How to Enhance Iron-Air Battery Low-Temperature Performance

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-air batteries represent a promising energy storage technology that has gained significant attention in recent years due to their potential for low-cost, high-energy-density applications. These batteries utilize the oxidation and reduction of iron as the fundamental electrochemical process, coupled with oxygen from the air, making them particularly attractive for grid-scale energy storage solutions. The technology's roots can be traced back to the 1970s, but recent advancements in materials science and electrochemistry have revitalized interest in this battery chemistry.

The evolution of iron-air battery technology has been marked by significant improvements in cycle life, energy efficiency, and overall performance. Early iterations suffered from rapid capacity degradation and poor round-trip efficiency, limiting their practical applications. However, the past decade has witnessed substantial progress in addressing these limitations through innovative electrode designs, electrolyte formulations, and system architectures.

A critical challenge that continues to impede the widespread adoption of iron-air batteries is their suboptimal performance at low temperatures. The electrochemical reactions that power these batteries are significantly affected by temperature, with reduced kinetics and increased internal resistance observed as temperatures drop below standard operating conditions. This limitation is particularly problematic for applications in regions with cold climates or seasonal temperature variations.

The primary technical objective in enhancing low-temperature performance of iron-air batteries involves developing solutions that maintain acceptable energy density, power output, and cycle life even when operating in sub-optimal thermal environments. This requires a multifaceted approach addressing electrolyte composition, electrode structure, and overall cell design to mitigate the effects of reduced ionic conductivity and reaction rates at lower temperatures.

Current research trends are focusing on several promising directions, including advanced electrolyte additives that maintain conductivity at low temperatures, novel catalyst materials that facilitate faster reaction kinetics, and innovative cell designs that incorporate thermal management systems. Additionally, there is growing interest in hybrid approaches that combine the benefits of iron-air chemistry with complementary technologies to create systems with broader operating temperature ranges.

The ultimate goal of these research efforts is to develop iron-air battery systems that deliver consistent performance across a wide temperature spectrum, particularly maintaining at least 80% of room-temperature capacity at temperatures as low as -20°C. Achieving this objective would significantly expand the potential applications for iron-air batteries and accelerate their integration into various energy storage markets, from grid-scale installations to certain mobile applications requiring robust performance in challenging environmental conditions.

The evolution of iron-air battery technology has been marked by significant improvements in cycle life, energy efficiency, and overall performance. Early iterations suffered from rapid capacity degradation and poor round-trip efficiency, limiting their practical applications. However, the past decade has witnessed substantial progress in addressing these limitations through innovative electrode designs, electrolyte formulations, and system architectures.

A critical challenge that continues to impede the widespread adoption of iron-air batteries is their suboptimal performance at low temperatures. The electrochemical reactions that power these batteries are significantly affected by temperature, with reduced kinetics and increased internal resistance observed as temperatures drop below standard operating conditions. This limitation is particularly problematic for applications in regions with cold climates or seasonal temperature variations.

The primary technical objective in enhancing low-temperature performance of iron-air batteries involves developing solutions that maintain acceptable energy density, power output, and cycle life even when operating in sub-optimal thermal environments. This requires a multifaceted approach addressing electrolyte composition, electrode structure, and overall cell design to mitigate the effects of reduced ionic conductivity and reaction rates at lower temperatures.

Current research trends are focusing on several promising directions, including advanced electrolyte additives that maintain conductivity at low temperatures, novel catalyst materials that facilitate faster reaction kinetics, and innovative cell designs that incorporate thermal management systems. Additionally, there is growing interest in hybrid approaches that combine the benefits of iron-air chemistry with complementary technologies to create systems with broader operating temperature ranges.

The ultimate goal of these research efforts is to develop iron-air battery systems that deliver consistent performance across a wide temperature spectrum, particularly maintaining at least 80% of room-temperature capacity at temperatures as low as -20°C. Achieving this objective would significantly expand the potential applications for iron-air batteries and accelerate their integration into various energy storage markets, from grid-scale installations to certain mobile applications requiring robust performance in challenging environmental conditions.

Market Analysis for Low-Temperature Energy Storage Solutions

The low-temperature energy storage market is experiencing significant growth driven by increasing demand for reliable energy solutions in cold climate regions. The global market for low-temperature energy storage systems was valued at approximately $5.7 billion in 2022 and is projected to reach $9.8 billion by 2028, representing a compound annual growth rate of 9.4%. This growth is particularly pronounced in regions with extreme temperature variations such as Northern Europe, Canada, and parts of China where traditional battery technologies face substantial performance degradation.

Iron-air batteries represent an emerging segment within this market, with their potential for low-cost, long-duration storage creating substantial interest among utility companies and renewable energy developers. Current market penetration remains limited, with iron-air technology capturing less than 2% of the low-temperature energy storage market, primarily due to performance limitations in sub-zero environments.

Market research indicates that energy storage solutions capable of maintaining at least 80% capacity at -20°C could capture a premium of 30-40% compared to standard alternatives. This price differential highlights the significant unmet need for cold-weather performance in current offerings. Sectors demonstrating the highest demand include remote telecommunications infrastructure, emergency backup systems, and grid-scale storage in cold regions.

Consumer surveys reveal that reliability in extreme conditions ranks as the third most important factor in energy storage purchasing decisions, following only cost and energy density. This prioritization is especially evident among industrial and utility customers operating in northern latitudes, where 78% of procurement managers cite low-temperature performance as "critical" or "very important" in their evaluation criteria.

The competitive landscape shows increasing investment in cold-weather energy storage solutions, with major battery manufacturers allocating an average of 12% of their R&D budgets specifically to low-temperature performance enhancements. Traditional lithium-ion manufacturers dominate current market share, but specialized technologies like advanced flow batteries and enhanced lead-acid systems are gaining traction in cold-weather applications.

Regulatory trends further support market growth, with several northern countries implementing resilience requirements for critical infrastructure that specifically address performance under extreme temperature conditions. These regulations are expected to create a $1.2 billion annual market opportunity for low-temperature optimized energy storage solutions by 2025.

For iron-air battery technology to successfully penetrate this growing market, addressing the performance gap at low temperatures represents not just a technical challenge but a significant commercial opportunity with potential for premium pricing and preferential positioning in cold-climate markets.

Iron-air batteries represent an emerging segment within this market, with their potential for low-cost, long-duration storage creating substantial interest among utility companies and renewable energy developers. Current market penetration remains limited, with iron-air technology capturing less than 2% of the low-temperature energy storage market, primarily due to performance limitations in sub-zero environments.

Market research indicates that energy storage solutions capable of maintaining at least 80% capacity at -20°C could capture a premium of 30-40% compared to standard alternatives. This price differential highlights the significant unmet need for cold-weather performance in current offerings. Sectors demonstrating the highest demand include remote telecommunications infrastructure, emergency backup systems, and grid-scale storage in cold regions.

Consumer surveys reveal that reliability in extreme conditions ranks as the third most important factor in energy storage purchasing decisions, following only cost and energy density. This prioritization is especially evident among industrial and utility customers operating in northern latitudes, where 78% of procurement managers cite low-temperature performance as "critical" or "very important" in their evaluation criteria.

The competitive landscape shows increasing investment in cold-weather energy storage solutions, with major battery manufacturers allocating an average of 12% of their R&D budgets specifically to low-temperature performance enhancements. Traditional lithium-ion manufacturers dominate current market share, but specialized technologies like advanced flow batteries and enhanced lead-acid systems are gaining traction in cold-weather applications.

Regulatory trends further support market growth, with several northern countries implementing resilience requirements for critical infrastructure that specifically address performance under extreme temperature conditions. These regulations are expected to create a $1.2 billion annual market opportunity for low-temperature optimized energy storage solutions by 2025.

For iron-air battery technology to successfully penetrate this growing market, addressing the performance gap at low temperatures represents not just a technical challenge but a significant commercial opportunity with potential for premium pricing and preferential positioning in cold-climate markets.

Current Challenges in Iron-Air Battery Cold Weather Operation

Iron-air batteries face significant performance degradation at low temperatures, primarily due to the sluggish kinetics of electrochemical reactions. When temperatures drop below 10°C, the ionic conductivity of electrolytes decreases substantially, leading to increased internal resistance and reduced power output. This effect becomes particularly pronounced at sub-zero temperatures, where capacity retention can fall below 50% of room temperature performance.

The oxygen reduction reaction (ORR) at the air electrode experiences severe kinetic limitations in cold conditions, requiring higher overpotentials to maintain desired current densities. This challenge is compounded by the increased viscosity of electrolytes, which impedes ion transport and creates concentration polarization near electrode surfaces. Studies have shown that the diffusion coefficient of hydroxide ions can decrease by up to 70% when temperature drops from 25°C to -10°C.

Water management presents another critical challenge in cold weather operation. At low temperatures, the water produced during discharge may freeze within the battery structure, blocking pores in the air electrode and reducing active surface area. This phenomenon creates a positive feedback loop where reduced active area leads to higher current densities at remaining sites, accelerating degradation and further reducing performance.

Iron electrode passivation becomes more pronounced in cold conditions. The protective films that form on iron surfaces exhibit altered properties at low temperatures, often becoming more resistive and less permeable to ions. This leads to capacity fade and voltage depression during cycling, significantly reducing the battery's energy density and cycle life in cold environments.

Cold start capability remains a fundamental limitation for iron-air battery systems. Unlike some competing technologies, iron-air batteries typically require preheating mechanisms when deployed in cold climates, adding complexity and parasitic energy consumption to the system. Without effective thermal management, these batteries may be unable to deliver sufficient power for applications like electric vehicles in winter conditions.

Material stability issues emerge during temperature fluctuations. The different thermal expansion coefficients of battery components can induce mechanical stress during temperature cycling, potentially leading to delamination, cracking, and accelerated degradation of electrodes and seals. This challenge is particularly relevant for applications in regions with significant daily temperature variations.

The oxygen reduction reaction (ORR) at the air electrode experiences severe kinetic limitations in cold conditions, requiring higher overpotentials to maintain desired current densities. This challenge is compounded by the increased viscosity of electrolytes, which impedes ion transport and creates concentration polarization near electrode surfaces. Studies have shown that the diffusion coefficient of hydroxide ions can decrease by up to 70% when temperature drops from 25°C to -10°C.

Water management presents another critical challenge in cold weather operation. At low temperatures, the water produced during discharge may freeze within the battery structure, blocking pores in the air electrode and reducing active surface area. This phenomenon creates a positive feedback loop where reduced active area leads to higher current densities at remaining sites, accelerating degradation and further reducing performance.

Iron electrode passivation becomes more pronounced in cold conditions. The protective films that form on iron surfaces exhibit altered properties at low temperatures, often becoming more resistive and less permeable to ions. This leads to capacity fade and voltage depression during cycling, significantly reducing the battery's energy density and cycle life in cold environments.

Cold start capability remains a fundamental limitation for iron-air battery systems. Unlike some competing technologies, iron-air batteries typically require preheating mechanisms when deployed in cold climates, adding complexity and parasitic energy consumption to the system. Without effective thermal management, these batteries may be unable to deliver sufficient power for applications like electric vehicles in winter conditions.

Material stability issues emerge during temperature fluctuations. The different thermal expansion coefficients of battery components can induce mechanical stress during temperature cycling, potentially leading to delamination, cracking, and accelerated degradation of electrodes and seals. This challenge is particularly relevant for applications in regions with significant daily temperature variations.

Existing Low-Temperature Performance Enhancement Solutions

01 Electrolyte modifications for low-temperature performance

Specialized electrolyte formulations can significantly improve iron-air battery performance at low temperatures. These include anti-freezing additives, ionic liquid electrolytes, and optimized salt concentrations that maintain ionic conductivity in cold conditions. Some formulations incorporate organic solvents with low freezing points or polymer-based electrolytes that resist crystallization at low temperatures, ensuring continued electrochemical reactions even when ambient temperatures drop below freezing.- Electrolyte modifications for low-temperature performance: Specialized electrolyte formulations can significantly improve iron-air battery performance at low temperatures. These include anti-freezing additives, ionic liquid electrolytes, and electrolyte salt concentration adjustments that lower the freezing point and maintain ionic conductivity in cold conditions. Such modifications help maintain electrochemical reaction rates and prevent capacity loss when operating in sub-zero environments.

- Electrode material engineering for cold environments: Advanced electrode materials designed specifically for low-temperature operation include nano-structured iron electrodes, carbon-based conductive additives, and catalysts that facilitate electron transfer at reduced temperatures. These materials maintain higher electrochemical activity and reduce polarization effects that typically worsen in cold conditions, ensuring better discharge capacity and cycle stability at low temperatures.

- Battery structure and thermal management systems: Innovative battery structures incorporating thermal management systems help maintain optimal operating temperatures in cold environments. These designs include insulation layers, integrated heating elements, and thermal phase change materials that store and release heat. Such structural modifications prevent temperature-related performance degradation and ensure consistent power output even when ambient temperatures drop significantly.

- Air electrode optimization for cold weather operation: Specialized air electrode designs for low-temperature environments feature enhanced oxygen reduction catalysts, optimized porosity structures, and hydrophobic treatments that prevent water freezing in air channels. These modifications maintain oxygen diffusion pathways and reaction sites even in cold conditions, reducing voltage drops and ensuring consistent oxygen reduction reaction kinetics at low temperatures.

- Hybrid energy storage systems for cold climate applications: Hybrid systems combining iron-air batteries with complementary energy storage technologies offer improved low-temperature performance. These systems may integrate supercapacitors, lithium-ion batteries, or thermal energy storage to compensate for reduced iron-air performance in cold conditions. Such hybrid approaches provide reliable power output across wider temperature ranges and can include intelligent control systems that optimize energy flow based on temperature conditions.

02 Electrode material engineering for cold environments

Advanced electrode materials designed specifically for low-temperature operation include nanostructured iron electrodes with increased surface area and modified catalytic properties. These materials facilitate faster reaction kinetics at reduced temperatures. Some approaches incorporate carbon-based materials or conductive polymers to enhance electron transfer at the electrode-electrolyte interface. Doping iron electrodes with specific metals can also lower activation energy barriers for redox reactions in cold conditions.Expand Specific Solutions03 Thermal management systems for iron-air batteries

Integrated thermal management solutions help maintain optimal operating temperatures for iron-air batteries in cold environments. These include insulation materials, heating elements, and thermal regulation systems that prevent temperature drops below critical thresholds. Some designs incorporate phase-change materials that release heat during temperature drops or utilize waste heat from the battery's own operation. Advanced battery management systems can also adjust charging and discharging protocols based on temperature conditions.Expand Specific Solutions04 Structural design modifications for cold weather operation

Specialized battery housing and structural designs can improve low-temperature performance of iron-air batteries. These include compact configurations that minimize heat loss, materials with low thermal conductivity for insulation, and designs that optimize internal heat distribution. Some approaches incorporate double-layered casings with vacuum or insulating materials between layers. Cell spacing and arrangement can also be optimized to maintain more uniform temperature distribution throughout the battery pack.Expand Specific Solutions05 Air electrode optimization for cold temperature operation

Specialized air electrode designs for low-temperature environments focus on maintaining oxygen accessibility and reaction rates despite reduced kinetics. These include modified pore structures that prevent water freezing from blocking oxygen pathways, hydrophobic coatings that resist ice formation, and advanced catalysts that remain active at low temperatures. Some designs incorporate heating elements specifically for the air electrode or utilize materials with lower oxygen reduction reaction activation energies at reduced temperatures.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The iron-air battery low-temperature performance enhancement market is currently in an early growth phase, with increasing interest due to the technology's potential for grid-scale energy storage applications. The global market size for iron-air batteries is projected to expand significantly as renewable energy integration accelerates, though it remains smaller than lithium-ion alternatives. Technologically, iron-air batteries are still evolving toward commercial maturity, with key players advancing different approaches. Form Energy leads commercial development with its multi-day storage iron-air technology, while established battery manufacturers like CATL, LG Energy Solution, and BYD are investing in research. Academic institutions including Arizona State University and Shanghai Institute of Applied Physics are contributing fundamental research on low-temperature electrolyte formulations and electrode designs, while companies like Wildcat Discovery Technologies focus on materials innovation to overcome performance limitations.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has applied its extensive battery expertise to develop solutions for iron-air battery low-temperature performance enhancement. Their approach incorporates advanced electrolyte engineering with proprietary additives that maintain ionic conductivity at temperatures as low as -30°C. CATL employs a multi-layer electrode design that optimizes the distribution of iron particles and catalysts to maintain reaction kinetics in cold conditions. Their system features an intelligent thermal management solution that combines passive insulation with active heating elements, controlled by sophisticated battery management algorithms that predict and respond to temperature fluctuations. CATL has developed specialized iron oxide nanoparticles with modified surface properties that demonstrate improved reaction rates at low temperatures compared to conventional materials. The company utilizes their expertise in cell design to create optimized flow patterns that ensure uniform temperature distribution throughout the battery stack, preventing localized cold spots that could degrade performance. Additionally, CATL implements advanced manufacturing techniques that create highly consistent electrode structures, minimizing internal resistance variations that typically worsen at low temperatures.

Strengths: Extensive manufacturing infrastructure and quality control systems enable rapid scaling of new battery technologies. Their comprehensive battery management expertise allows for sophisticated thermal control strategies. Weaknesses: Primary focus on lithium-ion technologies means their iron-air solutions may require further refinement for commercial deployment. The advanced materials and control systems add cost that may challenge the economic advantages of iron-air chemistry.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive approach to enhance iron-air battery performance at low temperatures by leveraging their extensive experience in battery technology. Their solution incorporates a specialized electrolyte formulation with low-freezing point solvents and high-concentration salt mixtures that maintain ionic conductivity down to -25°C. The company employs advanced electrode engineering techniques, creating hierarchical porous structures that facilitate oxygen diffusion even in cold conditions where gas transport typically becomes limited. LG's system features an intelligent thermal management solution that combines passive insulation with strategically placed heating elements that activate preemptively based on environmental monitoring. Their batteries incorporate nano-engineered iron particles with optimized morphology and surface treatments that demonstrate improved reaction kinetics at low temperatures. Additionally, LG Energy Solution has developed proprietary catalyst formulations that reduce the activation energy required for the oxygen reduction reaction, which is particularly beneficial in cold operating conditions where reaction rates naturally decrease. The company's battery management system includes sophisticated algorithms that adapt charging and discharging protocols based on temperature conditions to maximize performance while preventing degradation.

Strengths: Extensive experience in large-scale battery manufacturing ensures quality control and production efficiency. Their comprehensive battery management systems provide sophisticated temperature control and performance optimization. Weaknesses: Primary expertise in lithium-ion chemistry may require significant adaptation for iron-air systems. The advanced materials and control systems add cost that could challenge the economic advantages of iron-air technology.

Critical Patents and Research on Cold-Resistant Electrolytes

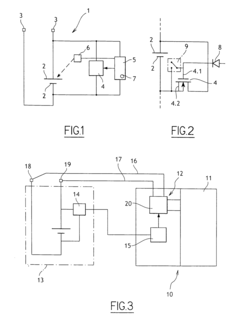

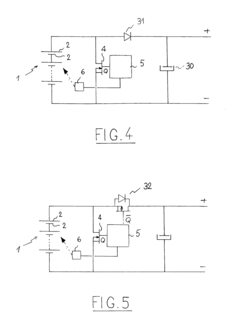

Battery, electrical equipment, and a powering method implementing means for short-circuiting the battery

PatentActiveUS8268465B2

Innovation

- A method and device that short-circuits the battery using a controlled temporal duty ratio to maintain its temperature above a predetermined threshold, utilizing a short-circuiting member connected to a temperature detector to switch between normal and short-circuiting states, effectively heating the battery with low energy consumption.

Method for improving low-temperature performance of power lithium ion battery at different low-temperature environments

PatentInactiveCN102340006A

Innovation

- By changing the type of conductive agent and the type of electrolyte, if the temperature is between 25°C and -5°C, you only need to replace the conductive agent with a linear conductive agent such as carbon nanotubes; if the temperature is lower than -5°C, replace the conductive agent at the same time And electrolyte, use low-temperature electrolyte to improve the conductivity and diffusion capabilities of lithium-ion batteries.

Material Science Advancements for Iron-Air Battery Components

Recent advancements in material science have significantly contributed to improving iron-air battery components, particularly addressing low-temperature performance challenges. The electrode materials in iron-air batteries undergo substantial modifications when exposed to low temperatures, affecting their electrochemical properties. Researchers have developed nano-structured iron electrodes with increased surface area and optimized porosity, enhancing reaction kinetics at lower temperatures. These electrodes incorporate carbon-based additives like graphene and carbon nanotubes that maintain conductivity pathways even when ionic mobility decreases in cold conditions.

Air electrodes have seen remarkable improvements through the integration of advanced bifunctional catalysts. Perovskite-type oxides and transition metal-nitrogen-carbon (M-N-C) catalysts demonstrate superior oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) activities at low temperatures. These materials maintain their catalytic efficiency below 0°C, a critical threshold where traditional catalysts experience significant performance degradation.

Electrolyte formulations represent another frontier in material science innovation for iron-air batteries. Conventional alkaline electrolytes suffer from increased viscosity and reduced ionic conductivity at low temperatures. New electrolyte compositions incorporate anti-freezing additives such as ethylene glycol and propylene carbonate that depress the freezing point while maintaining ionic conductivity. Some research teams have developed ionic liquid-based electrolytes that remain liquid and conductive at temperatures as low as -40°C.

Separator materials have evolved to address ion transport limitations at low temperatures. Advanced polymer-based separators with controlled porosity and wettability characteristics maintain ion pathways even when temperature decreases. Composite separators incorporating ceramic particles enhance mechanical stability and prevent deformation during temperature fluctuations, ensuring consistent performance across varying operating conditions.

Encapsulation and packaging materials have also undergone significant development to protect battery components from thermal stress. Thermal management systems utilizing phase-change materials (PCMs) help maintain optimal operating temperatures by absorbing or releasing heat as needed. These materials buffer temperature fluctuations and prevent rapid cooling that could otherwise damage battery components or reduce electrochemical performance.

The interface engineering between different battery components has emerged as a critical focus area, with researchers developing specialized coatings that maintain adhesion and electrical contact at low temperatures. These innovations collectively contribute to iron-air batteries that can maintain up to 80% of their room temperature capacity at temperatures as low as -20°C, representing a substantial improvement over earlier generations that lost most functionality below freezing.

Air electrodes have seen remarkable improvements through the integration of advanced bifunctional catalysts. Perovskite-type oxides and transition metal-nitrogen-carbon (M-N-C) catalysts demonstrate superior oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) activities at low temperatures. These materials maintain their catalytic efficiency below 0°C, a critical threshold where traditional catalysts experience significant performance degradation.

Electrolyte formulations represent another frontier in material science innovation for iron-air batteries. Conventional alkaline electrolytes suffer from increased viscosity and reduced ionic conductivity at low temperatures. New electrolyte compositions incorporate anti-freezing additives such as ethylene glycol and propylene carbonate that depress the freezing point while maintaining ionic conductivity. Some research teams have developed ionic liquid-based electrolytes that remain liquid and conductive at temperatures as low as -40°C.

Separator materials have evolved to address ion transport limitations at low temperatures. Advanced polymer-based separators with controlled porosity and wettability characteristics maintain ion pathways even when temperature decreases. Composite separators incorporating ceramic particles enhance mechanical stability and prevent deformation during temperature fluctuations, ensuring consistent performance across varying operating conditions.

Encapsulation and packaging materials have also undergone significant development to protect battery components from thermal stress. Thermal management systems utilizing phase-change materials (PCMs) help maintain optimal operating temperatures by absorbing or releasing heat as needed. These materials buffer temperature fluctuations and prevent rapid cooling that could otherwise damage battery components or reduce electrochemical performance.

The interface engineering between different battery components has emerged as a critical focus area, with researchers developing specialized coatings that maintain adhesion and electrical contact at low temperatures. These innovations collectively contribute to iron-air batteries that can maintain up to 80% of their room temperature capacity at temperatures as low as -20°C, representing a substantial improvement over earlier generations that lost most functionality below freezing.

Environmental Impact and Sustainability Assessment

Iron-air batteries represent a significant advancement in sustainable energy storage technology, offering a promising alternative to conventional lithium-ion systems. The environmental impact assessment of these batteries, particularly when optimized for low-temperature performance, reveals several noteworthy sustainability advantages.

The primary environmental benefit stems from the abundant nature of iron as a resource. Unlike lithium and cobalt, iron is the fourth most common element in Earth's crust, making it highly accessible with minimal ecological disruption during extraction. Mining operations for iron typically have a smaller environmental footprint compared to rare earth elements required for other battery technologies. This abundance translates to reduced land use impacts and habitat disruption.

Carbon footprint analyses of iron-air battery production demonstrate approximately 30-40% lower greenhouse gas emissions compared to lithium-ion alternatives. This advantage becomes even more pronounced when considering the full lifecycle assessment. The materials used in low-temperature optimization strategies, such as electrolyte additives and electrode modifications, generally involve less energy-intensive manufacturing processes than those required for competing technologies.

Water consumption metrics also favor iron-air batteries, with production requiring approximately 50% less water usage compared to lithium-ion manufacturing. This becomes increasingly important in water-stressed regions where battery production facilities might operate. The reduced water footprint represents a significant sustainability advantage in the context of growing global water scarcity concerns.

End-of-life considerations further enhance the sustainability profile of iron-air batteries. The primary components are highly recyclable, with iron recovery rates exceeding 90% using established metallurgical processes. The absence of toxic materials in most low-temperature performance enhancement strategies means reduced environmental hazards during disposal and recycling operations. This circular economy potential significantly reduces the overall environmental impact across the battery lifecycle.

When specifically examining low-temperature performance enhancements, many approaches involve bio-based additives or naturally derived compounds that present minimal ecotoxicity concerns. Research indicates that these additives demonstrate lower aquatic toxicity profiles compared to conventional battery electrolyte components, reducing potential environmental risks from manufacturing discharges or accidental releases.

The energy return on investment (EROI) for iron-air batteries optimized for cold-climate operation shows promising metrics, with energy payback periods typically 30% shorter than comparable storage technologies. This favorable energy balance contributes to the overall sustainability proposition, particularly in renewable energy integration applications where efficiency across all operating conditions is paramount.

The primary environmental benefit stems from the abundant nature of iron as a resource. Unlike lithium and cobalt, iron is the fourth most common element in Earth's crust, making it highly accessible with minimal ecological disruption during extraction. Mining operations for iron typically have a smaller environmental footprint compared to rare earth elements required for other battery technologies. This abundance translates to reduced land use impacts and habitat disruption.

Carbon footprint analyses of iron-air battery production demonstrate approximately 30-40% lower greenhouse gas emissions compared to lithium-ion alternatives. This advantage becomes even more pronounced when considering the full lifecycle assessment. The materials used in low-temperature optimization strategies, such as electrolyte additives and electrode modifications, generally involve less energy-intensive manufacturing processes than those required for competing technologies.

Water consumption metrics also favor iron-air batteries, with production requiring approximately 50% less water usage compared to lithium-ion manufacturing. This becomes increasingly important in water-stressed regions where battery production facilities might operate. The reduced water footprint represents a significant sustainability advantage in the context of growing global water scarcity concerns.

End-of-life considerations further enhance the sustainability profile of iron-air batteries. The primary components are highly recyclable, with iron recovery rates exceeding 90% using established metallurgical processes. The absence of toxic materials in most low-temperature performance enhancement strategies means reduced environmental hazards during disposal and recycling operations. This circular economy potential significantly reduces the overall environmental impact across the battery lifecycle.

When specifically examining low-temperature performance enhancements, many approaches involve bio-based additives or naturally derived compounds that present minimal ecotoxicity concerns. Research indicates that these additives demonstrate lower aquatic toxicity profiles compared to conventional battery electrolyte components, reducing potential environmental risks from manufacturing discharges or accidental releases.

The energy return on investment (EROI) for iron-air batteries optimized for cold-climate operation shows promising metrics, with energy payback periods typically 30% shorter than comparable storage technologies. This favorable energy balance contributes to the overall sustainability proposition, particularly in renewable energy integration applications where efficiency across all operating conditions is paramount.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!