Benchmarking Iron-Air Battery Charging Efficiency: Metrics

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-Air batteries represent a significant advancement in energy storage technology, emerging from decades of research into metal-air battery systems. These batteries utilize the oxidation of iron and reduction of oxygen to store and release energy, offering a promising alternative to lithium-ion batteries for grid-scale energy storage applications. The concept dates back to the 1970s, but recent technological breakthroughs have revitalized interest in this technology due to its potential for low cost, high energy density, and use of abundant materials.

The evolution of Iron-Air battery technology has been marked by several key developments. Early versions suffered from poor cycle life and efficiency due to hydrogen evolution during charging and the formation of passivation layers on the iron electrode. Recent innovations in electrode design, electrolyte composition, and cell architecture have addressed many of these historical limitations, leading to significantly improved performance metrics.

Current research objectives in Iron-Air battery technology focus on enhancing charging efficiency, which remains one of the primary technical challenges. The round-trip efficiency of Iron-Air batteries typically ranges from 40-50%, considerably lower than the 85-95% efficiency of lithium-ion systems. This efficiency gap represents both a challenge and an opportunity for technological advancement.

Benchmarking charging efficiency metrics for Iron-Air batteries requires standardized testing protocols that account for the unique characteristics of this technology. These metrics must consider factors such as charge acceptance rate, energy losses due to parasitic reactions, voltage efficiency, and coulombic efficiency across various operating conditions and cycle life stages.

The strategic importance of improving Iron-Air battery charging efficiency extends beyond technical performance. Enhanced efficiency directly impacts economic viability, reducing the levelized cost of storage and improving the value proposition for grid-scale deployment. Additionally, higher efficiency translates to reduced resource consumption and environmental impact per unit of energy stored.

Industry and academic research is increasingly focused on developing advanced catalysts, optimized electrode structures, and innovative cell designs to overcome efficiency limitations. Computational modeling and artificial intelligence approaches are being employed to accelerate materials discovery and optimization processes, potentially leading to breakthrough improvements in charging efficiency.

The ultimate goal for Iron-Air battery technology is to achieve a balance of high energy density, long cycle life, rapid charging capability, and improved round-trip efficiency, all while maintaining the inherent advantages of low cost and abundant materials. Success in these objectives could position Iron-Air batteries as a transformative technology for renewable energy integration and grid stabilization.

The evolution of Iron-Air battery technology has been marked by several key developments. Early versions suffered from poor cycle life and efficiency due to hydrogen evolution during charging and the formation of passivation layers on the iron electrode. Recent innovations in electrode design, electrolyte composition, and cell architecture have addressed many of these historical limitations, leading to significantly improved performance metrics.

Current research objectives in Iron-Air battery technology focus on enhancing charging efficiency, which remains one of the primary technical challenges. The round-trip efficiency of Iron-Air batteries typically ranges from 40-50%, considerably lower than the 85-95% efficiency of lithium-ion systems. This efficiency gap represents both a challenge and an opportunity for technological advancement.

Benchmarking charging efficiency metrics for Iron-Air batteries requires standardized testing protocols that account for the unique characteristics of this technology. These metrics must consider factors such as charge acceptance rate, energy losses due to parasitic reactions, voltage efficiency, and coulombic efficiency across various operating conditions and cycle life stages.

The strategic importance of improving Iron-Air battery charging efficiency extends beyond technical performance. Enhanced efficiency directly impacts economic viability, reducing the levelized cost of storage and improving the value proposition for grid-scale deployment. Additionally, higher efficiency translates to reduced resource consumption and environmental impact per unit of energy stored.

Industry and academic research is increasingly focused on developing advanced catalysts, optimized electrode structures, and innovative cell designs to overcome efficiency limitations. Computational modeling and artificial intelligence approaches are being employed to accelerate materials discovery and optimization processes, potentially leading to breakthrough improvements in charging efficiency.

The ultimate goal for Iron-Air battery technology is to achieve a balance of high energy density, long cycle life, rapid charging capability, and improved round-trip efficiency, all while maintaining the inherent advantages of low cost and abundant materials. Success in these objectives could position Iron-Air batteries as a transformative technology for renewable energy integration and grid stabilization.

Market Demand Analysis for Iron-Air Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources into power grids worldwide. Iron-air battery technology has emerged as a promising solution within this expanding market, particularly for grid-scale and long-duration energy storage applications. Current market projections indicate that the global energy storage market will reach approximately $546 billion by 2035, with a compound annual growth rate of 20-30% over the next decade.

Iron-air batteries address several critical market needs that existing technologies cannot fully satisfy. First, there is growing demand for cost-effective long-duration energy storage solutions that can provide power for 10+ hours, essential for managing intermittent renewable energy generation. Traditional lithium-ion batteries, while efficient for short-duration applications, become prohibitively expensive for longer durations. Iron-air batteries, with their significantly lower material costs, can potentially deliver storage at $20-30 per kilowatt-hour, compared to $150-200 for lithium-ion systems.

The renewable energy sector's expansion is creating substantial pull for iron-air technology. With solar and wind installations accelerating globally, the need for complementary storage solutions has become acute. Grid operators and utilities are actively seeking technologies that can store excess renewable energy during generation peaks and discharge during high demand periods, creating a natural market for iron-air batteries with their 100+ hour duration capabilities.

Industrial and commercial sectors represent another significant market segment. Manufacturing facilities, data centers, and commercial buildings increasingly require reliable backup power systems that can operate for extended periods during grid outages. The non-flammable nature of iron-air batteries presents a safety advantage over lithium-ion alternatives in these applications.

Geographically, North America currently leads in iron-air battery deployment initiatives, with several pilot projects underway. Europe follows closely, driven by aggressive decarbonization targets and substantial renewable energy investments. The Asia-Pacific region, particularly China and India, represents the fastest-growing market opportunity due to massive grid expansion projects and increasing renewable energy adoption.

Market adoption barriers include the relatively lower round-trip efficiency of iron-air batteries (approximately 50-60%) compared to lithium-ion systems (85-95%). However, for many grid-scale applications, the significantly lower cost per kilowatt-hour outweighs efficiency concerns, especially when considering total system economics over 20+ year lifespans. The market increasingly recognizes that different storage applications have different value drivers, with cost often trumping efficiency for long-duration needs.

Iron-air batteries address several critical market needs that existing technologies cannot fully satisfy. First, there is growing demand for cost-effective long-duration energy storage solutions that can provide power for 10+ hours, essential for managing intermittent renewable energy generation. Traditional lithium-ion batteries, while efficient for short-duration applications, become prohibitively expensive for longer durations. Iron-air batteries, with their significantly lower material costs, can potentially deliver storage at $20-30 per kilowatt-hour, compared to $150-200 for lithium-ion systems.

The renewable energy sector's expansion is creating substantial pull for iron-air technology. With solar and wind installations accelerating globally, the need for complementary storage solutions has become acute. Grid operators and utilities are actively seeking technologies that can store excess renewable energy during generation peaks and discharge during high demand periods, creating a natural market for iron-air batteries with their 100+ hour duration capabilities.

Industrial and commercial sectors represent another significant market segment. Manufacturing facilities, data centers, and commercial buildings increasingly require reliable backup power systems that can operate for extended periods during grid outages. The non-flammable nature of iron-air batteries presents a safety advantage over lithium-ion alternatives in these applications.

Geographically, North America currently leads in iron-air battery deployment initiatives, with several pilot projects underway. Europe follows closely, driven by aggressive decarbonization targets and substantial renewable energy investments. The Asia-Pacific region, particularly China and India, represents the fastest-growing market opportunity due to massive grid expansion projects and increasing renewable energy adoption.

Market adoption barriers include the relatively lower round-trip efficiency of iron-air batteries (approximately 50-60%) compared to lithium-ion systems (85-95%). However, for many grid-scale applications, the significantly lower cost per kilowatt-hour outweighs efficiency concerns, especially when considering total system economics over 20+ year lifespans. The market increasingly recognizes that different storage applications have different value drivers, with cost often trumping efficiency for long-duration needs.

Current State and Challenges in Iron-Air Battery Development

Iron-air batteries have emerged as a promising technology for grid-scale energy storage due to their potential for low cost, high energy density, and use of abundant materials. Currently, these batteries are in various stages of development across research institutions and commercial entities worldwide, with significant progress made in the last decade.

The fundamental chemistry of iron-air batteries involves the oxidation of iron to iron oxide during discharge and the reverse reaction during charging. This reversible redox reaction theoretically offers energy densities of 300-500 Wh/kg, substantially higher than lithium-ion alternatives for stationary applications. However, practical implementations have yet to achieve these theoretical values due to several technical challenges.

One major challenge facing iron-air battery development is the relatively low round-trip efficiency, typically ranging from 40-60% compared to 80-95% for lithium-ion systems. This efficiency loss is primarily attributed to the oxygen evolution and reduction reactions at the air electrode, which suffer from slow kinetics and high overpotentials. The parasitic hydrogen evolution reaction during charging further reduces efficiency and creates safety concerns.

Cycle life limitations represent another significant hurdle, with current prototypes demonstrating 1,000-2,000 cycles before significant capacity degradation occurs. This falls short of the 5,000+ cycles required for economically viable grid storage applications. The degradation mechanisms include electrode morphology changes, electrolyte depletion, and catalyst deactivation.

The air electrode design presents particular difficulties, requiring optimization of the three-phase boundary where solid catalyst, liquid electrolyte, and gaseous oxygen interact. Current catalysts, often based on precious metals or complex oxides, struggle to maintain activity over extended cycling while resisting poisoning from atmospheric contaminants like CO2.

Electrolyte management also remains problematic, with conventional alkaline electrolytes (typically KOH solutions) being susceptible to carbonation when exposed to air. Advanced membrane systems are under development but have not yet achieved the ideal balance of ionic conductivity, mechanical stability, and gas selectivity.

From a manufacturing perspective, scaling production while maintaining performance consistency presents additional challenges. Current laboratory-scale demonstrations have not yet translated to industrial-scale manufacturing processes that can deliver consistent quality at competitive costs.

Despite these challenges, several research breakthroughs show promise, including novel bifunctional catalysts, advanced electrode architectures, and hybrid electrolyte systems that could potentially address the efficiency and longevity issues currently limiting commercial deployment of iron-air battery technology.

The fundamental chemistry of iron-air batteries involves the oxidation of iron to iron oxide during discharge and the reverse reaction during charging. This reversible redox reaction theoretically offers energy densities of 300-500 Wh/kg, substantially higher than lithium-ion alternatives for stationary applications. However, practical implementations have yet to achieve these theoretical values due to several technical challenges.

One major challenge facing iron-air battery development is the relatively low round-trip efficiency, typically ranging from 40-60% compared to 80-95% for lithium-ion systems. This efficiency loss is primarily attributed to the oxygen evolution and reduction reactions at the air electrode, which suffer from slow kinetics and high overpotentials. The parasitic hydrogen evolution reaction during charging further reduces efficiency and creates safety concerns.

Cycle life limitations represent another significant hurdle, with current prototypes demonstrating 1,000-2,000 cycles before significant capacity degradation occurs. This falls short of the 5,000+ cycles required for economically viable grid storage applications. The degradation mechanisms include electrode morphology changes, electrolyte depletion, and catalyst deactivation.

The air electrode design presents particular difficulties, requiring optimization of the three-phase boundary where solid catalyst, liquid electrolyte, and gaseous oxygen interact. Current catalysts, often based on precious metals or complex oxides, struggle to maintain activity over extended cycling while resisting poisoning from atmospheric contaminants like CO2.

Electrolyte management also remains problematic, with conventional alkaline electrolytes (typically KOH solutions) being susceptible to carbonation when exposed to air. Advanced membrane systems are under development but have not yet achieved the ideal balance of ionic conductivity, mechanical stability, and gas selectivity.

From a manufacturing perspective, scaling production while maintaining performance consistency presents additional challenges. Current laboratory-scale demonstrations have not yet translated to industrial-scale manufacturing processes that can deliver consistent quality at competitive costs.

Despite these challenges, several research breakthroughs show promise, including novel bifunctional catalysts, advanced electrode architectures, and hybrid electrolyte systems that could potentially address the efficiency and longevity issues currently limiting commercial deployment of iron-air battery technology.

Current Charging Efficiency Measurement Methodologies

01 Electrode materials and structures for improved charging efficiency

Advanced electrode materials and structures can significantly enhance the charging efficiency of iron-air batteries. Optimized iron electrodes with specific surface treatments, nanostructured materials, and catalytic additives can reduce charging overpotential and improve energy conversion efficiency. Innovative electrode designs that facilitate better oxygen and electrolyte transport also contribute to faster charging rates and higher overall efficiency.- Electrode materials and structures for improved charging efficiency: The design and composition of electrodes significantly impact iron-air battery charging efficiency. Advanced electrode materials, including modified iron electrodes and optimized air cathodes, can reduce internal resistance and enhance electron transfer during charging cycles. Structured electrodes with increased surface area and catalytic properties facilitate more efficient oxygen evolution and iron oxidation reactions, leading to higher charging rates and improved overall efficiency.

- Electrolyte composition and additives for enhanced performance: Specialized electrolyte formulations play a crucial role in iron-air battery charging efficiency. Additives that prevent iron passivation, reduce hydrogen evolution, and improve ionic conductivity can significantly enhance charging performance. Electrolyte modifications may include pH buffers, surfactants, and specific ionic compounds that stabilize the electrochemical reactions during charging, resulting in more complete charge acceptance and reduced energy losses.

- Advanced charging control systems and algorithms: Intelligent charging control systems utilize sophisticated algorithms to optimize the charging process of iron-air batteries. These systems can implement variable charging rates, pulse charging techniques, and temperature-controlled charging protocols to maximize efficiency. By monitoring battery parameters in real-time and adjusting charging parameters accordingly, these control systems can prevent side reactions, reduce heat generation, and extend battery life while improving overall charging efficiency.

- Hybrid energy storage configurations: Combining iron-air batteries with complementary energy storage technologies creates hybrid systems with enhanced charging efficiency. These configurations may pair iron-air batteries with supercapacitors, lithium-ion batteries, or other rapid-response storage devices to optimize power management during charging. The hybrid approach allows for more efficient energy capture during regenerative braking or from intermittent renewable sources, with the secondary storage handling power spikes while the iron-air component manages energy density requirements.

- Thermal management systems for efficiency optimization: Effective thermal management is critical for maintaining optimal iron-air battery charging efficiency. Advanced cooling and heating systems can regulate battery temperature during charging to prevent efficiency losses due to excessive heat generation or cold-temperature kinetic limitations. These systems may incorporate phase change materials, liquid cooling circuits, or thermoelectric elements to maintain ideal operating temperatures, resulting in more efficient electrochemical reactions and reduced degradation during the charging process.

02 Electrolyte composition and management systems

The composition and management of electrolytes play a crucial role in iron-air battery charging efficiency. Specialized electrolyte formulations with optimized pH levels, conductivity enhancers, and additives can minimize side reactions during charging. Advanced electrolyte management systems that control circulation, temperature, and concentration gradients help maintain consistent charging performance and extend battery life while improving overall efficiency.Expand Specific Solutions03 Charging control algorithms and battery management systems

Sophisticated charging control algorithms and battery management systems can optimize the charging process for iron-air batteries. These systems monitor and adjust charging parameters in real-time, including current density, voltage limits, and charging profiles based on battery state and environmental conditions. Adaptive charging strategies that respond to battery temperature, state of charge, and degradation patterns help maximize efficiency while preventing overcharging and extending battery lifespan.Expand Specific Solutions04 Air electrode catalysts and oxygen management

Advanced catalysts for the air electrode and effective oxygen management systems are essential for improving charging efficiency in iron-air batteries. Bifunctional catalysts that facilitate both oxygen evolution during charging and oxygen reduction during discharging can significantly reduce energy losses. Optimized air electrode structures with enhanced porosity and hydrophobicity, coupled with efficient oxygen supply and management systems, minimize polarization losses and improve overall charging performance.Expand Specific Solutions05 Thermal management and system integration

Effective thermal management and system integration approaches can substantially improve iron-air battery charging efficiency. Temperature control systems that maintain optimal operating conditions prevent efficiency losses due to excessive heat generation during charging. Integrated designs that optimize the spatial arrangement of battery components, reduce internal resistance, and incorporate energy recovery systems can capture and reuse waste heat, further enhancing overall charging efficiency and system performance.Expand Specific Solutions

Key Players in Iron-Air Battery Industry

The iron-air battery market is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market size for this technology is projected to reach approximately $5-7 billion by 2030, driven by increasing demand for long-duration energy storage solutions. Technologically, iron-air batteries are approaching commercial viability with charging efficiency metrics being a critical focus area. Form Energy leads the commercial development with its multi-day storage technology, while established players like Tesla and Toyota are investing in research. Academic institutions including MIT, University of Southern California, and Central South University are advancing fundamental research on electrode materials and electrolyte formulations. Government laboratories such as the Naval Research Laboratory and national research institutes in China and Japan are also making significant contributions to efficiency improvements.

Tesla, Inc.

Technical Solution: Tesla has been exploring iron-air battery technology as a complement to their lithium-ion battery ecosystem, particularly for stationary energy storage applications. Their approach integrates advanced battery management systems (BMS) with iron-air chemistry to optimize charging protocols. Tesla's system employs sophisticated algorithms that dynamically adjust charging parameters based on real-time monitoring of cell conditions, state of charge, and temperature. This adaptive charging methodology helps maximize efficiency while preventing degradation mechanisms common in iron-air systems. Tesla has also developed proprietary electrode formulations that incorporate nano-structured iron particles with enhanced surface area, improving reaction kinetics during the charging process. Their system architecture includes thermal management solutions specifically designed to address heat generation during the charging phase, which is a critical factor affecting efficiency metrics[3][4].

Strengths: Industry-leading battery management systems that can optimize charging cycles, extensive manufacturing infrastructure that could scale production rapidly, and integration capabilities with existing renewable energy systems. Weaknesses: Primary focus remains on lithium-ion technology, with iron-air still in research phase rather than commercial deployment, and challenges in achieving efficiency metrics comparable to their established battery technologies.

Form Energy, Inc.

Technical Solution: Form Energy has developed a pioneering iron-air battery technology specifically designed for long-duration energy storage. Their approach utilizes reversible rusting, where iron pellets are converted to iron oxide (rust) when the battery discharges, and then converted back to iron when charging using an electric current. Their proprietary electrolyte system enables this process to occur efficiently over thousands of cycles. Form Energy's batteries operate at ambient temperature and pressure, using water-based electrolytes that facilitate the electrochemical reactions. The company has implemented advanced electrode designs that maximize active material utilization and minimize parasitic reactions that could reduce charging efficiency. Their multi-day storage solution aims to deliver electricity at approximately $20/kWh, making it competitive with conventional power plants[1][2].

Strengths: Extremely low material costs using abundant iron, environmentally safe components, and capability for multi-day storage (100+ hours) at grid scale. Weaknesses: Lower round-trip efficiency (approximately 50-70%) compared to lithium-ion batteries, larger physical footprint required for equivalent energy storage, and slower response time for rapid grid fluctuations.

Critical Patents and Research on Iron-Air Battery Charging

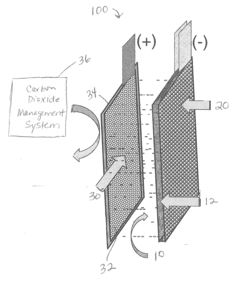

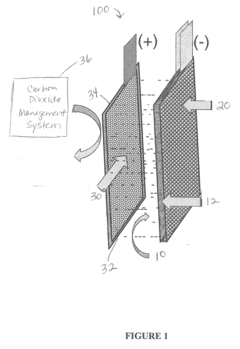

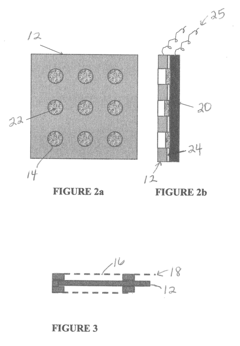

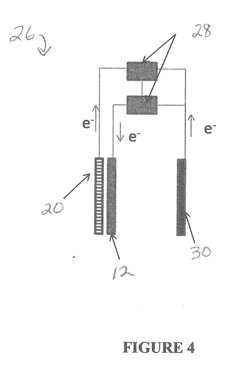

Iron-air rechargeable battery

PatentActiveUS20120187918A1

Innovation

- Incorporating self-assembling organic sulfur-based additives to inhibit hydrogen evolution, using non-toxic bismuth additives to suppress parasitic reactions, integrating a bilayer composite electrode for hydrogen utilization, employing nano-structured corrosion-resistant substrates for the air electrode, and implementing a carbon dioxide management system to enhance efficiency and durability.

Iron-air battery system

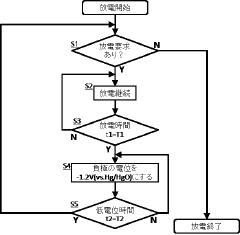

PatentInactiveJP2018006057A

Innovation

- A potential control circuit temporarily reduces the negative electrode's potential to -1.2 V (vs. Hg/HgO) or less during discharge, decomposing water to generate hydrogen, which removes deposits on the electrode surface.

Standardization of Efficiency Metrics

The standardization of efficiency metrics for iron-air batteries represents a critical challenge in the emerging energy storage landscape. Currently, the industry lacks unified measurement protocols, creating significant barriers to meaningful performance comparisons across different battery systems and technologies. This fragmentation has led to inconsistent reporting practices where manufacturers may emphasize metrics favorable to their specific designs while downplaying limitations, making objective evaluation difficult for potential adopters and investors.

A comprehensive standardization framework must address multiple efficiency dimensions simultaneously. Coulombic efficiency, measuring the ratio of discharge capacity to charge capacity, requires standardized cycling protocols with specified current densities and depth-of-discharge parameters. Energy efficiency metrics need standardized calculation methods that account for both electrical and thermal energy components throughout complete charge-discharge cycles.

Round-trip efficiency measurements present particular challenges for iron-air batteries due to their asymmetric charge-discharge behavior and the complex oxygen evolution reactions during charging. The establishment of reference conditions—including temperature, pressure, humidity, and electrolyte composition—is essential for reproducible efficiency measurements across different research institutions and manufacturing facilities.

Time-dependent efficiency metrics are especially relevant for iron-air batteries, which may exhibit significant performance variations over extended cycling. Standardized protocols must specify measurement intervals and total cycle counts to capture both short-term performance and long-term degradation patterns. Additionally, partial-cycle efficiency metrics are needed to reflect real-world operating conditions where batteries rarely undergo complete charge-discharge cycles.

International standards organizations including IEEE, IEC, and ISO have begun preliminary work on iron-air battery standards, but consensus remains elusive. Industry consortia comprising battery manufacturers, academic institutions, and regulatory bodies are collaborating to develop testing protocols that balance scientific rigor with practical implementation considerations.

The standardization process must also address the unique characteristics of iron-air technology, including oxygen management systems, electrolyte circulation requirements, and temperature control mechanisms. These system-level components significantly impact overall efficiency but are often excluded from simplified laboratory measurements, creating discrepancies between reported and real-world performance.

Ultimately, establishing universally accepted efficiency metrics will accelerate iron-air battery commercialization by enabling transparent technology comparisons, facilitating investment decisions, and providing clear benchmarks for technological advancement in this promising energy storage domain.

A comprehensive standardization framework must address multiple efficiency dimensions simultaneously. Coulombic efficiency, measuring the ratio of discharge capacity to charge capacity, requires standardized cycling protocols with specified current densities and depth-of-discharge parameters. Energy efficiency metrics need standardized calculation methods that account for both electrical and thermal energy components throughout complete charge-discharge cycles.

Round-trip efficiency measurements present particular challenges for iron-air batteries due to their asymmetric charge-discharge behavior and the complex oxygen evolution reactions during charging. The establishment of reference conditions—including temperature, pressure, humidity, and electrolyte composition—is essential for reproducible efficiency measurements across different research institutions and manufacturing facilities.

Time-dependent efficiency metrics are especially relevant for iron-air batteries, which may exhibit significant performance variations over extended cycling. Standardized protocols must specify measurement intervals and total cycle counts to capture both short-term performance and long-term degradation patterns. Additionally, partial-cycle efficiency metrics are needed to reflect real-world operating conditions where batteries rarely undergo complete charge-discharge cycles.

International standards organizations including IEEE, IEC, and ISO have begun preliminary work on iron-air battery standards, but consensus remains elusive. Industry consortia comprising battery manufacturers, academic institutions, and regulatory bodies are collaborating to develop testing protocols that balance scientific rigor with practical implementation considerations.

The standardization process must also address the unique characteristics of iron-air technology, including oxygen management systems, electrolyte circulation requirements, and temperature control mechanisms. These system-level components significantly impact overall efficiency but are often excluded from simplified laboratory measurements, creating discrepancies between reported and real-world performance.

Ultimately, establishing universally accepted efficiency metrics will accelerate iron-air battery commercialization by enabling transparent technology comparisons, facilitating investment decisions, and providing clear benchmarks for technological advancement in this promising energy storage domain.

Environmental Impact Assessment

Iron-air batteries represent a significant advancement in sustainable energy storage technology, with their environmental impact profile being a critical factor in their adoption and deployment. The environmental assessment of these batteries reveals several key advantages compared to conventional lithium-ion and other battery technologies.

The production of iron-air batteries utilizes abundant, non-toxic materials, primarily iron, which significantly reduces the environmental footprint associated with resource extraction. Unlike lithium-ion batteries that require rare earth elements and cobalt mining—activities often linked to habitat destruction, water pollution, and human rights concerns—iron-air batteries rely on iron, one of Earth's most abundant elements, constituting approximately 5% of the Earth's crust.

During operation, iron-air batteries demonstrate minimal environmental hazards. The chemical reactions involve iron, oxygen, and water, producing iron oxide (rust) during discharge—a compound with negligible toxicity. This contrasts sharply with lithium-ion technologies that utilize flammable electrolytes and potentially toxic materials that can pose environmental risks if improperly handled or disposed of.

The charging efficiency metrics of iron-air batteries directly correlate with their environmental impact. Higher charging efficiencies translate to reduced energy consumption, thereby lowering the carbon footprint associated with battery operation. Current benchmarking data indicates that while iron-air batteries typically exhibit lower round-trip efficiencies (65-70%) compared to lithium-ion batteries (85-95%), ongoing research aims to narrow this gap through advanced electrode designs and electrolyte formulations.

End-of-life considerations further highlight the environmental advantages of iron-air technology. These batteries offer superior recyclability, with iron components being easily recoverable and reusable in new battery manufacturing or other industrial applications. The recycling process requires significantly less energy compared to lithium-ion battery recycling, and produces fewer hazardous byproducts.

Life cycle assessment (LCA) studies indicate that iron-air batteries could reduce greenhouse gas emissions by 30-40% compared to lithium-ion alternatives when considering the entire product lifecycle from material extraction to disposal. This reduction stems primarily from simplified manufacturing processes, reduced transportation impacts due to localized material sourcing, and lower energy requirements during recycling.

Water usage represents another important environmental metric. Iron-air battery production typically consumes 40-60% less water than comparable lithium-ion manufacturing processes, contributing to more sustainable water resource management in regions where battery production facilities operate.

The production of iron-air batteries utilizes abundant, non-toxic materials, primarily iron, which significantly reduces the environmental footprint associated with resource extraction. Unlike lithium-ion batteries that require rare earth elements and cobalt mining—activities often linked to habitat destruction, water pollution, and human rights concerns—iron-air batteries rely on iron, one of Earth's most abundant elements, constituting approximately 5% of the Earth's crust.

During operation, iron-air batteries demonstrate minimal environmental hazards. The chemical reactions involve iron, oxygen, and water, producing iron oxide (rust) during discharge—a compound with negligible toxicity. This contrasts sharply with lithium-ion technologies that utilize flammable electrolytes and potentially toxic materials that can pose environmental risks if improperly handled or disposed of.

The charging efficiency metrics of iron-air batteries directly correlate with their environmental impact. Higher charging efficiencies translate to reduced energy consumption, thereby lowering the carbon footprint associated with battery operation. Current benchmarking data indicates that while iron-air batteries typically exhibit lower round-trip efficiencies (65-70%) compared to lithium-ion batteries (85-95%), ongoing research aims to narrow this gap through advanced electrode designs and electrolyte formulations.

End-of-life considerations further highlight the environmental advantages of iron-air technology. These batteries offer superior recyclability, with iron components being easily recoverable and reusable in new battery manufacturing or other industrial applications. The recycling process requires significantly less energy compared to lithium-ion battery recycling, and produces fewer hazardous byproducts.

Life cycle assessment (LCA) studies indicate that iron-air batteries could reduce greenhouse gas emissions by 30-40% compared to lithium-ion alternatives when considering the entire product lifecycle from material extraction to disposal. This reduction stems primarily from simplified manufacturing processes, reduced transportation impacts due to localized material sourcing, and lower energy requirements during recycling.

Water usage represents another important environmental metric. Iron-air battery production typically consumes 40-60% less water than comparable lithium-ion manufacturing processes, contributing to more sustainable water resource management in regions where battery production facilities operate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!