Green Alternatives for Electroless Nickel Processes

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Electroless Nickel Background and Objectives

Electroless nickel plating has been a cornerstone technology in surface finishing since its commercial introduction in the mid-20th century. This chemical deposition process, which deposits nickel-phosphorus alloys without electrical current, has become indispensable across automotive, electronics, aerospace, and oil and gas industries due to its uniform coating capabilities, excellent corrosion resistance, and hardness properties. However, traditional electroless nickel processes rely heavily on chemicals that pose significant environmental and health concerns.

The conventional electroless nickel baths typically contain nickel sulfate as the metal source, sodium hypophosphite as the reducing agent, and various complexing agents, stabilizers, and buffers. Many of these components, particularly lead-containing stabilizers, cadmium compounds, and certain chelating agents like EDTA, have been identified as environmentally hazardous. Additionally, the process generates wastewater with high levels of heavy metals and operates at elevated temperatures (85-95°C), resulting in substantial energy consumption.

Global regulatory frameworks have evolved significantly over the past two decades, with initiatives such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe, RoHS (Restriction of Hazardous Substances), and various national environmental protection policies imposing stricter controls on hazardous chemicals. This regulatory landscape has created an urgent need for greener alternatives in electroless nickel technology.

The technological evolution in this field shows a clear trajectory toward sustainability. Early developments focused on removing lead compounds from stabilizers, followed by efforts to reduce nickel concentration in plating baths. Recent innovations have explored alternative reducing agents to hypophosphite, which produces phosphite as a byproduct that contributes to eutrophication in water bodies.

The primary objective of this research is to comprehensively evaluate environmentally friendly alternatives for conventional electroless nickel processes that maintain or enhance the functional properties of the resulting coatings. Specific goals include identifying non-toxic stabilizers and complexing agents, developing lower-temperature processes to reduce energy consumption, exploring biodegradable alternatives to traditional chemicals, and assessing novel reducing agents with lower environmental impact.

Additionally, this research aims to establish quantifiable metrics for evaluating the environmental performance of electroless nickel processes, including carbon footprint, water usage efficiency, waste generation, and compliance with emerging global regulations. The ultimate goal is to develop a roadmap for transitioning the industry toward sustainable electroless nickel technologies that balance technical performance with environmental responsibility.

The conventional electroless nickel baths typically contain nickel sulfate as the metal source, sodium hypophosphite as the reducing agent, and various complexing agents, stabilizers, and buffers. Many of these components, particularly lead-containing stabilizers, cadmium compounds, and certain chelating agents like EDTA, have been identified as environmentally hazardous. Additionally, the process generates wastewater with high levels of heavy metals and operates at elevated temperatures (85-95°C), resulting in substantial energy consumption.

Global regulatory frameworks have evolved significantly over the past two decades, with initiatives such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe, RoHS (Restriction of Hazardous Substances), and various national environmental protection policies imposing stricter controls on hazardous chemicals. This regulatory landscape has created an urgent need for greener alternatives in electroless nickel technology.

The technological evolution in this field shows a clear trajectory toward sustainability. Early developments focused on removing lead compounds from stabilizers, followed by efforts to reduce nickel concentration in plating baths. Recent innovations have explored alternative reducing agents to hypophosphite, which produces phosphite as a byproduct that contributes to eutrophication in water bodies.

The primary objective of this research is to comprehensively evaluate environmentally friendly alternatives for conventional electroless nickel processes that maintain or enhance the functional properties of the resulting coatings. Specific goals include identifying non-toxic stabilizers and complexing agents, developing lower-temperature processes to reduce energy consumption, exploring biodegradable alternatives to traditional chemicals, and assessing novel reducing agents with lower environmental impact.

Additionally, this research aims to establish quantifiable metrics for evaluating the environmental performance of electroless nickel processes, including carbon footprint, water usage efficiency, waste generation, and compliance with emerging global regulations. The ultimate goal is to develop a roadmap for transitioning the industry toward sustainable electroless nickel technologies that balance technical performance with environmental responsibility.

Market Demand Analysis for Eco-friendly Plating Solutions

The global market for electroless nickel plating solutions is experiencing a significant shift toward environmentally friendly alternatives, driven by increasingly stringent environmental regulations and growing corporate sustainability commitments. Current market analysis indicates that the eco-friendly plating solutions segment is growing at approximately twice the rate of traditional plating chemicals, reflecting the urgent industry need for greener processes.

Environmental regulations, particularly in Europe under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and in North America under EPA guidelines, have created substantial market pressure to replace hazardous substances commonly used in traditional electroless nickel processes. These include formaldehyde, lead compounds, and certain phosphorus-based chemicals that pose significant environmental and health risks.

Consumer-facing industries, particularly automotive, electronics, and consumer goods, are demonstrating the strongest demand for green plating alternatives. Market research shows that manufacturers in these sectors are willing to pay a premium of 15-20% for environmentally compliant plating solutions that maintain performance standards while reducing environmental impact. This premium acceptance is creating a viable commercial pathway for new green technologies.

The Asia-Pacific region represents the fastest-growing market for eco-friendly plating solutions, with China, Japan, and South Korea leading adoption rates. This regional growth is attributed to both tightening domestic regulations and the need to meet international export standards. European markets remain the most mature in terms of green technology adoption, with established infrastructure for implementing sustainable plating processes.

Industry surveys reveal that end-users prioritize three key factors when considering green alternatives: comparable performance to traditional processes, regulatory compliance across multiple jurisdictions, and total cost of implementation including waste treatment and disposal. Solutions that address all three factors command the highest market potential.

The market size for green electroless nickel alternatives is projected to expand substantially over the next five years, with particular growth in applications requiring high corrosion resistance and uniform coating thickness. Sectors showing the strongest adoption potential include renewable energy components, medical devices, and advanced electronics.

Supply chain considerations are increasingly influencing market dynamics, with manufacturers seeking plating solutions that reduce overall environmental footprint throughout the product lifecycle. This has created new market opportunities for integrated solution providers who can address both the plating process and associated waste management challenges.

Environmental regulations, particularly in Europe under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and in North America under EPA guidelines, have created substantial market pressure to replace hazardous substances commonly used in traditional electroless nickel processes. These include formaldehyde, lead compounds, and certain phosphorus-based chemicals that pose significant environmental and health risks.

Consumer-facing industries, particularly automotive, electronics, and consumer goods, are demonstrating the strongest demand for green plating alternatives. Market research shows that manufacturers in these sectors are willing to pay a premium of 15-20% for environmentally compliant plating solutions that maintain performance standards while reducing environmental impact. This premium acceptance is creating a viable commercial pathway for new green technologies.

The Asia-Pacific region represents the fastest-growing market for eco-friendly plating solutions, with China, Japan, and South Korea leading adoption rates. This regional growth is attributed to both tightening domestic regulations and the need to meet international export standards. European markets remain the most mature in terms of green technology adoption, with established infrastructure for implementing sustainable plating processes.

Industry surveys reveal that end-users prioritize three key factors when considering green alternatives: comparable performance to traditional processes, regulatory compliance across multiple jurisdictions, and total cost of implementation including waste treatment and disposal. Solutions that address all three factors command the highest market potential.

The market size for green electroless nickel alternatives is projected to expand substantially over the next five years, with particular growth in applications requiring high corrosion resistance and uniform coating thickness. Sectors showing the strongest adoption potential include renewable energy components, medical devices, and advanced electronics.

Supply chain considerations are increasingly influencing market dynamics, with manufacturers seeking plating solutions that reduce overall environmental footprint throughout the product lifecycle. This has created new market opportunities for integrated solution providers who can address both the plating process and associated waste management challenges.

Current Status and Challenges in Green Electroless Nickel Technology

The global electroless nickel plating industry is currently undergoing significant transformation driven by environmental concerns and regulatory pressures. Traditional electroless nickel processes rely heavily on chemicals that pose substantial environmental and health risks, including nickel sulfate, sodium hypophosphite, and various complexing agents like EDTA and lactic acid. These conventional formulations often contain carcinogens, heavy metals, and substances with high aquatic toxicity that require specialized waste treatment.

In Europe, the implementation of REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations has placed strict limitations on several traditional electroless nickel chemicals. Similarly, in North America and Asia-Pacific regions, environmental protection agencies have established increasingly stringent discharge limits for nickel-containing wastewaters and hazardous chemicals, compelling industry adaptation.

The current state of green electroless nickel technology reveals several promising approaches. Reduced-nickel concentration baths represent an incremental improvement, decreasing nickel content by 20-30% while maintaining acceptable deposit properties. More advanced solutions include biodegradable complexing agents such as glycine and citrate-based formulations that replace conventional chelating agents while offering comparable stability and performance characteristics.

Hypophosphite alternatives constitute another significant research direction, with aminoborane and borohydride compounds showing potential as reducing agents with lower environmental impact. However, these alternatives typically come with higher costs and sometimes reduced bath stability, presenting adoption barriers for widespread industrial implementation.

The primary technical challenges facing green electroless nickel technology include maintaining bath stability without traditional stabilizers, achieving comparable deposition rates to conventional processes, and ensuring consistent deposit properties such as hardness, corrosion resistance, and wear resistance. Many green alternatives currently demonstrate 15-25% lower deposition rates and may require modified operating conditions, complicating industrial adoption.

Economic challenges also persist, with green formulations typically commanding a 30-50% price premium over conventional chemistries. This cost differential represents a significant barrier, particularly in price-sensitive market segments and regions with less stringent environmental regulations.

Infrastructure limitations present additional obstacles, as many existing plating facilities are designed for conventional chemistry parameters and may require substantial modification to accommodate green alternatives. The transition costs for equipment upgrades, process requalification, and operator training further complicate industry-wide adoption of environmentally friendly electroless nickel technologies.

In Europe, the implementation of REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations has placed strict limitations on several traditional electroless nickel chemicals. Similarly, in North America and Asia-Pacific regions, environmental protection agencies have established increasingly stringent discharge limits for nickel-containing wastewaters and hazardous chemicals, compelling industry adaptation.

The current state of green electroless nickel technology reveals several promising approaches. Reduced-nickel concentration baths represent an incremental improvement, decreasing nickel content by 20-30% while maintaining acceptable deposit properties. More advanced solutions include biodegradable complexing agents such as glycine and citrate-based formulations that replace conventional chelating agents while offering comparable stability and performance characteristics.

Hypophosphite alternatives constitute another significant research direction, with aminoborane and borohydride compounds showing potential as reducing agents with lower environmental impact. However, these alternatives typically come with higher costs and sometimes reduced bath stability, presenting adoption barriers for widespread industrial implementation.

The primary technical challenges facing green electroless nickel technology include maintaining bath stability without traditional stabilizers, achieving comparable deposition rates to conventional processes, and ensuring consistent deposit properties such as hardness, corrosion resistance, and wear resistance. Many green alternatives currently demonstrate 15-25% lower deposition rates and may require modified operating conditions, complicating industrial adoption.

Economic challenges also persist, with green formulations typically commanding a 30-50% price premium over conventional chemistries. This cost differential represents a significant barrier, particularly in price-sensitive market segments and regions with less stringent environmental regulations.

Infrastructure limitations present additional obstacles, as many existing plating facilities are designed for conventional chemistry parameters and may require substantial modification to accommodate green alternatives. The transition costs for equipment upgrades, process requalification, and operator training further complicate industry-wide adoption of environmentally friendly electroless nickel technologies.

Current Green Alternatives to Traditional Electroless Nickel Processes

01 Reduction of hazardous chemicals in electroless nickel processes

Environmental concerns have led to the development of electroless nickel processes that reduce or eliminate hazardous chemicals. These processes focus on replacing traditional toxic components with more environmentally friendly alternatives. Innovations include formulations with reduced formaldehyde, lead-free compositions, and processes that minimize the use of heavy metals. These advancements help decrease environmental pollution and improve workplace safety while maintaining coating quality and performance.- Reduction of hazardous chemicals in electroless nickel processes: Environmental concerns have led to the development of electroless nickel processes that reduce or eliminate hazardous chemicals such as lead, cadmium, and formaldehyde. These improved processes use alternative stabilizers and reducing agents that are less toxic while maintaining coating quality and performance. The reformulated baths help minimize environmental impact while complying with increasingly strict regulations on hazardous substances.

- Waste treatment and recycling methods for electroless nickel baths: Various waste treatment and recycling methods have been developed to address the environmental impact of spent electroless nickel baths. These include precipitation techniques to remove heavy metals, ion exchange systems, electrolytic recovery of nickel, and membrane filtration processes. These methods help reduce hazardous waste disposal and allow for the recovery and reuse of valuable materials, thereby minimizing the environmental footprint of electroless nickel plating operations.

- Energy-efficient electroless nickel plating processes: Innovations in electroless nickel plating have focused on developing more energy-efficient processes that operate at lower temperatures or require shorter processing times. These advancements reduce energy consumption and associated carbon emissions while maintaining or improving coating quality. Some processes incorporate optimized bath compositions and catalysts that accelerate deposition rates at lower temperatures, resulting in significant energy savings and reduced environmental impact.

- Water conservation and effluent reduction techniques: Water conservation has become a critical aspect of environmentally friendly electroless nickel processes. Techniques include closed-loop water systems, cascade rinsing, spray rinsing, and advanced filtration systems that allow water reuse. These approaches significantly reduce water consumption and minimize the volume of wastewater requiring treatment. Additionally, some processes incorporate bath maintenance procedures that extend solution life and reduce the frequency of bath disposal, further decreasing water usage and effluent generation.

- Green chemistry approaches for electroless nickel plating: Green chemistry principles are being applied to electroless nickel processes to develop more environmentally benign alternatives. These approaches include using bio-based reducing agents, environmentally friendly complexing agents, and biodegradable surfactants. Some processes utilize plant extracts or other renewable resources as bath components, replacing petroleum-derived chemicals. These green chemistry innovations help reduce the ecological footprint of electroless nickel plating while maintaining the functional properties required for industrial applications.

02 Waste treatment and recycling methods for electroless nickel baths

Effective waste treatment and recycling methods have been developed to address the environmental impact of spent electroless nickel baths. These methods include techniques for recovering nickel from waste solutions, regenerating bath components, and treating effluents before disposal. Advanced filtration systems, ion exchange processes, and chemical precipitation methods help reduce the environmental footprint of electroless nickel plating operations while also providing economic benefits through material recovery.Expand Specific Solutions03 Energy-efficient electroless nickel plating processes

Energy consumption is a significant environmental concern in electroless nickel plating. Innovative approaches have been developed to reduce energy requirements, including low-temperature plating processes, optimized bath formulations that operate at reduced temperatures, and more efficient heating systems. These energy-efficient processes not only reduce carbon emissions but also lower operational costs while maintaining or improving coating quality and deposition rates.Expand Specific Solutions04 Water conservation in electroless nickel plating

Water usage is a critical environmental aspect of electroless nickel processes. Advanced techniques for water conservation include closed-loop systems, cascade rinsing methods, and water recovery technologies. These approaches significantly reduce freshwater consumption and wastewater generation. Improved rinsing techniques and bath maintenance methods extend solution life and minimize the need for frequent bath replacements, further reducing the environmental impact of the plating process.Expand Specific Solutions05 Alternative catalysts and reducing agents for greener electroless nickel deposition

Traditional electroless nickel processes often use environmentally problematic catalysts and reducing agents. Research has focused on developing alternative, more environmentally friendly components. These include non-toxic reducing agents to replace sodium hypophosphite or formaldehyde, biodegradable complexing agents, and more sustainable catalysts. These alternative materials reduce the environmental footprint of electroless nickel processes while maintaining coating performance characteristics such as corrosion resistance, hardness, and wear resistance.Expand Specific Solutions

Key Industry Players in Green Electroless Nickel Development

The green alternatives for electroless nickel processes market is in a growth phase, driven by increasing environmental regulations and sustainability initiatives. The market size is expanding as industries seek eco-friendly surface treatment solutions, with an estimated annual growth rate of 5-7%. Technologically, the field is advancing from experimental to commercial implementation, with varying maturity levels across solutions. Leading players include Nihon Parkerizing, which has established commercial green nickel plating technologies, and Boeing, which is implementing sustainable surface treatment processes in aerospace applications. Research institutions like IIT Delhi, City University of Hong Kong, and CSIR are developing novel formulations, while companies such as Sumitomo Metal Mining and BYD are investing in environmentally friendly electroless nickel alternatives for battery and electronics applications.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed a comprehensive green electroless nickel plating technology that addresses multiple environmental concerns simultaneously. Their approach utilizes a combination of plant-derived reducing agents and biodegradable complexing agents to create a fully sustainable plating system. The technology employs modified glucose derivatives as primary reducing agents, which are both renewable and non-toxic. CSIR's process operates at moderate temperatures (75-80°C) and utilizes a proprietary buffer system that maintains stable pH without requiring frequent chemical additions. Their research has demonstrated deposition rates of 14-16 μm/hour with excellent adhesion properties (>30 MPa pull-off strength). The process incorporates advanced real-time monitoring systems that optimize chemical additions based on deposition kinetics, reducing waste by approximately 40%. CSIR has also developed specialized recovery techniques that extract and recycle over 95% of nickel from spent solutions, dramatically reducing environmental impact and raw material costs. Their technology produces coatings with phosphorus content ranging from 5-12% depending on application requirements, offering versatility comparable to conventional processes while eliminating hazardous waste streams.

Strengths: Comprehensive sustainability approach addressing multiple environmental aspects; excellent nickel recovery and recycling capabilities; versatile phosphorus content control; comparable performance to conventional processes in terms of corrosion protection and wear resistance. Weaknesses: Requires more sophisticated monitoring and control systems; slightly higher operational complexity; more sensitive to water quality variations; may require additional pre-treatment steps for certain substrate materials.

Nihon Parkerizing Co., Ltd.

Technical Solution: Nihon Parkerizing has developed an innovative green electroless nickel plating process that eliminates the use of traditional toxic reducing agents like sodium hypophosphite. Their technology utilizes environmentally benign organic compounds as reducing agents, combined with specialized stabilizers that prevent spontaneous decomposition while maintaining bath stability. The process operates at lower temperatures (65-75°C compared to conventional 85-95°C), reducing energy consumption by approximately 25%. Their formulation also achieves near-zero discharge of ammonia and significantly reduces phosphorus content in wastewater. The company has implemented closed-loop water recycling systems that recover and reuse over 90% of process water, dramatically reducing freshwater consumption and wastewater generation. Their latest generation technology incorporates biodegradable complexing agents derived from renewable resources, replacing traditional chelating agents like EDTA.

Strengths: Significantly reduced toxicity profile with elimination of carcinogenic compounds; lower energy consumption; excellent deposit uniformity even on complex geometries; reduced water usage. Weaknesses: Slightly slower deposition rates compared to conventional processes; higher initial implementation costs; may require more precise process control parameters; coating hardness may be 5-10% lower than traditional high-phosphorus coatings.

Critical Patents and Innovations in Eco-friendly Plating Chemistry

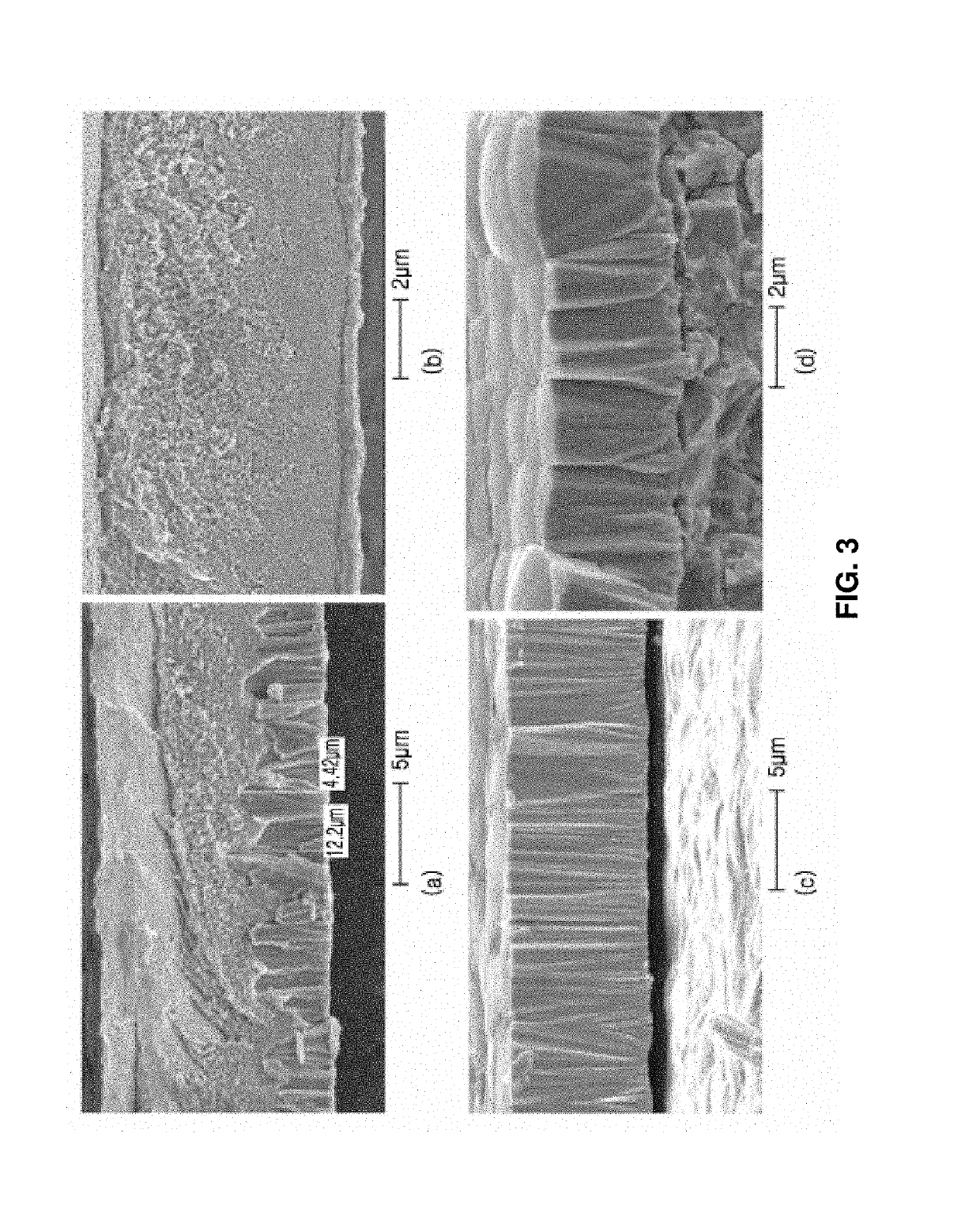

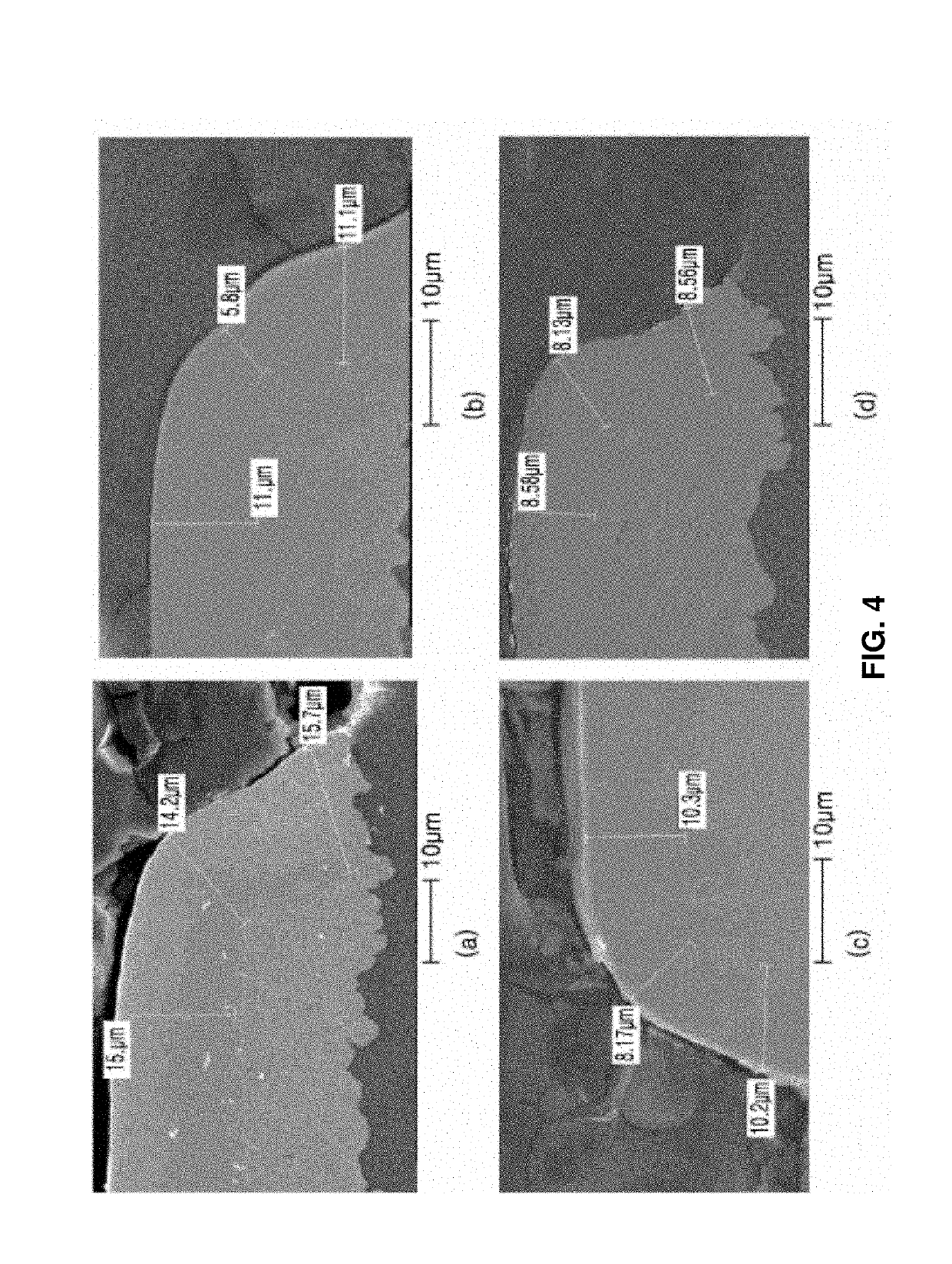

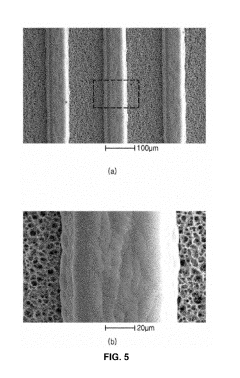

Electroless nickel plating solution, electroless nickel plating method using same, and flexible nickel plated layer formed by using same

PatentActiveUS10358724B2

Innovation

- An electroless nickel plating solution comprising sulfamic acid nickel, a reducer such as sodium hypophosphite, a complexing agent like glycine or citric acid, and a cyan-based stabilizer, which forms a flexible nickel plated layer with improved stability and hardness, preventing pit generation and maintaining properties over multiple uses.

Electroless nickel plating solution

PatentInactiveUS5306334A

Innovation

- A phosphorus-containing, crystalline nickel coating is achieved using an electroless nickel plating solution composed of nickel salt, organic acids, hypophosphite, thiourea, and ammonia, operated at a temperature below 60°C with minimal heavy metals, specifically less than 1 ppm thiourea, to produce a conductive layer with crystallites greater than 3 nanometers and surface resistivity less than 1 ohm/square.

Environmental Impact Assessment of Alternative Plating Technologies

The environmental impact assessment of alternative plating technologies reveals significant differences between traditional electroless nickel processes and emerging green alternatives. Conventional electroless nickel plating typically utilizes formaldehyde, sodium hypophosphite, and heavy metals as reducing agents, which pose substantial environmental hazards. These chemicals contribute to water pollution, soil contamination, and can bioaccumulate in aquatic ecosystems when improperly managed. Additionally, the high energy consumption and greenhouse gas emissions associated with traditional processes further exacerbate their environmental footprint.

Green alternatives demonstrate promising environmental advantages across multiple impact categories. Boron-based reducing agents, for instance, show a 30-40% reduction in aquatic toxicity compared to formaldehyde-based systems. Similarly, plant-extract based reducing agents derived from tea leaves and other botanical sources have demonstrated biodegradability rates exceeding 85%, significantly higher than conventional options which typically remain below 20%.

Life cycle assessment (LCA) studies comparing traditional and green electroless nickel processes indicate that the latter can reduce carbon footprint by approximately 25-35%. This reduction stems from lower processing temperatures, decreased chemical consumption, and reduced waste treatment requirements. Water usage metrics are equally compelling, with some green alternatives requiring up to 40% less water throughout their operational lifecycle.

Waste management considerations further highlight the advantages of green alternatives. Traditional processes generate hazardous sludge containing nickel, phosphorus, and other heavy metals, requiring specialized disposal methods. In contrast, many green alternatives produce waste streams with lower toxicity profiles and enhanced treatability, reducing end-of-life environmental impacts and disposal costs by an estimated 20-30%.

Regulatory compliance assessments indicate that green alternatives generally align better with increasingly stringent environmental regulations worldwide, including the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. This regulatory advantage translates to reduced compliance costs and lower risk of future operational restrictions.

Air quality impacts also differ significantly between traditional and green processes. Conventional electroless nickel plating can release volatile organic compounds (VOCs) and other air pollutants, whereas many green alternatives utilize non-volatile components that minimize air emissions. Measurements indicate potential reductions of 50-70% in VOC emissions when implementing certain green technologies, contributing to improved workplace air quality and reduced atmospheric pollution.

Green alternatives demonstrate promising environmental advantages across multiple impact categories. Boron-based reducing agents, for instance, show a 30-40% reduction in aquatic toxicity compared to formaldehyde-based systems. Similarly, plant-extract based reducing agents derived from tea leaves and other botanical sources have demonstrated biodegradability rates exceeding 85%, significantly higher than conventional options which typically remain below 20%.

Life cycle assessment (LCA) studies comparing traditional and green electroless nickel processes indicate that the latter can reduce carbon footprint by approximately 25-35%. This reduction stems from lower processing temperatures, decreased chemical consumption, and reduced waste treatment requirements. Water usage metrics are equally compelling, with some green alternatives requiring up to 40% less water throughout their operational lifecycle.

Waste management considerations further highlight the advantages of green alternatives. Traditional processes generate hazardous sludge containing nickel, phosphorus, and other heavy metals, requiring specialized disposal methods. In contrast, many green alternatives produce waste streams with lower toxicity profiles and enhanced treatability, reducing end-of-life environmental impacts and disposal costs by an estimated 20-30%.

Regulatory compliance assessments indicate that green alternatives generally align better with increasingly stringent environmental regulations worldwide, including the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. This regulatory advantage translates to reduced compliance costs and lower risk of future operational restrictions.

Air quality impacts also differ significantly between traditional and green processes. Conventional electroless nickel plating can release volatile organic compounds (VOCs) and other air pollutants, whereas many green alternatives utilize non-volatile components that minimize air emissions. Measurements indicate potential reductions of 50-70% in VOC emissions when implementing certain green technologies, contributing to improved workplace air quality and reduced atmospheric pollution.

Regulatory Compliance Framework for Green Plating Processes

The regulatory landscape for electroless nickel plating processes has undergone significant transformation in recent years, driven primarily by increasing environmental concerns and public health considerations. Key global regulations such as the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), RoHS (Restriction of Hazardous Substances), and ELV (End-of-Life Vehicles) directives have established stringent parameters for chemical usage in industrial processes, directly impacting traditional electroless nickel plating operations.

These regulatory frameworks specifically target the reduction or elimination of hazardous substances commonly found in conventional electroless nickel baths, including formaldehyde, lead compounds, cadmium, and certain phosphorus-containing chemicals. The REACH regulation, in particular, has placed several traditional plating chemicals on the Substances of Very High Concern (SVHC) list, necessitating authorization for continued use or substitution with greener alternatives.

In North America, the U.S. Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA) and Clean Water Act provisions that regulate wastewater discharge from plating operations. These regulations establish permissible limits for heavy metals and other contaminants, compelling manufacturers to adopt more environmentally responsible practices. Similarly, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or reproductive harm.

Asian markets have also strengthened their regulatory frameworks, with China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law imposing additional compliance requirements for plating operations. These regulations are increasingly harmonizing with international standards, creating a more unified global compliance landscape.

Industry-specific standards further complement these regulatory frameworks. ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety management systems provide structured approaches for organizations to identify, manage, and mitigate environmental impacts and workplace hazards associated with electroless nickel processes.

Compliance with these diverse regulatory requirements necessitates a systematic approach. Companies must implement comprehensive chemical inventory management systems, conduct regular environmental impact assessments, and establish robust waste treatment protocols. Documentation requirements have also expanded, with detailed safety data sheets, chemical risk assessments, and environmental performance reports becoming standard practice.

The financial implications of non-compliance are substantial, including significant fines, operational restrictions, and potential market access limitations. Beyond these direct penalties, companies face reputational damage and loss of business opportunities, particularly as supply chains increasingly prioritize environmental sustainability credentials.

These regulatory frameworks specifically target the reduction or elimination of hazardous substances commonly found in conventional electroless nickel baths, including formaldehyde, lead compounds, cadmium, and certain phosphorus-containing chemicals. The REACH regulation, in particular, has placed several traditional plating chemicals on the Substances of Very High Concern (SVHC) list, necessitating authorization for continued use or substitution with greener alternatives.

In North America, the U.S. Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA) and Clean Water Act provisions that regulate wastewater discharge from plating operations. These regulations establish permissible limits for heavy metals and other contaminants, compelling manufacturers to adopt more environmentally responsible practices. Similarly, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or reproductive harm.

Asian markets have also strengthened their regulatory frameworks, with China's Measures for Environmental Management of New Chemical Substances and Japan's Chemical Substances Control Law imposing additional compliance requirements for plating operations. These regulations are increasingly harmonizing with international standards, creating a more unified global compliance landscape.

Industry-specific standards further complement these regulatory frameworks. ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety management systems provide structured approaches for organizations to identify, manage, and mitigate environmental impacts and workplace hazards associated with electroless nickel processes.

Compliance with these diverse regulatory requirements necessitates a systematic approach. Companies must implement comprehensive chemical inventory management systems, conduct regular environmental impact assessments, and establish robust waste treatment protocols. Documentation requirements have also expanded, with detailed safety data sheets, chemical risk assessments, and environmental performance reports becoming standard practice.

The financial implications of non-compliance are substantial, including significant fines, operational restrictions, and potential market access limitations. Beyond these direct penalties, companies face reputational damage and loss of business opportunities, particularly as supply chains increasingly prioritize environmental sustainability credentials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!