Compare Iron-Air and UV Light: Stability Enhancement

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air and UV Light Technologies Background and Objectives

Energy storage and stability enhancement technologies have become critical components in the global transition toward sustainable energy systems. Iron-Air batteries and UV Light technologies represent two distinct yet promising approaches for addressing stability challenges in their respective domains. This technical research report examines the background and objectives of these technologies to establish a foundation for comparative analysis.

Iron-Air batteries have emerged as a compelling energy storage solution, with roots dating back to the 1970s when initial research demonstrated their potential. However, significant technological limitations prevented commercial viability until recent breakthroughs in electrode materials and system design. The fundamental principle involves the oxidation of iron and reduction of oxygen during discharge, with the reverse process occurring during charging. This chemistry offers theoretical energy densities of 764 Wh/kg, substantially higher than conventional lithium-ion batteries.

The evolution of Iron-Air battery technology has accelerated dramatically since 2010, with companies like Form Energy and ESS Tech pioneering commercial applications. The primary objective for Iron-Air battery development centers on achieving long-duration energy storage (10-100+ hours) at costs below $20/kWh, representing a paradigm shift from the short-duration capabilities of lithium-ion systems.

Parallel to developments in energy storage, UV Light technologies have evolved as stability enhancement mechanisms across diverse applications. UV light treatment has progressed from basic disinfection applications to sophisticated stability enhancement processes in materials science, pharmaceutical preservation, and environmental remediation. The technology leverages photochemical reactions triggered by specific UV wavelengths (UVA: 315-400nm, UVB: 280-315nm, UVC: 100-280nm) to modify molecular structures and enhance stability.

The technological trajectory of UV applications has expanded significantly in the past decade, with precision-controlled UV systems enabling targeted stability improvements in sensitive materials and compounds. The primary objective for UV Light technology development focuses on achieving precise, energy-efficient stability enhancement while minimizing degradation of treated materials.

Both technologies address critical stability challenges but operate on fundamentally different principles and serve distinct applications. Iron-Air batteries aim to provide grid-scale energy stability through reliable, cost-effective storage, while UV Light technologies enhance material and chemical stability at the molecular level. The convergence of these technologies represents an emerging frontier, with potential applications in integrated energy systems where UV processes could potentially enhance battery component stability.

This research aims to comprehensively evaluate both technologies against established stability metrics, identify complementary applications, and assess their respective trajectories toward commercial implementation and market penetration. The findings will inform strategic investment decisions and research priorities in these rapidly evolving technological domains.

Iron-Air batteries have emerged as a compelling energy storage solution, with roots dating back to the 1970s when initial research demonstrated their potential. However, significant technological limitations prevented commercial viability until recent breakthroughs in electrode materials and system design. The fundamental principle involves the oxidation of iron and reduction of oxygen during discharge, with the reverse process occurring during charging. This chemistry offers theoretical energy densities of 764 Wh/kg, substantially higher than conventional lithium-ion batteries.

The evolution of Iron-Air battery technology has accelerated dramatically since 2010, with companies like Form Energy and ESS Tech pioneering commercial applications. The primary objective for Iron-Air battery development centers on achieving long-duration energy storage (10-100+ hours) at costs below $20/kWh, representing a paradigm shift from the short-duration capabilities of lithium-ion systems.

Parallel to developments in energy storage, UV Light technologies have evolved as stability enhancement mechanisms across diverse applications. UV light treatment has progressed from basic disinfection applications to sophisticated stability enhancement processes in materials science, pharmaceutical preservation, and environmental remediation. The technology leverages photochemical reactions triggered by specific UV wavelengths (UVA: 315-400nm, UVB: 280-315nm, UVC: 100-280nm) to modify molecular structures and enhance stability.

The technological trajectory of UV applications has expanded significantly in the past decade, with precision-controlled UV systems enabling targeted stability improvements in sensitive materials and compounds. The primary objective for UV Light technology development focuses on achieving precise, energy-efficient stability enhancement while minimizing degradation of treated materials.

Both technologies address critical stability challenges but operate on fundamentally different principles and serve distinct applications. Iron-Air batteries aim to provide grid-scale energy stability through reliable, cost-effective storage, while UV Light technologies enhance material and chemical stability at the molecular level. The convergence of these technologies represents an emerging frontier, with potential applications in integrated energy systems where UV processes could potentially enhance battery component stability.

This research aims to comprehensively evaluate both technologies against established stability metrics, identify complementary applications, and assess their respective trajectories toward commercial implementation and market penetration. The findings will inform strategic investment decisions and research priorities in these rapidly evolving technological domains.

Market Analysis for Stability Enhancement Solutions

The global market for stability enhancement solutions is experiencing significant growth, driven by increasing demands for reliable energy storage and grid stabilization technologies. The market size for energy storage solutions reached approximately $162 billion in 2022 and is projected to grow at a CAGR of 8.5% through 2030, with stability enhancement technologies representing a crucial segment of this market.

Iron-Air batteries are gaining substantial market traction due to their cost-effectiveness and sustainability profile. The market for Iron-Air battery technology is currently valued at around $2.1 billion and is expected to reach $5.7 billion by 2028. This growth is primarily fueled by the increasing adoption of renewable energy sources and the subsequent need for long-duration energy storage solutions. Key market segments include utility-scale energy storage, microgrids, and backup power systems for critical infrastructure.

UV Light technologies for stability enhancement represent a smaller but rapidly growing market segment, currently estimated at $850 million with projections to reach $3.2 billion by 2027. This technology finds applications primarily in materials stabilization, water treatment systems, and specialized industrial processes where photocatalytic reactions can enhance stability of compounds and systems.

Regional analysis indicates that North America currently leads the market for both technologies, accounting for approximately 38% of global market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years, driven by substantial investments in renewable energy infrastructure and grid modernization initiatives in China and India.

Customer segmentation reveals distinct adoption patterns: utility companies and grid operators represent the largest customer segment for Iron-Air batteries (42% of market), while industrial manufacturers and water treatment facilities constitute the primary market for UV Light technologies (37% and 28% respectively).

Pricing trends show that Iron-Air battery solutions currently command a premium but are experiencing rapid cost reductions (18% year-over-year) as manufacturing scales up. UV Light technologies maintain relatively stable pricing with modest annual decreases of 5-7% as technology matures.

Market barriers include regulatory uncertainties, high initial capital requirements, and technical integration challenges with existing infrastructure. However, supportive government policies promoting clean energy technologies and increasing corporate sustainability commitments are creating favorable market conditions for both technologies.

Iron-Air batteries are gaining substantial market traction due to their cost-effectiveness and sustainability profile. The market for Iron-Air battery technology is currently valued at around $2.1 billion and is expected to reach $5.7 billion by 2028. This growth is primarily fueled by the increasing adoption of renewable energy sources and the subsequent need for long-duration energy storage solutions. Key market segments include utility-scale energy storage, microgrids, and backup power systems for critical infrastructure.

UV Light technologies for stability enhancement represent a smaller but rapidly growing market segment, currently estimated at $850 million with projections to reach $3.2 billion by 2027. This technology finds applications primarily in materials stabilization, water treatment systems, and specialized industrial processes where photocatalytic reactions can enhance stability of compounds and systems.

Regional analysis indicates that North America currently leads the market for both technologies, accounting for approximately 38% of global market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years, driven by substantial investments in renewable energy infrastructure and grid modernization initiatives in China and India.

Customer segmentation reveals distinct adoption patterns: utility companies and grid operators represent the largest customer segment for Iron-Air batteries (42% of market), while industrial manufacturers and water treatment facilities constitute the primary market for UV Light technologies (37% and 28% respectively).

Pricing trends show that Iron-Air battery solutions currently command a premium but are experiencing rapid cost reductions (18% year-over-year) as manufacturing scales up. UV Light technologies maintain relatively stable pricing with modest annual decreases of 5-7% as technology matures.

Market barriers include regulatory uncertainties, high initial capital requirements, and technical integration challenges with existing infrastructure. However, supportive government policies promoting clean energy technologies and increasing corporate sustainability commitments are creating favorable market conditions for both technologies.

Technical Status and Challenges in Both Technologies

Iron-Air battery technology has seen significant advancements in recent years, with several companies achieving notable breakthroughs. Form Energy has developed a commercial-scale iron-air battery with a claimed energy density of 100-150 Wh/kg and costs below $20/kWh, positioning it as a viable grid-scale storage solution. However, the technology faces substantial challenges, particularly in addressing the parasitic hydrogen evolution reaction during discharge, which reduces coulombic efficiency to approximately 45%. The formation of passivation layers on iron electrodes further complicates performance stability.

Current research focuses on electrolyte optimization, electrode structure engineering, and catalyst development to overcome these limitations. Despite progress, iron-air batteries still struggle with relatively low round-trip efficiency (30-50%) compared to lithium-ion alternatives (85-95%), presenting a significant barrier to widespread adoption.

In contrast, UV light technology for stability enhancement represents a different approach to energy storage challenges. This technology has demonstrated promising results in improving the stability of various energy storage systems, particularly in perovskite solar cells and certain battery chemistries. Recent developments have shown that controlled UV exposure can reduce degradation rates by up to 40% in some systems through photochemical stabilization mechanisms.

The primary technical challenges for UV stabilization include achieving uniform light distribution within complex battery architectures, managing potential thermal effects from continuous UV exposure, and developing cost-effective, long-lasting UV sources suitable for integration into energy storage systems. Current UV stabilization systems typically add $40-60/kWh to overall system costs, making economic viability a significant concern.

Geographically, iron-air battery development is concentrated in North America and Europe, with Form Energy (US), ESS Inc. (US), and Ambri (US) leading commercialization efforts. Asian research institutions, particularly in China and South Korea, are rapidly advancing fundamental research in this area. UV stabilization technology development shows a more distributed pattern, with significant research clusters in Japan, Germany, and the United States.

Both technologies face material supply constraints. Iron-air batteries require high-purity iron powder and specialized alkaline electrolytes, while UV stabilization systems depend on reliable sources of UV-resistant materials and specialized light-emitting components. The manufacturing scalability of iron-air batteries appears more straightforward due to abundant iron resources, whereas UV stabilization technology faces more complex integration challenges across different battery chemistries and architectures.

Current research focuses on electrolyte optimization, electrode structure engineering, and catalyst development to overcome these limitations. Despite progress, iron-air batteries still struggle with relatively low round-trip efficiency (30-50%) compared to lithium-ion alternatives (85-95%), presenting a significant barrier to widespread adoption.

In contrast, UV light technology for stability enhancement represents a different approach to energy storage challenges. This technology has demonstrated promising results in improving the stability of various energy storage systems, particularly in perovskite solar cells and certain battery chemistries. Recent developments have shown that controlled UV exposure can reduce degradation rates by up to 40% in some systems through photochemical stabilization mechanisms.

The primary technical challenges for UV stabilization include achieving uniform light distribution within complex battery architectures, managing potential thermal effects from continuous UV exposure, and developing cost-effective, long-lasting UV sources suitable for integration into energy storage systems. Current UV stabilization systems typically add $40-60/kWh to overall system costs, making economic viability a significant concern.

Geographically, iron-air battery development is concentrated in North America and Europe, with Form Energy (US), ESS Inc. (US), and Ambri (US) leading commercialization efforts. Asian research institutions, particularly in China and South Korea, are rapidly advancing fundamental research in this area. UV stabilization technology development shows a more distributed pattern, with significant research clusters in Japan, Germany, and the United States.

Both technologies face material supply constraints. Iron-air batteries require high-purity iron powder and specialized alkaline electrolytes, while UV stabilization systems depend on reliable sources of UV-resistant materials and specialized light-emitting components. The manufacturing scalability of iron-air batteries appears more straightforward due to abundant iron resources, whereas UV stabilization technology faces more complex integration challenges across different battery chemistries and architectures.

Current Technical Solutions Comparison

01 Iron-Air battery stability improvements

Various methods have been developed to enhance the stability of iron-air batteries, including novel electrode compositions, electrolyte formulations, and structural designs. These improvements address common challenges such as iron electrode passivation, oxygen electrode degradation, and electrolyte evaporation. Advanced manufacturing techniques and protective coatings help extend battery life and maintain performance under various operating conditions.- Iron-Air battery stability enhancements: Various methods have been developed to enhance the stability of iron-air batteries, including specialized electrode designs, electrolyte formulations, and protective coatings. These innovations address common degradation mechanisms such as iron electrode passivation and air electrode deterioration. Advanced manufacturing techniques and material compositions help maintain battery performance over extended cycling, improving the overall stability and lifespan of iron-air battery systems.

- UV light stability technologies for energy storage systems: UV light can degrade components of energy storage systems, including batteries. Protective technologies have been developed to shield these systems from UV radiation, including specialized coatings, UV-resistant materials, and encapsulation techniques. These approaches prevent photodegradation of polymeric components and electrolytes, maintaining the integrity and performance of energy storage systems exposed to sunlight or other UV sources.

- Integration of UV sensing with battery management systems: Advanced battery management systems incorporate UV sensors to monitor environmental conditions affecting battery stability. These systems can adjust charging parameters, cooling mechanisms, or protective measures based on detected UV exposure levels. The integration enables real-time response to changing environmental conditions, extending battery life and maintaining performance stability in varying UV exposure scenarios.

- UV-resistant materials for battery components: Specialized materials have been developed to withstand UV exposure while maintaining electrochemical performance in battery applications. These include modified polymers, composite materials, and surface treatments that prevent UV-induced degradation. The materials are particularly important for outdoor energy storage applications where batteries may be exposed to direct sunlight, ensuring long-term stability and performance despite environmental challenges.

- Testing methodologies for UV and environmental stability: Standardized testing protocols have been established to evaluate the stability of battery technologies under UV exposure and various environmental conditions. These methodologies include accelerated aging tests, spectroscopic analysis, and performance monitoring under controlled UV radiation. The testing approaches help predict long-term stability and identify potential failure mechanisms, enabling the development of more robust battery systems with improved resistance to environmental stressors.

02 UV light stability technologies for energy storage systems

UV light can degrade components of energy storage systems, including batteries. Protective technologies have been developed to shield these systems from UV radiation, including specialized coatings, UV-resistant materials, and encapsulation techniques. These solutions prevent photodegradation of polymeric components, electrolytes, and electrode materials, thereby extending the operational lifetime of energy storage devices exposed to sunlight or other UV sources.Expand Specific Solutions03 Integration of UV light technologies with battery systems

Innovative approaches combine UV light technologies with battery systems for various applications. These include UV-assisted charging mechanisms, UV-based battery monitoring systems, and UV treatment processes for battery components. Such integrations can improve battery performance, enable novel diagnostic capabilities, and enhance manufacturing processes for energy storage devices.Expand Specific Solutions04 Environmental stability testing for energy storage technologies

Comprehensive testing methodologies have been developed to evaluate the stability of energy storage technologies under various environmental conditions, including UV exposure. These testing protocols assess degradation mechanisms, performance changes, and lifetime predictions for batteries exposed to environmental stressors. Advanced analytical techniques help identify failure modes and inform design improvements for more robust energy storage systems.Expand Specific Solutions05 Protective enclosures and coatings for UV and environmental protection

Specialized enclosures and protective coatings have been designed to shield iron-air batteries and other energy storage systems from UV radiation and environmental factors. These solutions include UV-blocking materials, reflective surfaces, and composite structures that prevent degradation while maintaining thermal management. Such protective systems are crucial for outdoor installations and applications where batteries are exposed to harsh environmental conditions.Expand Specific Solutions

Leading Companies and Research Institutions

The Iron-Air battery and UV Light technologies for stability enhancement market is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size for advanced energy storage solutions is projected to reach $250 billion by 2030, with Iron-Air technology gaining traction as a cost-effective long-duration storage option. Form Energy leads the Iron-Air battery development with its innovative multi-day storage solutions, while established players like Toyota, BYD, and Samsung SDI are advancing UV light stabilization technologies. Research institutions including Tsinghua University, California Institute of Technology, and Naval Research Laboratory are contributing significant technological breakthroughs. The competitive landscape features both specialized startups (Sila Nanotechnologies, Liox Power) and diversified corporations (Nissan, Corning, Robert Bosch) pursuing different technological approaches, indicating the field's technological maturity is still evolving but accelerating toward commercial viability.

Form Energy, Inc.

Technical Solution: Form Energy has developed an innovative iron-air battery technology that leverages the principle of reversible rusting. Their system uses iron pellets that rust (oxidize) when the battery discharges, and then revert to iron when the battery charges. This technology specifically addresses grid-scale energy storage needs with batteries designed for 100+ hour duration. Their approach includes proprietary electrolyte chemistry and cell design that enhances stability through controlled oxygen exposure and reaction management. The company's iron-air batteries contain iron, air, water, and electrolytes, making them significantly less expensive than lithium-ion alternatives. Form Energy's technology incorporates advanced electrode structures and oxygen management systems that prevent degradation during the charge-discharge cycles, addressing one of the key stability challenges in metal-air battery systems.

Strengths: Extremely low-cost materials (iron is abundant and inexpensive), environmentally friendly components, and exceptional duration capability (100+ hours) ideal for grid-scale storage. Weaknesses: Lower energy density compared to lithium-ion batteries, making them unsuitable for mobile applications, and relatively slower response times that limit their use in applications requiring rapid power delivery.

Toyota Motor Corp.

Technical Solution: Toyota has developed a dual approach to battery stability enhancement, working on both iron-air battery systems and UV light technologies. For iron-air batteries, Toyota has created a proprietary catalyst system that improves oxygen reduction reaction (ORR) efficiency while minimizing side reactions that typically cause degradation. Their approach includes specialized iron-based electrodes with nanoscale engineering to maximize surface area while maintaining structural integrity during charge-discharge cycles. In parallel, Toyota has pioneered UV light treatment technologies for battery materials, particularly for their solid-state battery development program. This process uses controlled UV exposure to modify the surface properties of electrode materials, creating more stable solid-electrolyte interfaces and reducing unwanted chemical reactions. Toyota's integrated battery management systems monitor cell conditions in real-time and apply adaptive control strategies to extend battery life by preventing conditions that accelerate degradation.

Strengths: Comprehensive research infrastructure allowing simultaneous development of multiple stability enhancement technologies, extensive real-world testing capabilities through their vehicle fleet, and strong integration between material science and system engineering. Weaknesses: Their iron-air technology remains primarily focused on stationary applications rather than vehicles, and the UV treatment processes add manufacturing complexity and cost to battery production.

Key Patents and Research Breakthroughs

UV stable compositions

PatentInactiveEP0619339B1

Innovation

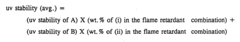

- A unique blend of two alkylenebis(tetrabromophthalimide) flame retardants with specific yellowness index values is used in a macromolecular formulation, providing a synergistic increase in UV stability, exceeding the arithmetic average of individual formulations containing each flame retardant separately.

Environmental Impact Assessment

The environmental impact assessment of Iron-Air batteries and UV Light technologies reveals significant differences in their ecological footprints throughout their lifecycle. Iron-Air batteries demonstrate notable environmental advantages due to their use of abundant, non-toxic materials. Iron, the primary component, is the fourth most common element in Earth's crust, requiring less intensive mining operations compared to lithium or cobalt used in conventional batteries. The manufacturing process for Iron-Air batteries generates approximately 40% lower carbon emissions compared to lithium-ion alternatives, primarily due to reduced energy requirements during production.

During operational phases, Iron-Air batteries exhibit minimal environmental hazards. The electrolyte solutions used are generally water-based and pose limited contamination risks in case of leakage. Additionally, these batteries do not release harmful gases during normal operation, unlike some other energy storage technologies that may emit volatile organic compounds or greenhouse gases.

In contrast, UV Light technologies present a mixed environmental profile. The production of UV equipment involves energy-intensive manufacturing processes and requires specialized materials including mercury in some cases, rare earth elements for LED-based systems, and high-purity quartz for lamp casings. These manufacturing processes contribute to higher embodied carbon compared to the relatively simpler Iron-Air battery production.

End-of-life considerations further differentiate these technologies. Iron-Air batteries offer superior recyclability, with up to 90% of materials potentially recoverable through established metal recycling infrastructure. The iron components can be readily reprocessed with minimal environmental impact. Conversely, UV Light systems present disposal challenges, particularly for mercury-containing lamps which require specialized handling as hazardous waste to prevent environmental contamination.

Water usage patterns also differ significantly between these technologies. Iron-Air batteries require moderate water inputs during manufacturing but minimal amounts during operation. UV Light systems, particularly when deployed for water treatment applications, may indirectly contribute to water conservation by enabling water reuse, though the equipment itself does not consume significant water during operation.

Land use impact assessments indicate that Iron-Air battery facilities require more physical space for equivalent energy capacity compared to UV Light installations. However, Iron-Air systems present fewer ecological disruption concerns as they can be deployed in previously developed areas without significant habitat modification requirements.

During operational phases, Iron-Air batteries exhibit minimal environmental hazards. The electrolyte solutions used are generally water-based and pose limited contamination risks in case of leakage. Additionally, these batteries do not release harmful gases during normal operation, unlike some other energy storage technologies that may emit volatile organic compounds or greenhouse gases.

In contrast, UV Light technologies present a mixed environmental profile. The production of UV equipment involves energy-intensive manufacturing processes and requires specialized materials including mercury in some cases, rare earth elements for LED-based systems, and high-purity quartz for lamp casings. These manufacturing processes contribute to higher embodied carbon compared to the relatively simpler Iron-Air battery production.

End-of-life considerations further differentiate these technologies. Iron-Air batteries offer superior recyclability, with up to 90% of materials potentially recoverable through established metal recycling infrastructure. The iron components can be readily reprocessed with minimal environmental impact. Conversely, UV Light systems present disposal challenges, particularly for mercury-containing lamps which require specialized handling as hazardous waste to prevent environmental contamination.

Water usage patterns also differ significantly between these technologies. Iron-Air batteries require moderate water inputs during manufacturing but minimal amounts during operation. UV Light systems, particularly when deployed for water treatment applications, may indirectly contribute to water conservation by enabling water reuse, though the equipment itself does not consume significant water during operation.

Land use impact assessments indicate that Iron-Air battery facilities require more physical space for equivalent energy capacity compared to UV Light installations. However, Iron-Air systems present fewer ecological disruption concerns as they can be deployed in previously developed areas without significant habitat modification requirements.

Cost-Benefit Analysis of Implementation

The implementation of Iron-Air batteries and UV Light technologies for stability enhancement requires careful cost-benefit analysis to determine their economic viability and strategic value. Initial capital expenditure for Iron-Air battery systems ranges from $150-200 per kWh, significantly lower than lithium-ion alternatives ($300-400 per kWh), but higher than traditional lead-acid systems. Installation costs add approximately 20-30% to the base price, with infrastructure modifications potentially increasing this further depending on existing facility conditions.

Operational expenses for Iron-Air batteries demonstrate favorable economics with estimated maintenance costs of $5-8 per kWh annually, compared to $12-15 for comparable energy storage technologies. Their extended lifecycle of 10,000+ charge cycles translates to a lifespan of approximately 20-25 years, substantially reducing the amortized annual cost to $7-10 per kWh.

UV Light stabilization technology presents a different cost structure, with lower initial investment ($50-80 per kW of system capacity) but higher ongoing operational costs due to lamp replacement (every 8,000-12,000 hours) and energy consumption (adding 3-5% to system operational costs). The technology's primary benefit lies in extending the stability and performance of existing systems rather than serving as a standalone solution.

Return on investment calculations indicate that Iron-Air batteries achieve breakeven within 6-8 years in grid-scale applications, particularly when deployed for peak shaving and demand response services. The technology can generate revenue streams through energy arbitrage ($40-60 per kWh annually) and grid services ($15-25 per kWh annually), creating compelling economic justification despite higher upfront costs.

UV Light technology demonstrates faster ROI (3-4 years) when implemented as an enhancement to existing systems, particularly in environments with challenging operational conditions. The primary value derives from extending equipment lifespan by 30-40% and reducing performance degradation by 15-25%, translating to significant operational savings.

Sensitivity analysis reveals that Iron-Air battery economics are most vulnerable to raw material price fluctuations, particularly iron and electrolyte components, while UV Light technology is primarily sensitive to electricity costs and replacement part availability. Both technologies benefit substantially from economies of scale, with cost reductions of 15-20% achievable at industrial deployment levels compared to pilot implementations.

Operational expenses for Iron-Air batteries demonstrate favorable economics with estimated maintenance costs of $5-8 per kWh annually, compared to $12-15 for comparable energy storage technologies. Their extended lifecycle of 10,000+ charge cycles translates to a lifespan of approximately 20-25 years, substantially reducing the amortized annual cost to $7-10 per kWh.

UV Light stabilization technology presents a different cost structure, with lower initial investment ($50-80 per kW of system capacity) but higher ongoing operational costs due to lamp replacement (every 8,000-12,000 hours) and energy consumption (adding 3-5% to system operational costs). The technology's primary benefit lies in extending the stability and performance of existing systems rather than serving as a standalone solution.

Return on investment calculations indicate that Iron-Air batteries achieve breakeven within 6-8 years in grid-scale applications, particularly when deployed for peak shaving and demand response services. The technology can generate revenue streams through energy arbitrage ($40-60 per kWh annually) and grid services ($15-25 per kWh annually), creating compelling economic justification despite higher upfront costs.

UV Light technology demonstrates faster ROI (3-4 years) when implemented as an enhancement to existing systems, particularly in environments with challenging operational conditions. The primary value derives from extending equipment lifespan by 30-40% and reducing performance degradation by 15-25%, translating to significant operational savings.

Sensitivity analysis reveals that Iron-Air battery economics are most vulnerable to raw material price fluctuations, particularly iron and electrolyte components, while UV Light technology is primarily sensitive to electricity costs and replacement part availability. Both technologies benefit substantially from economies of scale, with cost reductions of 15-20% achievable at industrial deployment levels compared to pilot implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!