Wear Resistance Improvement through Electroless Plating

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electroless Plating Technology Background and Objectives

Electroless plating technology emerged in the early 20th century with the pioneering work of Brenner and Riddell, who developed the first commercial electroless nickel plating process in the 1940s. This chemical deposition method, which operates without external electrical current, represented a significant advancement in surface engineering. Over subsequent decades, the technology has evolved from basic nickel-phosphorus coatings to sophisticated multi-component systems incorporating various metals and composite materials.

The evolution trajectory shows a clear trend toward more environmentally sustainable processes, with recent developments focusing on reducing or eliminating toxic chemicals such as formaldehyde and lead compounds. Additionally, there has been significant progress in developing precise control mechanisms for deposit properties, enabling tailored solutions for specific wear resistance applications.

Current research is increasingly concentrated on nano-enhanced electroless plating, where nanoparticles are co-deposited to create composite coatings with superior wear resistance properties. This approach has demonstrated potential to increase hardness values by 20-30% compared to conventional electroless deposits, while simultaneously improving corrosion resistance and reducing friction coefficients.

The primary technical objective in wear resistance improvement through electroless plating is to develop coatings that can withstand extreme mechanical stresses while maintaining dimensional accuracy and surface integrity. Specific goals include achieving hardness values exceeding 1000 HV after heat treatment, reducing friction coefficients below 0.2, and ensuring coating adhesion strength above 70 MPa across diverse substrate materials.

Secondary objectives focus on process optimization, including reducing deposition times by at least 30% compared to current standards, minimizing bath maintenance requirements, and developing more energy-efficient heating systems. These improvements aim to make high-performance wear-resistant coatings economically viable for broader industrial applications.

Long-term technological aspirations include the development of self-healing electroless coatings that can automatically repair wear damage, multi-functional surfaces that combine extreme wear resistance with other properties such as hydrophobicity or antimicrobial activity, and zero-waste plating processes that fully recycle all chemical components.

The technology roadmap anticipates significant breakthroughs in nano-composite electroless plating within the next 3-5 years, with commercial applications in high-value sectors such as aerospace and medical devices. Broader industrial adoption is expected within 5-10 years as process costs decrease and regulatory frameworks adapt to new chemical formulations.

The evolution trajectory shows a clear trend toward more environmentally sustainable processes, with recent developments focusing on reducing or eliminating toxic chemicals such as formaldehyde and lead compounds. Additionally, there has been significant progress in developing precise control mechanisms for deposit properties, enabling tailored solutions for specific wear resistance applications.

Current research is increasingly concentrated on nano-enhanced electroless plating, where nanoparticles are co-deposited to create composite coatings with superior wear resistance properties. This approach has demonstrated potential to increase hardness values by 20-30% compared to conventional electroless deposits, while simultaneously improving corrosion resistance and reducing friction coefficients.

The primary technical objective in wear resistance improvement through electroless plating is to develop coatings that can withstand extreme mechanical stresses while maintaining dimensional accuracy and surface integrity. Specific goals include achieving hardness values exceeding 1000 HV after heat treatment, reducing friction coefficients below 0.2, and ensuring coating adhesion strength above 70 MPa across diverse substrate materials.

Secondary objectives focus on process optimization, including reducing deposition times by at least 30% compared to current standards, minimizing bath maintenance requirements, and developing more energy-efficient heating systems. These improvements aim to make high-performance wear-resistant coatings economically viable for broader industrial applications.

Long-term technological aspirations include the development of self-healing electroless coatings that can automatically repair wear damage, multi-functional surfaces that combine extreme wear resistance with other properties such as hydrophobicity or antimicrobial activity, and zero-waste plating processes that fully recycle all chemical components.

The technology roadmap anticipates significant breakthroughs in nano-composite electroless plating within the next 3-5 years, with commercial applications in high-value sectors such as aerospace and medical devices. Broader industrial adoption is expected within 5-10 years as process costs decrease and regulatory frameworks adapt to new chemical formulations.

Market Demand for Enhanced Wear-Resistant Coatings

The global market for wear-resistant coatings has been experiencing significant growth, driven by increasing demands across multiple industrial sectors. The wear-resistant coatings market was valued at approximately 8.5 billion USD in 2022 and is projected to reach 11.7 billion USD by 2028, representing a compound annual growth rate of 5.5%. This growth trajectory underscores the critical importance of advanced coating technologies like electroless plating in modern manufacturing and industrial applications.

The automotive industry represents one of the largest market segments for wear-resistant coatings, particularly as vehicle manufacturers seek to improve fuel efficiency and reduce emissions through lightweight materials that require enhanced surface protection. Engine components, transmission systems, and brake assemblies all benefit from wear-resistant coatings that can withstand extreme operating conditions while maintaining dimensional stability and performance characteristics.

Aerospace applications constitute another high-value market segment, where the demand for coatings that can withstand extreme temperatures, pressure variations, and mechanical stress continues to grow. The stringent safety requirements and performance standards in this sector drive the need for advanced coating solutions that offer superior wear resistance without adding significant weight to components.

The oil and gas industry presents substantial market opportunities for wear-resistant coatings, particularly for drilling equipment, valves, and pumps that operate in highly corrosive environments. The economic impact of equipment failure in these applications can be enormous, creating strong incentives for operators to invest in premium coating technologies that extend service life and reduce maintenance requirements.

Manufacturing equipment across diverse industries represents another significant market segment, with particular emphasis on tooling applications where surface hardness and wear resistance directly impact productivity and product quality. The growing adoption of high-speed machining techniques has intensified the need for coatings that can maintain cutting edge integrity under increasingly demanding operating conditions.

Consumer electronics manufacturers are increasingly incorporating wear-resistant coatings in their products to enhance durability and customer satisfaction. The trend toward miniaturization in this sector creates unique challenges for coating technologies, as thinner layers must provide equivalent or superior protection compared to conventional approaches.

Geographically, Asia-Pacific represents the fastest-growing regional market for wear-resistant coatings, driven by rapid industrialization in countries like China and India. North America and Europe maintain significant market shares, with particular strength in high-value applications requiring advanced technical specifications and performance characteristics.

The automotive industry represents one of the largest market segments for wear-resistant coatings, particularly as vehicle manufacturers seek to improve fuel efficiency and reduce emissions through lightweight materials that require enhanced surface protection. Engine components, transmission systems, and brake assemblies all benefit from wear-resistant coatings that can withstand extreme operating conditions while maintaining dimensional stability and performance characteristics.

Aerospace applications constitute another high-value market segment, where the demand for coatings that can withstand extreme temperatures, pressure variations, and mechanical stress continues to grow. The stringent safety requirements and performance standards in this sector drive the need for advanced coating solutions that offer superior wear resistance without adding significant weight to components.

The oil and gas industry presents substantial market opportunities for wear-resistant coatings, particularly for drilling equipment, valves, and pumps that operate in highly corrosive environments. The economic impact of equipment failure in these applications can be enormous, creating strong incentives for operators to invest in premium coating technologies that extend service life and reduce maintenance requirements.

Manufacturing equipment across diverse industries represents another significant market segment, with particular emphasis on tooling applications where surface hardness and wear resistance directly impact productivity and product quality. The growing adoption of high-speed machining techniques has intensified the need for coatings that can maintain cutting edge integrity under increasingly demanding operating conditions.

Consumer electronics manufacturers are increasingly incorporating wear-resistant coatings in their products to enhance durability and customer satisfaction. The trend toward miniaturization in this sector creates unique challenges for coating technologies, as thinner layers must provide equivalent or superior protection compared to conventional approaches.

Geographically, Asia-Pacific represents the fastest-growing regional market for wear-resistant coatings, driven by rapid industrialization in countries like China and India. North America and Europe maintain significant market shares, with particular strength in high-value applications requiring advanced technical specifications and performance characteristics.

Current State and Challenges in Electroless Plating

Electroless plating technology has evolved significantly over the past decades, establishing itself as a critical surface treatment method across various industries. Currently, the global market for electroless plating is experiencing steady growth, with an estimated market value of $1.8 billion in 2022 and projected to reach $2.3 billion by 2027. This growth is primarily driven by increasing demands in electronics, automotive, and aerospace sectors where wear resistance is paramount.

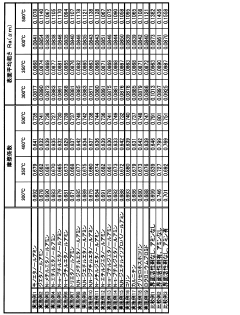

The current state of electroless plating technology demonstrates considerable maturity in nickel-phosphorus (Ni-P) coatings, which dominate approximately 65% of industrial applications. These coatings provide hardness values ranging from 500-1100 HV depending on phosphorus content and heat treatment. Nickel-boron (Ni-B) systems have also gained traction, offering superior hardness (up to 1500 HV after heat treatment) but at higher implementation costs.

Composite electroless plating represents the cutting edge of current technology, incorporating particles such as SiC, Al2O3, and diamond into the metal matrix to enhance wear resistance. Recent research indicates wear rate reductions of up to 70% compared to conventional electroless nickel coatings. However, particle distribution uniformity remains inconsistent across large surface areas.

Despite these advancements, several significant challenges persist in electroless plating for wear resistance applications. Bath stability continues to be problematic, with most industrial baths requiring replacement after 4-8 metal turnovers due to by-product accumulation and stabilizer depletion. This results in considerable waste generation and increased operational costs.

Coating thickness uniformity presents another major challenge, particularly for complex geometries. Current technologies struggle to maintain consistent deposition rates across recessed areas and internal surfaces, leading to variable wear performance across components. Industry data suggests thickness variations of 10-15% are common even in well-controlled processes.

Environmental concerns represent perhaps the most pressing challenge facing the industry. Traditional electroless plating baths contain formaldehyde, heavy metals, and other hazardous substances. Regulatory pressures, particularly in Europe and North America, are driving research toward greener alternatives, though these often demonstrate reduced performance or process reliability.

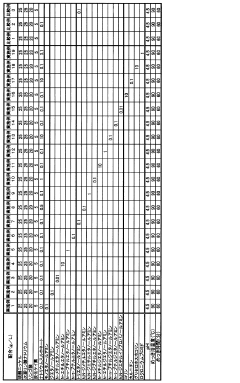

Geographically, electroless plating technology development shows distinct patterns. Asia-Pacific, particularly China and Japan, leads in production volume and process optimization, while North America and Europe focus on high-performance specialty applications and environmentally sustainable formulations. Recent patent analysis reveals that approximately 48% of innovations in wear-resistant electroless plating originate from Asia, 32% from North America, and 20% from Europe.

The current state of electroless plating technology demonstrates considerable maturity in nickel-phosphorus (Ni-P) coatings, which dominate approximately 65% of industrial applications. These coatings provide hardness values ranging from 500-1100 HV depending on phosphorus content and heat treatment. Nickel-boron (Ni-B) systems have also gained traction, offering superior hardness (up to 1500 HV after heat treatment) but at higher implementation costs.

Composite electroless plating represents the cutting edge of current technology, incorporating particles such as SiC, Al2O3, and diamond into the metal matrix to enhance wear resistance. Recent research indicates wear rate reductions of up to 70% compared to conventional electroless nickel coatings. However, particle distribution uniformity remains inconsistent across large surface areas.

Despite these advancements, several significant challenges persist in electroless plating for wear resistance applications. Bath stability continues to be problematic, with most industrial baths requiring replacement after 4-8 metal turnovers due to by-product accumulation and stabilizer depletion. This results in considerable waste generation and increased operational costs.

Coating thickness uniformity presents another major challenge, particularly for complex geometries. Current technologies struggle to maintain consistent deposition rates across recessed areas and internal surfaces, leading to variable wear performance across components. Industry data suggests thickness variations of 10-15% are common even in well-controlled processes.

Environmental concerns represent perhaps the most pressing challenge facing the industry. Traditional electroless plating baths contain formaldehyde, heavy metals, and other hazardous substances. Regulatory pressures, particularly in Europe and North America, are driving research toward greener alternatives, though these often demonstrate reduced performance or process reliability.

Geographically, electroless plating technology development shows distinct patterns. Asia-Pacific, particularly China and Japan, leads in production volume and process optimization, while North America and Europe focus on high-performance specialty applications and environmentally sustainable formulations. Recent patent analysis reveals that approximately 48% of innovations in wear-resistant electroless plating originate from Asia, 32% from North America, and 20% from Europe.

Current Technical Solutions for Wear Resistance Enhancement

01 Composite electroless plating for enhanced wear resistance

Composite electroless plating involves incorporating hard particles such as silicon carbide, diamond, or ceramic materials into the metal matrix during the plating process. These particles significantly enhance the wear resistance properties of the coating by providing additional hardness and reducing friction. The composite coatings can be applied to various substrates including steel, aluminum, and other metal components to extend their service life in high-wear applications.- Nickel-based electroless plating for wear resistance: Nickel-based electroless plating is widely used to enhance wear resistance of various components. The process involves depositing nickel alloys without using electrical current, resulting in uniform coatings even on complex geometries. These coatings provide excellent hardness, lubricity, and durability, making them suitable for applications requiring high wear resistance. The addition of phosphorus or boron to nickel during the plating process can further enhance the wear-resistant properties of the coating.

- Composite electroless plating with particles: Incorporating hard particles such as silicon carbide, diamond, or ceramic materials into electroless plating baths creates composite coatings with superior wear resistance. These particles are co-deposited with the metal matrix, forming a reinforced structure that significantly improves hardness and abrasion resistance. The distribution and concentration of particles in the coating can be controlled to optimize wear performance for specific applications. This technique is particularly effective for components subjected to severe wear conditions.

- Heat treatment of electroless plated coatings: Post-plating heat treatment processes can significantly enhance the wear resistance of electroless plated coatings. Heat treatment promotes crystallization, phase transformation, and precipitation hardening in the coating, resulting in increased hardness and improved wear resistance. The temperature and duration of the heat treatment must be carefully controlled to achieve optimal properties without causing substrate damage or coating deterioration. This process is particularly effective for nickel-phosphorus coatings, where heat treatment can increase hardness by forming nickel phosphide precipitates.

- Multi-layer electroless plating systems: Multi-layer electroless plating systems combine different coating compositions to achieve enhanced wear resistance. By depositing successive layers with varying properties, these systems can provide a combination of hardness, ductility, and corrosion resistance that exceeds what can be achieved with single-layer coatings. The interface between layers can be designed to improve adhesion and prevent delamination under wear conditions. This approach allows for customization of surface properties to meet specific wear requirements while maintaining other desirable characteristics.

- Electroless plating with nano-materials: Incorporating nanomaterials such as carbon nanotubes, graphene, or nano-sized metal particles into electroless plating baths creates advanced coatings with exceptional wear resistance. The nano-scale reinforcements provide unique tribological properties, including self-lubrication and enhanced hardness. These nano-enhanced coatings exhibit superior performance in high-stress wear applications and can maintain their properties under extreme conditions. The uniform distribution of nanomaterials throughout the coating is critical for achieving consistent wear resistance across the entire surface.

02 Nickel-based electroless plating formulations

Nickel-based electroless plating solutions are widely used for creating wear-resistant coatings. These formulations typically contain nickel salts, reducing agents, complexing agents, and stabilizers. The addition of phosphorus or boron compounds to nickel plating baths creates alloys with superior hardness and wear resistance. Post-plating heat treatment can further enhance the wear resistance properties by forming hard intermetallic compounds within the coating structure.Expand Specific Solutions03 Multi-layer electroless plating systems

Multi-layer electroless plating involves the application of different metal layers to achieve enhanced wear resistance. This approach typically combines a base layer for adhesion, intermediate layers for specific properties, and a top layer optimized for wear resistance. The combination of different metals such as nickel, copper, and cobalt in sequential layers creates a synergistic effect that provides superior wear resistance compared to single-layer coatings while maintaining other desirable properties like corrosion resistance.Expand Specific Solutions04 Additives and bath composition optimization

The wear resistance of electroless plated coatings can be significantly improved through the optimization of bath composition and the use of specific additives. Surfactants, grain refiners, and hardening agents can be incorporated into the plating solution to modify the microstructure of the deposited coating. These additives control grain size, reduce porosity, and enhance the overall hardness and wear resistance of the coating. Careful control of pH, temperature, and concentration of components in the plating bath is essential for achieving optimal wear resistance properties.Expand Specific Solutions05 Post-treatment processes for enhanced wear resistance

Various post-treatment processes can be applied to electroless plated components to further enhance their wear resistance. These include heat treatment, surface hardening, and the application of sealants or lubricants. Heat treatment at specific temperatures can transform the microstructure of the coating, increasing hardness and wear resistance. Other post-treatments like shot peening or burnishing can introduce compressive stresses in the surface layer, further improving wear resistance. These processes are particularly important for components subjected to extreme wear conditions.Expand Specific Solutions

Key Industry Players in Electroless Plating Market

Electroless plating for wear resistance improvement is currently in a growth phase, with the market expanding due to increasing demand in automotive, electronics, and industrial applications. The global market size is estimated to reach $2-3 billion by 2025, driven by the need for durable surface treatments. Technologically, the field shows varying maturity levels across different applications. Leading players like Toyota Motor Corp. and TDK Corp. have established advanced capabilities in automotive and electronics applications, while specialized companies such as Diamond Innovations and Sankei Giken Kogyo are developing innovative solutions for specific industrial needs. Research institutions like AIST and Fraunhofer-Gesellschaft are advancing fundamental technologies, while electronics giants Samsung and Canon are integrating electroless plating into their manufacturing processes to enhance product durability.

Dowa Metaltech Co. Ltd.

Technical Solution: Dowa Metaltech has established a proprietary electroless plating technology specifically designed for wear-critical components in automotive and industrial machinery applications. Their HARDLOY® electroless nickel-boron (Ni-B) coating system achieves exceptional hardness values of 650-750 HV without heat treatment, and up to 1200 HV after heat treatment at 350-400°C. The company has developed specialized bath formulations that enable uniform deposition on complex geometries while maintaining tight thickness tolerances (±2μm). Dowa's technology incorporates proprietary stabilizers that extend bath life by up to 40% compared to conventional systems, reducing waste and operational costs. Their most advanced offering combines electroless Ni-B with nano-diamond particles (0.1-0.3% by volume), creating a composite coating with superior wear resistance in high-load sliding applications, demonstrating wear rates 60% lower than standard electroless nickel in pin-on-disk testing.

Strengths: Exceptional as-plated hardness without requiring heat treatment; excellent thickness uniformity on complex parts; extended bath life reducing operational costs. Weaknesses: Higher initial cost compared to conventional plating; more complex bath maintenance requirements; potential adhesion challenges on certain substrate materials.

Advanced Industrial Science & Technology

Technical Solution: Advanced Industrial Science & Technology (AIST) has developed innovative electroless plating techniques focusing on nickel-phosphorus (Ni-P) coatings with enhanced wear resistance. Their approach involves precise control of phosphorus content (typically 5-12%) to optimize hardness and wear properties. AIST's research demonstrates that heat treatment of electroless Ni-P deposits at 400°C creates nickel phosphide precipitates that significantly increase hardness from 500 HV to over 1000 HV. They've also pioneered composite electroless plating by incorporating nano-sized ceramic particles (SiC, Al2O3) into the Ni-P matrix, creating a synergistic effect that improves wear resistance by up to 40% compared to conventional coatings. AIST has further developed environmentally friendly electroless plating baths that eliminate harmful chemicals while maintaining excellent coating performance, addressing growing sustainability concerns in industrial applications.

Strengths: Superior hardness after heat treatment; excellent incorporation of nano-particles for enhanced wear resistance; environmentally friendly formulations. Weaknesses: Heat treatment adds processing time and cost; potential for coating brittleness with very high phosphorus content; requires precise bath control for consistent results.

Core Innovations in Electroless Plating Materials and Processes

Electroless plating solution, plating film, plated article, and plating film forming method

PatentActiveJP2016014183A

Innovation

- An electroless plating solution containing a water-soluble nickel compound, reducing agent, complexing agent, silicon carbide particles, quaternary ammonium compounds or alkanolamines, and an anionic surfactant, forming a plating film through immersion and heat treatment to suppress friction and wear.

Environmental Impact and Sustainability Considerations

Electroless plating processes, while offering significant advantages for wear resistance improvement, present notable environmental challenges that must be addressed for sustainable implementation. Traditional electroless plating baths contain several potentially harmful chemicals, including heavy metals like nickel, copper, and cobalt, as well as reducing agents such as formaldehyde and sodium hypophosphite. These substances can pose serious environmental risks if not properly managed throughout the plating lifecycle.

The wastewater generated from electroless plating operations contains significant concentrations of these metals and chemicals, requiring comprehensive treatment before discharge. Current treatment methods typically involve precipitation, filtration, and ion exchange processes, which themselves generate secondary waste streams requiring disposal. Additionally, the high water consumption associated with rinsing operations in electroless plating contributes to resource depletion concerns.

Energy consumption represents another environmental consideration, as electroless plating processes often require maintained elevated temperatures (60-95°C) for extended periods. This thermal energy requirement translates to substantial carbon footprints, particularly when fossil fuel-derived electricity is utilized. Life cycle assessments of electroless plating technologies indicate that energy consumption during operation can account for up to 40% of the total environmental impact.

Recent sustainability innovations in the field include the development of green chemistry alternatives to traditional plating chemicals. Research has demonstrated promising results with bio-based reducing agents derived from plant extracts, which can replace conventional formaldehyde-based systems. Similarly, closed-loop water recycling systems have been implemented in advanced facilities, reducing freshwater consumption by up to 80% compared to conventional operations.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of surface treatment technologies. The European Union's REACH regulations and similar initiatives in North America and Asia have established stricter controls on hazardous substances used in plating processes. These regulatory pressures are driving industry innovation toward more environmentally benign alternatives while maintaining performance requirements.

The economic implications of environmental compliance must also be considered in technology adoption decisions. While implementing sustainable electroless plating systems typically requires higher initial capital investment, the long-term operational benefits—including reduced waste treatment costs, lower regulatory compliance expenses, and improved corporate sustainability profiles—often justify these investments with reasonable payback periods of 3-5 years.

The wastewater generated from electroless plating operations contains significant concentrations of these metals and chemicals, requiring comprehensive treatment before discharge. Current treatment methods typically involve precipitation, filtration, and ion exchange processes, which themselves generate secondary waste streams requiring disposal. Additionally, the high water consumption associated with rinsing operations in electroless plating contributes to resource depletion concerns.

Energy consumption represents another environmental consideration, as electroless plating processes often require maintained elevated temperatures (60-95°C) for extended periods. This thermal energy requirement translates to substantial carbon footprints, particularly when fossil fuel-derived electricity is utilized. Life cycle assessments of electroless plating technologies indicate that energy consumption during operation can account for up to 40% of the total environmental impact.

Recent sustainability innovations in the field include the development of green chemistry alternatives to traditional plating chemicals. Research has demonstrated promising results with bio-based reducing agents derived from plant extracts, which can replace conventional formaldehyde-based systems. Similarly, closed-loop water recycling systems have been implemented in advanced facilities, reducing freshwater consumption by up to 80% compared to conventional operations.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of surface treatment technologies. The European Union's REACH regulations and similar initiatives in North America and Asia have established stricter controls on hazardous substances used in plating processes. These regulatory pressures are driving industry innovation toward more environmentally benign alternatives while maintaining performance requirements.

The economic implications of environmental compliance must also be considered in technology adoption decisions. While implementing sustainable electroless plating systems typically requires higher initial capital investment, the long-term operational benefits—including reduced waste treatment costs, lower regulatory compliance expenses, and improved corporate sustainability profiles—often justify these investments with reasonable payback periods of 3-5 years.

Cost-Benefit Analysis of Electroless Plating Applications

The implementation of electroless plating for wear resistance improvement requires careful financial consideration to determine its economic viability. Initial investment costs for electroless plating systems include equipment acquisition, facility modifications, and staff training. For small to medium enterprises, these setup costs typically range from $50,000 to $200,000 depending on production scale and automation level. Ongoing operational expenses encompass chemical solutions, energy consumption, waste treatment, and maintenance, averaging $15-30 per square meter of plated surface.

When evaluating return on investment, several factors demonstrate favorable economics. Electroless plating significantly extends component lifespan, with nickel-phosphorus coatings increasing service life by 3-5 times for high-wear applications. This translates to reduced replacement frequency and associated downtime costs, which can exceed $10,000 per hour in manufacturing environments.

Quality improvements represent another economic benefit. Components with enhanced wear resistance maintain dimensional stability and performance characteristics longer, reducing warranty claims and customer dissatisfaction. Studies across automotive and industrial equipment sectors indicate a 30-40% reduction in warranty-related expenses following implementation of electroless plating wear resistance solutions.

Environmental compliance costs must also factor into the analysis. While electroless plating processes require waste treatment systems, their operational costs are offset by reduced material consumption through extended component lifecycles. Modern closed-loop systems further reduce chemical waste by up to 60%, improving the sustainability profile while lowering disposal costs.

Comparative analysis with alternative wear resistance technologies reveals electroless plating's competitive advantage. Thermal spray coating methods typically cost 2-3 times more per unit area, while PVD and CVD processes, though offering superior performance in certain applications, require 5-10 times higher capital investment. Electroless plating occupies an optimal middle ground, providing substantial wear improvement at moderate cost.

Industry-specific return on investment varies considerably. In precision engineering, ROI periods of 12-18 months are common, while heavy machinery applications may see returns within 6-9 months due to higher replacement costs of large components. Aerospace applications, despite longer certification cycles, demonstrate compelling lifetime value with ROI realized over 24-36 month periods through critical safety and reliability improvements.

When evaluating return on investment, several factors demonstrate favorable economics. Electroless plating significantly extends component lifespan, with nickel-phosphorus coatings increasing service life by 3-5 times for high-wear applications. This translates to reduced replacement frequency and associated downtime costs, which can exceed $10,000 per hour in manufacturing environments.

Quality improvements represent another economic benefit. Components with enhanced wear resistance maintain dimensional stability and performance characteristics longer, reducing warranty claims and customer dissatisfaction. Studies across automotive and industrial equipment sectors indicate a 30-40% reduction in warranty-related expenses following implementation of electroless plating wear resistance solutions.

Environmental compliance costs must also factor into the analysis. While electroless plating processes require waste treatment systems, their operational costs are offset by reduced material consumption through extended component lifecycles. Modern closed-loop systems further reduce chemical waste by up to 60%, improving the sustainability profile while lowering disposal costs.

Comparative analysis with alternative wear resistance technologies reveals electroless plating's competitive advantage. Thermal spray coating methods typically cost 2-3 times more per unit area, while PVD and CVD processes, though offering superior performance in certain applications, require 5-10 times higher capital investment. Electroless plating occupies an optimal middle ground, providing substantial wear improvement at moderate cost.

Industry-specific return on investment varies considerably. In precision engineering, ROI periods of 12-18 months are common, while heavy machinery applications may see returns within 6-9 months due to higher replacement costs of large components. Aerospace applications, despite longer certification cycles, demonstrate compelling lifetime value with ROI realized over 24-36 month periods through critical safety and reliability improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!