Electroless Plating Process Optimization for Uniformity

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electroless Plating Background and Objectives

Electroless plating, also known as chemical or auto-catalytic plating, has evolved significantly since its discovery in the early 19th century. The process gained industrial prominence in the 1940s when Abner Brenner at the National Bureau of Standards developed nickel-phosphorus electroless plating. This chemical deposition method, which operates without external electrical current, has become indispensable across multiple industries including electronics, automotive, aerospace, and medical devices manufacturing.

The technology has progressed through several developmental phases, from basic metal deposition to sophisticated multi-layer systems with precisely controlled properties. Recent advancements have focused on nano-scale applications, environmentally friendly formulations, and integration with advanced manufacturing processes. The evolution trajectory clearly indicates a shift toward more precise control mechanisms, sustainable chemistry, and enhanced performance characteristics.

Despite its widespread adoption, electroless plating continues to face significant challenges in achieving uniform deposition across complex geometries and maintaining consistent quality at scale. The uniformity issue represents one of the most persistent technical hurdles, affecting product reliability, performance, and manufacturing yields. Non-uniform plating manifests as thickness variations, inconsistent physical properties, and potential defects that compromise the integrity of the final product.

The primary objective of process optimization for uniformity is to develop robust methodologies that ensure consistent metal deposition regardless of substrate geometry, bath conditions, or production scale. This entails establishing precise control over multiple process parameters including temperature gradients, chemical concentration stability, pH regulation, and surface preparation protocols. Secondary objectives include reducing process variability, minimizing waste generation, and enhancing overall process efficiency.

Current research trends indicate growing interest in computational modeling approaches to predict and control deposition behavior, real-time monitoring systems for bath chemistry, and novel additive formulations that promote uniform growth. Additionally, there is increasing focus on understanding the fundamental mechanisms of autocatalytic reactions at the molecular level to enable more precise engineering of the plating process.

The achievement of optimal uniformity in electroless plating would unlock significant technological and economic benefits, including higher-performance electronic components, more reliable aerospace applications, and more durable medical implants. Furthermore, improved process control would reduce material waste, lower rejection rates, and decrease environmental impact, aligning with broader industry sustainability goals.

The technology has progressed through several developmental phases, from basic metal deposition to sophisticated multi-layer systems with precisely controlled properties. Recent advancements have focused on nano-scale applications, environmentally friendly formulations, and integration with advanced manufacturing processes. The evolution trajectory clearly indicates a shift toward more precise control mechanisms, sustainable chemistry, and enhanced performance characteristics.

Despite its widespread adoption, electroless plating continues to face significant challenges in achieving uniform deposition across complex geometries and maintaining consistent quality at scale. The uniformity issue represents one of the most persistent technical hurdles, affecting product reliability, performance, and manufacturing yields. Non-uniform plating manifests as thickness variations, inconsistent physical properties, and potential defects that compromise the integrity of the final product.

The primary objective of process optimization for uniformity is to develop robust methodologies that ensure consistent metal deposition regardless of substrate geometry, bath conditions, or production scale. This entails establishing precise control over multiple process parameters including temperature gradients, chemical concentration stability, pH regulation, and surface preparation protocols. Secondary objectives include reducing process variability, minimizing waste generation, and enhancing overall process efficiency.

Current research trends indicate growing interest in computational modeling approaches to predict and control deposition behavior, real-time monitoring systems for bath chemistry, and novel additive formulations that promote uniform growth. Additionally, there is increasing focus on understanding the fundamental mechanisms of autocatalytic reactions at the molecular level to enable more precise engineering of the plating process.

The achievement of optimal uniformity in electroless plating would unlock significant technological and economic benefits, including higher-performance electronic components, more reliable aerospace applications, and more durable medical implants. Furthermore, improved process control would reduce material waste, lower rejection rates, and decrease environmental impact, aligning with broader industry sustainability goals.

Market Analysis for Uniform Electroless Plating Applications

The global market for electroless plating applications requiring high uniformity has been experiencing steady growth, driven primarily by increasing demands in electronics, automotive, aerospace, and medical device industries. The market size for uniform electroless plating solutions reached approximately $2.3 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028.

Electronics manufacturing represents the largest application segment, accounting for nearly 42% of the total market share. The miniaturization trend in electronic components has intensified the need for highly uniform plating processes, as even minor variations in coating thickness can significantly impact device performance and reliability. Printed circuit boards (PCBs) and semiconductor packaging applications are particularly demanding, requiring coating uniformity variations of less than ±3% across surfaces.

The automotive sector has emerged as the fastest-growing application area, with a projected growth rate of 8.5% annually. This surge is primarily attributed to the increasing adoption of electronic components in vehicles and the growing electric vehicle market. Advanced driver assistance systems (ADAS) and autonomous driving technologies rely heavily on sensors and electronic control units that require uniform plating for consistent performance under varying environmental conditions.

Aerospace and defense applications, while smaller in volume, command premium pricing due to stringent quality requirements. These sectors prioritize long-term reliability under extreme conditions, making uniformity a critical factor in component selection and manufacturing processes. The market in this segment is characterized by long-term contracts and extensive qualification processes.

Geographically, Asia-Pacific dominates the market with approximately 58% share, led by manufacturing hubs in China, Taiwan, South Korea, and Japan. North America and Europe follow with 22% and 17% market shares respectively, with these regions focusing primarily on high-value applications in medical devices, defense, and advanced electronics.

Customer requirements are increasingly stringent, with industry specifications now commonly demanding uniformity tolerances below ±5% for standard applications and below ±2% for high-precision components. This trend has created a premium segment within the market, where manufacturers capable of delivering superior uniformity can command price premiums of 15-30% compared to standard plating services.

The competitive landscape reveals a fragmented market with specialized players focusing on specific industry verticals. Large chemical suppliers provide the base materials, while specialized plating service providers and equipment manufacturers compete on technical expertise and process control capabilities. Recent market consolidation through mergers and acquisitions indicates a trend toward integrated solution providers who can offer both materials and process optimization services.

Electronics manufacturing represents the largest application segment, accounting for nearly 42% of the total market share. The miniaturization trend in electronic components has intensified the need for highly uniform plating processes, as even minor variations in coating thickness can significantly impact device performance and reliability. Printed circuit boards (PCBs) and semiconductor packaging applications are particularly demanding, requiring coating uniformity variations of less than ±3% across surfaces.

The automotive sector has emerged as the fastest-growing application area, with a projected growth rate of 8.5% annually. This surge is primarily attributed to the increasing adoption of electronic components in vehicles and the growing electric vehicle market. Advanced driver assistance systems (ADAS) and autonomous driving technologies rely heavily on sensors and electronic control units that require uniform plating for consistent performance under varying environmental conditions.

Aerospace and defense applications, while smaller in volume, command premium pricing due to stringent quality requirements. These sectors prioritize long-term reliability under extreme conditions, making uniformity a critical factor in component selection and manufacturing processes. The market in this segment is characterized by long-term contracts and extensive qualification processes.

Geographically, Asia-Pacific dominates the market with approximately 58% share, led by manufacturing hubs in China, Taiwan, South Korea, and Japan. North America and Europe follow with 22% and 17% market shares respectively, with these regions focusing primarily on high-value applications in medical devices, defense, and advanced electronics.

Customer requirements are increasingly stringent, with industry specifications now commonly demanding uniformity tolerances below ±5% for standard applications and below ±2% for high-precision components. This trend has created a premium segment within the market, where manufacturers capable of delivering superior uniformity can command price premiums of 15-30% compared to standard plating services.

The competitive landscape reveals a fragmented market with specialized players focusing on specific industry verticals. Large chemical suppliers provide the base materials, while specialized plating service providers and equipment manufacturers compete on technical expertise and process control capabilities. Recent market consolidation through mergers and acquisitions indicates a trend toward integrated solution providers who can offer both materials and process optimization services.

Technical Challenges in Electroless Plating Uniformity

Electroless plating processes face significant technical challenges in achieving uniform deposition across substrate surfaces. The primary obstacle lies in maintaining consistent chemical reaction rates throughout the plating bath. Local variations in temperature, concentration gradients, and catalytic activity create non-uniform deposition patterns that compromise product quality and performance. These variations become particularly problematic when plating complex geometries with recessed areas, through-holes, or high aspect ratio features.

Bath stability represents another critical challenge, as electroless plating solutions are inherently metastable systems. The autocatalytic nature of these processes means that once initiated, reactions can accelerate unpredictably in certain regions, leading to thickness variations. Stabilizers added to control these reactions must be precisely balanced—too little results in spontaneous decomposition, while excessive amounts inhibit plating altogether or create uneven inhibition effects across different surface areas.

Surface preparation inconsistencies significantly impact plating uniformity. Variations in surface activation, catalyst distribution, or contaminant presence create preferential nucleation sites that lead to uneven growth patterns. This challenge is magnified when processing diverse substrate materials or components with mixed material compositions, as each surface may interact differently with the plating solution.

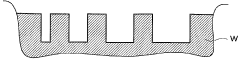

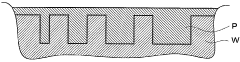

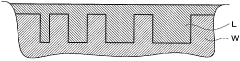

Mass transfer limitations constitute a fundamental physical constraint on uniformity. In areas with restricted solution flow—such as deep recesses, blind holes, or densely packed features—diffusion becomes the primary transport mechanism for reactants and byproducts. This creates concentration gradients that inevitably lead to thinner deposits in difficult-to-reach areas compared to exposed surfaces with better solution exchange.

The aging of plating baths introduces temporal variations in deposition characteristics. As baths are used, reactant depletion, byproduct accumulation, and stabilizer consumption progressively alter plating behavior. Without sophisticated real-time monitoring and replenishment systems, maintaining consistent plating conditions throughout bath life remains challenging.

Scale-up from laboratory to production environments introduces additional uniformity challenges. Parameters optimized at small scales often perform differently in larger production baths due to changed fluid dynamics, heat transfer characteristics, and mixing efficiency. Equipment design factors such as tank geometry, agitation methods, and filtration systems significantly impact solution homogeneity and, consequently, plating uniformity.

Advanced applications demanding nanoscale precision face even greater uniformity challenges. As feature sizes decrease and performance requirements increase in industries like semiconductor manufacturing and advanced electronics, even minor variations in deposit thickness or composition can have catastrophic effects on device functionality.

Bath stability represents another critical challenge, as electroless plating solutions are inherently metastable systems. The autocatalytic nature of these processes means that once initiated, reactions can accelerate unpredictably in certain regions, leading to thickness variations. Stabilizers added to control these reactions must be precisely balanced—too little results in spontaneous decomposition, while excessive amounts inhibit plating altogether or create uneven inhibition effects across different surface areas.

Surface preparation inconsistencies significantly impact plating uniformity. Variations in surface activation, catalyst distribution, or contaminant presence create preferential nucleation sites that lead to uneven growth patterns. This challenge is magnified when processing diverse substrate materials or components with mixed material compositions, as each surface may interact differently with the plating solution.

Mass transfer limitations constitute a fundamental physical constraint on uniformity. In areas with restricted solution flow—such as deep recesses, blind holes, or densely packed features—diffusion becomes the primary transport mechanism for reactants and byproducts. This creates concentration gradients that inevitably lead to thinner deposits in difficult-to-reach areas compared to exposed surfaces with better solution exchange.

The aging of plating baths introduces temporal variations in deposition characteristics. As baths are used, reactant depletion, byproduct accumulation, and stabilizer consumption progressively alter plating behavior. Without sophisticated real-time monitoring and replenishment systems, maintaining consistent plating conditions throughout bath life remains challenging.

Scale-up from laboratory to production environments introduces additional uniformity challenges. Parameters optimized at small scales often perform differently in larger production baths due to changed fluid dynamics, heat transfer characteristics, and mixing efficiency. Equipment design factors such as tank geometry, agitation methods, and filtration systems significantly impact solution homogeneity and, consequently, plating uniformity.

Advanced applications demanding nanoscale precision face even greater uniformity challenges. As feature sizes decrease and performance requirements increase in industries like semiconductor manufacturing and advanced electronics, even minor variations in deposit thickness or composition can have catastrophic effects on device functionality.

Current Methodologies for Plating Uniformity Enhancement

01 Bath composition optimization for uniform plating

Optimizing the electroless plating bath composition is crucial for achieving uniform deposition. This includes careful selection and balancing of reducing agents, complexing agents, stabilizers, and pH buffers. Proper formulation helps prevent localized depletion of reactants and ensures consistent deposition rates across the substrate surface. Controlling the concentration of metal ions and other components minimizes edge effects and improves thickness uniformity.- Bath composition optimization for uniform plating: Optimizing the electroless plating bath composition is crucial for achieving uniform deposition. This includes careful selection and balancing of reducing agents, complexing agents, stabilizers, and pH buffers. Proper formulation ensures consistent reaction rates across the substrate surface, preventing localized depletion of reactants that can lead to thickness variations. Controlled addition of stabilizers helps prevent spontaneous decomposition while maintaining uniform deposition rates.

- Process parameter control techniques: Maintaining precise control over process parameters such as temperature, pH, and agitation is essential for uniform electroless plating. Temperature gradients can cause uneven deposition rates, while pH fluctuations affect the stability and efficiency of the plating solution. Proper agitation techniques ensure homogeneous distribution of reactants and prevent boundary layer formation that could impede uniform deposition. Automated monitoring and feedback systems help maintain these parameters within optimal ranges throughout the plating process.

- Surface preparation and activation methods: Thorough surface preparation and activation are fundamental to achieving uniform electroless plating. This includes cleaning to remove contaminants, etching to increase surface area, and catalytic activation to create uniform nucleation sites. Advanced pretreatment techniques ensure consistent surface energy and wettability across the substrate. Proper activation creates evenly distributed catalytic sites that promote uniform initial deposition, which is critical as subsequent plating follows the pattern established in the early stages.

- Advanced plating equipment and fixtures: Specialized equipment and fixtures play a significant role in achieving uniform electroless plating. Custom-designed plating tanks with optimized flow dynamics help ensure even distribution of the plating solution. Specialized fixtures that properly position and rotate substrates prevent edge effects and solution stagnation. Advanced equipment features such as programmable agitation patterns, precise temperature control systems, and automated chemical replenishment systems contribute to maintaining consistent plating conditions throughout the process.

- Additives and modifiers for deposition control: Specialized additives and modifiers can significantly improve electroless plating uniformity. Surfactants reduce surface tension and improve wetting, ensuring even solution contact across complex geometries. Leveling agents help compensate for variations in current density, promoting deposition in recessed areas. Brighteners and grain refiners control the microstructure of the deposit, resulting in smoother and more uniform coatings. Careful selection and concentration control of these additives can address specific uniformity challenges related to substrate geometry or composition.

02 Process parameter control techniques

Maintaining precise control over process parameters such as temperature, pH, and agitation is essential for uniform electroless plating. Temperature gradients can cause uneven deposition rates, while pH fluctuations affect the stability of the plating solution. Proper agitation techniques ensure homogeneous distribution of reactants and prevent depletion zones. Advanced monitoring systems and feedback control mechanisms help maintain optimal conditions throughout the plating process.Expand Specific Solutions03 Substrate preparation and surface activation methods

Thorough substrate preparation and uniform surface activation are fundamental to achieving consistent electroless plating. This includes cleaning procedures to remove contaminants, etching to create uniform surface roughness, and activation processes to ensure catalytic sites are evenly distributed. Advanced pre-treatment techniques can modify surface properties to promote adhesion and uniform nucleation of the plating layer.Expand Specific Solutions04 Advanced plating equipment and fixture design

Specialized equipment and fixture designs significantly impact plating uniformity. This includes optimized tank configurations, advanced fluid delivery systems, and custom fixtures that ensure uniform solution contact with the substrate. Rotating fixtures or oscillating systems can prevent stagnation zones, while specialized holders minimize edge effects and shadowing. Equipment design considerations also include materials selection to prevent contamination and ensure consistent plating conditions.Expand Specific Solutions05 Additives and stabilizers for improved uniformity

Specific additives and stabilizers can be incorporated into electroless plating baths to enhance deposition uniformity. These include leveling agents that suppress deposition at high-current density areas, wetting agents that ensure uniform solution contact, and grain refiners that promote consistent microstructure. Stabilizers prevent spontaneous decomposition of the bath while allowing controlled deposition. The careful selection and concentration control of these additives is critical for achieving uniform plating results.Expand Specific Solutions

Industry Leaders in Electroless Plating Solutions

The electroless plating process optimization market is currently in a growth phase, with increasing demand for uniform coating solutions across semiconductor, electronics, and automotive industries. The global market size is estimated to exceed $2 billion, driven by miniaturization trends in electronics and advanced packaging requirements. From a technological maturity perspective, industry leaders demonstrate varying levels of specialization: Applied Materials, Lam Research, and Tokyo Electron lead in semiconductor applications with advanced process control systems; Taiwan Semiconductor Manufacturing and GLOBALFOUNDRIES implement cutting-edge plating technologies in high-volume manufacturing; while specialized players like MacDermid and Chemetall focus on chemical formulation innovations. Emerging competitors such as Taicang Jinlu and People & Technology are expanding capabilities in regional markets, particularly in Asia, where manufacturing capacity continues to grow rapidly.

Lam Research Corp.

Technical Solution: Lam Research has developed the SABRE® Electroless Plating platform specifically addressing uniformity challenges in electroless deposition processes. Their solution employs a unique "flow-controlled" architecture where the plating solution is delivered through precisely engineered distribution channels that ensure uniform chemical delivery across the substrate[1]. The system features dynamic flow control that adjusts delivery rates based on real-time feedback from embedded sensors monitoring deposition rates at multiple points across the wafer. Lam's technology incorporates proprietary "edge compensation" techniques that counteract the typically higher deposition rates at wafer edges by creating controlled boundary conditions in these regions[3]. Their platform also utilizes advanced pre-wetting technologies that ensure consistent surface activation prior to plating, eliminating non-uniform nucleation issues. Additionally, Lam has implemented sophisticated bath analysis and replenishment systems that maintain optimal chemical balance throughout extended production runs, preventing drift in plating performance that would otherwise lead to batch-to-batch uniformity variations.

Strengths: Exceptional edge-to-edge uniformity control, sophisticated flow management technology, and robust production stability for high-volume manufacturing. Weaknesses: System complexity requires specialized maintenance expertise, higher initial capital investment compared to basic plating systems, and potential challenges when adapting to novel substrate materials.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has pioneered a comprehensive electroless plating optimization framework focused on achieving sub-nanometer uniformity for advanced semiconductor nodes. Their approach combines chemical engineering innovations with precision equipment design to address uniformity challenges. TSMC's solution features a multi-component stabilizer system that maintains consistent bath chemistry even under high-throughput manufacturing conditions[2]. They've developed proprietary additives that promote uniform nucleation across different substrate topographies, particularly important for complex 3D structures in advanced nodes. TSMC's process employs a sequential pulse plating methodology that alternates between deposition and stabilization phases, allowing for more uniform metal distribution by preventing localized depletion zones[4]. Their system also incorporates advanced fluid dynamics modeling that optimizes flow patterns to ensure uniform boundary layer thickness across the entire wafer surface. Additionally, TSMC has implemented in-line metrology with feedback algorithms that can make real-time adjustments to process parameters based on uniformity measurements from previous wafers.

Strengths: Exceptional uniformity performance at advanced technology nodes, sophisticated bath chemistry management, and seamless integration with high-volume manufacturing workflows. Weaknesses: Highly customized solutions that may not be easily transferable to different applications, requires specialized chemical formulations that may increase operational costs.

Critical Patents and Research in Uniform Deposition

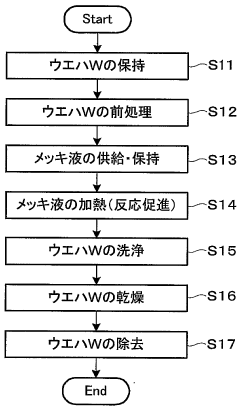

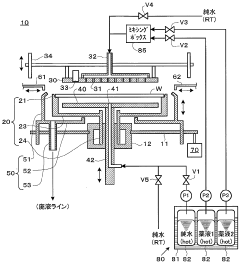

Method of electroless plating

PatentWO2004031447A1

Innovation

- An electroless plating method involving a plating solution supplying step, a reaction accelerating condition imparting step, and a plating film forming step, where the electroless plating solution is spread over the substrate before film formation, and conditions such as temperature and composition of the solution are controlled to accelerate the reaction, allowing for improved uniformity by using different plating solutions with varying film formation rates.

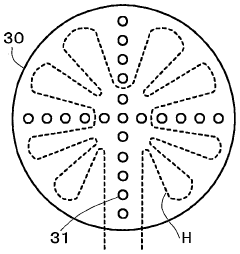

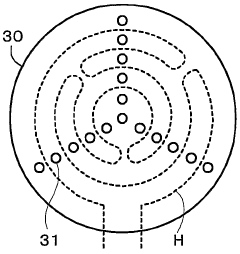

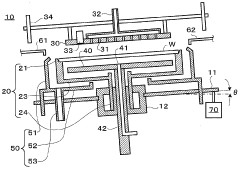

Electroless plating apparatus and electroless plating method

PatentWO2004027114A1

Innovation

- An electroless plating apparatus with a substrate holding mechanism, a plate for discharging processing liquid, and a gap adjustment system to control the liquid flow and temperature, ensuring uniformity and reducing the amount of processing liquid used, along with optional features like heating and tilting mechanisms for improved uniformity and efficiency.

Environmental Impact and Sustainability Considerations

The electroless plating industry faces increasing scrutiny regarding its environmental footprint, particularly concerning the chemicals used in the process. Traditional electroless plating baths contain heavy metals such as nickel, copper, and cobalt, along with reducing agents like formaldehyde and sodium hypophosphite that pose significant environmental risks when improperly managed. Wastewater from these processes typically contains metal ions, complexing agents, and stabilizers that can contaminate water bodies and soil if released untreated.

Recent regulatory frameworks worldwide have imposed stricter limits on effluent discharge parameters, compelling manufacturers to adopt more sustainable practices. The EU's REACH regulation, China's updated Environmental Protection Law, and the US EPA's guidelines have collectively pushed the industry toward greener alternatives and improved waste management systems. Companies failing to comply face substantial penalties, making environmental compliance a business imperative rather than an option.

Technological innovations are emerging to address these challenges while maintaining plating uniformity. Advanced filtration systems and ion exchange technologies have demonstrated up to 80% reduction in wastewater volume through effective metal recovery and bath regeneration. Closed-loop systems, though requiring higher initial investment, offer long-term operational savings while minimizing environmental impact. Several case studies from leading manufacturers indicate that implementing these systems can reduce fresh water consumption by 60-75% compared to conventional open systems.

The development of environmentally friendly alternatives to traditional chemicals represents another significant advancement. Biodegradable complexing agents derived from natural sources have shown promising results in laboratory tests, achieving comparable plating uniformity while reducing toxicity. Similarly, formaldehyde-free reducing agents are gaining traction, with sodium hypophosphite alternatives demonstrating reduced environmental persistence without compromising plating quality.

Energy efficiency improvements also contribute to sustainability goals. Optimized bath formulations that operate at lower temperatures (45-60°C versus traditional 70-90°C) reduce energy consumption by approximately 30%. Additionally, process optimization through precise control systems minimizes chemical usage and waste generation while enhancing plating uniformity, creating a win-win scenario for both environmental protection and product quality.

Life cycle assessment (LCA) studies comparing traditional and optimized electroless plating processes reveal that sustainability improvements need not compromise plating uniformity. In fact, several manufacturers have reported that environmentally optimized processes often deliver superior coating consistency due to better process control and monitoring systems implemented alongside environmental measures.

Recent regulatory frameworks worldwide have imposed stricter limits on effluent discharge parameters, compelling manufacturers to adopt more sustainable practices. The EU's REACH regulation, China's updated Environmental Protection Law, and the US EPA's guidelines have collectively pushed the industry toward greener alternatives and improved waste management systems. Companies failing to comply face substantial penalties, making environmental compliance a business imperative rather than an option.

Technological innovations are emerging to address these challenges while maintaining plating uniformity. Advanced filtration systems and ion exchange technologies have demonstrated up to 80% reduction in wastewater volume through effective metal recovery and bath regeneration. Closed-loop systems, though requiring higher initial investment, offer long-term operational savings while minimizing environmental impact. Several case studies from leading manufacturers indicate that implementing these systems can reduce fresh water consumption by 60-75% compared to conventional open systems.

The development of environmentally friendly alternatives to traditional chemicals represents another significant advancement. Biodegradable complexing agents derived from natural sources have shown promising results in laboratory tests, achieving comparable plating uniformity while reducing toxicity. Similarly, formaldehyde-free reducing agents are gaining traction, with sodium hypophosphite alternatives demonstrating reduced environmental persistence without compromising plating quality.

Energy efficiency improvements also contribute to sustainability goals. Optimized bath formulations that operate at lower temperatures (45-60°C versus traditional 70-90°C) reduce energy consumption by approximately 30%. Additionally, process optimization through precise control systems minimizes chemical usage and waste generation while enhancing plating uniformity, creating a win-win scenario for both environmental protection and product quality.

Life cycle assessment (LCA) studies comparing traditional and optimized electroless plating processes reveal that sustainability improvements need not compromise plating uniformity. In fact, several manufacturers have reported that environmentally optimized processes often deliver superior coating consistency due to better process control and monitoring systems implemented alongside environmental measures.

Quality Control and Testing Protocols

Quality control and testing protocols are fundamental to achieving consistent uniformity in electroless plating processes. The implementation of robust inspection methodologies begins with standardized sampling procedures that ensure representative assessment across production batches. These protocols typically include taking samples from multiple locations within a plated component and across different production runs to establish statistical validity.

Surface analysis techniques form the cornerstone of quality assessment in electroless plating. Scanning electron microscopy (SEM) provides detailed topographical imaging at micro and nano scales, revealing surface irregularities that may affect uniformity. X-ray fluorescence (XRF) spectroscopy enables non-destructive thickness measurement with precision typically within ±0.1μm, while atomic force microscopy (AFM) quantifies surface roughness parameters at the nanometer scale.

Adhesion testing represents another critical quality control measure, with methods including tape tests (ASTM D3359), scratch tests, and bend tests providing quantitative data on coating durability. These tests simulate real-world mechanical stresses and help predict long-term performance under various environmental conditions.

Electrochemical testing protocols, including polarization resistance measurements and electrochemical impedance spectroscopy (EIS), evaluate corrosion resistance properties of the plated layers. These techniques provide insights into the protective capabilities of the coating and can detect microscopic defects that might compromise performance.

Statistical process control (SPC) methodologies have revolutionized quality management in electroless plating operations. Implementation of control charts for key parameters such as thickness variation, surface roughness, and adhesion strength enables real-time monitoring of process stability. Establishing upper and lower control limits based on Six Sigma principles (±3σ) helps identify process drift before it results in defective products.

Advanced facilities incorporate automated optical inspection (AOI) systems that utilize machine vision algorithms to detect surface defects at production speeds. These systems can be calibrated to identify specific defect types such as pinholes, nodules, or thickness variations with increasing precision as machine learning capabilities improve.

Documentation and traceability systems complete the quality control framework, with each batch of plated components linked to specific process parameters, chemical bath compositions, and environmental conditions. This comprehensive data collection facilitates root cause analysis when uniformity issues arise and supports continuous improvement initiatives through trend analysis.

Surface analysis techniques form the cornerstone of quality assessment in electroless plating. Scanning electron microscopy (SEM) provides detailed topographical imaging at micro and nano scales, revealing surface irregularities that may affect uniformity. X-ray fluorescence (XRF) spectroscopy enables non-destructive thickness measurement with precision typically within ±0.1μm, while atomic force microscopy (AFM) quantifies surface roughness parameters at the nanometer scale.

Adhesion testing represents another critical quality control measure, with methods including tape tests (ASTM D3359), scratch tests, and bend tests providing quantitative data on coating durability. These tests simulate real-world mechanical stresses and help predict long-term performance under various environmental conditions.

Electrochemical testing protocols, including polarization resistance measurements and electrochemical impedance spectroscopy (EIS), evaluate corrosion resistance properties of the plated layers. These techniques provide insights into the protective capabilities of the coating and can detect microscopic defects that might compromise performance.

Statistical process control (SPC) methodologies have revolutionized quality management in electroless plating operations. Implementation of control charts for key parameters such as thickness variation, surface roughness, and adhesion strength enables real-time monitoring of process stability. Establishing upper and lower control limits based on Six Sigma principles (±3σ) helps identify process drift before it results in defective products.

Advanced facilities incorporate automated optical inspection (AOI) systems that utilize machine vision algorithms to detect surface defects at production speeds. These systems can be calibrated to identify specific defect types such as pinholes, nodules, or thickness variations with increasing precision as machine learning capabilities improve.

Documentation and traceability systems complete the quality control framework, with each batch of plated components linked to specific process parameters, chemical bath compositions, and environmental conditions. This comprehensive data collection facilitates root cause analysis when uniformity issues arise and supports continuous improvement initiatives through trend analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!