Measuring Mechanical Stability of Iron-Air Batteries

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-air batteries represent a promising energy storage technology that has garnered significant attention in recent years due to their potential for low-cost, long-duration energy storage applications. The concept of iron-air batteries dates back to the 1970s, but recent technological advancements have revitalized interest in this technology as a sustainable alternative to lithium-ion batteries for grid-scale energy storage.

The fundamental operating principle of iron-air batteries involves the oxidation of iron to iron oxide during discharge and the reduction back to iron during charging, utilizing oxygen from the air as the cathode reactant. This chemistry offers theoretical energy densities of approximately 1,200 Wh/kg, significantly higher than lead-acid batteries and comparable to some lithium-ion chemistries.

The evolution of iron-air battery technology has been marked by several key developments, including improvements in electrode materials, electrolyte formulations, and cell architectures. Early iterations faced challenges related to limited cycle life, poor round-trip efficiency, and rapid capacity degradation. However, recent innovations in nanotechnology and advanced materials science have addressed many of these limitations, leading to enhanced performance metrics.

A critical aspect of iron-air battery development that remains underexplored is the mechanical stability of these systems. As iron undergoes oxidation and reduction during cycling, significant volume changes occur within the electrode structure, leading to mechanical stresses that can compromise battery integrity and performance over time. Understanding and quantifying these mechanical phenomena is essential for developing robust, long-lasting iron-air battery systems.

The primary technical objectives for measuring mechanical stability in iron-air batteries include developing standardized testing protocols, identifying key performance indicators, and establishing correlations between mechanical properties and electrochemical performance. These measurements must account for the unique challenges posed by the iron electrode's volume expansion, which can exceed 200% during the Fe to Fe(OH)₂/Fe₃O₄ transition.

Current research aims to develop in-situ and ex-situ characterization techniques capable of monitoring structural changes at multiple length scales, from atomic-level transformations to macroscopic deformations. Advanced imaging techniques, such as synchrotron X-ray tomography and scanning electron microscopy, combined with mechanical testing methods like nanoindentation and stress analysis, are being explored to provide comprehensive insights into the mechanical behavior of iron electrodes.

The ultimate goal of this technical investigation is to establish design principles and material selection criteria that optimize the mechanical stability of iron-air batteries, thereby extending cycle life and improving overall system reliability for grid-scale energy storage applications. This work is crucial for enabling the commercial viability of iron-air technology as a sustainable solution for long-duration energy storage in renewable energy systems.

The fundamental operating principle of iron-air batteries involves the oxidation of iron to iron oxide during discharge and the reduction back to iron during charging, utilizing oxygen from the air as the cathode reactant. This chemistry offers theoretical energy densities of approximately 1,200 Wh/kg, significantly higher than lead-acid batteries and comparable to some lithium-ion chemistries.

The evolution of iron-air battery technology has been marked by several key developments, including improvements in electrode materials, electrolyte formulations, and cell architectures. Early iterations faced challenges related to limited cycle life, poor round-trip efficiency, and rapid capacity degradation. However, recent innovations in nanotechnology and advanced materials science have addressed many of these limitations, leading to enhanced performance metrics.

A critical aspect of iron-air battery development that remains underexplored is the mechanical stability of these systems. As iron undergoes oxidation and reduction during cycling, significant volume changes occur within the electrode structure, leading to mechanical stresses that can compromise battery integrity and performance over time. Understanding and quantifying these mechanical phenomena is essential for developing robust, long-lasting iron-air battery systems.

The primary technical objectives for measuring mechanical stability in iron-air batteries include developing standardized testing protocols, identifying key performance indicators, and establishing correlations between mechanical properties and electrochemical performance. These measurements must account for the unique challenges posed by the iron electrode's volume expansion, which can exceed 200% during the Fe to Fe(OH)₂/Fe₃O₄ transition.

Current research aims to develop in-situ and ex-situ characterization techniques capable of monitoring structural changes at multiple length scales, from atomic-level transformations to macroscopic deformations. Advanced imaging techniques, such as synchrotron X-ray tomography and scanning electron microscopy, combined with mechanical testing methods like nanoindentation and stress analysis, are being explored to provide comprehensive insights into the mechanical behavior of iron electrodes.

The ultimate goal of this technical investigation is to establish design principles and material selection criteria that optimize the mechanical stability of iron-air batteries, thereby extending cycle life and improving overall system reliability for grid-scale energy storage applications. This work is crucial for enabling the commercial viability of iron-air technology as a sustainable solution for long-duration energy storage in renewable energy systems.

Market Analysis for Iron-Air Energy Storage Solutions

The iron-air battery market is experiencing significant growth as the global energy storage sector expands rapidly. Current market valuations indicate that grid-scale energy storage solutions are projected to reach $30 billion by 2030, with iron-air technology positioned to capture a substantial portion of this market due to its cost advantages and environmental benefits. The compound annual growth rate (CAGR) for long-duration energy storage technologies is estimated at 24% through 2027, outpacing traditional lithium-ion solutions.

Market demand for iron-air batteries is primarily driven by the increasing integration of renewable energy sources into power grids worldwide. As solar and wind power generation continues to grow at rates exceeding 10% annually, the need for cost-effective, long-duration energy storage becomes critical for grid stability. Iron-air batteries, with their 100+ hour discharge capability, address a market gap that lithium-ion batteries cannot efficiently fill.

Utility companies represent the largest customer segment, accounting for approximately 65% of potential iron-air battery deployments. These organizations seek solutions that can provide multi-day backup power during extreme weather events and balance seasonal energy production variations. Commercial and industrial users constitute roughly 25% of the market, primarily interested in peak shaving applications and resilience against grid outages.

Geographically, North America currently leads market development with several pilot projects underway, particularly in regions with high renewable penetration like California and Texas. Europe follows closely, with significant interest from countries with ambitious decarbonization targets such as Germany and Denmark. The Asia-Pacific region, particularly China and Australia, represents the fastest-growing market segment with projected growth rates of 30% annually.

Competitive analysis reveals that Form Energy has established early market leadership with their iron-air technology, securing over $450 million in funding and multiple utility partnerships. Traditional energy storage providers like Tesla, Fluence, and ESS Inc. are monitoring the space closely, with some beginning R&D efforts in iron-air technology. Several startups focused specifically on mechanical stability innovations have emerged, including materials science companies developing specialized iron electrodes and battery housing designs.

Market barriers include the technology's relatively low energy density compared to lithium-ion, making it less suitable for space-constrained applications. Additionally, the lack of established performance standards specifically for mechanical stability in iron-air systems creates uncertainty for potential customers. However, the market opportunity remains substantial as the technology addresses the critical price point of under $20 per kilowatt-hour for long-duration storage, a threshold necessary for widespread adoption.

Market demand for iron-air batteries is primarily driven by the increasing integration of renewable energy sources into power grids worldwide. As solar and wind power generation continues to grow at rates exceeding 10% annually, the need for cost-effective, long-duration energy storage becomes critical for grid stability. Iron-air batteries, with their 100+ hour discharge capability, address a market gap that lithium-ion batteries cannot efficiently fill.

Utility companies represent the largest customer segment, accounting for approximately 65% of potential iron-air battery deployments. These organizations seek solutions that can provide multi-day backup power during extreme weather events and balance seasonal energy production variations. Commercial and industrial users constitute roughly 25% of the market, primarily interested in peak shaving applications and resilience against grid outages.

Geographically, North America currently leads market development with several pilot projects underway, particularly in regions with high renewable penetration like California and Texas. Europe follows closely, with significant interest from countries with ambitious decarbonization targets such as Germany and Denmark. The Asia-Pacific region, particularly China and Australia, represents the fastest-growing market segment with projected growth rates of 30% annually.

Competitive analysis reveals that Form Energy has established early market leadership with their iron-air technology, securing over $450 million in funding and multiple utility partnerships. Traditional energy storage providers like Tesla, Fluence, and ESS Inc. are monitoring the space closely, with some beginning R&D efforts in iron-air technology. Several startups focused specifically on mechanical stability innovations have emerged, including materials science companies developing specialized iron electrodes and battery housing designs.

Market barriers include the technology's relatively low energy density compared to lithium-ion, making it less suitable for space-constrained applications. Additionally, the lack of established performance standards specifically for mechanical stability in iron-air systems creates uncertainty for potential customers. However, the market opportunity remains substantial as the technology addresses the critical price point of under $20 per kilowatt-hour for long-duration storage, a threshold necessary for widespread adoption.

Current Challenges in Iron-Air Battery Mechanical Stability

Iron-air batteries face significant mechanical stability challenges that currently impede their widespread commercial adoption. The primary issue stems from the volumetric changes during charge-discharge cycles, with iron electrodes experiencing up to 300% volume expansion during oxidation. This expansion-contraction cycle creates substantial mechanical stress within the battery structure, leading to electrode crumbling, delamination from current collectors, and eventual capacity fade.

The air electrode presents its own set of mechanical challenges. Porous carbon structures that facilitate oxygen diffusion are susceptible to structural collapse under repeated cycling. The three-phase boundary where solid catalyst, liquid electrolyte, and gaseous oxygen interact is particularly vulnerable to mechanical degradation, affecting the oxygen reduction and evolution reactions critical to battery function.

Current measurement techniques for quantifying these mechanical stability issues remain inadequate. Traditional electrochemical testing provides indirect evidence of mechanical failure but fails to capture real-time structural changes. Researchers have attempted to adapt techniques from other fields, including in-situ X-ray diffraction and acoustic emission monitoring, but these methods often lack the resolution needed to detect microscopic cracks and deformations before catastrophic failure occurs.

The electrolyte system introduces additional complexity to mechanical stability assessment. Alkaline electrolytes, typically used in iron-air batteries, can accelerate corrosion of structural components under mechanical stress. The interaction between mechanical forces and chemical degradation creates a complex failure mechanism that current measurement protocols struggle to characterize accurately.

Temperature fluctuations during operation further complicate mechanical stability measurements. Thermal expansion coefficients differ across battery components, introducing additional stress factors that are difficult to isolate from purely mechanical effects. Most current testing protocols fail to account for these thermo-mechanical interactions.

Standardization remains a significant challenge in the field. Various research groups employ different methodologies for mechanical stability assessment, making direct comparisons between studies problematic. The lack of industry-wide standards for mechanical testing of iron-air batteries hinders collaborative progress and technology transfer from laboratory to commercial applications.

Long-term mechanical stability prediction represents perhaps the most formidable challenge. Accelerated testing protocols often fail to accurately simulate the gradual mechanical degradation that occurs over thousands of cycles in real-world applications. Bridging this gap between short-term laboratory testing and long-term performance prediction requires innovative approaches to mechanical stability measurement that can reliably extrapolate degradation trends.

The air electrode presents its own set of mechanical challenges. Porous carbon structures that facilitate oxygen diffusion are susceptible to structural collapse under repeated cycling. The three-phase boundary where solid catalyst, liquid electrolyte, and gaseous oxygen interact is particularly vulnerable to mechanical degradation, affecting the oxygen reduction and evolution reactions critical to battery function.

Current measurement techniques for quantifying these mechanical stability issues remain inadequate. Traditional electrochemical testing provides indirect evidence of mechanical failure but fails to capture real-time structural changes. Researchers have attempted to adapt techniques from other fields, including in-situ X-ray diffraction and acoustic emission monitoring, but these methods often lack the resolution needed to detect microscopic cracks and deformations before catastrophic failure occurs.

The electrolyte system introduces additional complexity to mechanical stability assessment. Alkaline electrolytes, typically used in iron-air batteries, can accelerate corrosion of structural components under mechanical stress. The interaction between mechanical forces and chemical degradation creates a complex failure mechanism that current measurement protocols struggle to characterize accurately.

Temperature fluctuations during operation further complicate mechanical stability measurements. Thermal expansion coefficients differ across battery components, introducing additional stress factors that are difficult to isolate from purely mechanical effects. Most current testing protocols fail to account for these thermo-mechanical interactions.

Standardization remains a significant challenge in the field. Various research groups employ different methodologies for mechanical stability assessment, making direct comparisons between studies problematic. The lack of industry-wide standards for mechanical testing of iron-air batteries hinders collaborative progress and technology transfer from laboratory to commercial applications.

Long-term mechanical stability prediction represents perhaps the most formidable challenge. Accelerated testing protocols often fail to accurately simulate the gradual mechanical degradation that occurs over thousands of cycles in real-world applications. Bridging this gap between short-term laboratory testing and long-term performance prediction requires innovative approaches to mechanical stability measurement that can reliably extrapolate degradation trends.

Existing Mechanical Stability Testing Methodologies

01 Electrode structure design for mechanical stability

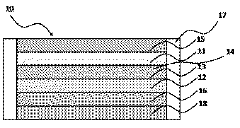

Specific electrode structure designs can significantly enhance the mechanical stability of iron-air batteries. These designs include reinforced electrode frameworks, composite structures that resist deformation during charge-discharge cycles, and specialized geometries that minimize physical stress. Such structural innovations help maintain electrode integrity during operation, preventing degradation that would otherwise lead to capacity loss and battery failure.- Electrode structure design for mechanical stability: The mechanical stability of iron-air batteries can be enhanced through innovative electrode structure designs. These include using reinforced iron electrodes with specific geometries, incorporating supporting frameworks, and developing composite structures that can withstand volume changes during charge-discharge cycles. Such designs help prevent electrode deformation and degradation, which are common causes of mechanical failure in iron-air batteries.

- Binder and additive formulations: Specialized binder and additive formulations play a crucial role in improving the mechanical stability of iron-air batteries. These formulations include polymer binders that enhance adhesion between active materials and current collectors, as well as additives that prevent particle agglomeration and maintain electrode integrity. The right combination of binders and additives can significantly reduce electrode pulverization and improve the overall mechanical robustness of the battery system.

- Housing and cell assembly techniques: Advanced housing designs and cell assembly techniques contribute to the mechanical stability of iron-air batteries. These include pressure-resistant casings, reinforced sealing methods, and innovative cell stacking approaches that distribute mechanical stress evenly. Proper housing and assembly can prevent deformation under pressure, minimize internal movement of components, and protect against external physical impacts, thereby extending battery life and performance.

- Electrolyte stabilization systems: Electrolyte stabilization systems are essential for maintaining the mechanical integrity of iron-air batteries. These systems include gel or polymer electrolytes that reduce mechanical stress, electrolyte additives that prevent dendrite formation, and controlled electrolyte distribution mechanisms. Stable electrolytes help maintain consistent ionic conductivity while preventing physical degradation of the electrodes, thereby enhancing the overall mechanical stability of the battery system.

- Thermal management for mechanical durability: Effective thermal management systems are crucial for ensuring the mechanical durability of iron-air batteries. These systems include heat dissipation structures, temperature regulation mechanisms, and thermal insulation designs that prevent thermal expansion and contraction stresses. By maintaining optimal operating temperatures and preventing thermal gradients, these systems help preserve the mechanical integrity of battery components and prevent stress-induced failures during operation.

02 Binder and additive formulations

The use of specialized binders and additives can improve the mechanical stability of iron-air batteries. These formulations help maintain electrode cohesion during cycling, prevent particle detachment, and enhance structural integrity. Polymeric binders, carbon-based additives, and other stabilizing compounds work together to create a more robust electrode matrix that can withstand the physical stresses associated with battery operation.Expand Specific Solutions03 Housing and encapsulation technologies

Advanced housing and encapsulation technologies play a crucial role in ensuring the mechanical stability of iron-air batteries. These technologies include pressure-resistant casings, flexible yet durable enclosures, and specialized sealing methods that prevent component movement while accommodating volume changes during cycling. Proper housing design protects internal components from external forces and helps maintain the structural integrity of the battery system.Expand Specific Solutions04 Electrolyte composition for stability enhancement

Optimized electrolyte compositions can contribute to the mechanical stability of iron-air batteries. Certain electrolyte formulations minimize electrode swelling and contraction during cycling, reduce corrosion effects that weaken structural components, and create a more stable interface between electrodes and electrolyte. These specialized compositions help maintain the physical integrity of battery components throughout extended operational lifetimes.Expand Specific Solutions05 Advanced manufacturing techniques

Innovative manufacturing techniques significantly improve the mechanical stability of iron-air batteries. These include precision assembly methods, controlled deposition processes for electrode materials, and specialized curing procedures that enhance structural integrity. Advanced manufacturing approaches ensure consistent component quality, precise alignment of battery elements, and optimal interfacial contacts, all contributing to enhanced mechanical robustness and operational reliability.Expand Specific Solutions

Leading Companies and Research Institutions in Iron-Air Technology

The iron-air battery market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size remains modest but is projected to expand significantly as renewable energy storage demands grow. Technologically, iron-air batteries are still evolving toward commercial maturity, with mechanical stability representing a critical challenge. Key players advancing this technology include LG Energy Solution, which is investing in metal-air battery research; Toyota Motor Corp, exploring alternative energy storage solutions; and academic institutions like Tsinghua University and Shanghai Institute of Applied Physics leading fundamental research. Research organizations such as Battelle Memorial Institute and Forschungszentrum Jülich are developing testing methodologies for mechanical stability assessment, while companies like Midtronics are contributing battery testing expertise to address durability challenges.

Toyota Motor Corp.

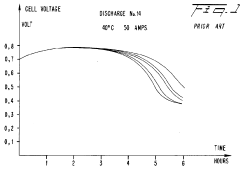

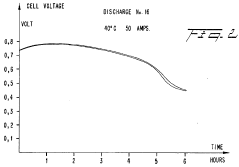

Technical Solution: Toyota has pioneered a mechanical stability measurement system specifically designed for metal-air batteries including iron-air systems. Their approach focuses on quantifying dimensional changes during cycling using precision laser displacement sensors with sub-micron accuracy. Toyota's methodology incorporates a custom-designed pressure chamber that simulates various mechanical stress conditions while simultaneously measuring electrochemical performance. They've developed specialized fixtures that maintain uniform pressure distribution across the cell while allowing for controlled deformation measurements. Their system includes real-time monitoring of internal gas evolution and its effect on mechanical integrity, which is particularly important for iron-air batteries where oxygen evolution/consumption dynamics significantly impact mechanical stability. Toyota has also implemented accelerated testing protocols that correlate mechanical degradation patterns with long-term performance metrics.

Strengths: Highly precise measurement capabilities integrated with electrochemical testing provides comprehensive performance data. Purpose-built testing equipment specifically designed for metal-air battery systems. Weaknesses: Proprietary testing methodologies may limit standardization across the industry. High capital investment required for specialized measurement equipment.

Battelle Memorial Institute

Technical Solution: Battelle has developed a comprehensive mechanical stability testing framework for iron-air batteries that combines in-situ and ex-situ measurement techniques. Their approach utilizes acoustic emission monitoring during cycling to detect microstructural changes and mechanical degradation in real-time. They've implemented specialized pressure sensors to measure electrode expansion/contraction during charge-discharge cycles, which is critical for iron electrodes that undergo significant volumetric changes. Battelle's testing protocol includes mechanical compression testing at various states of charge to determine structural integrity limits and employs high-resolution X-ray tomography to visualize internal structural changes non-destructively. Their methodology incorporates accelerated stress testing under controlled temperature and pressure conditions to predict long-term mechanical stability performance.

Strengths: Comprehensive multi-parameter approach allows correlation between mechanical failures and electrochemical performance. Advanced non-destructive testing capabilities provide insights without compromising battery integrity. Weaknesses: Complex testing setup requires specialized equipment and expertise, potentially limiting widespread adoption. Testing protocols may require significant customization for different iron-air battery designs.

Key Patents and Research on Iron-Air Battery Structure

Procedure to stabilize an iron air battery

PatentInactiveUS4032693A

Innovation

- Adding a sulphur-containing compound to the electrolyte at concentrations between 10 ppm and 1,000 ppm, which forms free sulphide ions, stabilizes both the air cathodes and iron electrodes, preventing deactivation and improving performance by potentially forming protective layers or blocking corrosion reactions.

Iron-air battery system

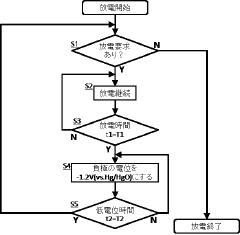

PatentInactiveJP2018006057A

Innovation

- A potential control circuit temporarily reduces the negative electrode's potential to -1.2 V (vs. Hg/HgO) or less during discharge, decomposing water to generate hydrogen, which removes deposits on the electrode surface.

Environmental Impact and Sustainability Factors

Iron-air batteries represent a significant advancement in sustainable energy storage technology, offering a promising alternative to conventional lithium-ion systems. The environmental impact and sustainability factors of these batteries are particularly noteworthy when considering their mechanical stability measurement protocols and overall lifecycle.

The production of iron-air batteries utilizes abundant, non-toxic materials, primarily iron, which is the fourth most common element in Earth's crust. This abundance translates to reduced environmental strain compared to lithium extraction, which often involves water-intensive mining operations in ecologically sensitive areas. The mechanical stability testing of these batteries must therefore incorporate sustainability metrics that account for resource availability and extraction impacts.

Carbon footprint assessments of iron-air battery production reveal significantly lower greenhouse gas emissions compared to conventional battery technologies. When measuring mechanical stability, researchers must consider how testing protocols themselves contribute to environmental impact. Non-destructive testing methods that minimize waste generation while accurately assessing structural integrity represent an important advancement in sustainable battery evaluation.

Lifecycle analysis indicates that iron-air batteries offer exceptional recyclability potential. The iron components can be recovered and repurposed with minimal energy input, creating a circular economy opportunity. Mechanical stability measurements should therefore include assessment of how structural degradation affects recyclability, establishing correlations between mechanical failure modes and end-of-life recovery processes.

Water usage represents another critical environmental factor. Iron-air battery production typically requires less water than competing technologies, though precise quantification varies by manufacturing process. Stability testing protocols should incorporate water conservation principles, particularly when stress testing involves liquid electrolytes or cooling systems.

The long-term environmental resilience of iron-air batteries depends significantly on their mechanical durability. Extended cycle life resulting from superior mechanical stability directly reduces waste generation and resource consumption associated with battery replacement. Testing methodologies that accurately predict real-world longevity therefore contribute substantially to sustainability goals.

Regulatory frameworks increasingly demand comprehensive environmental impact assessments for emerging energy technologies. Mechanical stability testing for iron-air batteries must align with these evolving standards, incorporating metrics that satisfy both technical performance requirements and environmental compliance. This integration of sustainability considerations into stability testing protocols represents a holistic approach to battery development that balances technological advancement with environmental stewardship.

The production of iron-air batteries utilizes abundant, non-toxic materials, primarily iron, which is the fourth most common element in Earth's crust. This abundance translates to reduced environmental strain compared to lithium extraction, which often involves water-intensive mining operations in ecologically sensitive areas. The mechanical stability testing of these batteries must therefore incorporate sustainability metrics that account for resource availability and extraction impacts.

Carbon footprint assessments of iron-air battery production reveal significantly lower greenhouse gas emissions compared to conventional battery technologies. When measuring mechanical stability, researchers must consider how testing protocols themselves contribute to environmental impact. Non-destructive testing methods that minimize waste generation while accurately assessing structural integrity represent an important advancement in sustainable battery evaluation.

Lifecycle analysis indicates that iron-air batteries offer exceptional recyclability potential. The iron components can be recovered and repurposed with minimal energy input, creating a circular economy opportunity. Mechanical stability measurements should therefore include assessment of how structural degradation affects recyclability, establishing correlations between mechanical failure modes and end-of-life recovery processes.

Water usage represents another critical environmental factor. Iron-air battery production typically requires less water than competing technologies, though precise quantification varies by manufacturing process. Stability testing protocols should incorporate water conservation principles, particularly when stress testing involves liquid electrolytes or cooling systems.

The long-term environmental resilience of iron-air batteries depends significantly on their mechanical durability. Extended cycle life resulting from superior mechanical stability directly reduces waste generation and resource consumption associated with battery replacement. Testing methodologies that accurately predict real-world longevity therefore contribute substantially to sustainability goals.

Regulatory frameworks increasingly demand comprehensive environmental impact assessments for emerging energy technologies. Mechanical stability testing for iron-air batteries must align with these evolving standards, incorporating metrics that satisfy both technical performance requirements and environmental compliance. This integration of sustainability considerations into stability testing protocols represents a holistic approach to battery development that balances technological advancement with environmental stewardship.

Scalability and Manufacturing Considerations

The scaling of iron-air battery technology from laboratory prototypes to commercial production presents significant manufacturing challenges that must be addressed to ensure mechanical stability across larger form factors. Current production methods for small-scale cells cannot be directly applied to mass manufacturing without considerable adaptation. The precision required in electrode alignment and assembly becomes increasingly difficult as battery dimensions increase, potentially leading to mechanical stress points that compromise long-term stability.

Material consistency represents another critical factor in scaling production. Variations in iron particle size distribution, electrode porosity, and electrolyte composition can significantly impact mechanical performance when multiplied across larger battery systems. Establishing robust quality control protocols for raw materials becomes essential to maintain consistent mechanical properties throughout the manufacturing process.

Assembly techniques must evolve to accommodate larger battery formats while preserving mechanical integrity. Traditional manual assembly methods used in laboratory settings are impractical for commercial production. Automated assembly lines require specialized equipment capable of handling delicate components while maintaining precise alignment tolerances. The development of custom manufacturing equipment specifically designed for iron-air battery production represents a significant investment but is necessary for consistent mechanical stability.

Environmental control during manufacturing emerges as a key consideration for mechanical stability. Iron electrodes are particularly susceptible to oxidation during production, which can compromise structural integrity before the battery even reaches deployment. Manufacturing facilities must implement stringent atmospheric controls, potentially including inert gas environments for critical assembly stages, adding complexity and cost to production infrastructure.

Post-production testing methodologies must scale accordingly to verify mechanical stability across larger production volumes. Non-destructive testing techniques such as ultrasonic inspection and computed tomography become increasingly valuable for identifying internal structural weaknesses without sacrificing production units. The development of accelerated mechanical stress testing protocols specific to iron-air batteries will be essential for quality assurance in mass production environments.

Cost considerations ultimately determine commercial viability. While laboratory-scale production can utilize premium materials and labor-intensive processes to ensure mechanical stability, commercial manufacturing must balance performance requirements against economic constraints. Material substitutions, process optimizations, and automation will be necessary to achieve acceptable mechanical stability at competitive price points, requiring careful engineering tradeoffs throughout the production chain.

Material consistency represents another critical factor in scaling production. Variations in iron particle size distribution, electrode porosity, and electrolyte composition can significantly impact mechanical performance when multiplied across larger battery systems. Establishing robust quality control protocols for raw materials becomes essential to maintain consistent mechanical properties throughout the manufacturing process.

Assembly techniques must evolve to accommodate larger battery formats while preserving mechanical integrity. Traditional manual assembly methods used in laboratory settings are impractical for commercial production. Automated assembly lines require specialized equipment capable of handling delicate components while maintaining precise alignment tolerances. The development of custom manufacturing equipment specifically designed for iron-air battery production represents a significant investment but is necessary for consistent mechanical stability.

Environmental control during manufacturing emerges as a key consideration for mechanical stability. Iron electrodes are particularly susceptible to oxidation during production, which can compromise structural integrity before the battery even reaches deployment. Manufacturing facilities must implement stringent atmospheric controls, potentially including inert gas environments for critical assembly stages, adding complexity and cost to production infrastructure.

Post-production testing methodologies must scale accordingly to verify mechanical stability across larger production volumes. Non-destructive testing techniques such as ultrasonic inspection and computed tomography become increasingly valuable for identifying internal structural weaknesses without sacrificing production units. The development of accelerated mechanical stress testing protocols specific to iron-air batteries will be essential for quality assurance in mass production environments.

Cost considerations ultimately determine commercial viability. While laboratory-scale production can utilize premium materials and labor-intensive processes to ensure mechanical stability, commercial manufacturing must balance performance requirements against economic constraints. Material substitutions, process optimizations, and automation will be necessary to achieve acceptable mechanical stability at competitive price points, requiring careful engineering tradeoffs throughout the production chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!