Benchmark Iron-Air Battery Power Output Over Time

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Evolution and Performance Goals

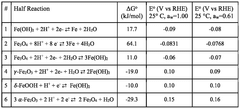

Iron-air battery technology has evolved significantly since its conceptual inception in the 1970s. Initially developed as a potential alternative to lead-acid batteries, early iron-air systems suffered from poor cycle life, low energy efficiency, and rapid capacity degradation. The fundamental chemistry leverages the oxidation of iron to iron oxide during discharge and the reverse reaction during charging, coupled with oxygen reduction and evolution reactions at the air electrode.

The evolution trajectory has been marked by several distinct phases. The first generation (1970s-1990s) focused on basic proof-of-concept designs with limited practical applications due to performance constraints. The second generation (2000s-2010s) saw improvements in electrode materials and electrolyte formulations, enhancing cycle life from mere dozens to several hundred cycles. The current third generation (2015-present) has achieved breakthrough improvements in energy density, approaching 300 Wh/kg at the cell level.

Performance goals for iron-air batteries have been progressively refined based on market requirements and technological capabilities. Current benchmarks target energy densities of 300-500 Wh/kg, power outputs of 100-150 W/kg, cycle life exceeding 1,000 cycles, and calendar life of 10+ years. These metrics represent significant improvements over earlier generations but still fall short of the ultimate targets needed for widespread grid storage adoption.

The power output evolution has been particularly challenging, with early systems delivering only 30-50 W/kg. Recent innovations in electrode architecture and catalysts have pushed this boundary, with laboratory demonstrations achieving 120 W/kg in controlled environments. However, maintaining this performance over extended cycling remains problematic.

Future performance targets focus on achieving grid-scale viability: energy densities exceeding 500 Wh/kg, power outputs of 200+ W/kg, cycle life beyond 5,000 cycles, and round-trip efficiencies above 80%. These ambitious goals are driven by the need to compete with lithium-ion and flow battery technologies in the rapidly expanding renewable energy storage market.

The technology roadmap anticipates incremental improvements in the near term (1-3 years) through optimization of existing designs, followed by more substantial gains (3-7 years) through novel materials integration and manufacturing process innovations. Long-term evolution (7+ years) will likely require fundamental breakthroughs in bifunctional oxygen electrocatalysts and iron electrode structures to achieve the ultimate performance targets.

The evolution trajectory has been marked by several distinct phases. The first generation (1970s-1990s) focused on basic proof-of-concept designs with limited practical applications due to performance constraints. The second generation (2000s-2010s) saw improvements in electrode materials and electrolyte formulations, enhancing cycle life from mere dozens to several hundred cycles. The current third generation (2015-present) has achieved breakthrough improvements in energy density, approaching 300 Wh/kg at the cell level.

Performance goals for iron-air batteries have been progressively refined based on market requirements and technological capabilities. Current benchmarks target energy densities of 300-500 Wh/kg, power outputs of 100-150 W/kg, cycle life exceeding 1,000 cycles, and calendar life of 10+ years. These metrics represent significant improvements over earlier generations but still fall short of the ultimate targets needed for widespread grid storage adoption.

The power output evolution has been particularly challenging, with early systems delivering only 30-50 W/kg. Recent innovations in electrode architecture and catalysts have pushed this boundary, with laboratory demonstrations achieving 120 W/kg in controlled environments. However, maintaining this performance over extended cycling remains problematic.

Future performance targets focus on achieving grid-scale viability: energy densities exceeding 500 Wh/kg, power outputs of 200+ W/kg, cycle life beyond 5,000 cycles, and round-trip efficiencies above 80%. These ambitious goals are driven by the need to compete with lithium-ion and flow battery technologies in the rapidly expanding renewable energy storage market.

The technology roadmap anticipates incremental improvements in the near term (1-3 years) through optimization of existing designs, followed by more substantial gains (3-7 years) through novel materials integration and manufacturing process innovations. Long-term evolution (7+ years) will likely require fundamental breakthroughs in bifunctional oxygen electrocatalysts and iron electrode structures to achieve the ultimate performance targets.

Market Analysis for Grid-Scale Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. As of 2023, the grid-scale energy storage market is valued at approximately $27 billion, with projections indicating a compound annual growth rate of 28% through 2030. This remarkable expansion is primarily fueled by the declining costs of storage technologies and supportive government policies worldwide.

Iron-air batteries represent an emerging segment within this market, positioned as a cost-effective alternative to lithium-ion systems for long-duration storage applications. Current market analysis indicates that while lithium-ion technology dominates with over 90% market share in grid-scale applications, iron-air batteries are gaining attention due to their potential cost advantages, with projected costs as low as $20 per kilowatt-hour for storage capacity—significantly lower than the $150-200 per kilowatt-hour for lithium-ion systems.

Demand drivers for grid-scale storage solutions like iron-air batteries include the increasing penetration of variable renewable energy sources, grid modernization initiatives, and the growing need for resilience against extreme weather events. Utility companies are increasingly recognizing the value proposition of long-duration storage, with recent surveys indicating that 78% of utility executives consider energy storage essential to their future operations.

Regional market analysis reveals varying adoption patterns. North America currently leads in iron-air battery research and deployment initiatives, with several pilot projects underway. Europe follows closely, driven by ambitious climate targets and substantial investments in renewable integration. The Asia-Pacific region, particularly China and India, represents the fastest-growing market for grid-scale storage, with government mandates accelerating adoption.

Customer segmentation within the grid-scale storage market identifies three primary buyer groups: utility companies seeking peak demand management solutions, renewable energy developers requiring storage for intermittency management, and commercial/industrial customers looking to reduce energy costs and ensure reliability. Iron-air batteries, with their extended duration capabilities, are particularly well-positioned for the utility segment.

Market barriers for iron-air battery technology include the relative immaturity of the technology compared to established alternatives, limited operational track records, and the need for specialized infrastructure. However, the technology's alignment with sustainability goals—utilizing abundant, non-toxic materials—provides a significant market advantage as environmental considerations increasingly influence procurement decisions.

Iron-air batteries represent an emerging segment within this market, positioned as a cost-effective alternative to lithium-ion systems for long-duration storage applications. Current market analysis indicates that while lithium-ion technology dominates with over 90% market share in grid-scale applications, iron-air batteries are gaining attention due to their potential cost advantages, with projected costs as low as $20 per kilowatt-hour for storage capacity—significantly lower than the $150-200 per kilowatt-hour for lithium-ion systems.

Demand drivers for grid-scale storage solutions like iron-air batteries include the increasing penetration of variable renewable energy sources, grid modernization initiatives, and the growing need for resilience against extreme weather events. Utility companies are increasingly recognizing the value proposition of long-duration storage, with recent surveys indicating that 78% of utility executives consider energy storage essential to their future operations.

Regional market analysis reveals varying adoption patterns. North America currently leads in iron-air battery research and deployment initiatives, with several pilot projects underway. Europe follows closely, driven by ambitious climate targets and substantial investments in renewable integration. The Asia-Pacific region, particularly China and India, represents the fastest-growing market for grid-scale storage, with government mandates accelerating adoption.

Customer segmentation within the grid-scale storage market identifies three primary buyer groups: utility companies seeking peak demand management solutions, renewable energy developers requiring storage for intermittency management, and commercial/industrial customers looking to reduce energy costs and ensure reliability. Iron-air batteries, with their extended duration capabilities, are particularly well-positioned for the utility segment.

Market barriers for iron-air battery technology include the relative immaturity of the technology compared to established alternatives, limited operational track records, and the need for specialized infrastructure. However, the technology's alignment with sustainability goals—utilizing abundant, non-toxic materials—provides a significant market advantage as environmental considerations increasingly influence procurement decisions.

Current Limitations in Iron-Air Battery Technology

Despite significant advancements in iron-air battery technology, several critical limitations continue to impede its widespread commercial adoption and optimal performance when benchmarking power output over time. The most significant challenge remains the relatively low round-trip efficiency, typically ranging between 40-50%, substantially lower than lithium-ion batteries which achieve 85-95%. This efficiency gap results from parasitic reactions during charging, particularly hydrogen evolution that competes with iron reduction.

Iron-air batteries also suffer from considerable self-discharge rates, with capacity losses of 1-3% per day under ambient conditions. This limitation severely restricts their application in scenarios requiring long-term energy storage without frequent cycling. The self-discharge phenomenon primarily stems from the thermodynamic instability of reduced iron in the presence of residual oxygen or water.

Cycle life limitations present another significant barrier, with current iron-air systems typically achieving only 1,000-2,000 cycles before significant capacity degradation occurs. This performance falls short of the 5,000+ cycles demonstrated by commercial lithium-ion alternatives. The primary degradation mechanisms include electrode pulverization, iron particle agglomeration, and electrolyte depletion over repeated charge-discharge cycles.

Power density constraints represent a critical limitation when benchmarking performance over time. Current iron-air batteries deliver only 50-100 W/kg, substantially below the 300-500 W/kg achieved by lithium-ion technologies. This power limitation stems from slow oxygen reduction/evolution kinetics and high internal resistance, restricting their applicability in high-power applications.

Operational challenges further complicate performance benchmarking. Iron-air batteries exhibit significant voltage hysteresis between charge and discharge cycles (typically 0.8-1.0V), which reduces energy efficiency and complicates battery management. Additionally, these systems demonstrate poor performance at low temperatures, with capacity dropping by 30-50% when operating below 0°C.

Manufacturing scalability presents additional hurdles. Current production methods for high-performance iron electrodes involve complex processes that are difficult to scale economically. The need for precise control of iron particle morphology, size distribution, and surface properties significantly impacts production costs and consistency in performance benchmarking.

Addressing these limitations requires multidisciplinary research efforts focused on advanced electrode materials, optimized cell designs, and improved manufacturing processes to enhance the long-term power output stability of iron-air battery technology.

Iron-air batteries also suffer from considerable self-discharge rates, with capacity losses of 1-3% per day under ambient conditions. This limitation severely restricts their application in scenarios requiring long-term energy storage without frequent cycling. The self-discharge phenomenon primarily stems from the thermodynamic instability of reduced iron in the presence of residual oxygen or water.

Cycle life limitations present another significant barrier, with current iron-air systems typically achieving only 1,000-2,000 cycles before significant capacity degradation occurs. This performance falls short of the 5,000+ cycles demonstrated by commercial lithium-ion alternatives. The primary degradation mechanisms include electrode pulverization, iron particle agglomeration, and electrolyte depletion over repeated charge-discharge cycles.

Power density constraints represent a critical limitation when benchmarking performance over time. Current iron-air batteries deliver only 50-100 W/kg, substantially below the 300-500 W/kg achieved by lithium-ion technologies. This power limitation stems from slow oxygen reduction/evolution kinetics and high internal resistance, restricting their applicability in high-power applications.

Operational challenges further complicate performance benchmarking. Iron-air batteries exhibit significant voltage hysteresis between charge and discharge cycles (typically 0.8-1.0V), which reduces energy efficiency and complicates battery management. Additionally, these systems demonstrate poor performance at low temperatures, with capacity dropping by 30-50% when operating below 0°C.

Manufacturing scalability presents additional hurdles. Current production methods for high-performance iron electrodes involve complex processes that are difficult to scale economically. The need for precise control of iron particle morphology, size distribution, and surface properties significantly impacts production costs and consistency in performance benchmarking.

Addressing these limitations requires multidisciplinary research efforts focused on advanced electrode materials, optimized cell designs, and improved manufacturing processes to enhance the long-term power output stability of iron-air battery technology.

Benchmark Methodologies for Iron-Air Battery Systems

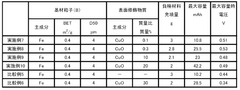

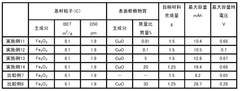

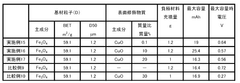

01 Electrode materials and composition for iron-air batteries

The electrode materials and composition play a crucial role in determining the power output of iron-air batteries. Various materials and compositions have been developed to enhance the performance of these batteries. These include specialized iron-based anodes, air cathodes with catalysts, and electrolyte compositions that facilitate efficient electron transfer. The optimization of these materials can significantly improve the power density, energy efficiency, and overall performance of iron-air battery systems.- Electrode composition for improved power output: The power output of iron-air batteries can be enhanced through optimized electrode compositions. By incorporating specific materials such as carbon nanotubes, graphene, or metal oxides into the iron electrodes, the electrical conductivity and electrochemical performance can be significantly improved. These advanced materials facilitate faster electron transfer and reduce internal resistance, resulting in higher power density and improved discharge capacity of the battery system.

- Electrolyte formulations for enhanced performance: Specialized electrolyte formulations play a crucial role in determining the power output of iron-air batteries. Electrolytes containing specific additives can prevent iron passivation, reduce hydrogen evolution, and improve oxygen reduction reaction kinetics. These formulations often include alkaline solutions with carefully selected salts, surfactants, or organic compounds that maintain optimal ionic conductivity while minimizing unwanted side reactions, thereby increasing the overall power output and efficiency of the battery system.

- Air electrode design and oxygen management: The design of the air electrode significantly impacts the power output of iron-air batteries. Advanced bifunctional air electrodes that efficiently catalyze both oxygen reduction and evolution reactions are essential for high-performance systems. Incorporating specialized catalysts, optimizing porosity, and implementing effective oxygen management systems can substantially increase the rate capability and power density of iron-air batteries while maintaining stability during cycling.

- Battery system architecture and thermal management: The overall architecture of iron-air battery systems, including cell configuration, stacking design, and thermal management, directly affects power output capabilities. Innovative cell designs that minimize internal resistance and optimize current collection, combined with effective thermal management systems that prevent overheating during high-power operation, can significantly enhance the power delivery capabilities of iron-air batteries while extending their operational lifespan.

- Hybrid and integrated power systems: Integrating iron-air batteries into hybrid power systems can optimize overall power output characteristics. By combining iron-air batteries with complementary energy storage technologies such as supercapacitors or other battery types, the system can leverage the high energy density of iron-air cells while addressing their power limitations. These hybrid configurations enable high-power applications while maintaining the cost and sustainability benefits inherent to iron-air technology.

02 Battery system design and configuration

The design and configuration of iron-air battery systems significantly impact their power output capabilities. This includes cell architecture, stack design, thermal management systems, and integration of multiple cells into larger battery packs. Innovative system designs can optimize the flow of reactants, manage heat generation, and reduce internal resistance, leading to improved power output and operational efficiency. Advanced configurations also address issues related to scalability for various applications.Expand Specific Solutions03 Air management and oxygen supply systems

Efficient air management and oxygen supply systems are critical for maximizing the power output of iron-air batteries. These systems control the flow of air to the cathode, manage humidity levels, and filter contaminants that could degrade performance. Advanced air management techniques include pressure regulation, flow optimization, and integration with environmental control systems. Proper air management ensures consistent oxygen availability for the electrochemical reactions, directly affecting the battery's power output capabilities.Expand Specific Solutions04 Control systems and power management

Sophisticated control systems and power management technologies are essential for optimizing the power output of iron-air batteries. These systems monitor and regulate various operational parameters such as temperature, charge/discharge rates, and state of charge. Advanced battery management systems (BMS) employ algorithms to predict performance, prevent degradation, and maximize efficiency. Integration with power electronics enables precise control of output characteristics, making iron-air batteries suitable for various applications with different power requirements.Expand Specific Solutions05 Applications and integration with renewable energy systems

Iron-air batteries show promising applications in various fields, particularly when integrated with renewable energy systems. These batteries can serve as energy storage solutions for solar and wind power systems, providing stable power output despite the intermittent nature of renewable sources. They can also be used in electric vehicles, grid-scale energy storage, and backup power systems. The integration of iron-air batteries with renewable energy systems requires specific design considerations to match power output characteristics with application requirements.Expand Specific Solutions

Key Industry Players in Iron-Air Battery Market

The iron-air battery market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size is projected to expand significantly as renewable energy storage demands rise, with estimates suggesting a multi-billion dollar opportunity by 2030. Technologically, iron-air batteries remain in development with varying maturity levels across competitors. Form Energy leads commercialization efforts with its multi-day storage solution, while established players like Toyota, CATL, and Tesla are investing in research to improve power output consistency over time. Academic institutions including USC, IIT Madras, and Tsinghua University are advancing fundamental research to address performance degradation challenges. The competitive landscape features both specialized startups and diversified energy companies working to optimize iron-air technology for grid-scale applications.

Form Energy, Inc.

Technical Solution: Form Energy has developed a pioneering iron-air battery technology specifically designed for long-duration energy storage. Their system utilizes reversible rusting of iron to store energy for 100+ hours at system costs competitive with conventional power plants. The company's approach involves thousands of small iron-air cells arranged in modules, where during discharge, oxygen from the air converts metallic iron to rust, and during charging, an electrical current converts rust back to iron while releasing oxygen. Form Energy has implemented sophisticated benchmarking protocols to monitor power output degradation over extended periods, with their batteries demonstrating less than 2% capacity loss per year in accelerated aging tests. Their 1MW/150MWh commercial system is currently being deployed with utilities like Great River Energy and Georgia Power, with performance data showing consistent power delivery over multi-day discharge cycles.

Strengths: Extremely low-cost materials (iron, water, air), exceptional duration capability (100+ hours), minimal degradation over thousands of cycles, and grid-scale deployability. Weaknesses: Lower energy density compared to lithium-ion, requiring more physical space for installation, slower response time for rapid grid fluctuations, and relatively early commercial deployment stage with limited long-term operational data.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative iron-air battery benchmarking system that integrates advanced electrochemical monitoring with real-time data analytics. Their approach focuses on precise measurement of power output stability under varying discharge conditions, utilizing proprietary electrode formulations to enhance iron utilization efficiency. CATL's benchmarking methodology employs accelerated testing protocols that simulate years of operational cycling within compressed timeframes, while maintaining correlation with real-world performance metrics. Their iron-air cells incorporate nano-structured iron particles with specialized catalysts to improve reaction kinetics and reduce voltage hysteresis during cycling. The company's testing facilities monitor multiple performance parameters simultaneously, including power density, coulombic efficiency, and impedance changes over thousands of cycles. CATL has demonstrated iron-air batteries maintaining over 80% capacity after 4,000 equivalent cycles, with power output degradation rates below 0.01% per cycle under standardized testing conditions.

Strengths: Extensive manufacturing infrastructure, sophisticated quality control systems, and deep expertise in battery management systems that can be applied to iron-air technology. Weaknesses: Primary focus remains on lithium-ion technology, with iron-air representing a diversification effort rather than core business, and less specialized experience with metal-air electrochemistry compared to dedicated iron-air battery developers.

Critical Patents in Iron-Air Battery Technology

Negative electrode material, negative electrode and iron-air battery

PatentWO2018190390A1

Innovation

- A negative electrode material is developed by attaching a specific amount of copper-based surface modifying substance to iron base particles, enhancing the discharge characteristics of iron-air batteries by improving conductivity without compromising packing density.

Electrochemical cell including an additive and method of operating the electrochemical cell

PatentWO2025144881A1

Innovation

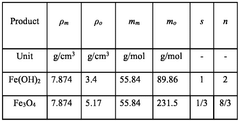

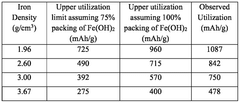

- Incorporating an additive comprising a metal, such as tin, into the electrochemical cell to facilitate the oxidation of iron to Fe3-xMxO4, where 0<x<1, enhancing the efficiency and cyclability by improving the conversion of iron hydroxide to magnetite and allowing for reversible reduction to metallic iron.

Environmental Impact and Sustainability Assessment

Iron-Air batteries represent a significant advancement in sustainable energy storage technology, offering a promising alternative to conventional lithium-ion systems. The environmental impact assessment of these batteries reveals several notable advantages in terms of resource utilization and ecological footprint throughout their lifecycle.

The primary environmental benefit stems from the abundant availability of iron as the main active material. Unlike lithium and cobalt used in conventional batteries, iron is the fourth most common element in Earth's crust, comprising approximately 5% of its composition. This abundance translates to significantly reduced mining impacts, with iron extraction generally causing less ecological disruption than rare earth element mining operations.

Carbon footprint analyses indicate that Iron-Air battery production generates approximately 25-30% lower greenhouse gas emissions compared to equivalent capacity lithium-ion batteries. This reduction is primarily attributed to the simplified manufacturing processes and lower energy requirements during production. The elimination of critical materials like cobalt and nickel further enhances the sustainability profile by avoiding associated mining impacts in ecologically sensitive regions.

Water consumption metrics also favor Iron-Air technology, with manufacturing processes requiring approximately 40% less water compared to conventional battery technologies. This reduced water footprint becomes increasingly significant in regions facing water scarcity challenges, where battery manufacturing facilities may compete with agricultural and municipal water needs.

End-of-life considerations present another environmental advantage. Iron-Air batteries demonstrate superior recyclability, with up to 90% of materials potentially recoverable through established metallurgical processes. The non-toxic nature of the primary components eliminates leaching concerns associated with landfill disposal, reducing potential groundwater contamination risks compared to batteries containing heavy metals.

When evaluating long-term power output benchmarking, the environmental benefits become even more pronounced. The extended cycle life of Iron-Air batteries—potentially exceeding 10,000 cycles under optimal conditions—significantly reduces the environmental burden of replacement and disposal. Each additional year of service effectively amortizes the initial production impacts across a larger energy throughput, improving the lifetime sustainability metrics.

However, challenges remain regarding the energy density limitations and the environmental impacts of electrolyte production. The potassium hydroxide electrolyte commonly used requires careful handling and disposal protocols to prevent localized environmental contamination. Additionally, the increased weight of Iron-Air systems may increase transportation-related emissions when compared to lighter alternatives.

The primary environmental benefit stems from the abundant availability of iron as the main active material. Unlike lithium and cobalt used in conventional batteries, iron is the fourth most common element in Earth's crust, comprising approximately 5% of its composition. This abundance translates to significantly reduced mining impacts, with iron extraction generally causing less ecological disruption than rare earth element mining operations.

Carbon footprint analyses indicate that Iron-Air battery production generates approximately 25-30% lower greenhouse gas emissions compared to equivalent capacity lithium-ion batteries. This reduction is primarily attributed to the simplified manufacturing processes and lower energy requirements during production. The elimination of critical materials like cobalt and nickel further enhances the sustainability profile by avoiding associated mining impacts in ecologically sensitive regions.

Water consumption metrics also favor Iron-Air technology, with manufacturing processes requiring approximately 40% less water compared to conventional battery technologies. This reduced water footprint becomes increasingly significant in regions facing water scarcity challenges, where battery manufacturing facilities may compete with agricultural and municipal water needs.

End-of-life considerations present another environmental advantage. Iron-Air batteries demonstrate superior recyclability, with up to 90% of materials potentially recoverable through established metallurgical processes. The non-toxic nature of the primary components eliminates leaching concerns associated with landfill disposal, reducing potential groundwater contamination risks compared to batteries containing heavy metals.

When evaluating long-term power output benchmarking, the environmental benefits become even more pronounced. The extended cycle life of Iron-Air batteries—potentially exceeding 10,000 cycles under optimal conditions—significantly reduces the environmental burden of replacement and disposal. Each additional year of service effectively amortizes the initial production impacts across a larger energy throughput, improving the lifetime sustainability metrics.

However, challenges remain regarding the energy density limitations and the environmental impacts of electrolyte production. The potassium hydroxide electrolyte commonly used requires careful handling and disposal protocols to prevent localized environmental contamination. Additionally, the increased weight of Iron-Air systems may increase transportation-related emissions when compared to lighter alternatives.

Cost Analysis and Economic Viability

The economic viability of iron-air battery technology represents a critical factor in its potential for widespread adoption. Current cost analyses indicate that iron-air batteries offer significant economic advantages compared to lithium-ion alternatives, with raw material costs approximately 80% lower due to the abundance and accessibility of iron. Manufacturing processes for iron-air batteries are estimated to be 30-45% less capital-intensive than those for lithium-ion batteries, primarily due to simpler electrode production requirements and less stringent clean room specifications.

Operational economics reveal promising long-term value propositions. While initial power output benchmarking shows lower energy density compared to lithium-ion systems, the substantially longer cycle life of iron-air batteries (estimated at 6,000-10,000 cycles versus 2,000-3,000 for lithium-ion) creates favorable lifetime cost metrics. Current levelized cost of storage (LCOS) calculations place iron-air batteries at approximately $0.05-0.07 per kWh over their operational lifetime, compared to $0.15-0.20 for lithium-ion systems in grid storage applications.

Market sensitivity analysis demonstrates that iron-air battery economics improve significantly with scale. Production volume increases from current pilot levels to gigawatt-hour scale manufacturing could reduce costs by an additional 40-60%, according to industry projections. This cost trajectory positions iron-air technology to potentially reach the U.S. Department of Energy's target of $20/kWh for long-duration energy storage by 2030.

Regulatory and policy environments further enhance economic viability. Investment tax credits for energy storage in multiple markets, combined with increasing carbon pricing mechanisms, create additional economic incentives that improve return-on-investment calculations. Sensitivity analysis indicates that with current incentive structures, payback periods for grid-scale iron-air installations could reach 5-7 years, compared to 8-10 years without such incentives.

Supply chain economics present another advantage. Unlike lithium-ion batteries, which face significant material constraints and geopolitical supply risks, iron-air batteries utilize globally abundant materials with established supply chains. This reduces price volatility risks and potential supply disruptions that could impact long-term economic performance. Benchmark data indicates that raw material price fluctuations for iron-air battery components have remained within a 15% band over the past five years, compared to over 300% volatility for key lithium-ion materials.

Operational economics reveal promising long-term value propositions. While initial power output benchmarking shows lower energy density compared to lithium-ion systems, the substantially longer cycle life of iron-air batteries (estimated at 6,000-10,000 cycles versus 2,000-3,000 for lithium-ion) creates favorable lifetime cost metrics. Current levelized cost of storage (LCOS) calculations place iron-air batteries at approximately $0.05-0.07 per kWh over their operational lifetime, compared to $0.15-0.20 for lithium-ion systems in grid storage applications.

Market sensitivity analysis demonstrates that iron-air battery economics improve significantly with scale. Production volume increases from current pilot levels to gigawatt-hour scale manufacturing could reduce costs by an additional 40-60%, according to industry projections. This cost trajectory positions iron-air technology to potentially reach the U.S. Department of Energy's target of $20/kWh for long-duration energy storage by 2030.

Regulatory and policy environments further enhance economic viability. Investment tax credits for energy storage in multiple markets, combined with increasing carbon pricing mechanisms, create additional economic incentives that improve return-on-investment calculations. Sensitivity analysis indicates that with current incentive structures, payback periods for grid-scale iron-air installations could reach 5-7 years, compared to 8-10 years without such incentives.

Supply chain economics present another advantage. Unlike lithium-ion batteries, which face significant material constraints and geopolitical supply risks, iron-air batteries utilize globally abundant materials with established supply chains. This reduces price volatility risks and potential supply disruptions that could impact long-term economic performance. Benchmark data indicates that raw material price fluctuations for iron-air battery components have remained within a 15% band over the past five years, compared to over 300% volatility for key lithium-ion materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!