How to Enhance Cycle Efficiency in Iron-Air Batteries

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-air batteries represent a promising energy storage technology that has garnered significant attention in recent years due to their potential for low-cost, long-duration energy storage applications. The concept of iron-air batteries dates back to the 1970s, but recent technological advancements have revitalized interest in this technology as a sustainable alternative to lithium-ion batteries for grid-scale energy storage.

The fundamental operating principle of iron-air batteries involves the reversible oxidation and reduction of iron. During discharge, iron metal is oxidized to iron oxide while oxygen from the air is reduced at the cathode. During charging, this process is reversed. This chemistry offers theoretical energy densities of approximately 1,200 Wh/kg, significantly higher than current lithium-ion technologies, while utilizing earth-abundant materials.

The evolution of iron-air battery technology has been marked by several key developments. Early versions suffered from poor cycle life and efficiency due to hydrogen evolution side reactions and electrode degradation. Recent innovations in electrode design, electrolyte composition, and cell architecture have addressed many of these challenges, leading to improved performance metrics.

Current research trends focus on enhancing the cycle efficiency, which remains a critical limitation. Typical iron-air batteries demonstrate round-trip efficiencies of 40-50%, substantially lower than the 85-95% achieved by lithium-ion batteries. This efficiency gap represents a significant barrier to widespread commercial adoption despite the technology's other advantages.

The primary technical objectives for advancing iron-air battery technology include increasing round-trip efficiency to at least 70%, extending cycle life beyond 5,000 cycles, and developing manufacturing processes suitable for large-scale production. These improvements would position iron-air batteries as economically viable solutions for grid-scale energy storage applications, particularly for durations exceeding 10 hours.

Environmental and economic factors are driving the development of iron-air technology. The abundance of iron in the Earth's crust (approximately 5%) makes it significantly less expensive than lithium, cobalt, and other critical battery materials. Additionally, iron-air batteries present minimal environmental concerns regarding resource depletion and end-of-life disposal.

The strategic importance of this technology lies in its potential to enable greater integration of intermittent renewable energy sources into electrical grids. By providing cost-effective long-duration storage, iron-air batteries could help address the temporal mismatch between renewable energy generation and demand patterns, facilitating the transition to a low-carbon energy system.

The fundamental operating principle of iron-air batteries involves the reversible oxidation and reduction of iron. During discharge, iron metal is oxidized to iron oxide while oxygen from the air is reduced at the cathode. During charging, this process is reversed. This chemistry offers theoretical energy densities of approximately 1,200 Wh/kg, significantly higher than current lithium-ion technologies, while utilizing earth-abundant materials.

The evolution of iron-air battery technology has been marked by several key developments. Early versions suffered from poor cycle life and efficiency due to hydrogen evolution side reactions and electrode degradation. Recent innovations in electrode design, electrolyte composition, and cell architecture have addressed many of these challenges, leading to improved performance metrics.

Current research trends focus on enhancing the cycle efficiency, which remains a critical limitation. Typical iron-air batteries demonstrate round-trip efficiencies of 40-50%, substantially lower than the 85-95% achieved by lithium-ion batteries. This efficiency gap represents a significant barrier to widespread commercial adoption despite the technology's other advantages.

The primary technical objectives for advancing iron-air battery technology include increasing round-trip efficiency to at least 70%, extending cycle life beyond 5,000 cycles, and developing manufacturing processes suitable for large-scale production. These improvements would position iron-air batteries as economically viable solutions for grid-scale energy storage applications, particularly for durations exceeding 10 hours.

Environmental and economic factors are driving the development of iron-air technology. The abundance of iron in the Earth's crust (approximately 5%) makes it significantly less expensive than lithium, cobalt, and other critical battery materials. Additionally, iron-air batteries present minimal environmental concerns regarding resource depletion and end-of-life disposal.

The strategic importance of this technology lies in its potential to enable greater integration of intermittent renewable energy sources into electrical grids. By providing cost-effective long-duration storage, iron-air batteries could help address the temporal mismatch between renewable energy generation and demand patterns, facilitating the transition to a low-carbon energy system.

Market Analysis for Iron-Air Energy Storage Solutions

The global energy storage market is witnessing unprecedented growth, with iron-air battery technology emerging as a promising solution for grid-scale applications. Current market projections indicate that the grid-scale energy storage market will reach approximately $15 billion by 2025, with a compound annual growth rate of 20-25%. Within this expanding landscape, iron-air batteries are positioned to capture significant market share due to their cost advantages and environmental benefits.

The primary market drivers for iron-air energy storage solutions include the increasing integration of renewable energy sources, growing grid instability concerns, and the global push toward decarbonization. As renewable penetration increases, the intermittency challenges create substantial demand for long-duration energy storage solutions, where iron-air batteries excel compared to lithium-ion alternatives.

Cost analysis reveals that iron-air batteries offer a compelling value proposition, with projected costs below $20 per kilowatt-hour for the storage component alone, significantly undercutting lithium-ion batteries which typically range from $80-150 per kilowatt-hour. This cost advantage is primarily derived from the abundance and low cost of iron as the primary material, representing a fraction of the cost of lithium, cobalt, and nickel used in conventional batteries.

Market segmentation shows that utility-scale applications represent the largest potential market for iron-air batteries, particularly for durations exceeding 10 hours. Secondary markets include microgrids, commercial and industrial backup power, and potentially residential applications as the technology matures and costs decrease further.

Regional analysis indicates that North America currently leads in iron-air battery deployment and investment, with significant projects announced in the United States. Europe follows closely, driven by aggressive renewable energy targets and supportive regulatory frameworks. The Asia-Pacific region, particularly China, is rapidly increasing investments in this technology, leveraging their manufacturing capabilities and material supply chains.

Competitive landscape assessment reveals that while established energy storage providers are beginning to incorporate iron-air technology into their portfolios, specialized startups focused exclusively on iron-air batteries are currently driving innovation. These companies have secured substantial funding, with leading players raising over $200 million in venture capital to scale their technologies.

Customer adoption analysis indicates growing interest from utilities and independent power producers, with several pilot projects transitioning to commercial deployments. However, market penetration remains in early stages, with technology validation and demonstration projects being critical to accelerating adoption rates in the coming years.

The primary market drivers for iron-air energy storage solutions include the increasing integration of renewable energy sources, growing grid instability concerns, and the global push toward decarbonization. As renewable penetration increases, the intermittency challenges create substantial demand for long-duration energy storage solutions, where iron-air batteries excel compared to lithium-ion alternatives.

Cost analysis reveals that iron-air batteries offer a compelling value proposition, with projected costs below $20 per kilowatt-hour for the storage component alone, significantly undercutting lithium-ion batteries which typically range from $80-150 per kilowatt-hour. This cost advantage is primarily derived from the abundance and low cost of iron as the primary material, representing a fraction of the cost of lithium, cobalt, and nickel used in conventional batteries.

Market segmentation shows that utility-scale applications represent the largest potential market for iron-air batteries, particularly for durations exceeding 10 hours. Secondary markets include microgrids, commercial and industrial backup power, and potentially residential applications as the technology matures and costs decrease further.

Regional analysis indicates that North America currently leads in iron-air battery deployment and investment, with significant projects announced in the United States. Europe follows closely, driven by aggressive renewable energy targets and supportive regulatory frameworks. The Asia-Pacific region, particularly China, is rapidly increasing investments in this technology, leveraging their manufacturing capabilities and material supply chains.

Competitive landscape assessment reveals that while established energy storage providers are beginning to incorporate iron-air technology into their portfolios, specialized startups focused exclusively on iron-air batteries are currently driving innovation. These companies have secured substantial funding, with leading players raising over $200 million in venture capital to scale their technologies.

Customer adoption analysis indicates growing interest from utilities and independent power producers, with several pilot projects transitioning to commercial deployments. However, market penetration remains in early stages, with technology validation and demonstration projects being critical to accelerating adoption rates in the coming years.

Current Challenges in Iron-Air Battery Cycle Efficiency

Iron-air batteries face significant cycle efficiency challenges that currently limit their widespread commercial adoption. The primary issue stems from the complex electrochemical reactions at the iron electrode, where the conversion between iron and iron oxide during charge-discharge cycles is accompanied by substantial volume changes. These morphological transformations lead to electrode degradation over time, reducing the battery's overall cycle life and efficiency.

Oxygen evolution during charging represents another major challenge. When iron-air batteries charge, oxygen is released at the air electrode, but this process competes with hydrogen evolution, particularly in alkaline electrolytes. This parasitic reaction consumes energy without contributing to the battery's capacity, directly reducing coulombic efficiency by up to 30% in some systems.

Electrolyte management presents multifaceted difficulties. The traditional potassium hydroxide electrolyte, while providing good ionic conductivity, promotes carbonate formation when exposed to atmospheric carbon dioxide. These carbonates gradually accumulate and reduce ionic conductivity, increasing internal resistance and lowering energy efficiency with each cycle. Additionally, water management in the electrolyte remains problematic, as water participates in the electrochemical reactions and its concentration must be carefully maintained.

The air electrode suffers from sluggish oxygen reduction reaction (ORR) kinetics during discharge, requiring high overpotentials that decrease energy efficiency. Current catalysts, typically based on precious metals or transition metal oxides, still fall short of providing the activity needed for practical applications at reasonable cost points.

Self-discharge represents another efficiency drain, occurring when the charged iron electrode spontaneously reacts with water in the electrolyte to produce hydrogen. This phenomenon can result in capacity losses of 1-2% per day in some designs, significantly impacting long-term storage capabilities.

Temperature sensitivity further complicates efficiency optimization. Iron-air batteries show marked performance variations across different operating temperatures, with efficiency typically peaking in a narrow range around room temperature and declining significantly at temperature extremes.

Manufacturing consistency presents additional challenges, as variations in electrode preparation, particularly in iron particle size distribution and air electrode porosity, can lead to significant cell-to-cell performance variations. This inconsistency complicates battery management systems and reduces overall system efficiency in multi-cell configurations.

Oxygen evolution during charging represents another major challenge. When iron-air batteries charge, oxygen is released at the air electrode, but this process competes with hydrogen evolution, particularly in alkaline electrolytes. This parasitic reaction consumes energy without contributing to the battery's capacity, directly reducing coulombic efficiency by up to 30% in some systems.

Electrolyte management presents multifaceted difficulties. The traditional potassium hydroxide electrolyte, while providing good ionic conductivity, promotes carbonate formation when exposed to atmospheric carbon dioxide. These carbonates gradually accumulate and reduce ionic conductivity, increasing internal resistance and lowering energy efficiency with each cycle. Additionally, water management in the electrolyte remains problematic, as water participates in the electrochemical reactions and its concentration must be carefully maintained.

The air electrode suffers from sluggish oxygen reduction reaction (ORR) kinetics during discharge, requiring high overpotentials that decrease energy efficiency. Current catalysts, typically based on precious metals or transition metal oxides, still fall short of providing the activity needed for practical applications at reasonable cost points.

Self-discharge represents another efficiency drain, occurring when the charged iron electrode spontaneously reacts with water in the electrolyte to produce hydrogen. This phenomenon can result in capacity losses of 1-2% per day in some designs, significantly impacting long-term storage capabilities.

Temperature sensitivity further complicates efficiency optimization. Iron-air batteries show marked performance variations across different operating temperatures, with efficiency typically peaking in a narrow range around room temperature and declining significantly at temperature extremes.

Manufacturing consistency presents additional challenges, as variations in electrode preparation, particularly in iron particle size distribution and air electrode porosity, can lead to significant cell-to-cell performance variations. This inconsistency complicates battery management systems and reduces overall system efficiency in multi-cell configurations.

Current Technical Solutions for Cycle Efficiency Enhancement

01 Electrode materials for improved cycle efficiency

Advanced electrode materials play a crucial role in enhancing the cycle efficiency of iron-air batteries. By optimizing the composition and structure of iron electrodes, researchers have developed materials that resist degradation during charge-discharge cycles. These innovations include nano-structured iron particles, composite materials with carbon supports, and specialized coatings that prevent passivation. These materials help maintain battery capacity over multiple cycles and improve overall energy conversion efficiency.- Electrode materials for improved cycle efficiency: Advanced electrode materials play a crucial role in enhancing the cycle efficiency of iron-air batteries. By optimizing the composition and structure of iron electrodes, researchers have developed materials that resist degradation during charge-discharge cycles. These innovations include nanostructured iron particles, composite materials with carbon supports, and specialized coatings that prevent passivation. These materials help maintain active surface area and electrical conductivity throughout multiple cycles, significantly improving the overall efficiency and lifespan of iron-air batteries.

- Electrolyte formulations for enhanced efficiency: Specialized electrolyte formulations have been developed to address efficiency challenges in iron-air batteries. These formulations include additives that prevent iron passivation, reduce hydrogen evolution, and improve oxygen reduction reaction kinetics. By carefully controlling electrolyte composition, pH levels, and ionic conductivity, researchers have achieved more efficient electron transfer and reduced side reactions during cycling. Advanced electrolytes also help manage water balance in the system, which is critical for maintaining consistent performance over multiple charge-discharge cycles.

- Air electrode design and catalysts: Innovations in air electrode design and catalyst systems have significantly improved the cycle efficiency of iron-air batteries. Bifunctional catalysts that effectively facilitate both oxygen reduction during discharge and oxygen evolution during charging reduce energy losses associated with these reactions. Advanced air electrode architectures featuring optimized porosity, hydrophobicity, and catalyst distribution enable more efficient oxygen transport and utilization. These improvements reduce polarization losses and increase the round-trip efficiency of iron-air battery systems.

- Battery management systems and charging protocols: Sophisticated battery management systems and optimized charging protocols have been developed to maximize the cycle efficiency of iron-air batteries. These systems monitor and control critical parameters such as temperature, state of charge, and current density during operation. Advanced charging algorithms prevent overcharging and minimize side reactions that would otherwise reduce efficiency. Pulse charging techniques and regenerative cycling methods help maintain electrode activity and prevent capacity fade over extended cycling, resulting in higher overall energy efficiency and longer battery life.

- Cell design and system integration: Innovative cell designs and system integration approaches have been developed to enhance the cycle efficiency of iron-air batteries. These include optimized cell geometries that improve reactant distribution, reduce internal resistance, and facilitate heat management. Advanced flow field designs enable more uniform reaction rates across electrode surfaces. Integrated systems that incorporate auxiliary components for gas management, humidity control, and thermal regulation help maintain optimal operating conditions throughout cycling. These design improvements collectively contribute to higher energy efficiency, better capacity retention, and extended cycle life.

02 Electrolyte formulations for enhanced performance

Specialized electrolyte formulations significantly impact the cycle efficiency of iron-air batteries. Researchers have developed electrolytes with additives that prevent iron passivation, reduce hydrogen evolution, and facilitate oxygen reduction reactions. These formulations often include alkaline solutions with specific conductivity enhancers and stabilizing agents. By optimizing the electrolyte composition, these innovations help maintain consistent performance across multiple charge-discharge cycles and extend battery lifespan.Expand Specific Solutions03 Air electrode design and oxygen management

Efficient oxygen management at the air electrode is essential for maintaining high cycle efficiency in iron-air batteries. Innovations in this area include bifunctional catalysts that facilitate both oxygen reduction and evolution reactions, porous electrode structures that optimize gas diffusion, and hydrophobic coatings that prevent flooding. These design improvements help reduce voltage losses during cycling, improve reaction kinetics, and maintain consistent performance over extended periods of operation.Expand Specific Solutions04 Battery management systems for efficiency optimization

Advanced battery management systems specifically designed for iron-air batteries help optimize cycle efficiency through intelligent control strategies. These systems monitor and regulate charging parameters, manage thermal conditions, and implement adaptive cycling protocols based on battery state. By preventing overcharging, controlling discharge rates, and maintaining optimal operating temperatures, these management systems extend battery life and maintain high energy conversion efficiency throughout the battery lifecycle.Expand Specific Solutions05 Cell architecture and system integration

Innovative cell architectures and system integration approaches significantly impact the cycle efficiency of iron-air batteries. These designs focus on optimizing the spatial arrangement of components, improving electrolyte circulation, and enhancing heat management. Some approaches include modular designs that allow for easy maintenance, integrated cooling systems that maintain optimal operating temperatures, and specialized sealing methods that prevent electrolyte leakage and air contamination. These architectural innovations help maintain consistent performance across multiple charge-discharge cycles.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The iron-air battery market is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market size is projected to expand rapidly as renewable energy storage demands increase, potentially reaching several billion dollars by 2030. Technologically, cycle efficiency remains a critical challenge, with leading companies pursuing different approaches. Form Energy has made substantial progress with its multi-day iron-air battery technology, while established players like Toyota, CATL, and Panasonic leverage their battery expertise to address efficiency limitations. Academic institutions including California Institute of Technology and Tsinghua University contribute fundamental research on electrode materials and electrolyte formulations. The competitive landscape features both specialized startups and diversified energy storage corporations working to overcome the iron oxidation and reduction inefficiencies that currently limit widespread adoption.

Form Energy, Inc.

Technical Solution: Form Energy has pioneered a commercial iron-air battery system specifically designed for long-duration energy storage. Their technology utilizes reversible rusting, where iron pellets are converted to rust when the battery discharges, and then converted back to iron when charging using an electric current. To enhance cycle efficiency, Form Energy employs a proprietary electrolyte chemistry that minimizes parasitic reactions and incorporates advanced electrode architectures with optimized porosity. Their system includes specialized oxygen evolution catalysts to reduce charging overpotentials and utilizes precise electronic control systems that manage charge/discharge rates based on real-time performance metrics. Form Energy's batteries are designed to deliver 100+ hours of energy storage at system costs competitive with conventional power plants, targeting less than $20/kWh, making them significantly less expensive than lithium-ion batteries for long-duration applications.

Strengths: Extremely low material costs using earth-abundant iron; scalable to grid-level storage; environmentally benign materials; exceptionally long discharge duration (100+ hours). Weaknesses: Lower round-trip efficiency compared to lithium-ion (approximately 50-70%); larger physical footprint due to lower energy density; primarily suited for stationary applications rather than mobile use cases.

Hunan University of Science & Technology

Technical Solution: Hunan University of Science & Technology has developed innovative approaches to iron-air battery efficiency enhancement through advanced electrode engineering and electrolyte optimization. Their research team has focused on creating hierarchically structured iron electrodes with controlled porosity that facilitate both electron transfer and oxygen diffusion. They've implemented nano-structuring techniques to increase the active surface area of iron electrodes while maintaining structural integrity over multiple charge-discharge cycles. The university's researchers have also developed composite electrolyte systems incorporating ionic liquids that suppress hydrogen evolution—a major efficiency-reducing side reaction in iron-air batteries. Their work includes the integration of bifunctional oxygen catalysts based on transition metal oxides that reduce overpotentials during both oxygen reduction and evolution reactions, thereby improving round-trip efficiency. Recent publications demonstrate cycle efficiency improvements of up to 15% compared to conventional iron-air configurations.

Strengths: Strong fundamental research approach with innovative materials science solutions; cost-effective methodologies suitable for commercial scaling; comprehensive understanding of reaction mechanisms. Weaknesses: Less immediate industrial application capability compared to commercial entities; research findings may require additional engineering development before commercial implementation; limited large-scale manufacturing experience.

Critical Patents and Research on Iron-Air Battery Efficiency

Iron-air rechargeable battery

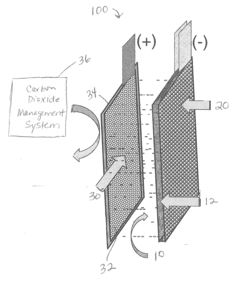

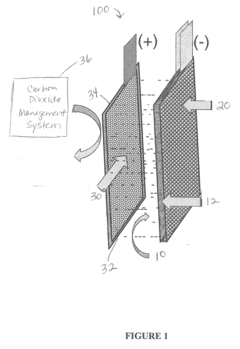

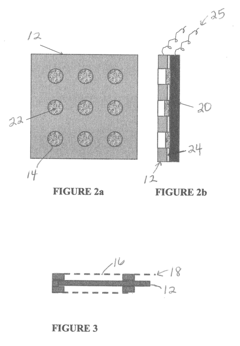

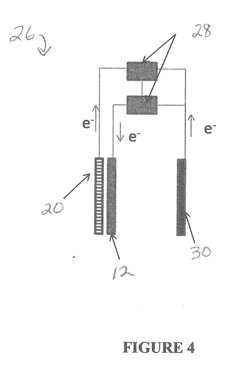

PatentActiveUS20120187918A1

Innovation

- Incorporating self-assembling organic sulfur-based additives to inhibit hydrogen evolution, using non-toxic bismuth additives to suppress parasitic reactions, integrating a bilayer composite electrode for hydrogen utilization, employing nano-structured corrosion-resistant substrates for the air electrode, and implementing a carbon dioxide management system to enhance efficiency and durability.

Iron-air rechargeable battery

PatentWO2012012731A2

Innovation

- Incorporating self-assembling organic sulfur-based additives to inhibit hydrogen evolution, using non-toxic bismuth additives to suppress parasitic reactions, integrating a bilayer composite electrode for hydrogen utilization, employing nano-structured corrosion-resistant substrates for the air electrode, and implementing a thin film nano-structured catalyst layer with a carbon dioxide management system to enhance efficiency and durability.

Environmental Impact and Sustainability Assessment

Iron-air batteries represent a promising sustainable energy storage solution due to their use of abundant, low-cost materials. The environmental footprint of these batteries is significantly smaller than conventional lithium-ion technologies, primarily because iron is the fourth most abundant element in the Earth's crust, requiring less intensive mining operations. This abundance translates to reduced habitat disruption and lower energy consumption during raw material extraction phases.

The manufacturing process of iron-air batteries demonstrates considerable environmental advantages. Carbon emissions associated with production are estimated to be 25-40% lower than those of lithium-ion batteries, primarily due to less energy-intensive material processing requirements. Additionally, the water usage in manufacturing is approximately 30% lower, contributing to overall resource conservation.

From a life-cycle perspective, enhancing cycle efficiency directly correlates with improved sustainability metrics. Each percentage point improvement in cycle efficiency extends battery lifespan, thereby reducing the frequency of replacement and associated manufacturing impacts. Current research indicates that optimizing iron electrode structures could potentially extend cycle life by 200-300%, dramatically reducing waste generation over time.

End-of-life considerations reveal another significant advantage of iron-air batteries. The primary components—iron and electrolyte materials—are highly recyclable, with recovery rates potentially exceeding 90% using existing metallurgical processes. This circular economy potential stands in stark contrast to the complex recycling challenges posed by conventional battery technologies.

When evaluating grid-scale implementation, iron-air batteries with enhanced cycle efficiency could reduce the carbon intensity of energy storage by an estimated 0.15-0.25 kg CO2e/kWh compared to alternative storage technologies. This improvement becomes particularly significant when considering the projected scale of deployment needed for renewable energy integration.

Safety considerations also factor into sustainability assessments. Iron-air batteries contain non-toxic, non-flammable components, eliminating many of the environmental and safety risks associated with thermal runaway events in conventional batteries. This reduces potential environmental contamination risks and improves overall system resilience.

Future sustainability improvements will likely focus on electrolyte formulations that minimize environmental impact while maximizing performance. Research into bio-derived electrolyte additives shows promise for further reducing the environmental footprint while simultaneously addressing cycle efficiency challenges through improved iron electrode stability.

The manufacturing process of iron-air batteries demonstrates considerable environmental advantages. Carbon emissions associated with production are estimated to be 25-40% lower than those of lithium-ion batteries, primarily due to less energy-intensive material processing requirements. Additionally, the water usage in manufacturing is approximately 30% lower, contributing to overall resource conservation.

From a life-cycle perspective, enhancing cycle efficiency directly correlates with improved sustainability metrics. Each percentage point improvement in cycle efficiency extends battery lifespan, thereby reducing the frequency of replacement and associated manufacturing impacts. Current research indicates that optimizing iron electrode structures could potentially extend cycle life by 200-300%, dramatically reducing waste generation over time.

End-of-life considerations reveal another significant advantage of iron-air batteries. The primary components—iron and electrolyte materials—are highly recyclable, with recovery rates potentially exceeding 90% using existing metallurgical processes. This circular economy potential stands in stark contrast to the complex recycling challenges posed by conventional battery technologies.

When evaluating grid-scale implementation, iron-air batteries with enhanced cycle efficiency could reduce the carbon intensity of energy storage by an estimated 0.15-0.25 kg CO2e/kWh compared to alternative storage technologies. This improvement becomes particularly significant when considering the projected scale of deployment needed for renewable energy integration.

Safety considerations also factor into sustainability assessments. Iron-air batteries contain non-toxic, non-flammable components, eliminating many of the environmental and safety risks associated with thermal runaway events in conventional batteries. This reduces potential environmental contamination risks and improves overall system resilience.

Future sustainability improvements will likely focus on electrolyte formulations that minimize environmental impact while maximizing performance. Research into bio-derived electrolyte additives shows promise for further reducing the environmental footprint while simultaneously addressing cycle efficiency challenges through improved iron electrode stability.

Cost Analysis and Economic Viability

The economic viability of iron-air batteries hinges on several interconnected cost factors that significantly impact their market competitiveness. Current cost estimates for iron-air battery systems range from $60-100 per kilowatt-hour (kWh), positioning them favorably against lithium-ion alternatives which typically cost $130-160/kWh. This cost advantage stems primarily from the abundant and inexpensive nature of iron as the primary electrode material, with global iron ore prices averaging $85-120 per ton compared to lithium carbonate at $15,000-20,000 per ton.

Manufacturing processes for iron-air batteries demonstrate promising economies of scale potential. Analysis indicates that production costs could decrease by approximately 15-20% with each doubling of manufacturing capacity, following typical learning curve models observed in other energy storage technologies. The capital expenditure required for establishing production facilities is estimated at $50-80 million for a 1 GWh annual capacity plant, representing a lower barrier to entry compared to lithium-ion manufacturing facilities.

Cycle efficiency improvements directly translate to economic benefits through extended battery lifespans. Current iron-air batteries achieving 350-500 cycles at 50% depth of discharge could potentially reach 1,000+ cycles with advanced efficiency enhancements, reducing the levelized cost of storage (LCOS) from current estimates of $0.20-0.25/kWh to potentially $0.08-0.12/kWh. This improvement would position iron-air technology as highly competitive in grid-scale applications.

Operational costs present both challenges and opportunities. While maintenance requirements remain relatively low due to the simple chemistry, the energy input costs for recharging represent a significant factor in total ownership expenses. Efficiency improvements that reduce charging energy requirements by 15-20% could decrease lifetime operational costs by $20-30/kWh of capacity, substantially enhancing economic viability in price-sensitive markets.

Market adoption scenarios indicate that iron-air batteries could capture 8-12% of the stationary energy storage market by 2030, representing a $4-6 billion annual market opportunity. This projection assumes continued efficiency improvements and manufacturing scale-up. Sensitivity analysis suggests that each 5% improvement in cycle efficiency correlates with approximately 7-9% enhancement in overall economic returns, underscoring the critical importance of efficiency optimization in commercialization strategies.

Regulatory factors and carbon pricing mechanisms further strengthen the economic case for iron-air technology. With carbon taxes or credits valued at $30-50 per ton of CO2 equivalent, the sustainable production profile of iron-air batteries could provide an additional $5-8/kWh advantage over fossil fuel alternatives in regulated markets, creating additional economic incentives for adoption and continued technological development.

Manufacturing processes for iron-air batteries demonstrate promising economies of scale potential. Analysis indicates that production costs could decrease by approximately 15-20% with each doubling of manufacturing capacity, following typical learning curve models observed in other energy storage technologies. The capital expenditure required for establishing production facilities is estimated at $50-80 million for a 1 GWh annual capacity plant, representing a lower barrier to entry compared to lithium-ion manufacturing facilities.

Cycle efficiency improvements directly translate to economic benefits through extended battery lifespans. Current iron-air batteries achieving 350-500 cycles at 50% depth of discharge could potentially reach 1,000+ cycles with advanced efficiency enhancements, reducing the levelized cost of storage (LCOS) from current estimates of $0.20-0.25/kWh to potentially $0.08-0.12/kWh. This improvement would position iron-air technology as highly competitive in grid-scale applications.

Operational costs present both challenges and opportunities. While maintenance requirements remain relatively low due to the simple chemistry, the energy input costs for recharging represent a significant factor in total ownership expenses. Efficiency improvements that reduce charging energy requirements by 15-20% could decrease lifetime operational costs by $20-30/kWh of capacity, substantially enhancing economic viability in price-sensitive markets.

Market adoption scenarios indicate that iron-air batteries could capture 8-12% of the stationary energy storage market by 2030, representing a $4-6 billion annual market opportunity. This projection assumes continued efficiency improvements and manufacturing scale-up. Sensitivity analysis suggests that each 5% improvement in cycle efficiency correlates with approximately 7-9% enhancement in overall economic returns, underscoring the critical importance of efficiency optimization in commercialization strategies.

Regulatory factors and carbon pricing mechanisms further strengthen the economic case for iron-air technology. With carbon taxes or credits valued at $30-50 per ton of CO2 equivalent, the sustainable production profile of iron-air batteries could provide an additional $5-8/kWh advantage over fossil fuel alternatives in regulated markets, creating additional economic incentives for adoption and continued technological development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!