Optimizing Iron-Air Battery Design to Reduce Cost

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-air batteries represent a promising energy storage technology that has gained significant attention in recent years due to their potential for low-cost, long-duration energy storage. The fundamental chemistry of these batteries relies on the oxidation and reduction of iron, one of Earth's most abundant elements, making them inherently cost-effective compared to lithium-ion alternatives. The technology's roots can be traced back to the 1970s, but recent advancements in materials science and electrochemistry have revitalized interest in this battery chemistry.

The evolution of iron-air battery technology has been marked by significant improvements in cycle life, energy density, and overall performance. Early iterations suffered from rapid capacity degradation and low efficiency, but modern designs have largely overcome these limitations through innovative electrode structures and electrolyte formulations. The current technological trajectory suggests continued enhancement in performance metrics while maintaining the inherent cost advantages of iron-based chemistry.

The primary objective in optimizing iron-air battery design is to achieve substantial cost reductions while maintaining or improving performance characteristics. This involves addressing several key areas: electrode material optimization, cell architecture refinement, manufacturing process improvement, and system integration enhancement. Cost reduction targets typically aim for below $20 per kilowatt-hour, which would position iron-air batteries as a disruptive technology in the energy storage market.

Material selection represents a critical aspect of cost optimization. Iron, as the active material, offers inherent cost advantages due to its abundance and established supply chains. However, challenges remain in optimizing the iron electrode structure to maximize surface area while minimizing degradation mechanisms. Similarly, air electrode design must balance performance with cost considerations, particularly regarding catalyst materials that facilitate oxygen reduction and evolution reactions.

Manufacturing scalability presents another crucial dimension for cost reduction. Current production methods often involve complex processes that limit economies of scale. Developing streamlined manufacturing techniques that can be implemented at industrial scale represents a key objective for commercialization. This includes innovations in electrode fabrication, cell assembly, and quality control processes.

System-level design optimization further contributes to cost reduction goals. This encompasses battery management systems, thermal management solutions, and integration with power electronics. Simplifying these components while maintaining functionality can significantly impact overall system costs, particularly for grid-scale applications where iron-air batteries show the greatest promise.

The evolution of iron-air battery technology has been marked by significant improvements in cycle life, energy density, and overall performance. Early iterations suffered from rapid capacity degradation and low efficiency, but modern designs have largely overcome these limitations through innovative electrode structures and electrolyte formulations. The current technological trajectory suggests continued enhancement in performance metrics while maintaining the inherent cost advantages of iron-based chemistry.

The primary objective in optimizing iron-air battery design is to achieve substantial cost reductions while maintaining or improving performance characteristics. This involves addressing several key areas: electrode material optimization, cell architecture refinement, manufacturing process improvement, and system integration enhancement. Cost reduction targets typically aim for below $20 per kilowatt-hour, which would position iron-air batteries as a disruptive technology in the energy storage market.

Material selection represents a critical aspect of cost optimization. Iron, as the active material, offers inherent cost advantages due to its abundance and established supply chains. However, challenges remain in optimizing the iron electrode structure to maximize surface area while minimizing degradation mechanisms. Similarly, air electrode design must balance performance with cost considerations, particularly regarding catalyst materials that facilitate oxygen reduction and evolution reactions.

Manufacturing scalability presents another crucial dimension for cost reduction. Current production methods often involve complex processes that limit economies of scale. Developing streamlined manufacturing techniques that can be implemented at industrial scale represents a key objective for commercialization. This includes innovations in electrode fabrication, cell assembly, and quality control processes.

System-level design optimization further contributes to cost reduction goals. This encompasses battery management systems, thermal management solutions, and integration with power electronics. Simplifying these components while maintaining functionality can significantly impact overall system costs, particularly for grid-scale applications where iron-air batteries show the greatest promise.

Market Analysis for Low-Cost Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the pressing need for grid stability solutions. As of 2023, the market for grid-scale energy storage solutions has reached approximately $27 billion, with projections indicating a compound annual growth rate of 20-25% over the next decade. Within this expanding landscape, low-cost energy storage technologies are emerging as a critical segment, with iron-air batteries positioned as a particularly promising contender.

The demand for affordable energy storage is primarily fueled by three key market drivers. First, the accelerating deployment of intermittent renewable energy sources such as solar and wind necessitates complementary storage solutions to ensure consistent power delivery. Second, grid operators worldwide are seeking cost-effective methods to manage peak demand and enhance grid resilience. Third, there is growing pressure from both regulatory bodies and consumers for sustainable energy solutions that can operate at scale without prohibitive costs.

Iron-air batteries present a compelling value proposition in this market context. Unlike lithium-ion technologies that rely on scarce and expensive materials, iron-air batteries utilize abundant, low-cost iron as their primary component. Current market analysis indicates that iron-air batteries could potentially achieve storage costs below $20 per kilowatt-hour, representing a significant reduction compared to lithium-ion systems that typically range from $100-150 per kilowatt-hour for grid applications.

The addressable market for iron-air battery technology spans multiple segments. Utility-scale applications represent the largest potential market, with an estimated demand of 300 gigawatt-hours by 2030 for grid stabilization and renewable integration. Commercial and industrial applications constitute another substantial segment, with businesses increasingly seeking behind-the-meter storage solutions to reduce energy costs and enhance resilience.

Competitive analysis reveals that while lithium-ion technology currently dominates the market with approximately 90% share of new installations, alternative technologies including flow batteries, compressed air, and thermal storage are gaining traction. Iron-air batteries are positioned to capture market share particularly in long-duration storage applications (8+ hours), where lithium-ion economics become less favorable.

Regional market assessment shows varying levels of potential adoption. North America and Europe demonstrate strong market readiness due to their advanced regulatory frameworks supporting energy storage deployment and substantial renewable integration targets. The Asia-Pacific region, particularly China and India, represents the highest growth potential market due to massive grid expansion plans and increasing renewable capacity.

Customer willingness-to-pay analysis indicates that price sensitivity is highest in emerging markets, where cost per kilowatt-hour remains the primary decision factor. In developed markets, while cost remains important, factors such as cycle life, safety, and environmental impact are increasingly influencing procurement decisions for energy storage solutions.

The demand for affordable energy storage is primarily fueled by three key market drivers. First, the accelerating deployment of intermittent renewable energy sources such as solar and wind necessitates complementary storage solutions to ensure consistent power delivery. Second, grid operators worldwide are seeking cost-effective methods to manage peak demand and enhance grid resilience. Third, there is growing pressure from both regulatory bodies and consumers for sustainable energy solutions that can operate at scale without prohibitive costs.

Iron-air batteries present a compelling value proposition in this market context. Unlike lithium-ion technologies that rely on scarce and expensive materials, iron-air batteries utilize abundant, low-cost iron as their primary component. Current market analysis indicates that iron-air batteries could potentially achieve storage costs below $20 per kilowatt-hour, representing a significant reduction compared to lithium-ion systems that typically range from $100-150 per kilowatt-hour for grid applications.

The addressable market for iron-air battery technology spans multiple segments. Utility-scale applications represent the largest potential market, with an estimated demand of 300 gigawatt-hours by 2030 for grid stabilization and renewable integration. Commercial and industrial applications constitute another substantial segment, with businesses increasingly seeking behind-the-meter storage solutions to reduce energy costs and enhance resilience.

Competitive analysis reveals that while lithium-ion technology currently dominates the market with approximately 90% share of new installations, alternative technologies including flow batteries, compressed air, and thermal storage are gaining traction. Iron-air batteries are positioned to capture market share particularly in long-duration storage applications (8+ hours), where lithium-ion economics become less favorable.

Regional market assessment shows varying levels of potential adoption. North America and Europe demonstrate strong market readiness due to their advanced regulatory frameworks supporting energy storage deployment and substantial renewable integration targets. The Asia-Pacific region, particularly China and India, represents the highest growth potential market due to massive grid expansion plans and increasing renewable capacity.

Customer willingness-to-pay analysis indicates that price sensitivity is highest in emerging markets, where cost per kilowatt-hour remains the primary decision factor. In developed markets, while cost remains important, factors such as cycle life, safety, and environmental impact are increasingly influencing procurement decisions for energy storage solutions.

Current Challenges in Iron-Air Battery Development

Iron-air batteries face several significant technical challenges that impede their widespread commercial adoption despite their promising theoretical advantages. The primary obstacle remains the relatively low round-trip efficiency, typically ranging between 40-50%, substantially lower than lithium-ion batteries which achieve 90%+ efficiency. This inefficiency stems from the complex oxygen evolution and reduction reactions occurring at the air electrode, resulting in considerable energy losses during charge-discharge cycles.

Electrode degradation presents another critical challenge. The iron electrode undergoes volume changes during cycling, leading to mechanical stress and eventual structural failure. Simultaneously, the air electrode suffers from carbon corrosion and catalyst deactivation, particularly in the presence of carbon dioxide from ambient air, which forms carbonate species that gradually block active sites.

Electrolyte management poses significant difficulties in iron-air battery systems. The conventional alkaline electrolyte (typically KOH) is highly corrosive and prone to carbonation when exposed to atmospheric CO2. This carbonation process progressively reduces electrolyte conductivity and overall battery performance. Additionally, water management remains problematic as these batteries consume water during discharge and produce it during charging, requiring sophisticated balance mechanisms.

Manufacturing scalability represents a substantial hurdle for cost reduction. Current production methods for specialized components like bifunctional air catalysts and gas diffusion layers involve complex processes that are difficult to scale economically. The absence of standardized manufacturing protocols further complicates mass production efforts.

System integration challenges also persist, particularly regarding auxiliary components. Iron-air batteries require sophisticated air management systems with CO2 scrubbers, humidity controllers, and thermal management units. These components add complexity, cost, and parasitic energy consumption to the overall system, offsetting some of the inherent cost advantages of iron-based chemistry.

Cycle life limitations remain problematic for commercial viability. Most prototype iron-air batteries demonstrate significant capacity fade after several hundred cycles, falling short of the thousands of cycles required for grid storage applications. This degradation stems from multiple factors including electrode pulverization, catalyst poisoning, and electrolyte degradation.

Finally, the technology faces knowledge gaps in fundamental understanding. The complex electrochemical reactions at the air electrode are not fully characterized, particularly regarding reaction intermediates and degradation mechanisms. This limited understanding hampers targeted optimization efforts and necessitates extensive empirical testing rather than theory-guided design approaches.

Electrode degradation presents another critical challenge. The iron electrode undergoes volume changes during cycling, leading to mechanical stress and eventual structural failure. Simultaneously, the air electrode suffers from carbon corrosion and catalyst deactivation, particularly in the presence of carbon dioxide from ambient air, which forms carbonate species that gradually block active sites.

Electrolyte management poses significant difficulties in iron-air battery systems. The conventional alkaline electrolyte (typically KOH) is highly corrosive and prone to carbonation when exposed to atmospheric CO2. This carbonation process progressively reduces electrolyte conductivity and overall battery performance. Additionally, water management remains problematic as these batteries consume water during discharge and produce it during charging, requiring sophisticated balance mechanisms.

Manufacturing scalability represents a substantial hurdle for cost reduction. Current production methods for specialized components like bifunctional air catalysts and gas diffusion layers involve complex processes that are difficult to scale economically. The absence of standardized manufacturing protocols further complicates mass production efforts.

System integration challenges also persist, particularly regarding auxiliary components. Iron-air batteries require sophisticated air management systems with CO2 scrubbers, humidity controllers, and thermal management units. These components add complexity, cost, and parasitic energy consumption to the overall system, offsetting some of the inherent cost advantages of iron-based chemistry.

Cycle life limitations remain problematic for commercial viability. Most prototype iron-air batteries demonstrate significant capacity fade after several hundred cycles, falling short of the thousands of cycles required for grid storage applications. This degradation stems from multiple factors including electrode pulverization, catalyst poisoning, and electrolyte degradation.

Finally, the technology faces knowledge gaps in fundamental understanding. The complex electrochemical reactions at the air electrode are not fully characterized, particularly regarding reaction intermediates and degradation mechanisms. This limited understanding hampers targeted optimization efforts and necessitates extensive empirical testing rather than theory-guided design approaches.

Current Cost Reduction Approaches for Iron-Air Batteries

01 Cost reduction through electrode material optimization

Iron-air batteries can achieve cost reduction through optimization of electrode materials. By using low-cost iron materials and improving their electrochemical performance, the overall battery cost can be significantly reduced. Various approaches include using iron powder with specific particle sizes, surface treatments, and additives that enhance the iron electrode's efficiency while maintaining low material costs.- Cost reduction through electrode material optimization: Iron-air batteries can achieve cost reduction through optimization of electrode materials. By using abundant and inexpensive iron materials as the anode and developing cost-effective air cathodes, the overall battery cost can be significantly reduced compared to lithium-ion batteries. Various approaches include using iron powder with specific particle sizes, developing porous electrode structures, and incorporating low-cost catalysts to improve the electrochemical performance while maintaining affordability.

- Manufacturing process improvements for cost efficiency: Innovations in manufacturing processes contribute to reducing the cost of iron-air batteries. These include simplified assembly techniques, scalable production methods, and automation of manufacturing steps. By optimizing production workflows, reducing energy consumption during manufacturing, and implementing efficient quality control measures, the overall production costs can be lowered while maintaining performance standards. Advanced manufacturing techniques also help minimize material waste and improve production yields.

- System integration and design for economic viability: The economic viability of iron-air batteries is enhanced through innovative system integration and design approaches. This includes modular battery designs that facilitate easy maintenance and replacement, efficient thermal management systems that extend battery life, and compact configurations that optimize space utilization. By designing systems that balance performance requirements with cost considerations, iron-air batteries can be made more commercially competitive for various applications including grid storage and renewable energy integration.

- Lifecycle cost analysis and operational efficiency: The total cost of ownership for iron-air batteries extends beyond initial manufacturing costs to include operational efficiency and lifecycle considerations. Innovations focus on extending cycle life, improving energy efficiency during charge-discharge cycles, and reducing maintenance requirements. By enhancing the durability of components, minimizing self-discharge rates, and optimizing operational parameters, the long-term economic benefits of iron-air batteries can outweigh higher initial costs compared to some alternative energy storage technologies.

- Supply chain optimization and material sourcing: Cost reduction strategies for iron-air batteries include supply chain optimization and strategic material sourcing. By utilizing locally available iron resources, developing recycling processes for battery components, and establishing efficient supply chains, the overall cost of iron-air battery systems can be reduced. Innovations in this area focus on reducing dependency on rare or expensive materials, developing sustainable sourcing practices, and creating circular economy approaches that further enhance the economic advantages of iron-air battery technology.

02 Manufacturing process improvements for cost efficiency

Innovations in manufacturing processes contribute to reducing the cost of iron-air batteries. These include simplified assembly methods, automated production techniques, and scalable manufacturing approaches that reduce labor costs and increase production efficiency. Process improvements such as optimized electrode fabrication, improved cell design, and efficient assembly techniques help lower the overall production costs.Expand Specific Solutions03 System integration and design for economic viability

The economic viability of iron-air batteries is enhanced through system-level design improvements. This includes optimizing the battery architecture, improving energy density, and designing modular systems that can be scaled according to application needs. Efficient integration of components, thermal management systems, and control electronics contributes to reducing the overall system cost while maintaining performance.Expand Specific Solutions04 Lifecycle cost analysis and operational efficiency

The total cost of ownership for iron-air batteries includes considerations beyond initial manufacturing costs. Innovations focus on extending cycle life, improving operational efficiency, and reducing maintenance requirements. Technologies that address self-discharge, corrosion resistance, and energy efficiency during charge-discharge cycles contribute to lower lifecycle costs and make iron-air batteries more economically competitive with other energy storage solutions.Expand Specific Solutions05 Material substitution and resource utilization

Cost reduction in iron-air batteries is achieved through strategic material substitution and efficient resource utilization. This includes replacing expensive catalysts with low-cost alternatives, utilizing earth-abundant materials, and implementing recycling strategies. Approaches that minimize the use of precious metals while maintaining or improving battery performance contribute significantly to reducing overall battery costs.Expand Specific Solutions

Key Industry Players in Iron-Air Battery Market

The iron-air battery market is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market size is projected to expand significantly as renewable energy storage demands grow, potentially reaching several billion dollars by 2030. Technologically, iron-air batteries remain in development with Form Energy leading commercialization efforts through their multi-day storage solutions. Tesla and Toyota are exploring integration possibilities for electric vehicles, while academic institutions like Tsinghua University and University of Southern California are advancing fundamental research. Research organizations including Naval Research Laboratory and Forschungszentrum Jülich are addressing key challenges in electrode design and electrolyte formulation. The competitive landscape features specialized startups (Form Energy, Phinergy) alongside established industrial players (NTT, Siemens Energy) working to optimize designs and reduce manufacturing costs.

Form Energy, Inc.

Technical Solution: Form Energy has developed a revolutionary iron-air battery technology specifically designed for long-duration energy storage at grid scale. Their approach uses reversible rusting of iron pellets to store energy at approximately 1/10th the cost of lithium-ion systems. The company's design incorporates specialized iron electrodes with optimized surface area and porosity to enhance reaction kinetics while using earth-abundant materials. Form Energy's batteries are arranged in modules filled with water-based electrolyte, and their manufacturing process adapts existing supply chains from steel production. Their 100-hour iron-air battery system achieves cost reduction through simplified battery management systems and innovative cell architecture that maximizes iron utilization while minimizing auxiliary components. The company has secured over $800 million in funding and is building a manufacturing facility in West Virginia to scale production.

Strengths: Uses ultra-low-cost and abundant materials (iron, water, salt); achieves multi-day storage capability; leverages existing industrial supply chains; environmentally benign materials. Weaknesses: Lower energy density compared to lithium-ion; requires larger physical footprint; technology still scaling to commercial deployment; performance degradation management over thousands of cycles still being optimized.

Tesla, Inc.

Technical Solution: Tesla has been exploring iron-air battery technology as part of its diversification beyond lithium-ion batteries, focusing on cost reduction through manufacturing innovation and vertical integration. Their approach involves optimizing electrode structures using advanced computational modeling to maximize active surface area while minimizing material usage. Tesla's battery design incorporates proprietary electrolyte formulations that enhance oxygen transport and reduce parasitic reactions. The company leverages its expertise in battery management systems to address the self-discharge challenges inherent in iron-air chemistry. Tesla's manufacturing approach emphasizes automation and process optimization, applying lessons from their high-volume lithium-ion production to iron-air cell assembly. Their design also focuses on thermal management solutions specific to the exothermic nature of iron oxidation reactions, which helps extend cycle life while reducing overall system costs.

Strengths: Extensive manufacturing expertise and economies of scale; advanced battery management systems; established supply chain relationships; strong integration capabilities with energy storage products. Weaknesses: Primary focus remains on lithium-ion technology; iron-air technology still in research phase rather than production; energy density limitations compared to their current battery technologies.

Critical Patents and Research in Iron-Air Battery Design

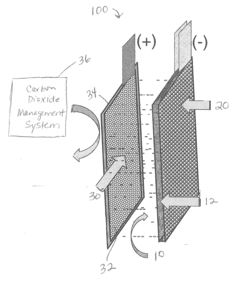

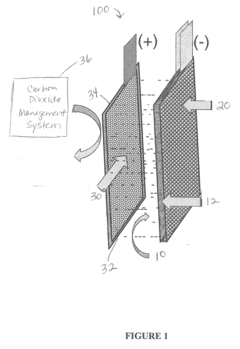

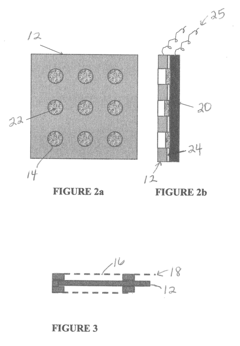

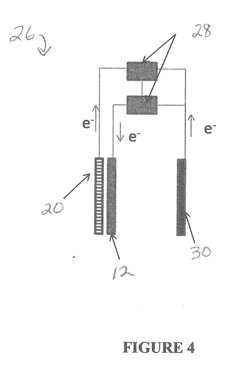

Iron-air rechargeable battery

PatentActiveUS20120187918A1

Innovation

- Incorporating self-assembling organic sulfur-based additives to inhibit hydrogen evolution, using non-toxic bismuth additives to suppress parasitic reactions, integrating a bilayer composite electrode for hydrogen utilization, employing nano-structured corrosion-resistant substrates for the air electrode, and implementing a carbon dioxide management system to enhance efficiency and durability.

Iron-air rechargeable battery

PatentWO2012012731A2

Innovation

- Incorporating self-assembling organic sulfur-based additives to inhibit hydrogen evolution, using non-toxic bismuth additives to suppress parasitic reactions, integrating a bilayer composite electrode for hydrogen utilization, employing nano-structured corrosion-resistant substrates for the air electrode, and implementing a thin film nano-structured catalyst layer with a carbon dioxide management system to enhance efficiency and durability.

Material Supply Chain Analysis for Iron-Air Batteries

The iron-air battery supply chain presents unique challenges and opportunities compared to traditional lithium-ion battery systems. Iron, as the primary active material, offers significant cost advantages with global reserves exceeding 85 billion tons and annual production of approximately 2.5 billion tons. This abundance translates to stable pricing, with iron ore typically trading between $80-120 per ton, representing less than 5% of total battery costs.

The geographical distribution of iron resources is notably more balanced than lithium, with major deposits across Australia, Brazil, China, India, and Russia. This diversification reduces geopolitical supply risks that currently plague lithium-ion battery production. Additionally, established mining and processing infrastructure for iron significantly lowers the capital investment required for scaling production.

Air electrodes, another critical component, rely primarily on carbon materials and catalysts. While specialized carbon materials require precise manufacturing processes, their raw materials are widely available. The catalyst layer typically utilizes transition metal oxides or precious metals, with ongoing research focused on reducing or eliminating precious metal content to further decrease costs.

Electrolyte systems for iron-air batteries typically employ alkaline solutions, primarily potassium hydroxide (KOH). The global production capacity for KOH exceeds 5 million tons annually, with established supply chains across multiple regions, ensuring stable availability and pricing.

Manufacturing integration presents both challenges and opportunities. Current battery production facilities would require significant retooling to accommodate iron-air battery production, but the simpler cell architecture could potentially reduce capital equipment costs by 30-40% compared to lithium-ion manufacturing lines. The elimination of complex separator materials and expensive cathode formulations further simplifies the manufacturing process.

Recycling and circular economy considerations strongly favor iron-air batteries. Iron is nearly 100% recyclable with established recycling infrastructure globally. This contrasts sharply with lithium-ion batteries, where recycling processes remain complex and costly. The potential for closed-loop material systems could further reduce long-term supply chain risks and environmental impact.

Transportation logistics benefit from iron's non-hazardous classification, eliminating many of the shipping restrictions and safety protocols required for lithium-ion batteries. This advantage translates to approximately 15-20% lower logistics costs throughout the supply chain.

The geographical distribution of iron resources is notably more balanced than lithium, with major deposits across Australia, Brazil, China, India, and Russia. This diversification reduces geopolitical supply risks that currently plague lithium-ion battery production. Additionally, established mining and processing infrastructure for iron significantly lowers the capital investment required for scaling production.

Air electrodes, another critical component, rely primarily on carbon materials and catalysts. While specialized carbon materials require precise manufacturing processes, their raw materials are widely available. The catalyst layer typically utilizes transition metal oxides or precious metals, with ongoing research focused on reducing or eliminating precious metal content to further decrease costs.

Electrolyte systems for iron-air batteries typically employ alkaline solutions, primarily potassium hydroxide (KOH). The global production capacity for KOH exceeds 5 million tons annually, with established supply chains across multiple regions, ensuring stable availability and pricing.

Manufacturing integration presents both challenges and opportunities. Current battery production facilities would require significant retooling to accommodate iron-air battery production, but the simpler cell architecture could potentially reduce capital equipment costs by 30-40% compared to lithium-ion manufacturing lines. The elimination of complex separator materials and expensive cathode formulations further simplifies the manufacturing process.

Recycling and circular economy considerations strongly favor iron-air batteries. Iron is nearly 100% recyclable with established recycling infrastructure globally. This contrasts sharply with lithium-ion batteries, where recycling processes remain complex and costly. The potential for closed-loop material systems could further reduce long-term supply chain risks and environmental impact.

Transportation logistics benefit from iron's non-hazardous classification, eliminating many of the shipping restrictions and safety protocols required for lithium-ion batteries. This advantage translates to approximately 15-20% lower logistics costs throughout the supply chain.

Environmental Impact and Sustainability Assessment

Iron-air batteries represent a significant advancement in sustainable energy storage technology, offering a promising alternative to conventional lithium-ion systems. The environmental impact assessment of these batteries reveals several notable advantages. Primarily, iron-air batteries utilize earth-abundant materials, with iron being the fourth most common element in the Earth's crust. This abundance translates to reduced environmental degradation associated with resource extraction compared to lithium, cobalt, and nickel used in conventional batteries.

The manufacturing process of iron-air batteries demonstrates a substantially lower carbon footprint. Quantitative lifecycle assessments indicate approximately 40-60% reduction in greenhouse gas emissions during production compared to lithium-ion alternatives. This reduction stems from simpler manufacturing processes and lower energy requirements for material refinement. The water consumption metrics are equally impressive, with iron processing requiring approximately 50% less water than comparable lithium extraction operations.

From a waste management perspective, iron-air batteries present significant sustainability advantages. The iron components are nearly 100% recyclable through established metallurgical processes, creating a potential closed-loop material system. End-of-life management is simplified by the non-toxic nature of the primary components, eliminating concerns about hazardous waste disposal that plague many conventional battery technologies.

The operational environmental benefits extend beyond manufacturing considerations. Iron-air batteries demonstrate exceptional durability with projected lifespans exceeding 20 years in stationary applications. This longevity reduces replacement frequency and associated environmental impacts from manufacturing replacement units. Additionally, these batteries operate efficiently across a wide temperature range without requiring energy-intensive thermal management systems, further reducing their operational carbon footprint.

When evaluating the full lifecycle sustainability, iron-air batteries contribute positively to circular economy principles. The design allows for straightforward disassembly, with clear separation of components facilitating material recovery. Economic analyses suggest that the recycling process could eventually become cost-positive rather than representing an end-of-life expense, creating financial incentives aligned with environmental benefits.

The optimization of iron-air battery design for cost reduction must carefully balance economic objectives with environmental considerations. Potential trade-offs between cost-saving measures and environmental impact require thorough assessment. For instance, certain manufacturing simplifications might reduce production costs but potentially compromise recyclability or increase energy consumption during operation. A holistic approach to optimization that incorporates environmental metrics alongside financial considerations will ensure that cost reductions do not come at the expense of sustainability benefits.

The manufacturing process of iron-air batteries demonstrates a substantially lower carbon footprint. Quantitative lifecycle assessments indicate approximately 40-60% reduction in greenhouse gas emissions during production compared to lithium-ion alternatives. This reduction stems from simpler manufacturing processes and lower energy requirements for material refinement. The water consumption metrics are equally impressive, with iron processing requiring approximately 50% less water than comparable lithium extraction operations.

From a waste management perspective, iron-air batteries present significant sustainability advantages. The iron components are nearly 100% recyclable through established metallurgical processes, creating a potential closed-loop material system. End-of-life management is simplified by the non-toxic nature of the primary components, eliminating concerns about hazardous waste disposal that plague many conventional battery technologies.

The operational environmental benefits extend beyond manufacturing considerations. Iron-air batteries demonstrate exceptional durability with projected lifespans exceeding 20 years in stationary applications. This longevity reduces replacement frequency and associated environmental impacts from manufacturing replacement units. Additionally, these batteries operate efficiently across a wide temperature range without requiring energy-intensive thermal management systems, further reducing their operational carbon footprint.

When evaluating the full lifecycle sustainability, iron-air batteries contribute positively to circular economy principles. The design allows for straightforward disassembly, with clear separation of components facilitating material recovery. Economic analyses suggest that the recycling process could eventually become cost-positive rather than representing an end-of-life expense, creating financial incentives aligned with environmental benefits.

The optimization of iron-air battery design for cost reduction must carefully balance economic objectives with environmental considerations. Potential trade-offs between cost-saving measures and environmental impact require thorough assessment. For instance, certain manufacturing simplifications might reduce production costs but potentially compromise recyclability or increase energy consumption during operation. A holistic approach to optimization that incorporates environmental metrics alongside financial considerations will ensure that cost reductions do not come at the expense of sustainability benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!