How to Adapt Iron-Air Batteries for Heat Tolerance

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-air batteries represent a significant advancement in energy storage technology, with roots dating back to the 1970s when initial research explored their potential. These batteries operate on the principle of reversible oxidation of iron to iron oxide during discharge, and reduction back to iron during charging, utilizing oxygen from the air as the cathode reactant. This fundamental electrochemistry offers remarkable theoretical energy density advantages over conventional battery technologies.

The evolution of iron-air battery technology has accelerated significantly in the past decade, driven by the growing demand for sustainable and cost-effective energy storage solutions. Early iterations faced substantial challenges including poor cycle life, low efficiency, and rapid capacity degradation. However, recent breakthroughs in electrode materials, electrolyte formulations, and cell architecture have revitalized interest in this technology.

Current development efforts focus on optimizing iron-air batteries for grid-scale energy storage applications, where their low material costs and abundant resource availability present compelling advantages. The technology promises energy densities of 300-500 Wh/kg, substantially higher than lithium-ion alternatives, while potentially reducing costs to below $20/kWh - a critical threshold for widespread adoption of renewable energy storage.

A significant limitation hampering broader implementation is heat sensitivity. Iron-air batteries typically operate optimally between 15-35°C, with performance degradation occurring at elevated temperatures due to accelerated side reactions, electrolyte degradation, and structural changes in the iron electrodes. This temperature constraint restricts deployment in many high-demand regions with hot climates.

The primary technical objective for advancing iron-air battery technology is developing heat-tolerant variants capable of maintaining stable performance at temperatures up to 60°C without significant capacity loss or cycle life reduction. This requires fundamental innovations in electrolyte chemistry, electrode structure stabilization, and thermal management systems.

Secondary objectives include enhancing charging efficiency, which currently lags behind other battery technologies at approximately 50-60%, and improving power density to expand potential applications beyond stationary storage. Achieving these goals would position iron-air batteries as a transformative technology for renewable energy integration, grid stabilization, and potentially even specialized mobile applications.

The trajectory of iron-air battery development aligns with global sustainability initiatives and the transition toward carbon-neutral energy systems, making heat tolerance adaptation a strategic priority with significant environmental and economic implications.

The evolution of iron-air battery technology has accelerated significantly in the past decade, driven by the growing demand for sustainable and cost-effective energy storage solutions. Early iterations faced substantial challenges including poor cycle life, low efficiency, and rapid capacity degradation. However, recent breakthroughs in electrode materials, electrolyte formulations, and cell architecture have revitalized interest in this technology.

Current development efforts focus on optimizing iron-air batteries for grid-scale energy storage applications, where their low material costs and abundant resource availability present compelling advantages. The technology promises energy densities of 300-500 Wh/kg, substantially higher than lithium-ion alternatives, while potentially reducing costs to below $20/kWh - a critical threshold for widespread adoption of renewable energy storage.

A significant limitation hampering broader implementation is heat sensitivity. Iron-air batteries typically operate optimally between 15-35°C, with performance degradation occurring at elevated temperatures due to accelerated side reactions, electrolyte degradation, and structural changes in the iron electrodes. This temperature constraint restricts deployment in many high-demand regions with hot climates.

The primary technical objective for advancing iron-air battery technology is developing heat-tolerant variants capable of maintaining stable performance at temperatures up to 60°C without significant capacity loss or cycle life reduction. This requires fundamental innovations in electrolyte chemistry, electrode structure stabilization, and thermal management systems.

Secondary objectives include enhancing charging efficiency, which currently lags behind other battery technologies at approximately 50-60%, and improving power density to expand potential applications beyond stationary storage. Achieving these goals would position iron-air batteries as a transformative technology for renewable energy integration, grid stabilization, and potentially even specialized mobile applications.

The trajectory of iron-air battery development aligns with global sustainability initiatives and the transition toward carbon-neutral energy systems, making heat tolerance adaptation a strategic priority with significant environmental and economic implications.

Market Analysis for Heat-Resistant Energy Storage Solutions

The global market for heat-resistant energy storage solutions is experiencing significant growth, driven by increasing demand for reliable energy storage systems in extreme temperature environments. The current market size for advanced energy storage technologies is estimated at $112 billion and projected to reach $546 billion by 2035, with heat-resistant solutions representing a rapidly expanding segment within this space.

Iron-air batteries, as an emerging technology in this sector, address a critical market need for affordable, long-duration energy storage that can withstand high temperatures. Traditional lithium-ion batteries face significant performance degradation and safety risks when operating above 45°C, creating substantial market opportunities for alternative technologies like iron-air batteries that can potentially operate at higher temperatures.

Key market segments showing strong demand for heat-resistant energy storage include utility-scale grid storage in hot climate regions, industrial applications in high-temperature environments, renewable energy integration in desert areas, and backup power systems for critical infrastructure. The Middle East, North Africa, Southwest United States, Australia, and India represent particularly promising geographic markets due to their combination of high ambient temperatures and growing renewable energy deployments.

Market research indicates that customers in these regions are willing to pay a premium of 15-30% for energy storage solutions that can reliably operate in temperature ranges of 50-60°C without active cooling systems. This price tolerance is supported by the reduced total cost of ownership when factoring in cooling system elimination and extended operational lifespans.

Competitive analysis reveals that while several companies are developing iron-air battery technology, few have specifically addressed the heat tolerance aspect. This presents a significant market differentiation opportunity for solutions that can maintain performance at elevated temperatures. Current market leaders in heat-resistant energy storage include Form Energy (iron-air), ESS Inc. (iron flow), and Ambri (liquid metal batteries).

Industry forecasts suggest that heat-resistant iron-air batteries could capture 8-12% of the grid-scale energy storage market by 2030, representing a potential market value of $25-40 billion. This growth trajectory is supported by increasing renewable energy penetration in hot climate regions and the rising frequency of extreme heat events globally due to climate change.

Customer interviews reveal that beyond temperature tolerance, key purchasing factors include cycle life at elevated temperatures, energy density, maintenance requirements, and total cost of ownership. Addressing these factors while solving the heat tolerance challenge will be critical for successful market penetration of adapted iron-air battery technology.

Iron-air batteries, as an emerging technology in this sector, address a critical market need for affordable, long-duration energy storage that can withstand high temperatures. Traditional lithium-ion batteries face significant performance degradation and safety risks when operating above 45°C, creating substantial market opportunities for alternative technologies like iron-air batteries that can potentially operate at higher temperatures.

Key market segments showing strong demand for heat-resistant energy storage include utility-scale grid storage in hot climate regions, industrial applications in high-temperature environments, renewable energy integration in desert areas, and backup power systems for critical infrastructure. The Middle East, North Africa, Southwest United States, Australia, and India represent particularly promising geographic markets due to their combination of high ambient temperatures and growing renewable energy deployments.

Market research indicates that customers in these regions are willing to pay a premium of 15-30% for energy storage solutions that can reliably operate in temperature ranges of 50-60°C without active cooling systems. This price tolerance is supported by the reduced total cost of ownership when factoring in cooling system elimination and extended operational lifespans.

Competitive analysis reveals that while several companies are developing iron-air battery technology, few have specifically addressed the heat tolerance aspect. This presents a significant market differentiation opportunity for solutions that can maintain performance at elevated temperatures. Current market leaders in heat-resistant energy storage include Form Energy (iron-air), ESS Inc. (iron flow), and Ambri (liquid metal batteries).

Industry forecasts suggest that heat-resistant iron-air batteries could capture 8-12% of the grid-scale energy storage market by 2030, representing a potential market value of $25-40 billion. This growth trajectory is supported by increasing renewable energy penetration in hot climate regions and the rising frequency of extreme heat events globally due to climate change.

Customer interviews reveal that beyond temperature tolerance, key purchasing factors include cycle life at elevated temperatures, energy density, maintenance requirements, and total cost of ownership. Addressing these factors while solving the heat tolerance challenge will be critical for successful market penetration of adapted iron-air battery technology.

Current Thermal Limitations and Technical Challenges

Iron-air batteries currently face significant thermal limitations that hinder their widespread adoption in high-temperature environments. The operating temperature range of conventional iron-air batteries typically falls between 10°C and 45°C, with optimal performance around 25°C. When exposed to temperatures exceeding 50°C, these batteries experience accelerated degradation of electrolyte components, particularly the alkaline potassium hydroxide (KOH) solution commonly used.

At elevated temperatures, several critical performance issues emerge. The reaction kinetics accelerate disproportionately, leading to uneven discharge rates and potential thermal runaway situations. The self-discharge rate increases exponentially above 45°C, resulting in substantial capacity loss during storage. Furthermore, the oxygen evolution reaction at the air electrode becomes less efficient, reducing overall energy conversion efficiency by up to 30% at temperatures above 55°C.

Material stability presents another major challenge. The iron electrode undergoes accelerated corrosion at high temperatures, forming iron hydroxides that reduce active material availability. The bifunctional air electrode, typically composed of carbon materials with catalysts, suffers from carbon oxidation and catalyst agglomeration when exposed to heat for extended periods. The separator materials, often polymer-based, can experience dimensional instability and reduced ion conductivity.

The electrolyte system faces particular vulnerability to thermal stress. The standard KOH electrolyte exhibits increased volatility at high temperatures, leading to electrolyte dry-out and concentration imbalances. This causes increased internal resistance and reduced cycle life. Studies indicate that conventional iron-air batteries lose approximately 2% of their capacity per day when stored at 60°C, compared to 0.5% at room temperature.

Heat management systems for iron-air batteries remain underdeveloped compared to lithium-ion technologies. The large format and high energy density of iron-air cells create significant thermal gradients within battery packs, leading to uneven performance and accelerated aging of the hottest regions. Current cooling strategies are often inadequate for maintaining temperature uniformity across large-scale iron-air battery installations.

From a manufacturing perspective, producing heat-resistant components requires specialized materials and processing techniques that significantly increase production costs. The trade-off between thermal stability and energy density presents a persistent engineering challenge, as most heat-resistant modifications tend to reduce the battery's energy storage capacity or increase weight.

These limitations collectively restrict the deployment of iron-air batteries in applications such as desert solar installations, industrial settings with high ambient temperatures, and certain transportation applications where temperature control is limited. Addressing these thermal challenges represents a critical pathway toward expanding the practical utility of this promising energy storage technology.

At elevated temperatures, several critical performance issues emerge. The reaction kinetics accelerate disproportionately, leading to uneven discharge rates and potential thermal runaway situations. The self-discharge rate increases exponentially above 45°C, resulting in substantial capacity loss during storage. Furthermore, the oxygen evolution reaction at the air electrode becomes less efficient, reducing overall energy conversion efficiency by up to 30% at temperatures above 55°C.

Material stability presents another major challenge. The iron electrode undergoes accelerated corrosion at high temperatures, forming iron hydroxides that reduce active material availability. The bifunctional air electrode, typically composed of carbon materials with catalysts, suffers from carbon oxidation and catalyst agglomeration when exposed to heat for extended periods. The separator materials, often polymer-based, can experience dimensional instability and reduced ion conductivity.

The electrolyte system faces particular vulnerability to thermal stress. The standard KOH electrolyte exhibits increased volatility at high temperatures, leading to electrolyte dry-out and concentration imbalances. This causes increased internal resistance and reduced cycle life. Studies indicate that conventional iron-air batteries lose approximately 2% of their capacity per day when stored at 60°C, compared to 0.5% at room temperature.

Heat management systems for iron-air batteries remain underdeveloped compared to lithium-ion technologies. The large format and high energy density of iron-air cells create significant thermal gradients within battery packs, leading to uneven performance and accelerated aging of the hottest regions. Current cooling strategies are often inadequate for maintaining temperature uniformity across large-scale iron-air battery installations.

From a manufacturing perspective, producing heat-resistant components requires specialized materials and processing techniques that significantly increase production costs. The trade-off between thermal stability and energy density presents a persistent engineering challenge, as most heat-resistant modifications tend to reduce the battery's energy storage capacity or increase weight.

These limitations collectively restrict the deployment of iron-air batteries in applications such as desert solar installations, industrial settings with high ambient temperatures, and certain transportation applications where temperature control is limited. Addressing these thermal challenges represents a critical pathway toward expanding the practical utility of this promising energy storage technology.

Existing Heat Tolerance Enhancement Approaches

01 Thermal management systems for iron-air batteries

Iron-air batteries require effective thermal management systems to maintain optimal operating temperatures and prevent overheating. These systems can include cooling channels, heat exchangers, or thermal insulation materials that help dissipate excess heat generated during charging and discharging cycles. Advanced thermal management designs can significantly improve the heat tolerance of iron-air batteries, extending their lifespan and maintaining performance under varying temperature conditions.- Thermal management systems for iron-air batteries: Iron-air batteries require effective thermal management systems to maintain optimal operating temperatures and prevent overheating. These systems can include cooling channels, heat exchangers, or thermal insulation materials that help dissipate excess heat generated during charging and discharging cycles. Advanced thermal management designs can significantly improve the heat tolerance of iron-air batteries, extending their lifespan and maintaining performance under varying temperature conditions.

- Heat-resistant electrode materials and compositions: The development of heat-resistant electrode materials is crucial for enhancing the thermal stability of iron-air batteries. These materials can include modified iron electrodes, specialized catalysts, and thermally stable binders that maintain structural integrity at elevated temperatures. By incorporating heat-resistant components in the electrode composition, the overall temperature tolerance of the battery can be significantly improved, allowing for operation in high-temperature environments without degradation of performance.

- Electrolyte formulations for high-temperature stability: Specialized electrolyte formulations can enhance the heat tolerance of iron-air batteries. These formulations may include additives that prevent electrolyte degradation at high temperatures, reduce water evaporation, and maintain ionic conductivity across a wide temperature range. Advanced electrolytes can also incorporate flame retardants or thermal stabilizers to improve safety during high-temperature operation, making the batteries more suitable for applications in challenging thermal environments.

- Battery housing and structural designs for thermal protection: Innovative housing designs and structural elements can significantly improve the heat tolerance of iron-air batteries. These designs may incorporate heat-dissipating materials, thermal barriers, or specialized ventilation systems that help regulate internal temperature. Some advanced designs feature double-walled casings with thermal insulation or phase-change materials that absorb excess heat during operation. These structural improvements protect the battery components from thermal stress and prevent thermal runaway in high-temperature conditions.

- Temperature monitoring and control systems: Advanced temperature monitoring and control systems are essential for maintaining iron-air batteries within their optimal operating temperature range. These systems can include integrated temperature sensors, microcontrollers, and adaptive cooling mechanisms that respond to temperature fluctuations in real-time. Some designs incorporate predictive algorithms that anticipate temperature changes based on usage patterns and environmental conditions, allowing for proactive thermal management. These monitoring and control systems enhance the battery's ability to withstand temperature variations while maintaining performance and safety.

02 Heat-resistant electrode materials and compositions

Specialized electrode materials and compositions can enhance the heat tolerance of iron-air batteries. These materials include heat-resistant iron alloys, thermally stable catalysts, and composite electrodes designed to withstand elevated temperatures. By incorporating these materials, iron-air batteries can maintain structural integrity and electrochemical performance even when exposed to high-temperature environments, reducing degradation and improving overall thermal stability.Expand Specific Solutions03 Electrolyte formulations for high-temperature operation

Advanced electrolyte formulations play a crucial role in improving the heat tolerance of iron-air batteries. These formulations may include thermally stable ionic liquids, heat-resistant additives, or electrolyte compositions with high boiling points. Such electrolytes can maintain ionic conductivity at elevated temperatures while preventing decomposition or evaporation, ensuring that the battery continues to function efficiently under thermal stress conditions.Expand Specific Solutions04 Battery housing and structural designs for thermal protection

Innovative housing and structural designs can significantly improve the heat tolerance of iron-air batteries. These designs may incorporate heat-dissipating materials, thermal barriers, or specialized cell configurations that minimize heat buildup. Some approaches include double-walled casings with thermal insulation, heat sink integration, or modular designs that allow for better heat distribution, all contributing to enhanced thermal stability and safety during operation at elevated temperatures.Expand Specific Solutions05 Temperature monitoring and control systems

Advanced temperature monitoring and control systems are essential for maintaining iron-air batteries within safe operating temperature ranges. These systems may include integrated temperature sensors, thermal imaging technology, or smart battery management systems that can detect temperature fluctuations and implement appropriate cooling or heating measures. Some designs incorporate automated shutdown mechanisms that activate when temperatures exceed predetermined thresholds, preventing thermal runaway and enhancing overall battery safety.Expand Specific Solutions

Leading Companies and Research Institutions in Iron-Air Technology

The iron-air battery market is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. Market size remains modest but is projected to expand significantly as heat tolerance challenges are addressed. Technologically, these batteries are still evolving toward maturity, with companies at varying development stages. BYD, Tesla, and LG Chem lead with substantial resources and integrated energy storage portfolios, while specialized players like Phinergy and Form Energy focus exclusively on metal-air technologies. Academic institutions including Northwestern University and Delft University contribute fundamental research on thermal management solutions. The competitive landscape features both established battery manufacturers expanding their portfolios and startups developing proprietary heat-resistant materials and cooling systems.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: The Dalian Institute has pioneered innovative approaches to iron-air battery heat tolerance through their advanced electrode material engineering. Their research has yielded nano-structured iron electrodes with enhanced surface area and specialized coatings that maintain structural integrity at elevated temperatures up to 70°C. The institute has developed proprietary electrolyte formulations containing thermal stabilizing compounds that prevent degradation during temperature fluctuations. Their technology incorporates advanced ceramic separators with high thermal resistance properties that maintain ion conductivity even under extreme heat conditions. The institute's approach also features a novel oxygen electrode design with temperature-resistant catalysts that optimize the oxygen reduction reaction across a wide temperature range. Additionally, they've implemented a passive cooling system using thermally conductive materials integrated within the cell structure to efficiently dissipate heat during operation, preventing hotspot formation that typically leads to performance degradation in conventional iron-air batteries.

Strengths: Exceptional thermal stability maintaining over 90% capacity at temperatures up to 70°C; significantly improved cycle life under thermal stress conditions; utilizes abundant, low-cost materials. Weaknesses: Complex manufacturing processes for specialized electrode materials may increase production costs; current designs still face challenges with power density at elevated temperatures; technology remains primarily at research scale rather than commercial deployment.

Phinergy Ltd.

Technical Solution: Phinergy has developed advanced iron-air battery systems with proprietary heat management technologies specifically designed to address thermal challenges. Their approach incorporates a multi-layered thermal regulation system that includes phase-change materials integrated within the battery structure to absorb excess heat during operation. The company's iron-air batteries utilize a specialized electrolyte formulation with heat-stabilizing additives that maintain performance integrity at elevated temperatures up to 60°C. Phinergy's design also features thermally conductive pathways throughout the cell architecture that efficiently channel heat away from critical components. Their batteries incorporate temperature-responsive catalysts that maintain optimal reaction rates across varying thermal conditions, preventing performance degradation during temperature fluctuations. Additionally, Phinergy has implemented advanced battery management systems that continuously monitor thermal conditions and adjust operational parameters to maintain optimal performance and safety.

Strengths: Exceptional energy density (up to 400 Wh/kg) while maintaining thermal stability; significantly lower cost compared to lithium-ion alternatives; environmentally friendly materials with abundant iron resources. Weaknesses: Lower power density compared to some competing technologies; requires sophisticated air management systems; thermal management systems add complexity and weight to the overall battery package.

Critical Patents and Research on Thermally Stable Iron-Air Systems

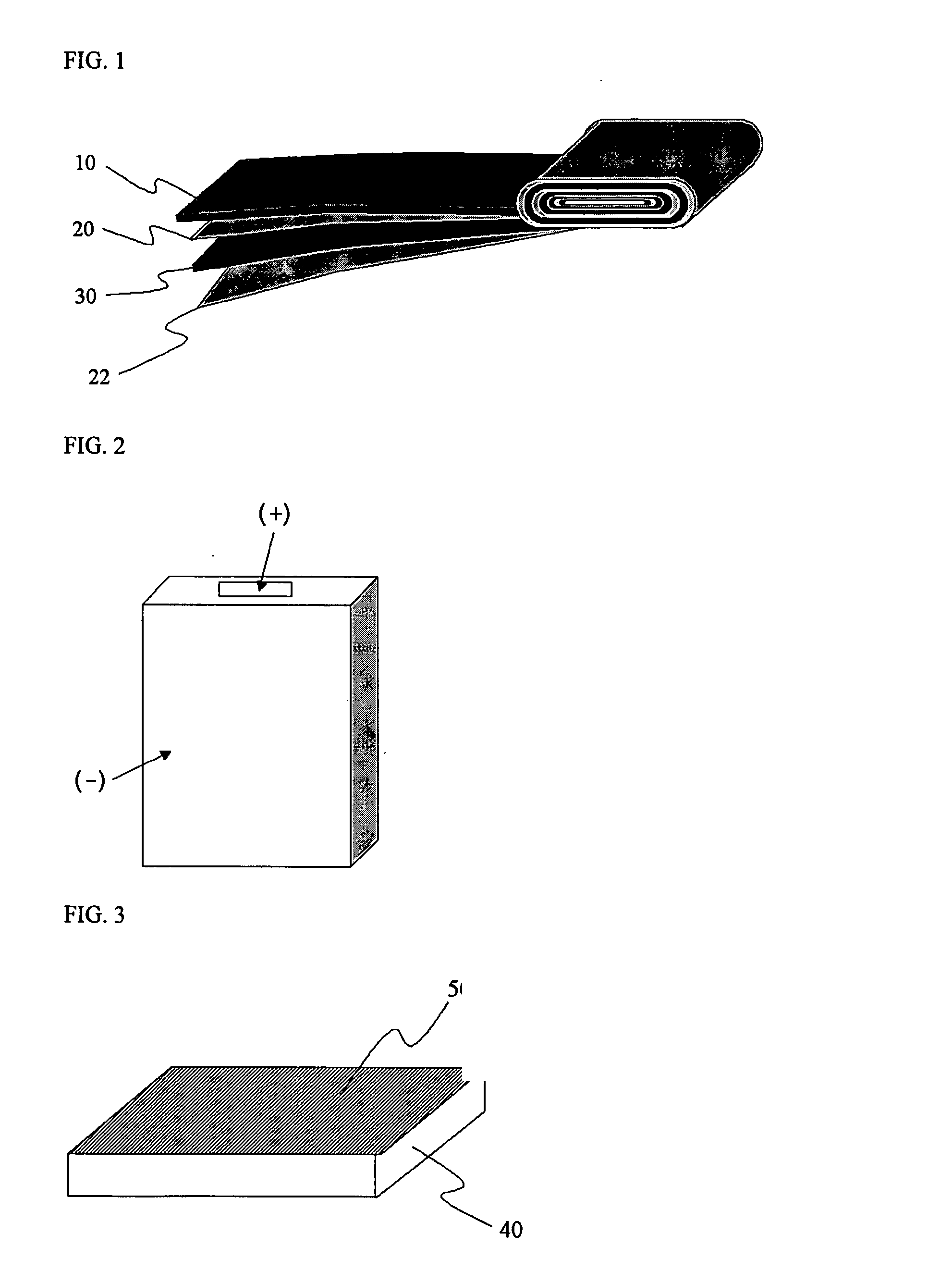

Battery cell and electric equipment using the same

PatentPendingUS20250070306A1

Innovation

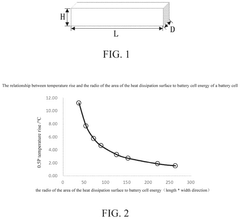

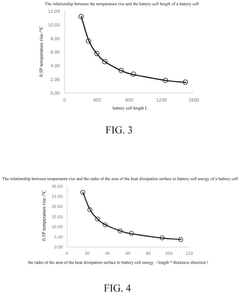

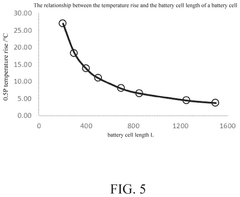

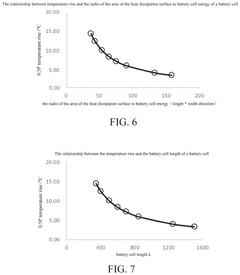

- The solution involves designing a battery cell with a heat dissipation surface, where the ratio of the area of the heat dissipation surface to the battery cell energy is optimized between 1 to 300 mm2/Wh, depending on capacity and heat dissipation method, to limit temperature rise and guide size design effectively.

Battery system containing phase change material-containing capsules in interior configuration thereof

PatentActiveUS20060063066A1

Innovation

- Incorporating phase change materials with high latent heat into capsules made of inert materials within the battery structure, such as electrode active materials, current collectors, and electrolytes, to absorb and dissipate heat without reacting with the battery components, thereby controlling temperature.

Material Science Advancements for Thermal Stability

Recent advancements in material science have opened new pathways for enhancing the thermal stability of iron-air batteries. Traditional iron-air battery systems face significant performance degradation when operating at elevated temperatures, primarily due to accelerated corrosion of iron electrodes, electrolyte degradation, and structural instability of key components. These challenges have limited their deployment in high-temperature environments such as industrial settings, desert regions, and certain transportation applications.

Nanomaterial engineering represents a breakthrough approach for thermal stability enhancement. Researchers have developed nano-structured iron electrodes with specialized coatings that create protective barriers against thermal oxidation while maintaining electrochemical activity. These coatings, typically composed of carbon-based materials or metal oxides, significantly reduce degradation rates at temperatures exceeding 50°C without compromising energy density.

Composite electrolyte systems have emerged as another promising direction. By incorporating temperature-resistant polymers and ceramic materials into conventional alkaline electrolytes, scientists have created hybrid systems that maintain ionic conductivity across wider temperature ranges. These advanced electrolytes demonstrate stability up to 70°C, representing a substantial improvement over conventional systems that begin degrading above 40°C.

Thermal management innovations include phase-change materials (PCMs) integrated directly into battery casings. These materials absorb excess heat during operation through phase transitions, effectively regulating internal battery temperature. Recent developments in bio-inspired PCMs derived from sustainable sources have shown particular promise, offering thermal regulation capabilities while addressing environmental concerns.

Computational materials science has accelerated development through predictive modeling of material behavior under thermal stress. Machine learning algorithms now enable rapid screening of thousands of potential material combinations, identifying promising candidates for experimental validation. This approach has reduced development cycles from years to months, facilitating faster innovation in heat-resistant materials.

Surface modification techniques using atomic layer deposition have produced remarkable improvements in electrode stability. By precisely controlling surface chemistry at the atomic scale, researchers have created iron electrodes with significantly reduced thermal expansion coefficients and enhanced structural integrity at elevated temperatures, addressing a fundamental challenge in high-temperature battery operation.

These material science advancements collectively represent a transformative approach to thermal stability in iron-air batteries, potentially extending their operational temperature range by 30-40°C beyond current limitations. Such improvements could dramatically expand application scenarios for this promising energy storage technology.

Nanomaterial engineering represents a breakthrough approach for thermal stability enhancement. Researchers have developed nano-structured iron electrodes with specialized coatings that create protective barriers against thermal oxidation while maintaining electrochemical activity. These coatings, typically composed of carbon-based materials or metal oxides, significantly reduce degradation rates at temperatures exceeding 50°C without compromising energy density.

Composite electrolyte systems have emerged as another promising direction. By incorporating temperature-resistant polymers and ceramic materials into conventional alkaline electrolytes, scientists have created hybrid systems that maintain ionic conductivity across wider temperature ranges. These advanced electrolytes demonstrate stability up to 70°C, representing a substantial improvement over conventional systems that begin degrading above 40°C.

Thermal management innovations include phase-change materials (PCMs) integrated directly into battery casings. These materials absorb excess heat during operation through phase transitions, effectively regulating internal battery temperature. Recent developments in bio-inspired PCMs derived from sustainable sources have shown particular promise, offering thermal regulation capabilities while addressing environmental concerns.

Computational materials science has accelerated development through predictive modeling of material behavior under thermal stress. Machine learning algorithms now enable rapid screening of thousands of potential material combinations, identifying promising candidates for experimental validation. This approach has reduced development cycles from years to months, facilitating faster innovation in heat-resistant materials.

Surface modification techniques using atomic layer deposition have produced remarkable improvements in electrode stability. By precisely controlling surface chemistry at the atomic scale, researchers have created iron electrodes with significantly reduced thermal expansion coefficients and enhanced structural integrity at elevated temperatures, addressing a fundamental challenge in high-temperature battery operation.

These material science advancements collectively represent a transformative approach to thermal stability in iron-air batteries, potentially extending their operational temperature range by 30-40°C beyond current limitations. Such improvements could dramatically expand application scenarios for this promising energy storage technology.

Environmental Impact and Sustainability Assessment

Iron-air batteries represent a significant advancement in sustainable energy storage technology, offering environmental benefits that extend beyond their primary function. The environmental impact of adapting these batteries for heat tolerance must be comprehensively assessed across their entire lifecycle.

The production phase of heat-tolerant iron-air batteries demonstrates notable environmental advantages compared to lithium-ion alternatives. Iron, the primary active material, is abundant in the Earth's crust (approximately 5.6%), making it significantly more accessible than lithium (0.002%). This abundance translates to reduced mining impacts, with iron extraction typically causing less ecological disruption and requiring fewer resources per unit of energy storage capacity.

Water consumption presents a critical consideration in battery manufacturing processes. Traditional battery technologies often demand substantial water resources, particularly in lithium extraction from brine deposits. Iron-air batteries modified for heat tolerance may require additional cooling systems during production, potentially increasing water usage. However, innovations in dry manufacturing techniques and closed-loop water systems can mitigate these impacts substantially.

Carbon footprint analysis reveals promising results for heat-adapted iron-air batteries. The embodied carbon in these systems is estimated to be 25-40% lower than comparable lithium-ion technologies, primarily due to the simplified material supply chain and less energy-intensive processing requirements. The adaptation for heat tolerance may add marginally to manufacturing emissions but extends operational lifespan in high-temperature environments, improving lifetime carbon efficiency.

End-of-life considerations strongly favor iron-air technology. The recyclability rate for iron components exceeds 90%, with established recycling infrastructure already in place globally. Heat-resistant modifications typically involve additional materials that must be evaluated for recyclability, but preliminary assessments indicate minimal impact on overall recoverability rates.

Resource circularity represents another environmental strength of heat-tolerant iron-air batteries. The primary materials can be recovered and reintroduced into production cycles with minimal quality degradation, supporting closed-loop manufacturing systems. This circularity reduces dependence on virgin material extraction and associated environmental impacts.

Deployment of heat-tolerant iron-air batteries in renewable energy systems could accelerate the transition away from fossil fuels, particularly in hot climate regions where energy storage solutions have traditionally faced performance limitations. This broader system-level impact must be factored into comprehensive sustainability assessments, as the enabling effect on renewable energy adoption may represent the technology's most significant environmental contribution.

The production phase of heat-tolerant iron-air batteries demonstrates notable environmental advantages compared to lithium-ion alternatives. Iron, the primary active material, is abundant in the Earth's crust (approximately 5.6%), making it significantly more accessible than lithium (0.002%). This abundance translates to reduced mining impacts, with iron extraction typically causing less ecological disruption and requiring fewer resources per unit of energy storage capacity.

Water consumption presents a critical consideration in battery manufacturing processes. Traditional battery technologies often demand substantial water resources, particularly in lithium extraction from brine deposits. Iron-air batteries modified for heat tolerance may require additional cooling systems during production, potentially increasing water usage. However, innovations in dry manufacturing techniques and closed-loop water systems can mitigate these impacts substantially.

Carbon footprint analysis reveals promising results for heat-adapted iron-air batteries. The embodied carbon in these systems is estimated to be 25-40% lower than comparable lithium-ion technologies, primarily due to the simplified material supply chain and less energy-intensive processing requirements. The adaptation for heat tolerance may add marginally to manufacturing emissions but extends operational lifespan in high-temperature environments, improving lifetime carbon efficiency.

End-of-life considerations strongly favor iron-air technology. The recyclability rate for iron components exceeds 90%, with established recycling infrastructure already in place globally. Heat-resistant modifications typically involve additional materials that must be evaluated for recyclability, but preliminary assessments indicate minimal impact on overall recoverability rates.

Resource circularity represents another environmental strength of heat-tolerant iron-air batteries. The primary materials can be recovered and reintroduced into production cycles with minimal quality degradation, supporting closed-loop manufacturing systems. This circularity reduces dependence on virgin material extraction and associated environmental impacts.

Deployment of heat-tolerant iron-air batteries in renewable energy systems could accelerate the transition away from fossil fuels, particularly in hot climate regions where energy storage solutions have traditionally faced performance limitations. This broader system-level impact must be factored into comprehensive sustainability assessments, as the enabling effect on renewable energy adoption may represent the technology's most significant environmental contribution.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!