pH and phosphorus content follows a non-linear pattern, making precise control essential. Current pH monitoring and adjustment systems often operate on feedback mechanisms that introduce inherent delays, causing phosphorus content to fluctuate between adjustments.

Bath loading effects further complicate phosphorus control. The surface area-to-volume ratio influences deposition kinetics and consequently phosphorus incorporation. When processing parts with varying geometries and sizes, maintaining consistent phosphorus levels becomes exceptionally difficult without sophisticated compensation mechanisms.

Aging effects in plating baths represent another unresolved challenge. As baths age, organic breakdown products accumulate and bath components deplete at different rates, altering the deposition mechanism and phosphorus co-deposition. Current replenishment strategies often fail to fully address these complex aging dynamics.

Analytical limitations also hinder progress in this field. Real-time monitoring of phosphorus content remains elusive, with most manufacturers relying on post-process testing. This creates a significant lag between production and quality verification, making proactive process adjustments impossible.

The industry also faces challenges in developing standardized models that accurately predict phosphorus content based on multiple process variables. Existing models typically account for only a few parameters and fail to capture the complex interrelationships between factors affecting phosphorus incorporation.

Established Phosphorus Content Classification and Properties

01 Phosphorus content classification in electroless nickel coatings

Electroless nickel coatings can be classified based on their phosphorus content into low (1-5%), medium (5-9%), and high (>9%) phosphorus deposits. Each category exhibits distinct properties and performance characteristics. Low phosphorus coatings offer superior hardness and wear resistance, medium phosphorus provides balanced properties, while high phosphorus coatings deliver enhanced corrosion resistance and ductility. The phosphorus content significantly influences the microstructure, with higher phosphorus content resulting in more amorphous structures.- High phosphorus content electroless nickel coatings: Electroless nickel coatings with high phosphorus content (typically 10-13%) offer superior corrosion resistance and are often used in harsh environments. These coatings provide excellent uniformity and can be applied to complex geometries. The high phosphorus content results in an amorphous structure that provides enhanced protection against chemical attack and improved wear resistance after proper heat treatment.

- Medium phosphorus content electroless nickel coatings: Medium phosphorus content (6-9%) electroless nickel coatings provide a balance between corrosion resistance and hardness. These coatings offer good wear resistance while maintaining reasonable corrosion protection. They are often used in applications requiring both properties, such as automotive components and industrial machinery. Medium phosphorus coatings can be heat treated to increase hardness without significantly compromising corrosion resistance.

- Low phosphorus content electroless nickel coatings: Low phosphorus content (1-5%) electroless nickel coatings provide excellent hardness and wear resistance. These coatings have a more crystalline structure compared to higher phosphorus variants, resulting in superior mechanical properties. They are particularly suitable for applications requiring high hardness and abrasion resistance, though they typically offer less corrosion protection than higher phosphorus alternatives. Heat treatment can further enhance the hardness of these coatings.

- Heat treatment effects on phosphorus content: Heat treatment significantly affects the properties of electroless nickel coatings with varying phosphorus content. For high phosphorus coatings, heat treatment at specific temperatures can transform the amorphous structure to crystalline, increasing hardness while potentially reducing corrosion resistance. For medium and low phosphorus coatings, heat treatment can optimize hardness without severely compromising other properties. The temperature and duration of heat treatment must be carefully controlled based on the phosphorus content to achieve desired properties.

- Phosphorus content control methods: Various methods can be employed to control the phosphorus content in electroless nickel coatings. These include adjusting the pH of the plating bath, controlling the concentration of reducing agents (typically sodium hypophosphite), modifying bath temperature, and adding specific stabilizers or complexing agents. The phosphorus content directly influences the coating's microstructure, which in turn determines its physical and chemical properties. Advanced formulations allow for precise control of phosphorus incorporation to meet specific application requirements.

02 Influence of phosphorus content on coating properties

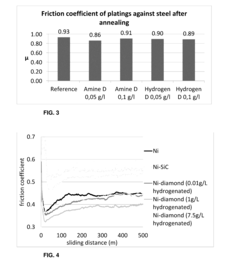

The phosphorus content in electroless nickel coatings directly affects various properties including hardness, wear resistance, corrosion resistance, and magnetic properties. Higher phosphorus content typically results in better corrosion resistance, especially in acidic environments, but lower as-deposited hardness. Lower phosphorus content provides greater hardness and wear resistance but reduced corrosion protection. The phosphorus content also determines the coating's magnetic properties, with high-phosphorus deposits being non-magnetic, which is crucial for certain applications.Expand Specific Solutions03 Heat treatment effects on phosphorus-containing nickel coatings

Heat treatment significantly alters the properties of electroless nickel-phosphorus coatings by causing crystallization and precipitation of nickel phosphide (Ni3P). When heated at temperatures between 300-400°C, the hardness of high-phosphorus coatings can increase dramatically, sometimes exceeding that of hard chrome. The optimal heat treatment temperature and duration depend on the phosphorus content, with different phosphorus levels requiring different heat treatment protocols to achieve maximum hardness or other desired properties.Expand Specific Solutions04 Bath composition and control for phosphorus content regulation

The phosphorus content in electroless nickel coatings can be controlled by adjusting the bath composition and operating parameters. Key factors include the ratio of nickel source to reducing agent (typically sodium hypophosphite), pH level, temperature, and stabilizer concentration. Higher hypophosphite concentrations and lower pH values generally result in higher phosphorus content. Precise control of these parameters is essential for achieving consistent phosphorus content and coating properties across production batches.Expand Specific Solutions05 Applications based on phosphorus content optimization

Different applications require specific phosphorus content levels in electroless nickel coatings to meet performance requirements. High phosphorus coatings (10-13%) are preferred for severe corrosion environments such as chemical processing equipment. Medium phosphorus coatings (6-9%) offer a balance of properties suitable for general engineering applications. Low phosphorus coatings (1-5%) are utilized in applications requiring maximum hardness and wear resistance, such as precision components and molds. The selection of appropriate phosphorus content is critical for optimizing component performance in specific operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in EN-P Industry

The electroless nickel coating market is in a mature growth phase, characterized by established technologies and steady expansion driven by industrial applications requiring corrosion resistance and uniform coating properties. The global market size is estimated at approximately $1.5-2 billion, with projected annual growth of 4-6% through 2028. Technologically, phosphorus content manipulation has reached high maturity, with companies like Atotech, MacDermid, and Chemetall leading innovation in high, medium, and low phosphorus formulations. Research institutions including Zhejiang University and IIT Roorkee collaborate with industrial players such as Henkel, Coventya, and Mitsui Kinzoku to advance coating performance optimization. The competitive landscape features established chemical conglomerates alongside specialized surface treatment providers developing proprietary phosphorus-content solutions for specific industrial applications.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced electroless nickel plating solutions with precisely controlled phosphorus content ranging from low (1-5%), medium (5-9%), to high (>9%). Their proprietary technology enables fine-tuning of phosphorus distribution within the coating matrix, resulting in optimized performance characteristics. Henkel's research has demonstrated that their high-phosphorus EN coatings (10-12% P) provide superior corrosion resistance in acidic environments, while their medium-phosphorus formulations (6-9% P) offer balanced hardness and corrosion protection. Their low-phosphorus solutions (2-4% P) deliver maximum hardness and wear resistance after heat treatment at 400°C, achieving hardness values up to 1000 HV. Henkel has also pioneered additives that stabilize the phosphorus distribution during deposition, preventing phosphorus segregation and ensuring consistent coating properties across complex geometries.

Strengths: Precise control over phosphorus content across the full spectrum (1-12%); excellent bath stability and deposition rate consistency; superior corrosion resistance in high-phosphorus formulations. Weaknesses: Higher cost compared to conventional solutions; more complex bath maintenance requirements; potential for reduced adhesion on certain substrates with higher phosphorus content.

Coventya Srl

Technical Solution: Coventya has developed innovative electroless nickel plating solutions with tailored phosphorus content for specific performance requirements. Their ENOVA series offers precise control over phosphorus incorporation (2-12%) to achieve targeted mechanical and chemical properties. Coventya's high-phosphorus formulations (10-12% P) provide exceptional corrosion protection in aggressive chemical environments, demonstrating salt spray resistance exceeding 1000 hours. Their medium-phosphorus systems (5-9% P) deliver balanced performance with hardness values of 500-600 HV as-deposited, increasing to 800-900 HV after heat treatment. Coventya's research has established correlations between phosphorus content and deposit properties, showing that corrosion resistance increases proportionally with phosphorus content while as-deposited hardness follows an inverse relationship. Their technology includes proprietary stabilizers that maintain consistent phosphorus co-deposition rates even at high bath loading, ensuring uniform coating properties across production batches.

Strengths: Exceptional bath stability and longevity; precise control over phosphorus content; excellent thickness distribution on complex geometries. Weaknesses: Higher cost compared to conventional solutions; requires more sophisticated analytical monitoring; potential for reduced deposition rates at extreme phosphorus contents.

Critical Patents and Research on Phosphorus Content Effects

Metallic coating and a method for producing the same

PatentActiveUS20170009350A1

Innovation

- Incorporating detonation nanodiamonds substantially free of negatively charged functionalities into electroless and electrolytic plating solutions, which enhances the stability and dispersion of nanodiamonds, allowing for improved mechanical, corrosion, and thermal properties of the resulting metal coatings without the need for surfactants and at various electrolyte conditions.

Environmental and Sustainability Aspects of EN-P Processes

The environmental impact of Electroless Nickel-Phosphorus (EN-P) coating processes has become increasingly significant as global sustainability standards evolve. Traditional EN-P plating operations utilize chemicals that pose substantial environmental concerns, particularly nickel compounds which are classified as carcinogenic and phosphorus-containing compounds that contribute to water eutrophication. The phosphorus content in these coatings directly influences the environmental footprint of the entire process.

High-phosphorus EN coatings typically require more aggressive chemical baths with higher concentrations of sodium hypophosphite, leading to increased waste treatment challenges. These baths generally operate at higher temperatures compared to medium and low-phosphorus alternatives, resulting in greater energy consumption and associated carbon emissions. Furthermore, the stability of high-phosphorus baths is often lower, necessitating more frequent disposal and replenishment.

Recent regulatory frameworks, including the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, have placed increasing pressure on the EN-P industry to develop more environmentally benign processes. This has catalyzed research into green alternatives that maintain coating performance while reducing environmental impact.

Several sustainable approaches have emerged in response to these challenges. The development of recovery systems for nickel and phosphorus compounds from spent plating baths has gained traction, with ion exchange and electrowinning technologies showing promising results for closing the material loop. Additionally, bath life extension technologies that maintain optimal phosphorus deposition rates while minimizing waste generation have demonstrated significant environmental benefits.

Low-phosphorus EN formulations have attracted attention for their potentially reduced environmental impact, operating at lower temperatures and with less aggressive chemistry. However, these must be balanced against performance requirements, as phosphorus content significantly affects coating properties including corrosion resistance and hardness.

Water consumption represents another critical environmental aspect of EN-P processes. High-phosphorus baths typically require more extensive rinsing operations due to the viscosity and adherence of the solutions, leading to increased water usage. Closed-loop water systems and advanced filtration technologies are being implemented to address this concern, with phosphorus content considerations factoring into system design.

The end-of-life recyclability of EN-P coated components also varies with phosphorus content. Higher phosphorus coatings may present additional challenges during recycling processes due to the formation of more complex nickel-phosphorus compounds that are difficult to separate during metal recovery operations. This has implications for circular economy initiatives and overall product lifecycle assessment.

High-phosphorus EN coatings typically require more aggressive chemical baths with higher concentrations of sodium hypophosphite, leading to increased waste treatment challenges. These baths generally operate at higher temperatures compared to medium and low-phosphorus alternatives, resulting in greater energy consumption and associated carbon emissions. Furthermore, the stability of high-phosphorus baths is often lower, necessitating more frequent disposal and replenishment.

Recent regulatory frameworks, including the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, have placed increasing pressure on the EN-P industry to develop more environmentally benign processes. This has catalyzed research into green alternatives that maintain coating performance while reducing environmental impact.

Several sustainable approaches have emerged in response to these challenges. The development of recovery systems for nickel and phosphorus compounds from spent plating baths has gained traction, with ion exchange and electrowinning technologies showing promising results for closing the material loop. Additionally, bath life extension technologies that maintain optimal phosphorus deposition rates while minimizing waste generation have demonstrated significant environmental benefits.

Low-phosphorus EN formulations have attracted attention for their potentially reduced environmental impact, operating at lower temperatures and with less aggressive chemistry. However, these must be balanced against performance requirements, as phosphorus content significantly affects coating properties including corrosion resistance and hardness.

Water consumption represents another critical environmental aspect of EN-P processes. High-phosphorus baths typically require more extensive rinsing operations due to the viscosity and adherence of the solutions, leading to increased water usage. Closed-loop water systems and advanced filtration technologies are being implemented to address this concern, with phosphorus content considerations factoring into system design.

The end-of-life recyclability of EN-P coated components also varies with phosphorus content. Higher phosphorus coatings may present additional challenges during recycling processes due to the formation of more complex nickel-phosphorus compounds that are difficult to separate during metal recovery operations. This has implications for circular economy initiatives and overall product lifecycle assessment.

Quality Control and Testing Methods for Phosphorus Content

Quality control for phosphorus content in electroless nickel coatings requires systematic testing methods to ensure coating performance meets specifications. The industry has established several standardized techniques for accurate phosphorus measurement, each with specific advantages and limitations.

X-ray fluorescence spectroscopy (XRF) represents the most widely adopted non-destructive testing method, offering rapid analysis without sample preparation. Modern XRF equipment can detect phosphorus content with precision of ±0.1%, making it ideal for production environments where quick verification is essential. However, XRF measurements can be influenced by coating thickness and substrate composition, necessitating careful calibration with standards of known phosphorus content.

Atomic absorption spectroscopy (AAS) and inductively coupled plasma (ICP) techniques provide higher accuracy for phosphorus determination, typically achieving ±0.05% precision. These methods require dissolving coating samples in acid solutions, making them destructive but more definitive for critical applications. ICP-OES (Optical Emission Spectroscopy) has become increasingly preferred due to its superior detection limits and multi-element analysis capabilities.

Energy dispersive spectroscopy (EDS) coupled with scanning electron microscopy offers the advantage of microstructural correlation with compositional analysis. This technique proves valuable for investigating phosphorus distribution across coating cross-sections, revealing potential segregation or gradient effects that may impact performance.

Statistical process control (SPC) methodologies have been implemented by leading manufacturers to monitor phosphorus content throughout production cycles. Control charts tracking phosphorus levels help identify process drift before specifications are violated. Industry standards typically define acceptable phosphorus content ranges: low phosphorus (1-5%), medium phosphorus (6-9%), and high phosphorus (10-13%), with tolerances of ±1% commonly specified.

Calibration protocols represent a critical aspect of quality control systems. Reference materials certified for phosphorus content must be regularly used to verify instrument accuracy. NIST-traceable standards are preferred for establishing measurement traceability and ensuring consistency across testing laboratories.

Documentation requirements have become increasingly stringent, with coating specifications often mandating detailed phosphorus content reporting. Modern quality systems incorporate automated data collection with statistical analysis capabilities, enabling real-time process adjustments when phosphorus levels deviate from target values.

X-ray fluorescence spectroscopy (XRF) represents the most widely adopted non-destructive testing method, offering rapid analysis without sample preparation. Modern XRF equipment can detect phosphorus content with precision of ±0.1%, making it ideal for production environments where quick verification is essential. However, XRF measurements can be influenced by coating thickness and substrate composition, necessitating careful calibration with standards of known phosphorus content.

Atomic absorption spectroscopy (AAS) and inductively coupled plasma (ICP) techniques provide higher accuracy for phosphorus determination, typically achieving ±0.05% precision. These methods require dissolving coating samples in acid solutions, making them destructive but more definitive for critical applications. ICP-OES (Optical Emission Spectroscopy) has become increasingly preferred due to its superior detection limits and multi-element analysis capabilities.

Energy dispersive spectroscopy (EDS) coupled with scanning electron microscopy offers the advantage of microstructural correlation with compositional analysis. This technique proves valuable for investigating phosphorus distribution across coating cross-sections, revealing potential segregation or gradient effects that may impact performance.

Statistical process control (SPC) methodologies have been implemented by leading manufacturers to monitor phosphorus content throughout production cycles. Control charts tracking phosphorus levels help identify process drift before specifications are violated. Industry standards typically define acceptable phosphorus content ranges: low phosphorus (1-5%), medium phosphorus (6-9%), and high phosphorus (10-13%), with tolerances of ±1% commonly specified.

Calibration protocols represent a critical aspect of quality control systems. Reference materials certified for phosphorus content must be regularly used to verify instrument accuracy. NIST-traceable standards are preferred for establishing measurement traceability and ensuring consistency across testing laboratories.

Documentation requirements have become increasingly stringent, with coating specifications often mandating detailed phosphorus content reporting. Modern quality systems incorporate automated data collection with statistical analysis capabilities, enabling real-time process adjustments when phosphorus levels deviate from target values.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!