Uniform Coating Deposition on Complex Geometries

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Complex Geometry Coating Background and Objectives

The field of uniform coating deposition on complex geometries has evolved significantly over the past several decades, driven by increasing demands across multiple industries including aerospace, automotive, medical devices, and microelectronics. Initially, coating technologies were primarily developed for flat or simple curved surfaces, with limited capability to address intricate three-dimensional structures. The evolution began with basic spray coating methods in the 1950s and has progressed through various technological innovations including chemical vapor deposition (CVD), physical vapor deposition (PVD), and more recently, atomic layer deposition (ALD).

The fundamental challenge in this domain lies in achieving consistent thickness, adhesion, and functional properties across surfaces with varying angles, recesses, protrusions, and internal features. Traditional coating methods typically suffer from phenomena such as edge effects, shadowing, and non-uniform distribution of coating materials when applied to complex geometries. These limitations have historically constrained product design and performance across multiple industries.

Recent technological advancements have been driven by miniaturization trends in electronics, increased performance requirements in aerospace components, and the growing complexity of medical implants. The development of computational fluid dynamics models and simulation tools has significantly enhanced our understanding of coating behavior on complex surfaces, allowing for more precise process control and optimization.

The primary objectives of current research in this field include developing coating methodologies that can maintain uniformity regardless of substrate complexity, reducing process variability, minimizing material waste, and ensuring consistent functional properties throughout the coated surface. Additionally, there is growing emphasis on environmentally sustainable coating processes that reduce solvent usage and hazardous emissions while maintaining or improving coating performance.

From an industrial perspective, achieving uniform coatings on complex geometries represents a critical enabling technology for next-generation products across multiple sectors. In aerospace, it facilitates thermal barrier coatings on turbine blades with intricate cooling channels. In medical devices, it enables consistent drug-eluting coatings on stents and implants with complex surface features. In electronics, it supports the conformal coating of increasingly three-dimensional circuit architectures.

The trajectory of this technology indicates movement toward hybrid approaches that combine multiple deposition techniques, in-situ monitoring systems for real-time process control, and advanced pre-treatment methods to optimize surface properties before coating application. The ultimate goal is to develop versatile, scalable coating technologies that can adapt to virtually any geometric complexity while maintaining precise control over coating characteristics.

The fundamental challenge in this domain lies in achieving consistent thickness, adhesion, and functional properties across surfaces with varying angles, recesses, protrusions, and internal features. Traditional coating methods typically suffer from phenomena such as edge effects, shadowing, and non-uniform distribution of coating materials when applied to complex geometries. These limitations have historically constrained product design and performance across multiple industries.

Recent technological advancements have been driven by miniaturization trends in electronics, increased performance requirements in aerospace components, and the growing complexity of medical implants. The development of computational fluid dynamics models and simulation tools has significantly enhanced our understanding of coating behavior on complex surfaces, allowing for more precise process control and optimization.

The primary objectives of current research in this field include developing coating methodologies that can maintain uniformity regardless of substrate complexity, reducing process variability, minimizing material waste, and ensuring consistent functional properties throughout the coated surface. Additionally, there is growing emphasis on environmentally sustainable coating processes that reduce solvent usage and hazardous emissions while maintaining or improving coating performance.

From an industrial perspective, achieving uniform coatings on complex geometries represents a critical enabling technology for next-generation products across multiple sectors. In aerospace, it facilitates thermal barrier coatings on turbine blades with intricate cooling channels. In medical devices, it enables consistent drug-eluting coatings on stents and implants with complex surface features. In electronics, it supports the conformal coating of increasingly three-dimensional circuit architectures.

The trajectory of this technology indicates movement toward hybrid approaches that combine multiple deposition techniques, in-situ monitoring systems for real-time process control, and advanced pre-treatment methods to optimize surface properties before coating application. The ultimate goal is to develop versatile, scalable coating technologies that can adapt to virtually any geometric complexity while maintaining precise control over coating characteristics.

Market Analysis for Uniform Coating Solutions

The global market for uniform coating solutions on complex geometries is experiencing robust growth, driven primarily by increasing demands across aerospace, automotive, medical device, and semiconductor industries. Current market valuation stands at approximately 8.7 billion USD with a compound annual growth rate projected at 6.2% through 2028, according to recent industry analyses.

The aerospace sector represents the largest market segment, accounting for nearly 31% of the total market share. This dominance stems from the critical need for precision coatings on turbine blades, engine components, and structural elements that must withstand extreme temperatures and mechanical stress. Uniform coating quality directly impacts fuel efficiency and component lifespan, making it a high-value application.

Medical device manufacturing follows as the second-largest market segment at 24%, where uniform coatings on implants, surgical instruments, and diagnostic equipment are essential for biocompatibility, wear resistance, and functionality. The growing trend toward minimally invasive procedures has increased demand for complex-shaped instruments requiring specialized coating solutions.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the fastest growth rate at 8.4% annually, driven by rapid industrialization in China and India, alongside significant investments in semiconductor and electronics manufacturing.

Customer requirements are evolving toward more environmentally sustainable coating solutions with reduced VOC emissions and energy consumption. This shift is particularly pronounced in European markets where regulatory pressures are accelerating the transition to water-based and powder coating technologies.

The market exhibits moderate fragmentation with the top five players controlling approximately 42% of global market share. These major players are increasingly focusing on developing integrated solutions that combine advanced materials science with precision application technologies to address the challenges of coating complex geometries.

Price sensitivity varies significantly by application segment. High-performance industries like aerospace and medical devices prioritize coating quality and performance over cost considerations, while consumer electronics and automotive sectors maintain stronger price pressure on suppliers, driving innovation in cost-effective application methods.

Future market growth will likely be fueled by emerging applications in renewable energy components, particularly wind turbine blades and solar panel structures, where uniform protective coatings significantly impact operational efficiency and service life in challenging environmental conditions.

The aerospace sector represents the largest market segment, accounting for nearly 31% of the total market share. This dominance stems from the critical need for precision coatings on turbine blades, engine components, and structural elements that must withstand extreme temperatures and mechanical stress. Uniform coating quality directly impacts fuel efficiency and component lifespan, making it a high-value application.

Medical device manufacturing follows as the second-largest market segment at 24%, where uniform coatings on implants, surgical instruments, and diagnostic equipment are essential for biocompatibility, wear resistance, and functionality. The growing trend toward minimally invasive procedures has increased demand for complex-shaped instruments requiring specialized coating solutions.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the fastest growth rate at 8.4% annually, driven by rapid industrialization in China and India, alongside significant investments in semiconductor and electronics manufacturing.

Customer requirements are evolving toward more environmentally sustainable coating solutions with reduced VOC emissions and energy consumption. This shift is particularly pronounced in European markets where regulatory pressures are accelerating the transition to water-based and powder coating technologies.

The market exhibits moderate fragmentation with the top five players controlling approximately 42% of global market share. These major players are increasingly focusing on developing integrated solutions that combine advanced materials science with precision application technologies to address the challenges of coating complex geometries.

Price sensitivity varies significantly by application segment. High-performance industries like aerospace and medical devices prioritize coating quality and performance over cost considerations, while consumer electronics and automotive sectors maintain stronger price pressure on suppliers, driving innovation in cost-effective application methods.

Future market growth will likely be fueled by emerging applications in renewable energy components, particularly wind turbine blades and solar panel structures, where uniform protective coatings significantly impact operational efficiency and service life in challenging environmental conditions.

Technical Barriers in Complex Surface Coating

Achieving uniform coating deposition on complex geometries presents numerous technical challenges that have persistently hindered manufacturing processes across various industries. The fundamental barrier stems from the inherent physics of coating materials interacting with irregular surfaces, creating issues such as edge build-up, shadowing effects, and non-uniform thickness distribution. These problems are particularly pronounced in applications requiring precise coating specifications, such as aerospace components, medical implants, and advanced electronics.

Surface tension phenomena represent a significant obstacle, as coating materials naturally tend to accumulate at edges, corners, and recessed areas due to capillary forces. This results in thickness variations that can compromise both aesthetic and functional properties of the final product. Additionally, the viscosity characteristics of coating materials often change during application processes, further complicating uniform distribution across complex three-dimensional structures.

Geometric complexity itself introduces multiple variables that must be simultaneously controlled. Features such as deep recesses, sharp angles, undercuts, and varying surface curvatures create zones where conventional coating methods struggle to maintain consistency. The "line-of-sight" limitation in many deposition techniques (particularly physical vapor deposition and spray coating) means that surfaces not directly exposed to the coating source receive insufficient material coverage.

Temperature gradients across complex parts present another substantial challenge. Uneven heating or cooling during thermal spray processes or curing stages can lead to differential shrinkage, coating stress, and adhesion failures. These thermal inconsistencies are especially problematic for large components with varying thicknesses or materials with different thermal expansion coefficients.

The scaling of laboratory solutions to industrial production environments introduces additional complications. Techniques that work effectively for small, simple geometries often fail when applied to larger, more complex parts or when production volumes increase. This scaling barrier has prevented many promising coating technologies from achieving widespread industrial implementation.

Equipment limitations further constrain potential solutions, as existing coating machinery is frequently designed for planar or simple curved surfaces. The development of specialized equipment capable of navigating complex geometries while maintaining precise control over coating parameters requires significant engineering innovation and capital investment.

Finally, real-time monitoring and quality control present persistent challenges. The inability to accurately measure coating thickness and uniformity on complex surfaces during application processes means that defects are often discovered only after completion, resulting in costly rework or rejection of components.

Surface tension phenomena represent a significant obstacle, as coating materials naturally tend to accumulate at edges, corners, and recessed areas due to capillary forces. This results in thickness variations that can compromise both aesthetic and functional properties of the final product. Additionally, the viscosity characteristics of coating materials often change during application processes, further complicating uniform distribution across complex three-dimensional structures.

Geometric complexity itself introduces multiple variables that must be simultaneously controlled. Features such as deep recesses, sharp angles, undercuts, and varying surface curvatures create zones where conventional coating methods struggle to maintain consistency. The "line-of-sight" limitation in many deposition techniques (particularly physical vapor deposition and spray coating) means that surfaces not directly exposed to the coating source receive insufficient material coverage.

Temperature gradients across complex parts present another substantial challenge. Uneven heating or cooling during thermal spray processes or curing stages can lead to differential shrinkage, coating stress, and adhesion failures. These thermal inconsistencies are especially problematic for large components with varying thicknesses or materials with different thermal expansion coefficients.

The scaling of laboratory solutions to industrial production environments introduces additional complications. Techniques that work effectively for small, simple geometries often fail when applied to larger, more complex parts or when production volumes increase. This scaling barrier has prevented many promising coating technologies from achieving widespread industrial implementation.

Equipment limitations further constrain potential solutions, as existing coating machinery is frequently designed for planar or simple curved surfaces. The development of specialized equipment capable of navigating complex geometries while maintaining precise control over coating parameters requires significant engineering innovation and capital investment.

Finally, real-time monitoring and quality control present persistent challenges. The inability to accurately measure coating thickness and uniformity on complex surfaces during application processes means that defects are often discovered only after completion, resulting in costly rework or rejection of components.

Current Methodologies for Complex Geometry Coating

01 Process control methods for uniform coating deposition

Various process control methods can be implemented to achieve uniform coating deposition. These include optimizing deposition parameters such as temperature, pressure, and flow rates during the coating process. Advanced monitoring systems can provide real-time feedback to adjust process variables, ensuring consistent coating thickness across substrates. Proper substrate preparation and positioning within deposition chambers also contribute significantly to coating uniformity.- Process control methods for uniform coating deposition: Various process control methods can be implemented to achieve uniform coating deposition. These include optimizing deposition parameters such as temperature, pressure, and flow rates during the coating process. Advanced monitoring systems can provide real-time feedback to adjust process variables, ensuring consistent coating thickness across substrates. Statistical process control techniques help maintain quality standards and reduce variations in coating uniformity.

- Equipment design for improved coating uniformity: Specialized equipment designs play a crucial role in achieving uniform coating deposition. This includes optimized chamber geometries, advanced nozzle designs, and substrate positioning systems that ensure even distribution of coating materials. Rotating or oscillating substrate holders can prevent preferential deposition patterns. Custom-designed fixtures and masks help control deposition patterns and edge effects, resulting in more uniform coatings across complex substrate geometries.

- Material formulation techniques for uniform coatings: The formulation of coating materials significantly impacts deposition uniformity. Adjusting viscosity, surface tension, and rheological properties can improve flow characteristics and substrate wetting. Additives such as surfactants and leveling agents help prevent surface defects and promote even spreading. Particle size distribution control in suspension-based coatings ensures consistent material deposition and prevents agglomeration that could lead to non-uniform coverage.

- Pre-treatment and surface preparation methods: Proper substrate preparation is essential for achieving uniform coating deposition. Surface cleaning techniques remove contaminants that could interfere with coating adhesion. Chemical or physical activation methods can modify surface energy to improve wetting characteristics. Primer layers or adhesion promoters create consistent foundation surfaces for subsequent coating layers. Controlled surface roughness profiles help ensure uniform coating adhesion and thickness distribution.

- Post-deposition treatments for coating uniformity: Various post-deposition treatments can enhance coating uniformity after the initial application process. Heat treatment or annealing processes promote material flow and self-leveling effects. Polishing or planarization techniques can remove high spots and fill in low areas. UV curing with controlled exposure ensures consistent cross-linking throughout the coating. These post-processing methods help compensate for any non-uniformities that occurred during the initial deposition phase.

02 Equipment design for improved coating uniformity

Specialized equipment designs can significantly enhance coating uniformity. This includes optimized chamber geometries, advanced target configurations in sputtering systems, and customized fixtures for substrate holding. Rotational mechanisms that provide multi-axis movement during deposition ensure even coverage across complex geometries. Equipment modifications such as shields, baffles, and specialized nozzles help control deposition patterns and minimize edge effects.Expand Specific Solutions03 Material formulation approaches for uniform coatings

The composition and formulation of coating materials significantly impact deposition uniformity. Adjusting viscosity, surface tension, and rheological properties can improve flow characteristics and substrate wetting. Additives that enhance leveling properties help eliminate thickness variations. For solution-based coatings, solvent selection and concentration play crucial roles in achieving uniform film formation during drying and curing processes.Expand Specific Solutions04 Substrate preparation techniques for uniform coating

Proper substrate preparation is essential for achieving uniform coating deposition. This includes cleaning protocols to remove contaminants, surface treatments to modify wettability, and priming layers to improve adhesion. Physical and chemical pretreatments can create consistent surface energy across the substrate. Techniques such as plasma treatment, chemical etching, and mechanical polishing help eliminate surface irregularities that could lead to coating variations.Expand Specific Solutions05 Advanced monitoring and correction systems

Advanced monitoring and correction systems enable real-time assessment and adjustment of coating uniformity. These include optical thickness monitors, laser interferometry, and spectroscopic ellipsometry for in-situ measurement. Automated feedback control systems can make immediate adjustments to deposition parameters when variations are detected. Post-deposition analysis techniques help identify patterns of non-uniformity, allowing for process refinement in subsequent coating operations.Expand Specific Solutions

Industry Leaders in Advanced Coating Systems

The uniform coating deposition on complex geometries market is currently in a growth phase, characterized by increasing demand across aerospace, semiconductor, and medical device industries. The global market size is estimated to exceed $5 billion, driven by advancements in precision manufacturing and surface engineering technologies. Technical maturity varies significantly among key players, with established leaders like Applied Materials, Air Liquide, and 3M demonstrating advanced capabilities in thin-film deposition. Research institutions such as CNRS and CEA are pioneering next-generation coating methodologies, while specialized firms like SilcoTek and NanoMech focus on niche applications. Companies including PPG Industries and Saint-Gobain are expanding their portfolios through proprietary technologies for industrial-scale implementation, creating a competitive landscape balanced between established corporations and innovative specialists.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive approach to uniform coating deposition on complex geometries through their Precision Coating Technology platform. Their solution combines specialized fluid dynamics modeling with proprietary spray technologies to achieve consistent coverage on irregular surfaces. The company's Dual Rotating System employs synchronized rotation of both the substrate and spray heads, creating multiple deposition angles that reach recessed areas and complex contours. 3M's adaptive spray technology utilizes real-time feedback from optical sensors to adjust spray parameters including pressure, viscosity, and droplet size based on the specific geometry being coated. For nanoscale applications, they've developed a vapor phase deposition system that uses controlled diffusion principles to ensure uniform molecular distribution even in high aspect ratio features. Their hybrid approach combines conventional spray methods with electrostatic assistance, where charged particles are attracted to the substrate surface with controlled field strength variations that compensate for geometric complexity. This technology has demonstrated coating thickness variations of less than 5% even on parts with complex 3D geometries including undercuts and deep recesses.

Strengths: Exceptional versatility across diverse substrate materials and geometries; proprietary formulations optimize adhesion on challenging surfaces; scalable from laboratory to high-volume production. Weaknesses: Some solutions require multiple process steps increasing production time; certain techniques have limitations with thermally sensitive substrates; specialized equipment requires significant operator training.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) systems specifically designed for uniform coating on complex geometries. Their EnCoRe™ II system utilizes a proprietary rotating substrate technology that ensures 360-degree coverage on intricate parts. The system incorporates multi-directional plasma sources that can be independently controlled to adjust deposition angles and intensities based on the target geometry. Applied Materials has also pioneered Atomic Layer Deposition (ALD) technology that achieves conformal coating at the atomic level by sequentially introducing precursor gases that react only with the surface, creating uniform monolayers regardless of surface complexity. Their FlexAL® system combines plasma enhancement with ALD to improve film quality while maintaining conformality on high-aspect-ratio structures. Recent innovations include AI-driven deposition control systems that analyze real-time sensor data to dynamically adjust process parameters, compensating for geometric variations and ensuring coating uniformity even on the most challenging surfaces.

Strengths: Industry-leading precision in nanometer-scale deposition control; comprehensive process monitoring capabilities; extensive material compatibility across metals, oxides, and nitrides. Weaknesses: High capital equipment costs; complex systems require specialized technical expertise; some processes have relatively slow deposition rates for high-volume manufacturing.

Key Patents in Uniform Deposition Technology

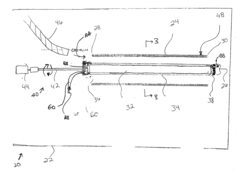

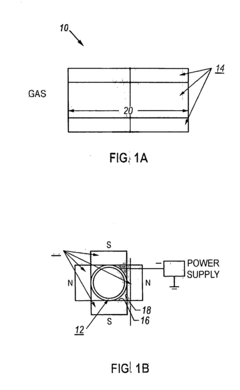

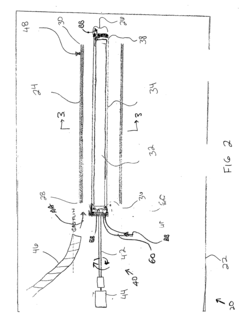

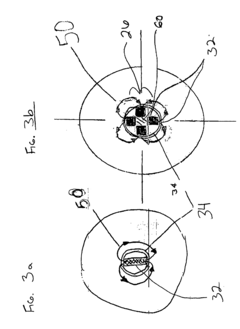

Method for depositing coatings on the interior surfaces of tubular structures

PatentInactiveUS20040191436A1

Innovation

- A method involving the induction of a magnetic field and application of a bias voltage within a tubular structure, combined with exposure to a gaseous precursor material, to ionize and uniformly deposit a coating on the interior surface using plasma enhanced chemical vapor deposition (PECVD), which includes sputter cleaning and the use of inert gases to prepare the surface.

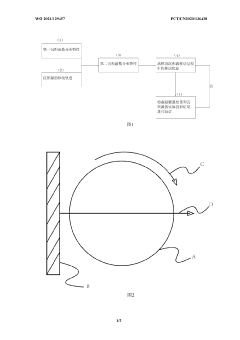

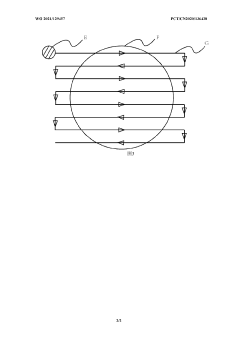

Uniform coating method, coating device, and computer readable storage medium

PatentWO2021129457A1

Innovation

- By calculating and optimizing the movement trajectory and movement status of the deposition source, determining the first deposition function distribution characteristics of the deposition source according to the surface shape of the optical element to be deposited, planning the movement trajectory and status of the deposition source, realizing virtual coating and adjusting the actual deposition results until achieve uniformity.

Material Science Innovations for Complex Surfaces

Recent advancements in material science have opened new frontiers for addressing the persistent challenge of uniform coating deposition on complex geometries. The development of adaptive nanomaterials with self-organizing properties represents a significant breakthrough in this field. These materials can respond to surface variations and adjust their deposition characteristics accordingly, ensuring more consistent coverage across irregular surfaces.

Computational fluid dynamics (CFD) modeling has been instrumental in optimizing coating processes for complex geometries. Advanced simulation techniques now allow for precise prediction of flow patterns and material behavior during deposition, enabling engineers to design more effective application methods tailored to specific surface complexities. These models incorporate multi-physics approaches that account for surface tension, viscosity changes, and substrate-coating interactions.

Biomimetic approaches have emerged as a promising direction, drawing inspiration from natural systems that achieve uniform coverage on complex structures. For instance, the lotus leaf's self-cleaning properties have informed the development of superhydrophobic coatings that can maintain consistent performance even on intricate surfaces. Similarly, the adhesive mechanisms of gecko feet have inspired new bonding technologies for challenging substrates.

Smart responsive polymers represent another innovative approach, offering coatings that can self-level and adapt to surface irregularities. These materials undergo controlled phase transitions or crosslinking reactions in response to specific stimuli (temperature, pH, light), allowing them to penetrate and cover complex geometries more effectively than traditional coating materials. Their ability to flow into recessed areas before solidifying addresses one of the most persistent challenges in coating technology.

Plasma-enhanced deposition techniques have revolutionized the application of thin films on complex three-dimensional objects. By creating a reactive gas environment, these methods achieve more conformal coverage by allowing coating precursors to reach otherwise inaccessible surface features. The combination of plasma technology with rotating or articulating substrate holders has further improved uniformity on complex parts.

Gradient-engineered materials offer another solution pathway, where coating composition and properties gradually change across the surface to accommodate varying geometric features. This approach allows for optimized adhesion, thickness, and functional properties throughout the coated object, even when surface characteristics vary significantly from one region to another.

Computational fluid dynamics (CFD) modeling has been instrumental in optimizing coating processes for complex geometries. Advanced simulation techniques now allow for precise prediction of flow patterns and material behavior during deposition, enabling engineers to design more effective application methods tailored to specific surface complexities. These models incorporate multi-physics approaches that account for surface tension, viscosity changes, and substrate-coating interactions.

Biomimetic approaches have emerged as a promising direction, drawing inspiration from natural systems that achieve uniform coverage on complex structures. For instance, the lotus leaf's self-cleaning properties have informed the development of superhydrophobic coatings that can maintain consistent performance even on intricate surfaces. Similarly, the adhesive mechanisms of gecko feet have inspired new bonding technologies for challenging substrates.

Smart responsive polymers represent another innovative approach, offering coatings that can self-level and adapt to surface irregularities. These materials undergo controlled phase transitions or crosslinking reactions in response to specific stimuli (temperature, pH, light), allowing them to penetrate and cover complex geometries more effectively than traditional coating materials. Their ability to flow into recessed areas before solidifying addresses one of the most persistent challenges in coating technology.

Plasma-enhanced deposition techniques have revolutionized the application of thin films on complex three-dimensional objects. By creating a reactive gas environment, these methods achieve more conformal coverage by allowing coating precursors to reach otherwise inaccessible surface features. The combination of plasma technology with rotating or articulating substrate holders has further improved uniformity on complex parts.

Gradient-engineered materials offer another solution pathway, where coating composition and properties gradually change across the surface to accommodate varying geometric features. This approach allows for optimized adhesion, thickness, and functional properties throughout the coated object, even when surface characteristics vary significantly from one region to another.

Quality Control Methods for Coating Uniformity

Quality control in uniform coating deposition on complex geometries requires systematic approaches to ensure consistent results. Real-time monitoring systems represent the cornerstone of modern quality control methods, employing advanced sensors that can detect thickness variations during the deposition process. These systems typically utilize optical interferometry, eddy current measurements, or laser triangulation techniques to provide immediate feedback on coating uniformity, allowing for process adjustments before defects become permanent.

Statistical process control (SPC) methodologies have been adapted specifically for coating applications on complex geometries. By establishing control limits based on historical performance data, manufacturers can identify when processes drift toward unacceptable variation. Implementation of SPC charts for key parameters such as thickness distribution, surface roughness, and adhesion strength enables early detection of potential uniformity issues.

Destructive and non-destructive testing protocols form complementary approaches to quality assessment. Cross-sectional analysis provides definitive thickness measurements at specific points but requires sample sacrifice. In contrast, non-destructive methods such as ultrasonic testing, X-ray fluorescence, and thermal imaging allow comprehensive inspection without compromising the coated component. The integration of these methods creates a robust verification system for coating uniformity across complex surfaces.

Advanced image analysis techniques have revolutionized quality control for complex geometries. Computer vision systems equipped with machine learning algorithms can detect subtle patterns in coating distribution that might escape human inspection. These systems compare captured images against ideal reference models, highlighting areas of potential non-uniformity and providing quantitative metrics for quality assessment.

Standardized testing procedures ensure consistency across different production batches and facilities. Organizations such as ASTM International and ISO have developed specific protocols for evaluating coating uniformity, including salt spray testing, adhesion testing, and thickness mapping. Adherence to these standards facilitates objective quality assessment and enables meaningful comparison between different coating technologies and suppliers.

Digital twin technology represents the cutting edge of quality control for complex geometries. By creating virtual models that simulate the coating process and predict outcomes based on input parameters, manufacturers can anticipate uniformity issues before physical production begins. These models continuously improve through machine learning algorithms that incorporate real production data, creating an increasingly accurate predictive capability for quality control.

Statistical process control (SPC) methodologies have been adapted specifically for coating applications on complex geometries. By establishing control limits based on historical performance data, manufacturers can identify when processes drift toward unacceptable variation. Implementation of SPC charts for key parameters such as thickness distribution, surface roughness, and adhesion strength enables early detection of potential uniformity issues.

Destructive and non-destructive testing protocols form complementary approaches to quality assessment. Cross-sectional analysis provides definitive thickness measurements at specific points but requires sample sacrifice. In contrast, non-destructive methods such as ultrasonic testing, X-ray fluorescence, and thermal imaging allow comprehensive inspection without compromising the coated component. The integration of these methods creates a robust verification system for coating uniformity across complex surfaces.

Advanced image analysis techniques have revolutionized quality control for complex geometries. Computer vision systems equipped with machine learning algorithms can detect subtle patterns in coating distribution that might escape human inspection. These systems compare captured images against ideal reference models, highlighting areas of potential non-uniformity and providing quantitative metrics for quality assessment.

Standardized testing procedures ensure consistency across different production batches and facilities. Organizations such as ASTM International and ISO have developed specific protocols for evaluating coating uniformity, including salt spray testing, adhesion testing, and thickness mapping. Adherence to these standards facilitates objective quality assessment and enables meaningful comparison between different coating technologies and suppliers.

Digital twin technology represents the cutting edge of quality control for complex geometries. By creating virtual models that simulate the coating process and predict outcomes based on input parameters, manufacturers can anticipate uniformity issues before physical production begins. These models continuously improve through machine learning algorithms that incorporate real production data, creating an increasingly accurate predictive capability for quality control.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!