Optimize Electrolyte Composition in Iron-Air Batteries

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-air batteries represent a promising energy storage technology that has garnered significant attention in recent years due to their potential for low-cost, high-energy-density applications. The development of these batteries can be traced back to the 1970s, when initial research explored iron as an electrode material for energy storage. However, technological limitations at that time prevented widespread commercialization, leading to a period of reduced interest.

The resurgence of interest in iron-air batteries began in the early 2000s, driven by the growing demand for sustainable energy storage solutions and advancements in materials science. This renewed focus has been further accelerated by the global push toward renewable energy integration and grid-scale storage requirements, positioning iron-air batteries as a potential alternative to lithium-ion technology for stationary applications.

Iron-air batteries operate on the principle of reversible oxidation of iron at the anode and reduction of oxygen from air at the cathode, with an electrolyte serving as the medium for ion transport. The electrolyte composition plays a critical role in determining battery performance, including energy density, cycle life, and charging efficiency. Traditional electrolytes have faced challenges related to iron passivation, hydrogen evolution, and carbonate formation, which have limited practical implementation.

Current technological evolution trends indicate a shift toward advanced alkaline electrolytes with specific additives designed to mitigate these issues. Research is increasingly focused on understanding the complex electrochemical interfaces and developing electrolyte formulations that can enhance the stability and efficiency of iron electrodes while minimizing side reactions.

The primary technical objectives for electrolyte optimization include: increasing the ionic conductivity to improve charge transfer kinetics; enhancing the stability of the iron electrode to prevent passivation; reducing parasitic hydrogen evolution reactions that decrease coulombic efficiency; and developing electrolyte additives that can form protective layers on electrode surfaces without impeding the desired electrochemical reactions.

Additionally, researchers aim to create electrolyte compositions that remain stable across wide temperature ranges and extended cycling, addressing the practical requirements for commercial deployment. The ultimate goal is to develop an electrolyte system that enables iron-air batteries to achieve energy densities exceeding 500 Wh/kg at the cell level, with cycle lives of over 1,000 cycles and round-trip efficiencies above 80%.

These ambitious targets reflect the potential of iron-air technology to revolutionize grid-scale energy storage by providing a cost-effective solution using earth-abundant materials, potentially reducing storage costs to below $20/kWh, a threshold considered critical for widespread adoption of renewable energy systems.

The resurgence of interest in iron-air batteries began in the early 2000s, driven by the growing demand for sustainable energy storage solutions and advancements in materials science. This renewed focus has been further accelerated by the global push toward renewable energy integration and grid-scale storage requirements, positioning iron-air batteries as a potential alternative to lithium-ion technology for stationary applications.

Iron-air batteries operate on the principle of reversible oxidation of iron at the anode and reduction of oxygen from air at the cathode, with an electrolyte serving as the medium for ion transport. The electrolyte composition plays a critical role in determining battery performance, including energy density, cycle life, and charging efficiency. Traditional electrolytes have faced challenges related to iron passivation, hydrogen evolution, and carbonate formation, which have limited practical implementation.

Current technological evolution trends indicate a shift toward advanced alkaline electrolytes with specific additives designed to mitigate these issues. Research is increasingly focused on understanding the complex electrochemical interfaces and developing electrolyte formulations that can enhance the stability and efficiency of iron electrodes while minimizing side reactions.

The primary technical objectives for electrolyte optimization include: increasing the ionic conductivity to improve charge transfer kinetics; enhancing the stability of the iron electrode to prevent passivation; reducing parasitic hydrogen evolution reactions that decrease coulombic efficiency; and developing electrolyte additives that can form protective layers on electrode surfaces without impeding the desired electrochemical reactions.

Additionally, researchers aim to create electrolyte compositions that remain stable across wide temperature ranges and extended cycling, addressing the practical requirements for commercial deployment. The ultimate goal is to develop an electrolyte system that enables iron-air batteries to achieve energy densities exceeding 500 Wh/kg at the cell level, with cycle lives of over 1,000 cycles and round-trip efficiencies above 80%.

These ambitious targets reflect the potential of iron-air technology to revolutionize grid-scale energy storage by providing a cost-effective solution using earth-abundant materials, potentially reducing storage costs to below $20/kWh, a threshold considered critical for widespread adoption of renewable energy systems.

Market Analysis for Iron-Air Energy Storage Solutions

The global energy storage market is experiencing significant growth, with iron-air battery technology emerging as a promising solution for grid-scale applications. Current market projections indicate that the grid energy storage market will reach approximately $15.1 billion by 2025, with an annual growth rate of 20-25%. Within this expanding market, iron-air batteries are positioned to capture a substantial share due to their cost advantages and sustainability profile compared to lithium-ion alternatives.

Iron-air battery technology addresses several critical market needs that existing solutions cannot fully satisfy. The primary market driver is the increasing integration of renewable energy sources into power grids worldwide. As solar and wind power generation continues to grow, the demand for long-duration energy storage solutions that can provide 10+ hours of discharge capacity is becoming more pronounced. Iron-air batteries excel in this application segment, offering duration capabilities that lithium-ion batteries cannot economically match.

Cost considerations represent another significant market factor favoring iron-air technology. With raw material costs for iron approximately 1/40th the cost of lithium per kilogram, iron-air batteries can potentially achieve system costs below $20/kWh at scale—significantly undercutting the $100-150/kWh range for lithium-ion systems. This cost advantage is particularly compelling for utility companies and grid operators seeking economical solutions for large-scale deployment.

The geographical distribution of market demand shows particular concentration in regions with aggressive renewable energy targets. North America currently leads adoption, with several pilot projects underway in California and the northeastern United States. Europe follows closely, driven by stringent carbon reduction policies, while the Asia-Pacific region shows rapidly growing interest, particularly in China and Australia where renewable integration challenges are acute.

Market segmentation analysis reveals that utility-scale applications represent the primary near-term opportunity, accounting for approximately 70% of potential iron-air battery deployments. Commercial and industrial applications constitute a secondary market segment at roughly 25%, with the remaining 5% distributed across specialized applications such as microgrids and remote power systems.

Competitive analysis indicates that while iron-air technology faces competition from other emerging long-duration storage technologies such as flow batteries and compressed air energy storage, its combination of low cost, abundant materials, and scalability provides distinct market advantages. The technology's environmental profile—using earth-abundant materials with minimal toxicity concerns—also aligns with increasing market demand for sustainable energy solutions.

Customer adoption barriers primarily center on technology maturity concerns and the need for demonstrated long-term reliability. Market research indicates that utility customers require operational data demonstrating 10+ year lifespans before committing to large-scale deployments, highlighting the importance of accelerated life testing and pilot installations in market development strategies.

Iron-air battery technology addresses several critical market needs that existing solutions cannot fully satisfy. The primary market driver is the increasing integration of renewable energy sources into power grids worldwide. As solar and wind power generation continues to grow, the demand for long-duration energy storage solutions that can provide 10+ hours of discharge capacity is becoming more pronounced. Iron-air batteries excel in this application segment, offering duration capabilities that lithium-ion batteries cannot economically match.

Cost considerations represent another significant market factor favoring iron-air technology. With raw material costs for iron approximately 1/40th the cost of lithium per kilogram, iron-air batteries can potentially achieve system costs below $20/kWh at scale—significantly undercutting the $100-150/kWh range for lithium-ion systems. This cost advantage is particularly compelling for utility companies and grid operators seeking economical solutions for large-scale deployment.

The geographical distribution of market demand shows particular concentration in regions with aggressive renewable energy targets. North America currently leads adoption, with several pilot projects underway in California and the northeastern United States. Europe follows closely, driven by stringent carbon reduction policies, while the Asia-Pacific region shows rapidly growing interest, particularly in China and Australia where renewable integration challenges are acute.

Market segmentation analysis reveals that utility-scale applications represent the primary near-term opportunity, accounting for approximately 70% of potential iron-air battery deployments. Commercial and industrial applications constitute a secondary market segment at roughly 25%, with the remaining 5% distributed across specialized applications such as microgrids and remote power systems.

Competitive analysis indicates that while iron-air technology faces competition from other emerging long-duration storage technologies such as flow batteries and compressed air energy storage, its combination of low cost, abundant materials, and scalability provides distinct market advantages. The technology's environmental profile—using earth-abundant materials with minimal toxicity concerns—also aligns with increasing market demand for sustainable energy solutions.

Customer adoption barriers primarily center on technology maturity concerns and the need for demonstrated long-term reliability. Market research indicates that utility customers require operational data demonstrating 10+ year lifespans before committing to large-scale deployments, highlighting the importance of accelerated life testing and pilot installations in market development strategies.

Electrolyte Challenges in Iron-Air Battery Development

Iron-air batteries face significant electrolyte-related challenges that currently limit their commercial viability despite their promising theoretical energy density and cost advantages. The primary electrolyte used in these systems—typically potassium hydroxide (KOH)—presents several critical issues that require innovative solutions.

The highly alkaline environment necessary for iron electrode operation causes accelerated corrosion of battery components, particularly at the iron electrode where parasitic hydrogen evolution occurs. This side reaction not only consumes water from the electrolyte but also reduces coulombic efficiency and creates safety concerns due to hydrogen gas accumulation.

Electrolyte carbonation represents another major challenge, as atmospheric CO2 readily reacts with KOH to form potassium carbonate (K2CO3), progressively degrading electrolyte conductivity and overall battery performance. This issue becomes particularly problematic in open-air cathode designs where continuous CO2 exposure is unavoidable.

The conventional electrolyte composition also struggles with iron electrode passivation, where iron oxide/hydroxide layers form on active material surfaces, inhibiting electron transfer and reducing capacity utilization. These passivation layers significantly impact the battery's rate capability and cycle life.

Water management presents a complex challenge in iron-air systems. The oxygen reduction and evolution reactions at the air electrode consume and generate water respectively, while electrolyte evaporation and hydrogen evolution further complicate the water balance. Maintaining optimal electrolyte concentration is critical yet difficult across varying operational conditions.

Electrolyte additives have shown promise in addressing some of these challenges. Sulfide compounds can suppress hydrogen evolution, while bismuth and other metal additives may improve iron electrode performance. However, finding the optimal combination that addresses multiple issues simultaneously without introducing new problems remains elusive.

Temperature sensitivity further complicates electrolyte optimization, as viscosity, conductivity, and reaction kinetics all vary significantly with temperature changes. This creates additional challenges for developing iron-air batteries that can operate reliably across wide temperature ranges.

Recent research has explored alternative electrolyte systems, including mixed alkaline solutions, organic additives, and even non-aqueous formulations. While these approaches show potential for addressing specific challenges, they often introduce new complications regarding stability, cost, or compatibility with existing manufacturing processes.

The highly alkaline environment necessary for iron electrode operation causes accelerated corrosion of battery components, particularly at the iron electrode where parasitic hydrogen evolution occurs. This side reaction not only consumes water from the electrolyte but also reduces coulombic efficiency and creates safety concerns due to hydrogen gas accumulation.

Electrolyte carbonation represents another major challenge, as atmospheric CO2 readily reacts with KOH to form potassium carbonate (K2CO3), progressively degrading electrolyte conductivity and overall battery performance. This issue becomes particularly problematic in open-air cathode designs where continuous CO2 exposure is unavoidable.

The conventional electrolyte composition also struggles with iron electrode passivation, where iron oxide/hydroxide layers form on active material surfaces, inhibiting electron transfer and reducing capacity utilization. These passivation layers significantly impact the battery's rate capability and cycle life.

Water management presents a complex challenge in iron-air systems. The oxygen reduction and evolution reactions at the air electrode consume and generate water respectively, while electrolyte evaporation and hydrogen evolution further complicate the water balance. Maintaining optimal electrolyte concentration is critical yet difficult across varying operational conditions.

Electrolyte additives have shown promise in addressing some of these challenges. Sulfide compounds can suppress hydrogen evolution, while bismuth and other metal additives may improve iron electrode performance. However, finding the optimal combination that addresses multiple issues simultaneously without introducing new problems remains elusive.

Temperature sensitivity further complicates electrolyte optimization, as viscosity, conductivity, and reaction kinetics all vary significantly with temperature changes. This creates additional challenges for developing iron-air batteries that can operate reliably across wide temperature ranges.

Recent research has explored alternative electrolyte systems, including mixed alkaline solutions, organic additives, and even non-aqueous formulations. While these approaches show potential for addressing specific challenges, they often introduce new complications regarding stability, cost, or compatibility with existing manufacturing processes.

Current Electrolyte Composition Strategies and Performance

01 Alkaline electrolyte compositions for iron-air batteries

Alkaline electrolytes, typically containing potassium hydroxide (KOH) or sodium hydroxide (NaOH), are commonly used in iron-air batteries. These electrolytes facilitate the electrochemical reactions between iron electrodes and oxygen from the air. The concentration of the alkaline solution is critical for optimizing battery performance, with typical concentrations ranging from 20-45% by weight. These electrolytes provide high ionic conductivity and support the redox reactions necessary for battery operation.- Alkaline electrolyte compositions: Alkaline electrolytes are commonly used in iron-air batteries, typically consisting of potassium hydroxide (KOH) or sodium hydroxide (NaOH) solutions. These electrolytes provide high ionic conductivity necessary for efficient battery operation. The concentration of the alkaline solution is critical for optimizing battery performance, with typical concentrations ranging from 20-45% by weight. Some formulations include additives to prevent iron passivation and enhance oxygen reduction reactions at the air electrode.

- Additives for performance enhancement: Various additives are incorporated into iron-air battery electrolytes to improve performance characteristics. These include sulfide compounds to prevent passivation of the iron electrode, bismuth compounds to enhance charging efficiency, and surfactants to improve wetting properties. Other additives such as lithium hydroxide can increase ionic conductivity, while certain organic compounds may be added to reduce hydrogen evolution. These additives work synergistically to extend cycle life and improve the overall efficiency of iron-air batteries.

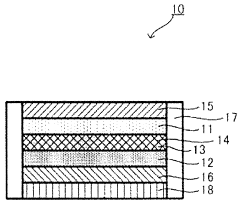

- Solid and gel electrolyte systems: Advanced iron-air batteries utilize solid or gel electrolyte systems to overcome limitations of liquid electrolytes. These include polymer-based electrolytes infused with alkaline solutions, ceramic ion conductors, and composite electrolytes combining inorganic and organic materials. Solid electrolytes can prevent electrolyte leakage, improve safety, and potentially increase energy density. Gel electrolytes offer a middle ground with improved mechanical stability while maintaining good ionic conductivity necessary for battery operation.

- Electrolyte stabilizers and pH buffers: Stabilizing agents and pH buffers are crucial components in iron-air battery electrolytes to maintain optimal operating conditions. These include carbonates to buffer pH changes during cycling, chelating agents to control metal ion activity, and inhibitors to prevent unwanted side reactions. Some formulations incorporate silicates or borates to improve the stability of the electrolyte over extended cycling. These additives help maintain consistent performance and extend the operational lifetime of iron-air batteries.

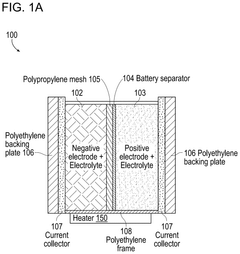

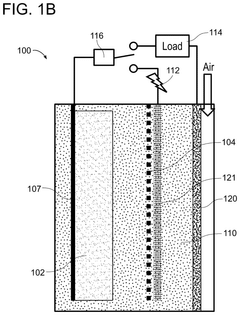

- Dual-electrolyte and hybrid systems: Innovative iron-air battery designs employ dual-electrolyte or hybrid electrolyte systems to optimize performance. These configurations may use different electrolyte compositions for the iron electrode and air electrode compartments, separated by ion-selective membranes. Some designs incorporate ionic liquids or organic electrolytes in combination with traditional alkaline solutions. These advanced electrolyte architectures aim to simultaneously optimize iron electrode stability and oxygen reduction kinetics, leading to improved energy density and cycle life.

02 Additives to prevent iron electrode passivation

Various additives are incorporated into iron-air battery electrolytes to prevent passivation of the iron electrode, which can significantly reduce battery capacity and cycle life. These additives include sulfides, bismuth compounds, and organic compounds that help maintain the active surface area of the iron electrode. By preventing the formation of passive films on the iron surface, these additives ensure continued electrochemical activity and improve the overall performance and longevity of iron-air batteries.Expand Specific Solutions03 Gel and polymer-based electrolyte systems

Gel and polymer-based electrolyte systems represent an advancement in iron-air battery technology, offering improved safety and stability compared to traditional liquid electrolytes. These systems typically incorporate polymers such as polyvinyl alcohol (PVA), polyethylene oxide (PEO), or other polymer matrices that immobilize the electrolyte solution. The gel-polymer electrolytes reduce leakage risks while maintaining good ionic conductivity, and can also help mitigate issues related to electrolyte evaporation and carbonation during long-term operation.Expand Specific Solutions04 Electrolyte additives for oxygen reduction reaction enhancement

Specific additives are incorporated into iron-air battery electrolytes to enhance the oxygen reduction reaction (ORR) at the air electrode. These additives include transition metal oxides, carbon-based materials with high surface area, and catalytic compounds that facilitate the conversion of oxygen to hydroxide ions. By improving the kinetics of the ORR, these additives help reduce polarization losses, increase discharge capacity, and improve the overall energy efficiency of iron-air batteries.Expand Specific Solutions05 Electrolyte compositions for improved cycle life and stability

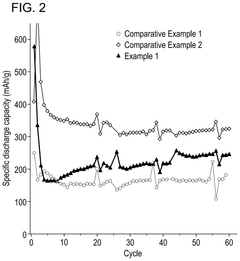

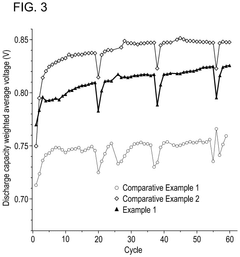

Advanced electrolyte formulations focus on improving the cycle life and stability of iron-air batteries. These compositions often include combinations of inhibitors to prevent hydrogen evolution, stabilizers to maintain electrolyte properties over time, and buffering agents to control pH fluctuations during cycling. Some formulations also incorporate ionic liquids or specialized salts that reduce side reactions and electrolyte degradation. These optimized electrolyte systems significantly extend battery lifespan while maintaining high energy density and performance characteristics.Expand Specific Solutions

Leading Companies and Research Institutions in Iron-Air Technology

The iron-air battery electrolyte optimization landscape is currently in an early growth phase, with market size projected to expand significantly as renewable energy storage demands increase. The technology is approaching commercial viability, though still requires refinement for mass deployment. Form Energy leads the field with its multi-day storage solutions, while established players like Toyota, Sumitomo Chemical, and CATL bring significant R&D capabilities to electrolyte development. Academic institutions including Kyushu University and USC contribute fundamental research, while specialized materials companies like Santoku and Capchem develop advanced electrolyte formulations. The competitive dynamics reflect a blend of startups, major industrial corporations, and research institutions working to overcome technical challenges in stability, conductivity, and cycle life of iron-air battery electrolytes.

Form Energy, Inc.

Technical Solution: Form Energy has developed a proprietary aqueous electrolyte formulation for their iron-air batteries that enables long-duration energy storage. Their electrolyte composition incorporates specific alkaline additives that enhance the reversibility of the iron oxidation/reduction reactions while minimizing hydrogen evolution. The company's approach focuses on optimizing electrolyte pH levels (typically between 13-14) and incorporating proprietary organic and inorganic additives that form a protective layer on the iron electrode surface, preventing passivation during discharge cycles. Form Energy's electrolyte also contains carefully selected ionic conductivity enhancers that maintain performance across thousands of deep discharge cycles, enabling their batteries to deliver electricity at approximately 1/10th the cost of lithium-ion systems for long-duration applications[1][2]. Their multi-day storage capability (100+ hours) is directly linked to their advanced electrolyte formulation that balances iron dissolution rates with oxygen reduction kinetics.

Strengths: Enables extremely low-cost long-duration storage (reportedly <$20/kWh system cost), supports multi-day discharge cycles, and utilizes earth-abundant materials. Their electrolyte formulation specifically addresses iron passivation issues that historically limited iron-air battery commercialization. Weaknesses: Lower energy density compared to lithium-ion, potential precipitation issues during extended cycling, and sensitivity to carbon dioxide contamination requiring specialized sealing.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced alkaline electrolyte systems for iron-air batteries featuring a hybrid organic-inorganic composition. Their approach incorporates potassium hydroxide (KOH) as the primary ionic conductor at concentrations between 25-30 wt%, supplemented with lithium hydroxide additives to enhance oxygen reduction reaction kinetics. Toyota's proprietary electrolyte formulation includes specific surfactants and chelating agents that control iron dissolution and redeposition processes during cycling. Their research has demonstrated that incorporating certain organic polymers into the electrolyte creates a dynamic protective interface on the iron electrode that allows oxygen transport while minimizing unwanted side reactions. Toyota's electrolyte optimization focuses on temperature stability (-20°C to 60°C) for automotive applications, with particular attention to electrolyte viscosity modifiers that maintain performance across this range[3]. Recent developments include nano-dispersed catalysts within the electrolyte that accelerate the oxygen evolution reaction during charging, addressing one of the key efficiency limitations in iron-air systems.

Strengths: Excellent temperature stability suitable for automotive applications, enhanced cycle life through controlled iron dissolution/deposition, and compatibility with existing manufacturing infrastructure. Their electrolyte formulations demonstrate superior oxygen reduction kinetics. Weaknesses: Higher cost compared to simpler alkaline formulations, potential for carbonate formation from CO2 exposure requiring hermetic sealing, and limited energy density compared to Toyota's primary battery technologies.

Key Patents and Research on Advanced Electrolyte Systems

Additive for iron-air batteries

PatentPendingUS20250140990A1

Innovation

- An alkaline electrolyte with a total hydroxide concentration greater than 1 molar, containing a trivalent element such as aluminum, sulfur, and tin, is used to improve the performance of iron-air batteries.

Electrolyte for iron-air batteries and iron-air battery

PatentActiveUS10044082B2

Innovation

- An electrolyte solution containing discharge reaction promoters such as SCN−, S2O32−, or (CH3)2NCSS− anions, along with cations like Li+, K+, Na+, Rb+, Cs+, and Fr+, specifically Na2S2O3, is used to stabilize the discharge capacity without the need for precise concentration control, inhibiting re-passivation and promoting iron dissolution.

Materials Sustainability and Supply Chain Considerations

The sustainability of materials used in iron-air batteries represents a critical factor in their long-term commercial viability. The electrolyte composition optimization must consider not only performance metrics but also the environmental impact and supply chain resilience. Iron-based materials offer significant advantages in this regard, as iron is the fourth most abundant element in Earth's crust, comprising approximately 5% of its composition. This abundance translates to lower extraction costs and reduced geopolitical supply risks compared to lithium, cobalt, and other critical battery materials.

Current electrolyte formulations for iron-air batteries typically contain potassium hydroxide (KOH), which faces moderate supply constraints. Global potassium reserves are estimated at 250 billion tons, with annual production capacity of approximately 40 million tons. However, the concentration of production in a few countries—Canada, Russia, and Belarus account for over 60% of global potassium mining—creates potential supply vulnerabilities that must be addressed through diversified sourcing strategies.

Water-based electrolytes present a substantial sustainability advantage over organic electrolytes used in lithium-ion systems, eliminating concerns about toxic and flammable solvents. This reduces both environmental impact and safety risks throughout the battery lifecycle. However, the high purity requirements for electrolyte components can increase energy consumption during manufacturing, partially offsetting these benefits.

The additives used to optimize electrolyte performance warrant particular attention from a sustainability perspective. Common additives such as bismuth sulfide and carbon-based materials have varying environmental footprints. Bismuth, while less toxic than many heavy metals, has limited global production of approximately 8,500 tons annually, potentially creating supply bottlenecks as demand increases. Developing alternative additives based on more abundant elements represents a promising research direction.

Recycling considerations must also factor into electrolyte composition decisions. Electrolytes designed with end-of-life recovery in mind can significantly improve the overall sustainability profile of iron-air batteries. Current recycling technologies can recover approximately 80% of iron content, but electrolyte recovery rates remain substantially lower at 30-40%, presenting an opportunity for improvement through compositional optimization.

Regional availability of materials varies significantly, with implications for localized manufacturing strategies. North America possesses substantial iron resources but limited potassium reserves, while regions like Brazil and Australia have abundant resources of both materials. This geographic distribution suggests that regionally optimized electrolyte formulations may prove advantageous, balancing performance requirements with local material availability.

Current electrolyte formulations for iron-air batteries typically contain potassium hydroxide (KOH), which faces moderate supply constraints. Global potassium reserves are estimated at 250 billion tons, with annual production capacity of approximately 40 million tons. However, the concentration of production in a few countries—Canada, Russia, and Belarus account for over 60% of global potassium mining—creates potential supply vulnerabilities that must be addressed through diversified sourcing strategies.

Water-based electrolytes present a substantial sustainability advantage over organic electrolytes used in lithium-ion systems, eliminating concerns about toxic and flammable solvents. This reduces both environmental impact and safety risks throughout the battery lifecycle. However, the high purity requirements for electrolyte components can increase energy consumption during manufacturing, partially offsetting these benefits.

The additives used to optimize electrolyte performance warrant particular attention from a sustainability perspective. Common additives such as bismuth sulfide and carbon-based materials have varying environmental footprints. Bismuth, while less toxic than many heavy metals, has limited global production of approximately 8,500 tons annually, potentially creating supply bottlenecks as demand increases. Developing alternative additives based on more abundant elements represents a promising research direction.

Recycling considerations must also factor into electrolyte composition decisions. Electrolytes designed with end-of-life recovery in mind can significantly improve the overall sustainability profile of iron-air batteries. Current recycling technologies can recover approximately 80% of iron content, but electrolyte recovery rates remain substantially lower at 30-40%, presenting an opportunity for improvement through compositional optimization.

Regional availability of materials varies significantly, with implications for localized manufacturing strategies. North America possesses substantial iron resources but limited potassium reserves, while regions like Brazil and Australia have abundant resources of both materials. This geographic distribution suggests that regionally optimized electrolyte formulations may prove advantageous, balancing performance requirements with local material availability.

Scalability and Manufacturing Process Integration

Scaling up iron-air battery production from laboratory to commercial scale presents significant challenges related to electrolyte composition optimization. The transition requires maintaining consistent electrolyte performance while adapting to industrial manufacturing processes. Current laboratory-scale electrolyte formulations often utilize high-purity reagents and precise mixing conditions that may not be economically viable at scale.

Manufacturing integration of optimized electrolytes demands consideration of several critical factors. First, the sourcing of raw materials must transition from analytical-grade chemicals to industrial-grade alternatives without compromising electrochemical performance. This shift typically introduces additional impurities that may affect battery cycling stability and requires robust formulation adjustments to maintain performance metrics.

Process parameters for large-scale electrolyte preparation differ substantially from laboratory methods. Industrial mixing equipment operates under different shear conditions and temperature gradients compared to laboratory magnetic stirrers or ultrasonic baths. These differences can affect the dissolution kinetics of electrolyte components and the formation of any complex species critical to battery performance. Manufacturers must develop specific protocols that account for these equipment-specific variations.

Quality control represents another crucial aspect of electrolyte manufacturing integration. Continuous monitoring systems must be implemented to ensure consistent ionic conductivity, pH levels, and viscosity across production batches. Automated in-line measurement technologies can provide real-time feedback for process adjustments, reducing batch-to-batch variations that could compromise battery performance.

Environmental considerations also impact scalability of electrolyte production. Water-based electrolytes for iron-air batteries offer advantages in terms of reduced environmental impact compared to organic solvent-based alternatives used in lithium-ion technologies. However, the handling of concentrated alkaline solutions requires specialized equipment and safety protocols when scaled to industrial volumes.

Cost optimization represents a final critical consideration. While laboratory formulations may prioritize performance regardless of material costs, commercial viability demands careful balance between performance and economics. This often necessitates reformulation with lower-cost alternatives for certain additives or the development of recovery systems for expensive electrolyte components. Sensitivity analysis of cost-performance relationships can guide manufacturers in identifying the optimal formulation for specific market applications.

Integration with existing battery manufacturing lines requires consideration of electrolyte filling processes, which must be adapted to the specific viscosity and corrosivity profiles of iron-air battery electrolytes. Specialized dispensing equipment and sealing technologies may be necessary to ensure proper cell assembly without contamination or leakage risks.

Manufacturing integration of optimized electrolytes demands consideration of several critical factors. First, the sourcing of raw materials must transition from analytical-grade chemicals to industrial-grade alternatives without compromising electrochemical performance. This shift typically introduces additional impurities that may affect battery cycling stability and requires robust formulation adjustments to maintain performance metrics.

Process parameters for large-scale electrolyte preparation differ substantially from laboratory methods. Industrial mixing equipment operates under different shear conditions and temperature gradients compared to laboratory magnetic stirrers or ultrasonic baths. These differences can affect the dissolution kinetics of electrolyte components and the formation of any complex species critical to battery performance. Manufacturers must develop specific protocols that account for these equipment-specific variations.

Quality control represents another crucial aspect of electrolyte manufacturing integration. Continuous monitoring systems must be implemented to ensure consistent ionic conductivity, pH levels, and viscosity across production batches. Automated in-line measurement technologies can provide real-time feedback for process adjustments, reducing batch-to-batch variations that could compromise battery performance.

Environmental considerations also impact scalability of electrolyte production. Water-based electrolytes for iron-air batteries offer advantages in terms of reduced environmental impact compared to organic solvent-based alternatives used in lithium-ion technologies. However, the handling of concentrated alkaline solutions requires specialized equipment and safety protocols when scaled to industrial volumes.

Cost optimization represents a final critical consideration. While laboratory formulations may prioritize performance regardless of material costs, commercial viability demands careful balance between performance and economics. This often necessitates reformulation with lower-cost alternatives for certain additives or the development of recovery systems for expensive electrolyte components. Sensitivity analysis of cost-performance relationships can guide manufacturers in identifying the optimal formulation for specific market applications.

Integration with existing battery manufacturing lines requires consideration of electrolyte filling processes, which must be adapted to the specific viscosity and corrosivity profiles of iron-air battery electrolytes. Specialized dispensing equipment and sealing technologies may be necessary to ensure proper cell assembly without contamination or leakage risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!