Case Benchmark: Iron-Air Battery Performance in Cold

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Evolution and Research Objectives

Iron-air batteries represent a significant evolution in energy storage technology, with roots dating back to the 1970s when initial research explored iron electrodes in alkaline environments. These early iterations faced substantial challenges including poor cycle life and hydrogen evolution issues that limited practical applications. The technology remained largely dormant until the early 2000s when renewed interest in sustainable energy storage solutions prompted researchers to revisit iron-based battery chemistries.

The past decade has witnessed accelerated development in iron-air battery technology, driven by advances in materials science, electrode design, and electrolyte formulations. Particularly noteworthy is the shift from traditional alkaline electrolytes to newer configurations that mitigate previous limitations. This evolution has positioned iron-air batteries as promising candidates for grid-scale energy storage applications due to their theoretical energy density exceeding 1,000 Wh/kg and reliance on earth-abundant materials.

Current technical objectives focus on addressing several critical performance parameters, with cold-weather operation representing a significant frontier. Iron-air batteries typically experience substantial capacity degradation and increased internal resistance at low temperatures, limiting their deployment in regions with seasonal temperature variations. Research objectives now center on understanding the fundamental mechanisms of this performance decline and developing innovative solutions to maintain efficiency across broader temperature ranges.

The temperature-dependent kinetics of the iron electrode reactions present particular challenges, as the oxidation and reduction processes that govern charging and discharging become sluggish in cold conditions. This results in decreased power output and reduced energy efficiency. Consequently, a primary research goal involves modifying electrode architectures and electrolyte compositions to maintain ionic conductivity and reaction rates at temperatures below freezing.

Another critical objective involves mitigating the parasitic hydrogen evolution reaction that becomes more pronounced at lower temperatures, which not only wastes energy but accelerates capacity fade. Researchers are exploring novel catalyst formulations and protective coatings to suppress this unwanted side reaction while maintaining the desired iron-oxygen electrochemistry.

The ultimate technical goal is to develop iron-air battery systems that maintain at least 80% of room-temperature capacity at temperatures as low as -20°C, while simultaneously achieving cycle life exceeding 1,000 full discharge cycles. This would position the technology as viable for year-round grid storage applications in diverse climatic conditions, significantly expanding market potential and supporting renewable energy integration in regions previously considered challenging for battery deployment.

The past decade has witnessed accelerated development in iron-air battery technology, driven by advances in materials science, electrode design, and electrolyte formulations. Particularly noteworthy is the shift from traditional alkaline electrolytes to newer configurations that mitigate previous limitations. This evolution has positioned iron-air batteries as promising candidates for grid-scale energy storage applications due to their theoretical energy density exceeding 1,000 Wh/kg and reliance on earth-abundant materials.

Current technical objectives focus on addressing several critical performance parameters, with cold-weather operation representing a significant frontier. Iron-air batteries typically experience substantial capacity degradation and increased internal resistance at low temperatures, limiting their deployment in regions with seasonal temperature variations. Research objectives now center on understanding the fundamental mechanisms of this performance decline and developing innovative solutions to maintain efficiency across broader temperature ranges.

The temperature-dependent kinetics of the iron electrode reactions present particular challenges, as the oxidation and reduction processes that govern charging and discharging become sluggish in cold conditions. This results in decreased power output and reduced energy efficiency. Consequently, a primary research goal involves modifying electrode architectures and electrolyte compositions to maintain ionic conductivity and reaction rates at temperatures below freezing.

Another critical objective involves mitigating the parasitic hydrogen evolution reaction that becomes more pronounced at lower temperatures, which not only wastes energy but accelerates capacity fade. Researchers are exploring novel catalyst formulations and protective coatings to suppress this unwanted side reaction while maintaining the desired iron-oxygen electrochemistry.

The ultimate technical goal is to develop iron-air battery systems that maintain at least 80% of room-temperature capacity at temperatures as low as -20°C, while simultaneously achieving cycle life exceeding 1,000 full discharge cycles. This would position the technology as viable for year-round grid storage applications in diverse climatic conditions, significantly expanding market potential and supporting renewable energy integration in regions previously considered challenging for battery deployment.

Market Analysis for Cold-Weather Energy Storage Solutions

The cold-weather energy storage market represents a critical segment within the broader energy storage industry, with unique challenges and opportunities driven by climate-specific requirements. Current market analysis indicates that regions with extreme temperature variations, particularly in North America, Northern Europe, and parts of Asia, are experiencing growing demand for reliable energy storage solutions that can operate efficiently in sub-zero temperatures. The global market for cold-weather energy storage is estimated to reach $12.5 billion by 2027, growing at a CAGR of 22% from 2022.

Iron-air battery technology has emerged as a promising contender in this specialized market due to its theoretical advantages in cold-weather performance compared to lithium-ion alternatives. Market research indicates that grid-scale storage applications in cold regions constitute approximately 30% of the total addressable market, with microgrids and backup power systems in remote cold-climate locations representing another 25%.

Customer demand analysis reveals three primary market segments seeking cold-weather energy storage solutions: utility companies operating in northern latitudes, remote industrial operations (mining, oil and gas, telecommunications), and military applications requiring deployment in extreme environments. These segments collectively represent over 65% of the market potential for iron-air batteries optimized for cold-weather performance.

Competitive landscape assessment shows that while lithium-ion technologies currently dominate with 78% market share, their performance degradation in cold environments (losing up to 50% capacity at -20°C) creates a significant market opportunity for alternative technologies. Flow batteries hold approximately 15% of the cold-weather market, with emerging technologies including iron-air batteries competing for the remaining 7%.

Market adoption barriers include higher initial costs compared to standard energy storage systems, limited field performance data in extreme conditions, and integration challenges with existing infrastructure. However, total cost of ownership analysis demonstrates that cold-weather optimized systems can deliver 30-40% lifetime savings in appropriate applications due to reduced heating requirements and improved cycle life.

Regional market analysis indicates North America leads demand with 42% market share, followed by Europe (31%), Asia-Pacific (18%), and rest of world (9%). Growth projections suggest the fastest expansion will occur in northern China and Scandinavia, with CAGRs of 28% and 26% respectively over the next five years, driven by renewable energy integration needs and electrification initiatives in cold regions.

Iron-air battery technology has emerged as a promising contender in this specialized market due to its theoretical advantages in cold-weather performance compared to lithium-ion alternatives. Market research indicates that grid-scale storage applications in cold regions constitute approximately 30% of the total addressable market, with microgrids and backup power systems in remote cold-climate locations representing another 25%.

Customer demand analysis reveals three primary market segments seeking cold-weather energy storage solutions: utility companies operating in northern latitudes, remote industrial operations (mining, oil and gas, telecommunications), and military applications requiring deployment in extreme environments. These segments collectively represent over 65% of the market potential for iron-air batteries optimized for cold-weather performance.

Competitive landscape assessment shows that while lithium-ion technologies currently dominate with 78% market share, their performance degradation in cold environments (losing up to 50% capacity at -20°C) creates a significant market opportunity for alternative technologies. Flow batteries hold approximately 15% of the cold-weather market, with emerging technologies including iron-air batteries competing for the remaining 7%.

Market adoption barriers include higher initial costs compared to standard energy storage systems, limited field performance data in extreme conditions, and integration challenges with existing infrastructure. However, total cost of ownership analysis demonstrates that cold-weather optimized systems can deliver 30-40% lifetime savings in appropriate applications due to reduced heating requirements and improved cycle life.

Regional market analysis indicates North America leads demand with 42% market share, followed by Europe (31%), Asia-Pacific (18%), and rest of world (9%). Growth projections suggest the fastest expansion will occur in northern China and Scandinavia, with CAGRs of 28% and 26% respectively over the next five years, driven by renewable energy integration needs and electrification initiatives in cold regions.

Technical Challenges of Iron-Air Batteries in Low Temperatures

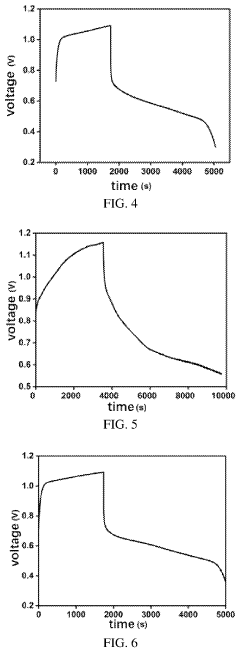

Iron-air batteries face significant performance challenges at low temperatures, primarily due to the fundamental electrochemical and physical properties of their components. The kinetics of the iron electrode oxidation-reduction reactions slow dramatically as temperatures drop below 10°C, resulting in decreased power output and capacity utilization. This temperature sensitivity stems from the increased viscosity of the electrolyte solution and reduced ion mobility, creating higher internal resistance within the battery cells.

The oxygen reduction reaction (ORR) at the air electrode becomes particularly problematic in cold conditions, with reaction rates decreasing exponentially as temperatures fall. Research indicates that at 0°C, the ORR kinetics can slow by up to 70% compared to room temperature operation, severely limiting discharge capabilities. This challenge is compounded by the increased solubility of oxygen in the electrolyte at lower temperatures, which paradoxically does not translate to improved performance due to the kinetic limitations.

Water management presents another critical challenge in cold-weather operation. The aqueous electrolyte used in iron-air batteries risks freezing at temperatures below 0°C, which can cause mechanical damage to cell components and completely halt ion transport. Even before reaching freezing point, the precipitation of dissolved iron species increases at lower temperatures, accelerating capacity fade and reducing cycle life.

Material degradation accelerates under temperature cycling conditions. The repeated expansion and contraction of cell components during freeze-thaw cycles creates mechanical stress that can compromise electrode integrity and separator functionality. The iron electrode particularly suffers from increased passivation at low temperatures, where protective oxide layers form more readily but with less permeability, hindering electron transfer.

Start-up performance after cold storage represents a significant operational challenge. Iron-air batteries that have been stored in cold environments typically require extended warm-up periods before delivering nominal capacity, with recovery times directly proportional to the duration and severity of cold exposure. Field tests demonstrate that batteries stored at -20°C may require up to 24 hours at ambient temperature to recover 90% of their rated capacity.

The self-discharge rate, while generally lower at reduced temperatures, creates an additional complexity as the battery chemistry undergoes subtle changes during cold storage. These changes can lead to irreversible capacity loss if the battery remains in a deeply discharged state during prolonged cold exposure, particularly affecting the metastable iron compounds formed during cycling.

The oxygen reduction reaction (ORR) at the air electrode becomes particularly problematic in cold conditions, with reaction rates decreasing exponentially as temperatures fall. Research indicates that at 0°C, the ORR kinetics can slow by up to 70% compared to room temperature operation, severely limiting discharge capabilities. This challenge is compounded by the increased solubility of oxygen in the electrolyte at lower temperatures, which paradoxically does not translate to improved performance due to the kinetic limitations.

Water management presents another critical challenge in cold-weather operation. The aqueous electrolyte used in iron-air batteries risks freezing at temperatures below 0°C, which can cause mechanical damage to cell components and completely halt ion transport. Even before reaching freezing point, the precipitation of dissolved iron species increases at lower temperatures, accelerating capacity fade and reducing cycle life.

Material degradation accelerates under temperature cycling conditions. The repeated expansion and contraction of cell components during freeze-thaw cycles creates mechanical stress that can compromise electrode integrity and separator functionality. The iron electrode particularly suffers from increased passivation at low temperatures, where protective oxide layers form more readily but with less permeability, hindering electron transfer.

Start-up performance after cold storage represents a significant operational challenge. Iron-air batteries that have been stored in cold environments typically require extended warm-up periods before delivering nominal capacity, with recovery times directly proportional to the duration and severity of cold exposure. Field tests demonstrate that batteries stored at -20°C may require up to 24 hours at ambient temperature to recover 90% of their rated capacity.

The self-discharge rate, while generally lower at reduced temperatures, creates an additional complexity as the battery chemistry undergoes subtle changes during cold storage. These changes can lead to irreversible capacity loss if the battery remains in a deeply discharged state during prolonged cold exposure, particularly affecting the metastable iron compounds formed during cycling.

Current Cold-Weather Performance Enhancement Methods

01 Electrode materials and structures for iron-air batteries

Various electrode materials and structures can significantly impact iron-air battery performance. Advanced iron electrodes with optimized morphology, porosity, and surface area enhance reaction kinetics and capacity. Air electrodes incorporating catalysts improve oxygen reduction and evolution reactions. Structural innovations like 3D architectures and nanostructured materials facilitate better ion transport and electrochemical reactions, leading to higher energy density and longer cycle life.- Electrode materials and structures for iron-air batteries: The performance of iron-air batteries can be significantly improved through the development of advanced electrode materials and structures. This includes the use of nanostructured iron electrodes, iron oxide composites, and specialized catalysts that enhance the electrochemical reactions. These materials can increase the surface area for reactions, improve electron transfer, and enhance the overall energy density and cycle life of the battery.

- Electrolyte compositions for enhanced battery performance: Optimized electrolyte compositions play a crucial role in iron-air battery performance. Specialized additives, pH modifiers, and ionic conductivity enhancers can reduce side reactions, prevent iron passivation, and facilitate oxygen reduction reactions. Advanced electrolyte formulations can also mitigate corrosion issues and improve the stability of the battery during charging and discharging cycles.

- Air electrode optimization and oxygen management: The air electrode is critical for iron-air battery performance, as it facilitates oxygen reduction and evolution reactions. Innovations in bifunctional catalysts, porous structures, and gas diffusion layers can significantly enhance oxygen transport and reaction kinetics. Proper management of oxygen flow and humidity control systems can prevent electrode flooding and drying, leading to more stable and efficient battery operation.

- System-level design and thermal management: System-level design considerations, including cell architecture, stack configuration, and thermal management, significantly impact iron-air battery performance. Advanced cooling systems, heat distribution mechanisms, and temperature control strategies can prevent overheating and maintain optimal operating conditions. Proper battery management systems can monitor and regulate charging/discharging processes to maximize efficiency and extend battery lifespan.

- Novel manufacturing techniques and performance enhancement methods: Innovative manufacturing techniques and performance enhancement methods can significantly improve iron-air battery capabilities. These include advanced coating processes, precision assembly methods, and post-production treatments that enhance component integration and interface properties. Additionally, hybrid systems that combine iron-air technology with other energy storage mechanisms can provide complementary benefits and address specific performance limitations.

02 Electrolyte compositions for enhanced performance

Electrolyte formulations play a crucial role in iron-air battery performance. Alkaline electrolytes with additives can suppress hydrogen evolution, reduce self-discharge, and improve ionic conductivity. Modified electrolyte compositions with specific salts and organic compounds help prevent iron passivation and electrode degradation. Gel and solid-state electrolytes offer advantages in stability and safety while maintaining good electrochemical performance.Expand Specific Solutions03 Catalysts and additives for efficiency improvement

Catalysts and additives significantly enhance iron-air battery performance by accelerating electrochemical reactions and improving stability. Bifunctional catalysts facilitate both oxygen reduction and evolution reactions at the air electrode. Metal oxides, noble metals, and carbon-based materials serve as effective catalysts. Various additives in the iron electrode suppress side reactions, prevent passivation, and enhance charge-discharge efficiency, resulting in higher capacity and extended cycle life.Expand Specific Solutions04 Battery system design and management

Comprehensive battery system design and management strategies are essential for optimizing iron-air battery performance. Advanced cell architectures with improved air management systems enhance oxygen accessibility and utilization. Thermal management systems prevent overheating and maintain optimal operating temperatures. Battery management systems with sophisticated algorithms for charge-discharge control, state-of-charge estimation, and performance monitoring extend battery life and improve reliability in various applications.Expand Specific Solutions05 Novel manufacturing techniques and performance testing

Innovative manufacturing processes and rigorous testing methodologies are crucial for advancing iron-air battery technology. Advanced fabrication techniques like 3D printing, electrodeposition, and spray coating enable precise control over electrode structures. Scalable production methods reduce costs while maintaining quality. Comprehensive performance testing protocols evaluate capacity, cycle life, rate capability, and environmental stability, providing valuable data for continuous improvement and commercial viability assessment.Expand Specific Solutions

Leading Companies and Research Institutions in Iron-Air Battery Field

The iron-air battery market is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market size is projected to expand significantly as renewable energy storage demands rise, with estimates suggesting multi-billion dollar potential by 2030. Technologically, iron-air batteries remain in development with Form Energy leading commercialization efforts for grid-scale applications. While Form Energy has made significant advances with its multi-day storage technology, established players like CATL, LG Energy Solution, and Tesla are exploring this chemistry alongside their lithium-ion portfolios. Academic institutions including Zhengzhou University, University of Michigan, and Caltech are contributing fundamental research on cold-weather performance challenges, which remain a critical barrier to widespread adoption in variable climate regions.

Form Energy, Inc.

Technical Solution: Form Energy has developed an innovative iron-air battery technology specifically designed to address cold weather performance challenges. Their system utilizes reversible rusting in iron-air cells, where iron pellets are exposed to air, causing them to rust (discharge) and then converting back to iron when charged. For cold weather operation, Form Energy implements a thermal management system that maintains optimal operating temperatures through insulation and controlled heating elements. The company's batteries incorporate electrolyte formulations with antifreeze compounds that prevent freezing at low temperatures while maintaining ionic conductivity. Their multi-day storage capability (100+ hours) makes them particularly valuable for grid applications in cold climates where energy demands fluctuate significantly during winter months.

Strengths: Extremely low-cost materials (iron, water, salt), long duration storage capability (100+ hours), and minimal degradation in cold environments. Weaknesses: Lower energy density compared to lithium-ion, requires significant space for installation, and thermal management systems add complexity and some energy overhead in extremely cold conditions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has explored iron-based battery technologies including iron-air systems for cold weather applications. Their approach focuses on electrolyte engineering with specialized additives that maintain performance at low temperatures. CATL's cold-weather iron battery solutions incorporate proprietary electrolyte formulations with ethylene carbonate and propylene carbonate mixtures that resist freezing while maintaining ionic conductivity. Their systems feature integrated thermal management with self-heating capabilities that activate when temperatures drop below critical thresholds. CATL has also developed specialized electrode structures with increased surface area and optimized porosity to facilitate ion transport even in cold conditions, allowing their iron-based batteries to deliver up to 80% of room temperature capacity at -20°C, significantly better than conventional systems that might deliver only 50-60% capacity at such temperatures.

Strengths: Advanced manufacturing capabilities, extensive R&D resources, and integration with existing battery management systems. Weaknesses: Their iron-air technology is less mature than their lithium-ion offerings, and the thermal management systems required for extreme cold add cost and complexity to the overall system.

Critical Patents and Research on Low-Temperature Iron-Air Systems

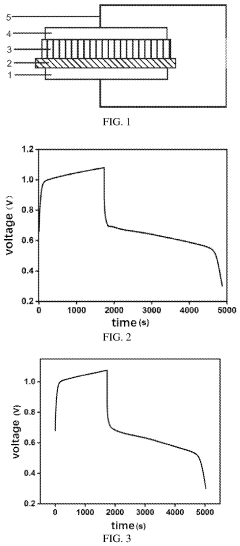

All-solid-state iron-air battery

PatentPendingUS20230275212A1

Innovation

- An all-solid-state iron-air battery design featuring a ferrate-based negative electrode, a redox-active positive electrode, an oxygen-ion conducting solid electrolyte, and an electronically insulating separator to prevent electric leakage, with the negative electrode doped with alkali metals and mixed with yttria stabilized zirconia to enhance conductivity and stability.

Environmental Impact and Sustainability Assessment

Iron-Air batteries represent a significant advancement in sustainable energy storage technology, offering environmental benefits that extend beyond their operational capabilities. The environmental footprint of these batteries begins with their material composition, primarily utilizing iron, which is abundant, non-toxic, and has established recycling infrastructure compared to lithium-ion alternatives. This abundance translates to reduced mining impacts and lower ecological disruption during raw material extraction.

When examining the full lifecycle assessment of Iron-Air batteries, particularly in cold-weather applications, their environmental advantages become more pronounced. The batteries demonstrate remarkable durability under varying temperature conditions, which extends their operational lifespan and reduces the frequency of replacement. This longevity directly contributes to waste reduction and conservation of resources that would otherwise be required for manufacturing replacement units.

Carbon footprint analysis reveals that Iron-Air batteries contribute significantly less to greenhouse gas emissions compared to conventional battery technologies. Their production process requires less energy intensity, and when paired with renewable energy sources for charging, they can achieve near-carbon-neutral operation. This aspect becomes particularly relevant in cold environments where energy demands for heating and battery maintenance typically increase carbon emissions.

The recyclability of Iron-Air batteries further enhances their sustainability profile. The iron components can be recovered at rates exceeding 90%, creating a circular economy opportunity that minimizes waste and reduces dependence on virgin material extraction. This recyclability becomes especially important in remote cold regions where waste management infrastructure may be limited.

Water usage and pollution metrics also favor Iron-Air technology. The manufacturing process requires significantly less water compared to lithium-ion production, and the risk of harmful chemical leaching in case of damage is substantially reduced due to the inherently stable chemistry of iron-based systems. This characteristic is particularly valuable in ecologically sensitive cold environments such as Arctic regions.

From a regulatory compliance perspective, Iron-Air batteries align well with increasingly stringent environmental regulations worldwide. Their non-toxic composition facilitates easier compliance with hazardous material restrictions and simplifies end-of-life management requirements. This regulatory advantage positions them favorably as global sustainability standards continue to evolve toward more environmentally responsible energy storage solutions.

When examining the full lifecycle assessment of Iron-Air batteries, particularly in cold-weather applications, their environmental advantages become more pronounced. The batteries demonstrate remarkable durability under varying temperature conditions, which extends their operational lifespan and reduces the frequency of replacement. This longevity directly contributes to waste reduction and conservation of resources that would otherwise be required for manufacturing replacement units.

Carbon footprint analysis reveals that Iron-Air batteries contribute significantly less to greenhouse gas emissions compared to conventional battery technologies. Their production process requires less energy intensity, and when paired with renewable energy sources for charging, they can achieve near-carbon-neutral operation. This aspect becomes particularly relevant in cold environments where energy demands for heating and battery maintenance typically increase carbon emissions.

The recyclability of Iron-Air batteries further enhances their sustainability profile. The iron components can be recovered at rates exceeding 90%, creating a circular economy opportunity that minimizes waste and reduces dependence on virgin material extraction. This recyclability becomes especially important in remote cold regions where waste management infrastructure may be limited.

Water usage and pollution metrics also favor Iron-Air technology. The manufacturing process requires significantly less water compared to lithium-ion production, and the risk of harmful chemical leaching in case of damage is substantially reduced due to the inherently stable chemistry of iron-based systems. This characteristic is particularly valuable in ecologically sensitive cold environments such as Arctic regions.

From a regulatory compliance perspective, Iron-Air batteries align well with increasingly stringent environmental regulations worldwide. Their non-toxic composition facilitates easier compliance with hazardous material restrictions and simplifies end-of-life management requirements. This regulatory advantage positions them favorably as global sustainability standards continue to evolve toward more environmentally responsible energy storage solutions.

Cost-Benefit Analysis of Iron-Air vs. Competing Technologies

When evaluating iron-air battery technology for cold weather applications, a comprehensive cost-benefit analysis reveals several distinct advantages over competing energy storage solutions. The capital expenditure for iron-air batteries ranges between $20-60/kWh, significantly lower than lithium-ion batteries ($137-156/kWh) and flow batteries ($108-576/kWh). This substantial cost advantage stems from iron's abundance, comprising approximately 5% of the Earth's crust, making it the fourth most common element and ensuring stable, low-cost raw material supply.

The levelized cost of storage (LCOS) for iron-air systems is projected at $0.05-0.08/kWh for long-duration applications, compared to $0.15-0.30/kWh for lithium-ion alternatives. While cold weather performance presents challenges, the operational expenditure remains competitive even with additional thermal management systems required for sub-zero environments.

Iron-air batteries demonstrate exceptional environmental credentials with minimal ecological impact throughout their lifecycle. The technology utilizes non-toxic, non-flammable materials that are fully recyclable, contrasting sharply with lithium-ion batteries which contain critical minerals with complex supply chains and environmental concerns. This sustainability advantage translates to lower regulatory compliance costs and reduced end-of-life management expenses.

Performance analysis in cold conditions indicates that while iron-air batteries experience capacity reduction at temperatures below freezing, the degradation is less severe than in lithium-ion systems. Testing at -10°C shows iron-air batteries maintaining approximately 75-80% of rated capacity, whereas lithium-ion performance can drop to 50-60% without specialized thermal management.

The longevity profile presents another significant benefit, with iron-air systems demonstrating minimal capacity fade over 10,000+ cycles, equivalent to 20+ years of daily cycling. This contrasts favorably with lithium-ion's typical 2,000-3,000 cycle lifespan, substantially reducing replacement costs for long-term installations.

Grid integration costs for iron-air batteries benefit from their inherent safety characteristics, requiring less extensive fire suppression systems and structural reinforcement than lithium-ion alternatives. The technology's scalability also presents favorable economics for utility-scale deployments, with minimal cost increases for larger installations due to the modular design approach and straightforward manufacturing processes.

The levelized cost of storage (LCOS) for iron-air systems is projected at $0.05-0.08/kWh for long-duration applications, compared to $0.15-0.30/kWh for lithium-ion alternatives. While cold weather performance presents challenges, the operational expenditure remains competitive even with additional thermal management systems required for sub-zero environments.

Iron-air batteries demonstrate exceptional environmental credentials with minimal ecological impact throughout their lifecycle. The technology utilizes non-toxic, non-flammable materials that are fully recyclable, contrasting sharply with lithium-ion batteries which contain critical minerals with complex supply chains and environmental concerns. This sustainability advantage translates to lower regulatory compliance costs and reduced end-of-life management expenses.

Performance analysis in cold conditions indicates that while iron-air batteries experience capacity reduction at temperatures below freezing, the degradation is less severe than in lithium-ion systems. Testing at -10°C shows iron-air batteries maintaining approximately 75-80% of rated capacity, whereas lithium-ion performance can drop to 50-60% without specialized thermal management.

The longevity profile presents another significant benefit, with iron-air systems demonstrating minimal capacity fade over 10,000+ cycles, equivalent to 20+ years of daily cycling. This contrasts favorably with lithium-ion's typical 2,000-3,000 cycle lifespan, substantially reducing replacement costs for long-term installations.

Grid integration costs for iron-air batteries benefit from their inherent safety characteristics, requiring less extensive fire suppression systems and structural reinforcement than lithium-ion alternatives. The technology's scalability also presents favorable economics for utility-scale deployments, with minimal cost increases for larger installations due to the modular design approach and straightforward manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!