Electroless Nickel Boron Coatings for High Temperature Use

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electroless Ni-B Coating Development History and Objectives

Electroless nickel-boron (Ni-B) coatings emerged in the mid-20th century as an alternative to electroless nickel-phosphorus (Ni-P) coatings, with the first significant research conducted in the 1950s. The development was driven by the need for coatings with superior hardness and wear resistance compared to traditional electroplating methods. Early formulations utilized borohydride compounds as reducing agents, which distinguished them from the hypophosphite-reduced Ni-P systems.

The 1960s and 1970s witnessed substantial advancements in Ni-B coating technology, with researchers focusing on optimizing bath compositions and operating parameters. During this period, the unique properties of Ni-B coatings, particularly their exceptional hardness (up to 900 HV in the as-deposited state) and potential for even greater hardness after heat treatment (exceeding 1200 HV), began to attract industrial attention.

By the 1980s, commercial applications of Ni-B coatings started to emerge, primarily in industries requiring components with excellent wear resistance and lubricity. The automotive and aerospace sectors were early adopters, utilizing these coatings for precision components subject to high mechanical stress and wear conditions.

The 1990s marked a period of refinement in Ni-B coating technology, with significant improvements in bath stability, deposition rates, and coating uniformity. Researchers also began exploring the incorporation of additional elements and particles to create composite coatings with enhanced properties tailored for specific applications.

The early 2000s saw increased interest in the high-temperature capabilities of Ni-B coatings, as industries sought alternatives to traditional coatings that degraded under extreme thermal conditions. This period witnessed extensive research into the thermal stability of Ni-B coatings and their phase transformation behavior at elevated temperatures.

Current research objectives for high-temperature Ni-B coatings focus on several key areas. Primarily, there is a push to extend the operational temperature range beyond 500°C while maintaining structural integrity and functional properties. Researchers aim to optimize the nickel-to-boron ratio to achieve the ideal balance between hardness, ductility, and thermal stability.

Another critical objective is to enhance the oxidation resistance of Ni-B coatings at elevated temperatures, as oxidation represents a significant degradation mechanism in high-temperature environments. This includes investigating the formation of protective oxide layers and the incorporation of oxidation-resistant elements into the coating matrix.

Additionally, current research seeks to develop environmentally friendly Ni-B plating processes that reduce or eliminate hazardous chemicals while maintaining coating performance. This aligns with global trends toward sustainable manufacturing practices and stricter environmental regulations in surface finishing industries.

The 1960s and 1970s witnessed substantial advancements in Ni-B coating technology, with researchers focusing on optimizing bath compositions and operating parameters. During this period, the unique properties of Ni-B coatings, particularly their exceptional hardness (up to 900 HV in the as-deposited state) and potential for even greater hardness after heat treatment (exceeding 1200 HV), began to attract industrial attention.

By the 1980s, commercial applications of Ni-B coatings started to emerge, primarily in industries requiring components with excellent wear resistance and lubricity. The automotive and aerospace sectors were early adopters, utilizing these coatings for precision components subject to high mechanical stress and wear conditions.

The 1990s marked a period of refinement in Ni-B coating technology, with significant improvements in bath stability, deposition rates, and coating uniformity. Researchers also began exploring the incorporation of additional elements and particles to create composite coatings with enhanced properties tailored for specific applications.

The early 2000s saw increased interest in the high-temperature capabilities of Ni-B coatings, as industries sought alternatives to traditional coatings that degraded under extreme thermal conditions. This period witnessed extensive research into the thermal stability of Ni-B coatings and their phase transformation behavior at elevated temperatures.

Current research objectives for high-temperature Ni-B coatings focus on several key areas. Primarily, there is a push to extend the operational temperature range beyond 500°C while maintaining structural integrity and functional properties. Researchers aim to optimize the nickel-to-boron ratio to achieve the ideal balance between hardness, ductility, and thermal stability.

Another critical objective is to enhance the oxidation resistance of Ni-B coatings at elevated temperatures, as oxidation represents a significant degradation mechanism in high-temperature environments. This includes investigating the formation of protective oxide layers and the incorporation of oxidation-resistant elements into the coating matrix.

Additionally, current research seeks to develop environmentally friendly Ni-B plating processes that reduce or eliminate hazardous chemicals while maintaining coating performance. This aligns with global trends toward sustainable manufacturing practices and stricter environmental regulations in surface finishing industries.

High Temperature Applications Market Analysis

The high temperature applications market for specialized coatings has been experiencing robust growth, driven primarily by increasing demands in aerospace, automotive, industrial machinery, and energy sectors. The global high temperature coatings market was valued at approximately 3.5 billion USD in 2020 and is projected to reach 5.2 billion USD by 2026, growing at a CAGR of 4.8% during the forecast period.

Aerospace and defense sectors represent the largest market segments for high temperature coatings, accounting for nearly 30% of the total market share. These industries require materials that can withstand extreme operating conditions, including temperatures exceeding 600°C while maintaining structural integrity and corrosion resistance. The automotive industry follows closely, particularly with the growing emphasis on improving engine efficiency and reducing emissions, which necessitates components capable of withstanding higher operating temperatures.

The energy sector, especially power generation and oil & gas industries, presents significant growth opportunities for high temperature coatings. With the global transition toward cleaner energy sources, there is increasing investment in technologies such as concentrated solar power, geothermal energy, and advanced nuclear reactors, all of which require materials capable of functioning reliably at elevated temperatures.

Regionally, North America and Europe currently dominate the high temperature coatings market, collectively accounting for approximately 60% of global demand. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization in countries like China and India, expanding manufacturing bases, and increasing investments in infrastructure development.

The market for electroless nickel boron coatings specifically is gaining traction due to their superior hardness, wear resistance, and lubricity compared to traditional high temperature coatings. Industries requiring components with exceptional surface properties at elevated temperatures are increasingly adopting these coatings, with the market segment growing at approximately 5.3% annually.

Key market drivers include stringent environmental regulations promoting cleaner technologies, increasing demand for energy-efficient systems, and the growing need for extended component lifespans in harsh operating environments. Additionally, the trend toward miniaturization in electronics and the development of advanced manufacturing techniques are creating new application opportunities for specialized high temperature coatings.

Market challenges include the high cost of advanced coating materials and application processes, technical limitations in achieving optimal performance across wide temperature ranges, and competition from alternative materials and technologies. Despite these challenges, the market outlook remains positive, supported by continuous innovation and expanding application areas.

Aerospace and defense sectors represent the largest market segments for high temperature coatings, accounting for nearly 30% of the total market share. These industries require materials that can withstand extreme operating conditions, including temperatures exceeding 600°C while maintaining structural integrity and corrosion resistance. The automotive industry follows closely, particularly with the growing emphasis on improving engine efficiency and reducing emissions, which necessitates components capable of withstanding higher operating temperatures.

The energy sector, especially power generation and oil & gas industries, presents significant growth opportunities for high temperature coatings. With the global transition toward cleaner energy sources, there is increasing investment in technologies such as concentrated solar power, geothermal energy, and advanced nuclear reactors, all of which require materials capable of functioning reliably at elevated temperatures.

Regionally, North America and Europe currently dominate the high temperature coatings market, collectively accounting for approximately 60% of global demand. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization in countries like China and India, expanding manufacturing bases, and increasing investments in infrastructure development.

The market for electroless nickel boron coatings specifically is gaining traction due to their superior hardness, wear resistance, and lubricity compared to traditional high temperature coatings. Industries requiring components with exceptional surface properties at elevated temperatures are increasingly adopting these coatings, with the market segment growing at approximately 5.3% annually.

Key market drivers include stringent environmental regulations promoting cleaner technologies, increasing demand for energy-efficient systems, and the growing need for extended component lifespans in harsh operating environments. Additionally, the trend toward miniaturization in electronics and the development of advanced manufacturing techniques are creating new application opportunities for specialized high temperature coatings.

Market challenges include the high cost of advanced coating materials and application processes, technical limitations in achieving optimal performance across wide temperature ranges, and competition from alternative materials and technologies. Despite these challenges, the market outlook remains positive, supported by continuous innovation and expanding application areas.

Current Status and Challenges in Ni-B Coating Technology

Electroless Nickel Boron (Ni-B) coating technology has gained significant attention in high-temperature applications due to its superior hardness, wear resistance, and corrosion protection properties. Currently, the global market for Ni-B coatings is experiencing steady growth, particularly in aerospace, automotive, and industrial sectors where components are exposed to extreme thermal conditions.

The state-of-the-art Ni-B coatings can withstand temperatures up to 400-450°C while maintaining structural integrity and functional properties. However, when exposed to temperatures exceeding 500°C, these coatings often experience phase transformations, oxidation, and degradation of mechanical properties, limiting their effectiveness in ultra-high temperature environments.

A significant technical challenge lies in the boron content optimization. Higher boron content (5-8 wt%) improves hardness and wear resistance but compromises ductility and thermal stability. Conversely, lower boron content enhances thermal stability but reduces hardness. This trade-off presents a fundamental challenge for researchers developing coatings for high-temperature applications.

The deposition process itself faces several technical hurdles. Bath stability remains problematic, with precipitation of nickel boride particles occurring during prolonged operation, affecting coating quality and consistency. Additionally, the slow deposition rate (typically 10-20 μm/hour) increases production time and costs, making large-scale industrial implementation challenging.

Geographically, research and development in Ni-B coating technology is concentrated in North America, Europe, and East Asia, with Japan and the United States leading in patent filings. China has recently emerged as a significant contributor, particularly in developing cost-effective deposition methods and exploring novel additives to enhance high-temperature performance.

Environmental concerns represent another major challenge, as traditional electroless Ni-B baths contain toxic reducing agents like sodium borohydride and stabilizers that pose waste treatment difficulties. Regulatory pressures in Europe and North America are driving research toward greener alternatives, though these often come with performance trade-offs.

The adhesion of Ni-B coatings to various substrate materials at elevated temperatures remains problematic, with thermal expansion coefficient mismatches leading to coating delamination during thermal cycling. This is particularly challenging for applications requiring repeated heating and cooling cycles.

Recent research has focused on incorporating ceramic particles or developing multilayer structures to enhance high-temperature stability, though these approaches introduce additional process complexity and cost considerations. The development of standardized testing protocols for high-temperature performance evaluation also remains underdeveloped, hampering comparative analysis across different formulations and processing techniques.

The state-of-the-art Ni-B coatings can withstand temperatures up to 400-450°C while maintaining structural integrity and functional properties. However, when exposed to temperatures exceeding 500°C, these coatings often experience phase transformations, oxidation, and degradation of mechanical properties, limiting their effectiveness in ultra-high temperature environments.

A significant technical challenge lies in the boron content optimization. Higher boron content (5-8 wt%) improves hardness and wear resistance but compromises ductility and thermal stability. Conversely, lower boron content enhances thermal stability but reduces hardness. This trade-off presents a fundamental challenge for researchers developing coatings for high-temperature applications.

The deposition process itself faces several technical hurdles. Bath stability remains problematic, with precipitation of nickel boride particles occurring during prolonged operation, affecting coating quality and consistency. Additionally, the slow deposition rate (typically 10-20 μm/hour) increases production time and costs, making large-scale industrial implementation challenging.

Geographically, research and development in Ni-B coating technology is concentrated in North America, Europe, and East Asia, with Japan and the United States leading in patent filings. China has recently emerged as a significant contributor, particularly in developing cost-effective deposition methods and exploring novel additives to enhance high-temperature performance.

Environmental concerns represent another major challenge, as traditional electroless Ni-B baths contain toxic reducing agents like sodium borohydride and stabilizers that pose waste treatment difficulties. Regulatory pressures in Europe and North America are driving research toward greener alternatives, though these often come with performance trade-offs.

The adhesion of Ni-B coatings to various substrate materials at elevated temperatures remains problematic, with thermal expansion coefficient mismatches leading to coating delamination during thermal cycling. This is particularly challenging for applications requiring repeated heating and cooling cycles.

Recent research has focused on incorporating ceramic particles or developing multilayer structures to enhance high-temperature stability, though these approaches introduce additional process complexity and cost considerations. The development of standardized testing protocols for high-temperature performance evaluation also remains underdeveloped, hampering comparative analysis across different formulations and processing techniques.

Existing High-Temperature Ni-B Coating Solutions

01 Composition and preparation of electroless nickel boron coatings

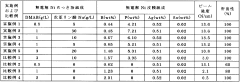

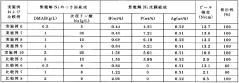

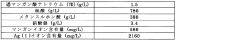

Electroless nickel boron coatings are prepared using specific bath compositions containing nickel salts, boron-containing reducing agents, and stabilizers. The process involves the chemical reduction of nickel ions in solution without the use of electrical current. These coatings typically contain varying percentages of boron, which significantly affects the properties of the final coating. The bath composition and operating conditions such as temperature, pH, and concentration of components are critical factors in determining the quality and characteristics of the resulting coating.- Composition and preparation of electroless nickel boron coatings: Electroless nickel boron coatings are prepared using specific bath compositions containing nickel salts, boron-containing reducing agents, and stabilizers. The process involves the chemical deposition of nickel and boron on a substrate without the use of electricity. The composition typically includes nickel sulfate or nickel chloride as the nickel source and sodium borohydride or dimethylamine borane as the boron source. These coatings can be applied to various substrates including metals, plastics, and ceramics, providing a uniform coating thickness even on complex geometries.

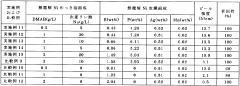

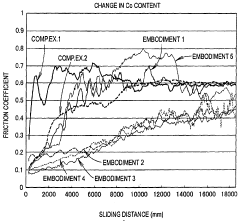

- Properties and characteristics of nickel boron coatings: Electroless nickel boron coatings exhibit excellent hardness, wear resistance, and corrosion protection. These coatings typically contain 0.5-10% boron by weight, which significantly enhances their hardness compared to pure nickel coatings. The as-deposited hardness can range from 600-900 HV, which can be further increased to 1100-1300 HV through heat treatment. Nickel boron coatings also provide good lubricity, low friction coefficient, and excellent solderability. They maintain their properties at elevated temperatures and show superior resistance to chemical attack in various environments.

- Surface treatment and post-processing techniques: Various surface treatment and post-processing techniques are employed to enhance the properties of electroless nickel boron coatings. Heat treatment at temperatures ranging from 300-400°C can significantly increase the hardness and wear resistance of these coatings by forming nickel boride precipitates. Surface activation processes using palladium catalysts are often used to improve coating adhesion and uniformity. Additional post-processing techniques include polishing to reduce surface roughness, passivation treatments to enhance corrosion resistance, and the application of topcoats for specific functional requirements.

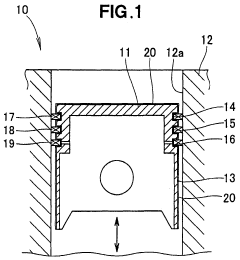

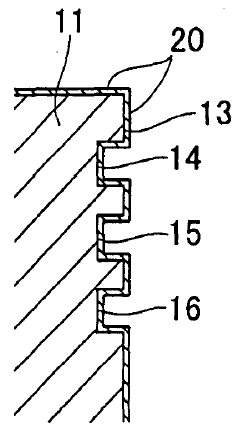

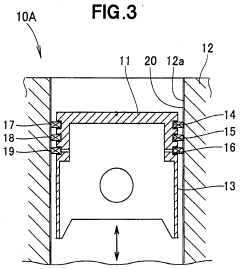

- Applications in industrial components and machinery: Electroless nickel boron coatings find extensive applications in industrial components and machinery due to their excellent tribological properties. They are widely used in automotive parts, hydraulic components, valves, pumps, and precision engineering components where wear resistance and low friction are critical. These coatings are particularly valuable for components subject to sliding wear, such as pistons, cylinders, and bearing surfaces. The uniform coating thickness achieved through the electroless process makes it ideal for coating complex geometries and internal surfaces that are difficult to plate using traditional electroplating methods.

- Advanced formulations and composite coatings: Recent developments in electroless nickel boron technology include advanced formulations and composite coatings with enhanced properties. These include the incorporation of nanoparticles such as silicon carbide, diamond, or aluminum oxide to further improve hardness and wear resistance. Multilayer coatings combining nickel boron with other materials like nickel phosphorus or hard chrome provide synergistic properties. Environmentally friendly formulations that eliminate or reduce hazardous chemicals are also being developed. Additionally, functionalized nickel boron coatings with specific properties such as hydrophobicity, antimicrobial activity, or electromagnetic shielding are emerging for specialized applications.

02 Enhanced hardness and wear resistance properties

Electroless nickel boron coatings exhibit exceptional hardness and wear resistance properties, making them suitable for applications requiring durability and longevity. These coatings can achieve hardness values comparable to hard chrome plating, especially after heat treatment. The incorporation of boron in the nickel matrix creates a microstructure that resists abrasion, erosion, and sliding wear. The wear resistance can be further enhanced through post-deposition heat treatments that promote the formation of nickel boride precipitates within the coating structure.Expand Specific Solutions03 Corrosion resistance and protective applications

Electroless nickel boron coatings provide excellent corrosion protection for various substrate materials, including steel, aluminum, and copper alloys. These coatings form a uniform protective barrier that shields the underlying material from aggressive environments, chemicals, and moisture. The corrosion resistance is attributed to the amorphous nature of the coating and the presence of boron, which enhances the passivation behavior. These coatings are particularly effective in marine, chemical processing, and oil and gas applications where exposure to corrosive media is common.Expand Specific Solutions04 Surface modification and functional properties

Electroless nickel boron coatings can be modified to enhance specific functional properties such as lubricity, solderability, and electromagnetic characteristics. The incorporation of additional elements or particles into the coating can create composite coatings with tailored properties. Surface treatments and post-deposition processes can alter the surface morphology and chemistry to improve adhesion, reduce friction, or enhance other functional characteristics. These modifications expand the range of applications for nickel boron coatings in various industries.Expand Specific Solutions05 Advanced applications in specialized industries

Electroless nickel boron coatings find applications in specialized industries such as aerospace, automotive, electronics, and medical devices. In aerospace and automotive sectors, these coatings are used for components requiring high wear resistance and dimensional stability. In electronics, they provide solderability, conductivity, and protection against environmental factors. The coatings' uniform deposition on complex geometries makes them suitable for precision components and medical devices where consistent performance and biocompatibility are essential. Recent developments have focused on enhancing the sustainability and environmental aspects of the coating process.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electroless nickel boron coating market for high temperature applications is in a growth phase, driven by increasing demand in aerospace, automotive, and industrial sectors. The market is characterized by a mix of established industrial giants like United Technologies Corp., Honeywell International, and Honda Motor Co., alongside specialized coating technology companies such as Atotech Deutschland, Oerlikon Metco, and Modumetal. Technical innovation is concentrated in three main regions: North America, Europe, and Asia, with significant research contributions from academic institutions like Zhejiang University and Central South University. The technology is approaching maturity for standard applications, but development continues for extreme temperature environments, with companies like Höganäs AB and Tata Steel advancing nanolaminated alloys and composite coatings to enhance performance characteristics.

Höganäs AB

Technical Solution: Höganäs has developed specialized electroless nickel boron coating solutions for high temperature applications through their advanced powder metallurgy expertise. Their proprietary THERMTECH coating system incorporates precisely controlled nickel-boron alloy compositions with optimized particle size distribution to achieve exceptional thermal stability. The company utilizes a unique two-stage deposition process that creates a gradient structure with varying boron content (4-9%) from substrate to surface, minimizing internal stress and enhancing adhesion during thermal cycling. Höganäs' technology incorporates specialized heat treatment protocols that promote controlled crystallization, resulting in hardness values exceeding 950 HV that are maintained at temperatures up to 550°C. Their process employs proprietary stabilizers and complexing agents that ensure uniform deposition while preventing premature bath decomposition. The company has also developed specialized surface preparation techniques that enhance coating adhesion on difficult substrates like high-alloy steels and superalloys. Höganäs' coatings demonstrate exceptional resistance to high-temperature wear mechanisms, with tribological testing showing minimal friction coefficient increases even after extended exposure to elevated temperatures.

Strengths: Exceptional wear resistance at elevated temperatures, excellent thermal stability due to gradient structure, and superior adhesion to difficult substrate materials. Weaknesses: Requires specialized equipment and precise process control, higher production costs compared to conventional coatings, and may have limitations in coating complex internal geometries.

Atotech Deutschland GmbH & Co. KG

Technical Solution: Atotech has developed advanced electroless nickel boron coating systems specifically engineered for high temperature applications. Their proprietary technology utilizes optimized chemical formulations with controlled boron content (typically 5-7%) to achieve superior thermal stability. The company's ENIBOR HT series employs specialized stabilizers and complexing agents that prevent premature bath decomposition while ensuring uniform deposition rates. This technology creates dense, amorphous coatings with exceptional hardness (up to 1100 HV after heat treatment) and maintains structural integrity at temperatures exceeding 500°C. Atotech's process incorporates precise pH control systems and proprietary additives that enhance the coating's resistance to oxidation at elevated temperatures. Their multi-stage deposition technique creates layered structures that minimize internal stress and prevent cracking during thermal cycling, making these coatings particularly suitable for components in turbines, aerospace applications, and high-temperature industrial equipment.

Strengths: Superior hardness retention after thermal exposure, excellent wear resistance at elevated temperatures, and strong adhesion to various substrate materials. The coatings provide exceptional corrosion protection even after thermal cycling. Weaknesses: Higher production costs compared to standard electroless nickel processes, requires precise bath control parameters, and may have thickness limitations for certain complex geometries.

Key Patents and Research Breakthroughs

Electroless nickel plating coat and pretreatment method for forming the electroless nickel plating coat

PatentActiveJP2021080513A

Innovation

- An electroless nickel plating film and pretreatment method using boron, phosphorus, and silver or copper catalysts, eliminating the need for palladium, with specific compositions and conditions to ensure good film properties.

Internal combustion engine

PatentActiveIN1367CHE2013A

Innovation

- An electroless nickel coating with a composition of 0.6 to 2.8 wt% phosphorus, 0.5 to 1.8 wt% cobalt, and 0.005 to 0.5 wt% tungsten, applied to the sliding surfaces of pistons and cylinders, providing exceptional wear resistance and low friction while being environmentally friendly and cost-effective.

Environmental Impact and Sustainability Considerations

The environmental impact of electroless nickel boron (Ni-B) coatings for high temperature applications represents a critical consideration in modern industrial sustainability frameworks. Traditional coating processes often involve hazardous chemicals and generate significant waste streams that pose environmental risks. Electroless Ni-B processes typically utilize reducing agents such as sodium borohydride or dimethylamine borane, which require careful handling and disposal to prevent water and soil contamination.

When examining the life cycle assessment of high-temperature Ni-B coatings, several environmental advantages emerge compared to alternative surface treatments. The extended service life of Ni-B coated components in high-temperature environments reduces replacement frequency, thereby decreasing material consumption and associated environmental impacts from manufacturing replacement parts. Additionally, the superior wear resistance of these coatings contributes to reduced material waste through prolonged component lifespans.

Energy consumption represents another significant environmental factor. While the electroless deposition process requires precise temperature control and extended immersion times, resulting in notable energy usage, this initial energy investment is often offset by operational efficiencies. Components with high-temperature Ni-B coatings frequently demonstrate improved thermal efficiency and reduced friction, potentially lowering energy consumption during their operational lifetime.

Waste management challenges persist in electroless Ni-B processing. The baths eventually become depleted and require disposal, containing residual nickel compounds and boron-containing chemicals that must be treated as hazardous waste. Advanced waste treatment technologies, including ion exchange systems and electrochemical recovery methods, are increasingly being implemented to recover valuable metals and reduce environmental burden. These recovery systems can reclaim up to 98% of nickel from spent baths, significantly reducing raw material demands.

Recent innovations in green chemistry approaches are transforming electroless Ni-B coating processes. Research into bio-based reducing agents derived from renewable resources shows promise for replacing conventional petroleum-based chemicals. Additionally, water consumption reduction strategies, such as closed-loop rinsing systems and bath life extension technologies, are being adopted to minimize the process's environmental footprint.

Regulatory compliance frameworks worldwide are evolving to address the environmental aspects of surface treatment technologies. The implementation of REACH regulations in Europe and similar initiatives globally has driven manufacturers to develop more environmentally benign electroless Ni-B formulations with reduced toxicity profiles. These regulatory pressures continue to accelerate innovation toward more sustainable coating technologies that maintain high-temperature performance while reducing environmental impact.

When examining the life cycle assessment of high-temperature Ni-B coatings, several environmental advantages emerge compared to alternative surface treatments. The extended service life of Ni-B coated components in high-temperature environments reduces replacement frequency, thereby decreasing material consumption and associated environmental impacts from manufacturing replacement parts. Additionally, the superior wear resistance of these coatings contributes to reduced material waste through prolonged component lifespans.

Energy consumption represents another significant environmental factor. While the electroless deposition process requires precise temperature control and extended immersion times, resulting in notable energy usage, this initial energy investment is often offset by operational efficiencies. Components with high-temperature Ni-B coatings frequently demonstrate improved thermal efficiency and reduced friction, potentially lowering energy consumption during their operational lifetime.

Waste management challenges persist in electroless Ni-B processing. The baths eventually become depleted and require disposal, containing residual nickel compounds and boron-containing chemicals that must be treated as hazardous waste. Advanced waste treatment technologies, including ion exchange systems and electrochemical recovery methods, are increasingly being implemented to recover valuable metals and reduce environmental burden. These recovery systems can reclaim up to 98% of nickel from spent baths, significantly reducing raw material demands.

Recent innovations in green chemistry approaches are transforming electroless Ni-B coating processes. Research into bio-based reducing agents derived from renewable resources shows promise for replacing conventional petroleum-based chemicals. Additionally, water consumption reduction strategies, such as closed-loop rinsing systems and bath life extension technologies, are being adopted to minimize the process's environmental footprint.

Regulatory compliance frameworks worldwide are evolving to address the environmental aspects of surface treatment technologies. The implementation of REACH regulations in Europe and similar initiatives globally has driven manufacturers to develop more environmentally benign electroless Ni-B formulations with reduced toxicity profiles. These regulatory pressures continue to accelerate innovation toward more sustainable coating technologies that maintain high-temperature performance while reducing environmental impact.

Comparative Analysis with Alternative Coating Technologies

When evaluating Electroless Nickel Boron (EN-B) coatings for high-temperature applications, it is essential to compare their performance against alternative coating technologies. Hard chrome plating, traditionally dominant in industrial applications, offers excellent wear resistance but falls short in high-temperature environments above 400°C where significant hardness degradation occurs. Additionally, environmental concerns regarding hexavalent chromium have accelerated the search for alternatives, positioning EN-B coatings favorably in this transition.

Thermal spray coatings, particularly High-Velocity Oxygen Fuel (HVOF) and plasma-sprayed ceramics, present formidable competition in high-temperature scenarios. While these coatings can withstand temperatures exceeding 800°C, they typically require more complex application equipment and post-processing. EN-B coatings offer advantages in uniform deposition on complex geometries and lower implementation costs, though they generally cannot match the absolute temperature resistance of ceramic-based thermal sprays.

Physical Vapor Deposition (PVD) coatings, including titanium nitride (TiN) and chromium nitride (CrN), demonstrate excellent high-temperature oxidation resistance up to 600°C. However, these line-of-sight processes struggle with complex geometries where EN-B coatings excel. The significantly higher capital investment for PVD equipment also positions EN-B as more economically viable for many applications despite its somewhat lower temperature ceiling.

Chemical Vapor Deposition (CVD) technologies produce exceptional high-temperature coatings like silicon carbide and titanium carbonitride that maintain stability at temperatures approaching 1000°C. These coatings typically require processing temperatures of 800-1000°C, potentially causing substrate distortion. EN-B coatings, applied at under 100°C, eliminate this risk while still providing respectable performance up to 500-600°C in optimized formulations.

Diffusion coatings such as pack cementation and slurry coatings offer outstanding high-temperature protection through the formation of intermetallic compounds. While these coatings can withstand temperatures above 700°C, they typically require lengthy high-temperature processing cycles. EN-B coatings provide a more efficient application process with faster turnaround times, though with more moderate temperature capabilities.

When considering overall value proposition, EN-B coatings occupy a strategic middle ground, offering an attractive combination of reasonable high-temperature performance, excellent wear resistance, corrosion protection, and cost-effective application. Their ability to be applied to complex geometries with minimal capital investment makes them particularly valuable for components with intricate features operating in moderate to high-temperature environments.

Thermal spray coatings, particularly High-Velocity Oxygen Fuel (HVOF) and plasma-sprayed ceramics, present formidable competition in high-temperature scenarios. While these coatings can withstand temperatures exceeding 800°C, they typically require more complex application equipment and post-processing. EN-B coatings offer advantages in uniform deposition on complex geometries and lower implementation costs, though they generally cannot match the absolute temperature resistance of ceramic-based thermal sprays.

Physical Vapor Deposition (PVD) coatings, including titanium nitride (TiN) and chromium nitride (CrN), demonstrate excellent high-temperature oxidation resistance up to 600°C. However, these line-of-sight processes struggle with complex geometries where EN-B coatings excel. The significantly higher capital investment for PVD equipment also positions EN-B as more economically viable for many applications despite its somewhat lower temperature ceiling.

Chemical Vapor Deposition (CVD) technologies produce exceptional high-temperature coatings like silicon carbide and titanium carbonitride that maintain stability at temperatures approaching 1000°C. These coatings typically require processing temperatures of 800-1000°C, potentially causing substrate distortion. EN-B coatings, applied at under 100°C, eliminate this risk while still providing respectable performance up to 500-600°C in optimized formulations.

Diffusion coatings such as pack cementation and slurry coatings offer outstanding high-temperature protection through the formation of intermetallic compounds. While these coatings can withstand temperatures above 700°C, they typically require lengthy high-temperature processing cycles. EN-B coatings provide a more efficient application process with faster turnaround times, though with more moderate temperature capabilities.

When considering overall value proposition, EN-B coatings occupy a strategic middle ground, offering an attractive combination of reasonable high-temperature performance, excellent wear resistance, corrosion protection, and cost-effective application. Their ability to be applied to complex geometries with minimal capital investment makes them particularly valuable for components with intricate features operating in moderate to high-temperature environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!