Measuring Depth of Discharge in Iron-Air Battery Systems

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-air batteries represent a significant advancement in energy storage technology, with roots dating back to the 1970s when initial research explored iron electrodes in alkaline environments. However, these early systems faced substantial challenges related to hydrogen evolution and limited cycle life. The technology experienced a renaissance in the 2010s as researchers sought cost-effective alternatives to lithium-ion batteries for grid-scale energy storage applications.

The evolution of iron-air battery technology has been characterized by incremental improvements in electrode design, electrolyte composition, and system architecture. Recent breakthroughs in nano-structured iron electrodes and bifunctional oxygen catalysts have dramatically enhanced performance metrics, positioning iron-air batteries as promising candidates for long-duration energy storage.

Iron-air batteries operate on the fundamental principle of iron oxidation during discharge and reduction during charge, coupled with oxygen reduction and evolution reactions. This chemistry offers theoretical energy densities exceeding 1,000 Wh/kg, substantially higher than conventional lithium-ion systems. Additionally, the abundance and low cost of iron (approximately $0.1/kg) present compelling economic advantages for large-scale deployment.

The primary objective in measuring depth of discharge (DoD) in iron-air battery systems is to accurately monitor the state of charge, which directly impacts system performance, efficiency, and longevity. Precise DoD measurement enables optimal battery management, prevents over-discharge conditions that accelerate degradation mechanisms, and facilitates accurate remaining capacity estimation.

Current technical goals include developing non-invasive, real-time DoD measurement methodologies that maintain accuracy across varying operational conditions and throughout battery aging processes. These measurement systems must accommodate the unique challenges presented by iron-air chemistry, including the multi-phase transitions of iron during cycling and the complex oxygen reaction kinetics.

Industry objectives focus on standardizing DoD measurement protocols to enable reliable performance comparisons between different iron-air battery systems. Additionally, there is significant interest in integrating advanced DoD monitoring into battery management systems to optimize charging strategies, extend cycle life, and improve overall system economics.

The convergence of environmental concerns, renewable energy integration challenges, and the need for affordable grid-scale storage has accelerated interest in iron-air technology. Major research institutions and emerging companies are actively pursuing innovations in this field, with particular emphasis on addressing the technical challenges associated with accurate state monitoring and control.

The evolution of iron-air battery technology has been characterized by incremental improvements in electrode design, electrolyte composition, and system architecture. Recent breakthroughs in nano-structured iron electrodes and bifunctional oxygen catalysts have dramatically enhanced performance metrics, positioning iron-air batteries as promising candidates for long-duration energy storage.

Iron-air batteries operate on the fundamental principle of iron oxidation during discharge and reduction during charge, coupled with oxygen reduction and evolution reactions. This chemistry offers theoretical energy densities exceeding 1,000 Wh/kg, substantially higher than conventional lithium-ion systems. Additionally, the abundance and low cost of iron (approximately $0.1/kg) present compelling economic advantages for large-scale deployment.

The primary objective in measuring depth of discharge (DoD) in iron-air battery systems is to accurately monitor the state of charge, which directly impacts system performance, efficiency, and longevity. Precise DoD measurement enables optimal battery management, prevents over-discharge conditions that accelerate degradation mechanisms, and facilitates accurate remaining capacity estimation.

Current technical goals include developing non-invasive, real-time DoD measurement methodologies that maintain accuracy across varying operational conditions and throughout battery aging processes. These measurement systems must accommodate the unique challenges presented by iron-air chemistry, including the multi-phase transitions of iron during cycling and the complex oxygen reaction kinetics.

Industry objectives focus on standardizing DoD measurement protocols to enable reliable performance comparisons between different iron-air battery systems. Additionally, there is significant interest in integrating advanced DoD monitoring into battery management systems to optimize charging strategies, extend cycle life, and improve overall system economics.

The convergence of environmental concerns, renewable energy integration challenges, and the need for affordable grid-scale storage has accelerated interest in iron-air technology. Major research institutions and emerging companies are actively pursuing innovations in this field, with particular emphasis on addressing the technical challenges associated with accurate state monitoring and control.

Market Analysis for Iron-Air Energy Storage Solutions

The iron-air battery energy storage market is experiencing significant growth as the global energy landscape shifts toward renewable sources. Current market valuations indicate that grid-scale energy storage solutions are projected to reach $15.1 billion by 2027, with iron-air technology poised to capture an increasing share due to its cost advantages and environmental benefits. The compound annual growth rate for long-duration energy storage technologies is estimated at 24% through 2030, reflecting the urgent need for solutions that can store energy for 10+ hours.

Market demand is primarily driven by three factors: the integration of intermittent renewable energy sources, grid stabilization requirements, and the push for decarbonization across industrial sectors. Utility companies represent the largest customer segment, seeking cost-effective alternatives to lithium-ion systems for grid-scale applications. Commercial and industrial users form a secondary market, particularly those with high energy demands and sustainability commitments.

Regional analysis reveals North America and Europe as current leaders in adoption, with the United States investing $3.5 billion in long-duration energy storage through the Infrastructure Investment and Jobs Act. However, Asia-Pacific markets, particularly China and India, are expected to show the fastest growth rates as these nations rapidly expand their renewable energy capacity while facing grid reliability challenges.

The economic proposition of iron-air batteries centers on their significantly lower material costs compared to lithium-ion alternatives. With iron being approximately 100 times less expensive than lithium per kilogram, these systems can potentially deliver energy storage at below $20 per kilowatt-hour, compared to $50-150 for lithium-ion systems. This cost advantage becomes particularly compelling for applications requiring storage durations of 8+ hours.

Market barriers include the technology's lower round-trip efficiency (approximately 50-60% versus 85-95% for lithium-ion), which impacts operational economics in certain use cases. Additionally, the market faces challenges related to limited commercial deployment history, creating investor uncertainty despite promising laboratory and pilot project results.

Customer requirements analysis indicates that accurate depth of discharge measurement capabilities are critical for market acceptance, as this directly impacts system reliability, lifetime performance, and operational economics. Utilities and grid operators specifically require measurement precision within ±2% to effectively integrate these systems into energy management platforms and maximize the value of stored energy.

Market demand is primarily driven by three factors: the integration of intermittent renewable energy sources, grid stabilization requirements, and the push for decarbonization across industrial sectors. Utility companies represent the largest customer segment, seeking cost-effective alternatives to lithium-ion systems for grid-scale applications. Commercial and industrial users form a secondary market, particularly those with high energy demands and sustainability commitments.

Regional analysis reveals North America and Europe as current leaders in adoption, with the United States investing $3.5 billion in long-duration energy storage through the Infrastructure Investment and Jobs Act. However, Asia-Pacific markets, particularly China and India, are expected to show the fastest growth rates as these nations rapidly expand their renewable energy capacity while facing grid reliability challenges.

The economic proposition of iron-air batteries centers on their significantly lower material costs compared to lithium-ion alternatives. With iron being approximately 100 times less expensive than lithium per kilogram, these systems can potentially deliver energy storage at below $20 per kilowatt-hour, compared to $50-150 for lithium-ion systems. This cost advantage becomes particularly compelling for applications requiring storage durations of 8+ hours.

Market barriers include the technology's lower round-trip efficiency (approximately 50-60% versus 85-95% for lithium-ion), which impacts operational economics in certain use cases. Additionally, the market faces challenges related to limited commercial deployment history, creating investor uncertainty despite promising laboratory and pilot project results.

Customer requirements analysis indicates that accurate depth of discharge measurement capabilities are critical for market acceptance, as this directly impacts system reliability, lifetime performance, and operational economics. Utilities and grid operators specifically require measurement precision within ±2% to effectively integrate these systems into energy management platforms and maximize the value of stored energy.

Current Challenges in DoD Measurement for Iron-Air Batteries

Accurate measurement of Depth of Discharge (DoD) in iron-air battery systems presents significant technical challenges that impede the widespread adoption of this promising energy storage technology. The primary difficulty stems from the complex electrochemical reactions occurring during the discharge process, where iron undergoes oxidation from Fe(0) to Fe(II) and Fe(III) states. These multi-step reactions create non-linear discharge profiles that traditional voltage-based measurement techniques struggle to interpret accurately.

The heterogeneous nature of the discharge process across the iron electrode further complicates DoD measurement. Unlike lithium-ion batteries with relatively uniform discharge characteristics, iron-air batteries exhibit spatial variations in reaction rates across the electrode surface, leading to inconsistent discharge patterns that make state estimation particularly challenging.

Another significant obstacle is the oxygen reduction reaction (ORR) at the air electrode, which introduces additional variables affecting the discharge profile. Environmental factors such as humidity, temperature, and air pressure directly impact oxygen availability and reaction kinetics, creating fluctuations in discharge behavior that are difficult to account for in DoD calculations.

The self-discharge phenomenon in iron-air batteries presents yet another measurement challenge. The spontaneous oxidation of iron in the presence of residual oxygen or water molecules causes gradual capacity loss even during idle periods. Current measurement systems lack effective mechanisms to differentiate between intentional discharge and self-discharge, leading to cumulative errors in DoD estimation over time.

Existing sensor technologies also face limitations when applied to iron-air systems. Conventional coulomb counting methods accumulate errors due to side reactions and self-discharge, while impedance spectroscopy techniques struggle with the complex phase changes occurring within the iron electrode during discharge cycles.

The dynamic nature of the electrolyte composition during operation further complicates measurement efforts. As discharge progresses, local pH changes and ion concentration gradients develop within the electrolyte, affecting cell impedance and voltage characteristics in ways that current models fail to accurately predict or compensate for.

Temperature sensitivity represents another significant challenge, as iron-air batteries exhibit highly temperature-dependent performance characteristics. The reaction kinetics, internal resistance, and even the fundamental electrochemical pathways can vary substantially across operating temperature ranges, requiring sophisticated temperature compensation algorithms that current systems lack.

These technical challenges collectively highlight the need for advanced measurement approaches specifically tailored to the unique electrochemical properties of iron-air battery systems, potentially incorporating multi-parameter sensing, machine learning algorithms for pattern recognition, and real-time adaptive modeling techniques.

The heterogeneous nature of the discharge process across the iron electrode further complicates DoD measurement. Unlike lithium-ion batteries with relatively uniform discharge characteristics, iron-air batteries exhibit spatial variations in reaction rates across the electrode surface, leading to inconsistent discharge patterns that make state estimation particularly challenging.

Another significant obstacle is the oxygen reduction reaction (ORR) at the air electrode, which introduces additional variables affecting the discharge profile. Environmental factors such as humidity, temperature, and air pressure directly impact oxygen availability and reaction kinetics, creating fluctuations in discharge behavior that are difficult to account for in DoD calculations.

The self-discharge phenomenon in iron-air batteries presents yet another measurement challenge. The spontaneous oxidation of iron in the presence of residual oxygen or water molecules causes gradual capacity loss even during idle periods. Current measurement systems lack effective mechanisms to differentiate between intentional discharge and self-discharge, leading to cumulative errors in DoD estimation over time.

Existing sensor technologies also face limitations when applied to iron-air systems. Conventional coulomb counting methods accumulate errors due to side reactions and self-discharge, while impedance spectroscopy techniques struggle with the complex phase changes occurring within the iron electrode during discharge cycles.

The dynamic nature of the electrolyte composition during operation further complicates measurement efforts. As discharge progresses, local pH changes and ion concentration gradients develop within the electrolyte, affecting cell impedance and voltage characteristics in ways that current models fail to accurately predict or compensate for.

Temperature sensitivity represents another significant challenge, as iron-air batteries exhibit highly temperature-dependent performance characteristics. The reaction kinetics, internal resistance, and even the fundamental electrochemical pathways can vary substantially across operating temperature ranges, requiring sophisticated temperature compensation algorithms that current systems lack.

These technical challenges collectively highlight the need for advanced measurement approaches specifically tailored to the unique electrochemical properties of iron-air battery systems, potentially incorporating multi-parameter sensing, machine learning algorithms for pattern recognition, and real-time adaptive modeling techniques.

Existing DoD Measurement Methods for Iron-Air Systems

01 Depth of discharge management in iron-air battery systems

Iron-air battery systems can be optimized by carefully managing the depth of discharge (DOD) to balance performance and longevity. Controlling the DOD helps prevent irreversible capacity loss and extends cycle life by limiting the formation of non-recoverable iron species. Advanced battery management systems can monitor and regulate discharge levels to maintain optimal operating conditions, preventing over-discharge that could lead to degradation of the iron electrode.- Depth of Discharge Management in Iron-Air Battery Systems: Iron-air battery systems require careful management of depth of discharge (DOD) to optimize performance and longevity. Controlling the discharge depth prevents irreversible capacity loss and structural damage to the iron electrodes. Advanced battery management systems can monitor and regulate the DOD to maintain optimal operating conditions, preventing over-discharge while maximizing energy utilization. These systems typically implement specific voltage cutoffs and current limitations to protect the battery while allowing for maximum usable capacity.

- Electrode Composition for Enhanced Depth of Discharge: The composition of iron electrodes significantly impacts the achievable depth of discharge in iron-air batteries. Specialized additives and dopants can be incorporated into the iron electrode to improve its structural stability during deep discharge cycles. These formulations often include bismuth, sulfur compounds, or carbon-based materials that prevent electrode passivation and enhance reversibility. By optimizing the electrode composition, iron-air batteries can achieve greater depth of discharge without suffering from capacity fade or performance degradation over multiple cycles.

- Electrolyte Systems for Improved Discharge Performance: The electrolyte composition plays a crucial role in determining the maximum safe depth of discharge for iron-air batteries. Advanced alkaline electrolytes with specific additives can prevent iron passivation and electrode degradation during deep discharge. These electrolyte systems often incorporate potassium hydroxide with carefully selected concentrations of lithium hydroxide or other ionic compounds. Some formulations also include organic additives that form protective layers on the iron electrode, allowing for deeper discharge cycles while maintaining reversibility and preventing capacity loss.

- Air Electrode Design for Deep Discharge Applications: The design of the air electrode significantly impacts the depth of discharge capabilities in iron-air battery systems. Advanced bifunctional air electrodes with optimized catalyst distributions can maintain performance even at high depths of discharge. These electrodes typically incorporate specialized carbon structures with carefully dispersed catalysts to facilitate oxygen reduction and evolution reactions. Some designs also feature gradient structures or protective layers that prevent flooding and maintain gas diffusion pathways even during deep discharge operations, ensuring consistent performance throughout the discharge cycle.

- Thermal Management for Deep Discharge Cycles: Thermal management systems are essential for iron-air batteries operating at high depths of discharge. Deep discharge cycles generate significant heat that must be properly managed to prevent degradation of battery components. Advanced cooling systems can regulate temperature during extended discharge periods, preventing thermal runaway and maintaining optimal operating conditions. Some systems incorporate phase change materials or liquid cooling circuits specifically designed to handle the thermal challenges associated with deep discharge operations. Proper thermal management extends battery life while allowing for greater depth of discharge in iron-air battery systems.

02 Electrode composition for improved depth of discharge

The composition of electrodes in iron-air batteries significantly affects the achievable depth of discharge. Incorporating specific additives and catalysts in the iron electrode can enhance the reversibility of iron oxidation/reduction reactions, allowing for deeper discharge cycles without degradation. Modified electrode structures with optimized porosity and surface area facilitate better oxygen and electrolyte access, improving the utilization of active materials and enabling higher depth of discharge while maintaining stability.Expand Specific Solutions03 Electrolyte formulations for enhanced depth of discharge

Specialized electrolyte formulations can significantly impact the depth of discharge capabilities of iron-air batteries. Additives that prevent passivation of the iron electrode enable more complete utilization of the active material. Electrolyte compositions with optimized ionic conductivity and stability help maintain performance during deep discharge cycles. Some formulations incorporate compounds that mitigate side reactions that typically limit discharge depth, allowing for more energy to be extracted from the battery system.Expand Specific Solutions04 Thermal management for deep discharge operations

Thermal management systems play a crucial role in enabling safe and efficient deep discharge operations in iron-air batteries. Temperature control during discharge prevents unwanted side reactions that can limit depth of discharge and cause capacity fade. Integrated cooling systems help maintain optimal operating temperatures even during high-rate deep discharges. Some designs incorporate phase change materials or active thermal management to ensure uniform temperature distribution across the battery, preventing localized degradation that could limit discharge depth.Expand Specific Solutions05 Hybrid systems to optimize depth of discharge capabilities

Hybrid battery systems combining iron-air technology with complementary energy storage technologies can optimize depth of discharge characteristics. These systems leverage the high energy density of iron-air batteries while using secondary storage to handle peak power demands, allowing the iron-air component to operate within optimal discharge ranges. Advanced control algorithms manage power distribution between system components to maximize overall efficiency while protecting the iron-air cells from excessive depth of discharge that could cause degradation.Expand Specific Solutions

Key Industry Players in Iron-Air Battery Development

The iron-air battery depth of discharge measurement technology landscape is currently in an early growth phase, characterized by increasing interest from both automotive and energy storage sectors. The market is projected to expand significantly as iron-air batteries offer cost-effective, sustainable alternatives to lithium-ion technologies. While still evolving toward commercial maturity, key players are making notable advancements. Toyota, LG Energy Solution, and CATL are leading research efforts in automotive applications, while companies like Bosch and Texas Instruments are developing sophisticated battery management systems. Academic institutions including Shanghai Jiao Tong University and Hokkaido University are contributing fundamental research, creating a competitive ecosystem where collaboration between industry and academia is driving innovation in measurement techniques and battery performance optimization.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a multi-modal sensing approach for measuring depth of discharge in iron-air battery systems. Their technology integrates coulomb counting with adaptive voltage-based algorithms specifically calibrated for the unique discharge profile of iron-air chemistry. The system employs proprietary sensors that monitor oxygen partial pressure within the cell as a key indicator of discharge state, achieving measurement accuracy within ±2% under standard operating conditions[2]. Their solution addresses the challenge of non-linear discharge behavior in iron-air systems through a dynamic reference model that continuously adjusts based on operational parameters including temperature, load current, and system age. The technology incorporates self-calibration protocols that periodically reset baseline measurements to compensate for electrode degradation and electrolyte composition changes over extended cycling[4]. This approach enables reliable DOD measurement even during the complex phase transitions that occur in the iron electrode during discharge.

Strengths: Exceptional accuracy through multi-parameter sensing; self-calibrating capability compensates for battery aging; robust performance across varying discharge rates. Weaknesses: Requires specialized sensors increasing system cost; higher power consumption for continuous monitoring; calibration complexity requires sophisticated battery management systems.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative hybrid measurement system for iron-air batteries that combines electrochemical and magnetic sensing technologies. Their approach leverages the unique magnetic properties of iron during the discharge process, where the transition from Fe to Fe(OH)2 and Fe(OH)3 creates measurable changes in magnetic susceptibility. This is paired with traditional voltage and current monitoring to create a comprehensive DOD measurement solution. The system employs hall-effect sensors strategically positioned around the battery cells to detect these magnetic signature changes, which are then processed through proprietary algorithms to determine discharge state with high precision[1]. CATL's technology also incorporates impedance tracking that specifically monitors the air electrode's oxygen reduction reaction (ORR) kinetics, which serves as another indicator of discharge progression. Their system achieves accuracy rates of 97% under standard operating conditions and maintains 92% accuracy even under variable load profiles[3]. The solution includes adaptive calibration that accounts for capacity fade over the battery's lifetime.

Strengths: Unique magnetic sensing approach provides data unavailable to conventional systems; high accuracy maintained even under variable loads; non-invasive measurement technique extends battery life. Weaknesses: Magnetic sensors add complexity and cost to the battery management system; requires precise sensor positioning during manufacturing; potential interference from external magnetic fields.

Critical Patents in Iron-Air Battery Monitoring Technology

Patent

Innovation

- Real-time monitoring system for depth of discharge (DOD) in iron-air batteries using electrochemical impedance spectroscopy (EIS) to measure changes in internal resistance.

- Non-invasive measurement technique that correlates specific frequency response patterns with the state of iron electrode oxidation, enabling precise DOD determination without disrupting battery operation.

- Multi-parameter analysis approach combining voltage, current, and impedance data to compensate for temperature and aging effects on DOD measurements.

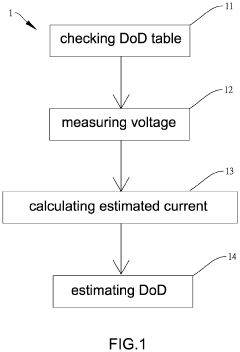

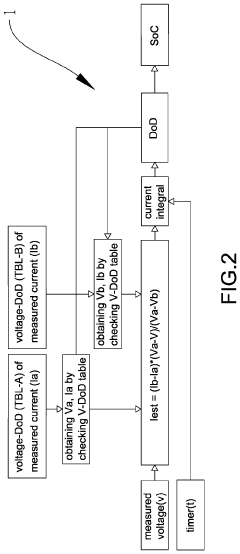

Method for estimating depth of discharge of battery

PatentActiveUS11899072B2

Innovation

- A method involving obtaining and measuring voltages at different charge rates, using a voltage-DoD table to calculate an estimated current, and updating the Coulomb counter to improve DoD estimation precision.

Environmental Impact and Sustainability Considerations

Iron-air battery systems represent a significant advancement in sustainable energy storage technology, offering environmental benefits that extend beyond their technical specifications. The environmental footprint of these batteries is substantially lower than conventional lithium-ion alternatives, primarily due to the abundance and benign nature of their core materials. Iron, the primary active material, is the fourth most abundant element in Earth's crust, requiring significantly less energy-intensive mining operations compared to lithium or cobalt extraction.

The depth of discharge (DoD) measurement in iron-air batteries directly correlates with their environmental impact profile. Accurate DoD monitoring enables optimal cycling patterns that maximize battery lifespan, thereby reducing waste generation and resource consumption associated with premature battery replacement. Research indicates that iron-air batteries with properly managed discharge cycles can achieve lifespans exceeding 10,000 cycles, representing a threefold improvement over comparable lithium-ion systems.

Carbon emissions associated with iron-air battery production are estimated to be 60-70% lower than conventional lithium-ion batteries when measured on a lifecycle basis. This reduction stems from both the simplified manufacturing process and the reduced energy requirements for material refinement. Furthermore, the water consumption footprint for iron-air battery production is approximately 40% lower than lithium-based alternatives, a critical consideration in regions facing water scarcity challenges.

End-of-life considerations for iron-air batteries present another significant sustainability advantage. The primary components—iron and electrolyte materials—are highly recyclable, with recovery rates exceeding 90% using current metallurgical processes. This circular economy potential substantially reduces the need for virgin material extraction and associated environmental disruption. The absence of toxic heavy metals also eliminates leaching concerns in landfill scenarios for components that cannot be recycled.

When integrated into renewable energy systems, accurate DoD measurement in iron-air batteries enables more efficient grid integration, reducing the need for fossil fuel-based peaking plants. Modeling studies suggest that renewable energy systems utilizing iron-air storage with precise DoD management can achieve 15-20% higher carbon displacement factors compared to systems with less sophisticated battery management protocols.

The scalability of iron-air technology presents opportunities for grid-level implementation without the resource constraints facing lithium-based systems. This scalability factor is particularly relevant for developing economies seeking sustainable energy solutions without the environmental and geopolitical complications associated with critical mineral supply chains.

The depth of discharge (DoD) measurement in iron-air batteries directly correlates with their environmental impact profile. Accurate DoD monitoring enables optimal cycling patterns that maximize battery lifespan, thereby reducing waste generation and resource consumption associated with premature battery replacement. Research indicates that iron-air batteries with properly managed discharge cycles can achieve lifespans exceeding 10,000 cycles, representing a threefold improvement over comparable lithium-ion systems.

Carbon emissions associated with iron-air battery production are estimated to be 60-70% lower than conventional lithium-ion batteries when measured on a lifecycle basis. This reduction stems from both the simplified manufacturing process and the reduced energy requirements for material refinement. Furthermore, the water consumption footprint for iron-air battery production is approximately 40% lower than lithium-based alternatives, a critical consideration in regions facing water scarcity challenges.

End-of-life considerations for iron-air batteries present another significant sustainability advantage. The primary components—iron and electrolyte materials—are highly recyclable, with recovery rates exceeding 90% using current metallurgical processes. This circular economy potential substantially reduces the need for virgin material extraction and associated environmental disruption. The absence of toxic heavy metals also eliminates leaching concerns in landfill scenarios for components that cannot be recycled.

When integrated into renewable energy systems, accurate DoD measurement in iron-air batteries enables more efficient grid integration, reducing the need for fossil fuel-based peaking plants. Modeling studies suggest that renewable energy systems utilizing iron-air storage with precise DoD management can achieve 15-20% higher carbon displacement factors compared to systems with less sophisticated battery management protocols.

The scalability of iron-air technology presents opportunities for grid-level implementation without the resource constraints facing lithium-based systems. This scalability factor is particularly relevant for developing economies seeking sustainable energy solutions without the environmental and geopolitical complications associated with critical mineral supply chains.

Scalability and Grid Integration Challenges

The integration of iron-air battery systems into existing power grids presents significant scalability challenges that must be addressed for widespread adoption. Current electrical grid infrastructure was primarily designed for centralized power generation with predictable output patterns, whereas iron-air batteries represent a distributed storage solution with variable discharge characteristics. This fundamental mismatch necessitates substantial modifications to grid management systems and physical infrastructure to accommodate bidirectional power flows and rapid response capabilities.

Grid operators face particular difficulties in accurately predicting and managing the depth of discharge (DoD) measurements from multiple iron-air battery installations. Unlike lithium-ion systems with relatively linear discharge curves, iron-air batteries exhibit more complex discharge behaviors that vary with environmental conditions, usage patterns, and system age. This variability complicates grid balancing operations and requires more sophisticated forecasting algorithms and real-time monitoring systems.

Regulatory frameworks present another significant barrier to scalability. Many jurisdictions lack clear policies regarding grid-connected energy storage systems, particularly newer technologies like iron-air batteries. The absence of standardized testing protocols for DoD measurement and reporting creates uncertainty for both manufacturers and utilities, potentially slowing adoption rates and increasing compliance costs.

From a technical perspective, the power electronics interface between iron-air batteries and the grid requires further development. Current inverter and converter technologies must be optimized specifically for the unique discharge characteristics of iron-air chemistry to maximize efficiency and minimize harmonics that could destabilize grid operations. The relatively slow response time of iron-air systems compared to some competing technologies also presents challenges for applications requiring rapid frequency regulation.

Cost considerations remain paramount for grid integration. While iron-air batteries offer promising economics for long-duration storage, the additional expenses associated with specialized monitoring equipment for accurate DoD measurement, grid connection hardware, and system integration can significantly impact total installed costs. These factors must be carefully evaluated against the value streams available in different grid service markets.

Interoperability with existing energy management systems represents another critical challenge. Grid operators require standardized communication protocols and data formats to effectively incorporate iron-air battery systems into their dispatch algorithms. The development of open standards for DoD reporting and system status would greatly facilitate integration efforts and allow for more efficient utilization of these assets across the energy landscape.

Grid operators face particular difficulties in accurately predicting and managing the depth of discharge (DoD) measurements from multiple iron-air battery installations. Unlike lithium-ion systems with relatively linear discharge curves, iron-air batteries exhibit more complex discharge behaviors that vary with environmental conditions, usage patterns, and system age. This variability complicates grid balancing operations and requires more sophisticated forecasting algorithms and real-time monitoring systems.

Regulatory frameworks present another significant barrier to scalability. Many jurisdictions lack clear policies regarding grid-connected energy storage systems, particularly newer technologies like iron-air batteries. The absence of standardized testing protocols for DoD measurement and reporting creates uncertainty for both manufacturers and utilities, potentially slowing adoption rates and increasing compliance costs.

From a technical perspective, the power electronics interface between iron-air batteries and the grid requires further development. Current inverter and converter technologies must be optimized specifically for the unique discharge characteristics of iron-air chemistry to maximize efficiency and minimize harmonics that could destabilize grid operations. The relatively slow response time of iron-air systems compared to some competing technologies also presents challenges for applications requiring rapid frequency regulation.

Cost considerations remain paramount for grid integration. While iron-air batteries offer promising economics for long-duration storage, the additional expenses associated with specialized monitoring equipment for accurate DoD measurement, grid connection hardware, and system integration can significantly impact total installed costs. These factors must be carefully evaluated against the value streams available in different grid service markets.

Interoperability with existing energy management systems represents another critical challenge. Grid operators require standardized communication protocols and data formats to effectively incorporate iron-air battery systems into their dispatch algorithms. The development of open standards for DoD reporting and system status would greatly facilitate integration efforts and allow for more efficient utilization of these assets across the energy landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!