Benchmarking Iron-Air Battery Renewable Integration

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-air battery technology represents a significant advancement in the field of energy storage, emerging as a promising solution for grid-scale applications. The technology's development can be traced back to the 1970s, when initial research on iron-based batteries began. However, it wasn't until the past decade that substantial progress was made in addressing key technical challenges, particularly around cycle life and energy efficiency.

The evolution of iron-air batteries has been accelerated by the growing need for long-duration energy storage solutions to support renewable energy integration. Traditional lithium-ion batteries, while effective for short-duration applications, face limitations in cost-effectiveness and resource availability when scaled to grid-level storage requirements. Iron-air technology offers a compelling alternative due to its use of abundant, low-cost materials and potential for multi-day storage capabilities.

The fundamental operating principle of iron-air batteries involves the oxidation and reduction of iron at the anode, coupled with oxygen reduction and evolution reactions at the cathode. During discharge, iron is oxidized to iron oxide while oxygen from the air is reduced. During charging, the process reverses. This chemistry enables theoretical energy densities exceeding 1,000 Wh/kg, though practical systems currently achieve significantly lower values.

Recent technological breakthroughs have focused on improving the reversibility of the iron electrode, enhancing oxygen electrode catalysts, and developing advanced electrolyte formulations. These improvements have collectively addressed historical challenges related to capacity fade, parasitic hydrogen evolution, and limited round-trip efficiency.

The primary objective of current iron-air battery development is to create economically viable systems capable of providing 100+ hours of energy storage at costs below $20/kWh - a target that would revolutionize renewable energy integration. Secondary goals include improving round-trip efficiency from current levels (approximately 50-60%) to 70-80%, extending cycle life to 5,000+ cycles, and developing manufacturing processes suitable for gigawatt-scale production.

In the context of renewable integration benchmarking, iron-air technology aims to provide the missing link between intermittent renewable generation and reliable grid operation. By enabling cost-effective multi-day storage, these systems could fundamentally transform how renewable energy is deployed and utilized, potentially eliminating the need for fossil fuel backup generation and enabling truly carbon-free electrical grids.

The technology roadmap anticipates commercial deployment of grid-scale iron-air systems beginning in 2024-2025, with widespread adoption potentially occurring in the latter half of this decade if current development trajectories are maintained.

The evolution of iron-air batteries has been accelerated by the growing need for long-duration energy storage solutions to support renewable energy integration. Traditional lithium-ion batteries, while effective for short-duration applications, face limitations in cost-effectiveness and resource availability when scaled to grid-level storage requirements. Iron-air technology offers a compelling alternative due to its use of abundant, low-cost materials and potential for multi-day storage capabilities.

The fundamental operating principle of iron-air batteries involves the oxidation and reduction of iron at the anode, coupled with oxygen reduction and evolution reactions at the cathode. During discharge, iron is oxidized to iron oxide while oxygen from the air is reduced. During charging, the process reverses. This chemistry enables theoretical energy densities exceeding 1,000 Wh/kg, though practical systems currently achieve significantly lower values.

Recent technological breakthroughs have focused on improving the reversibility of the iron electrode, enhancing oxygen electrode catalysts, and developing advanced electrolyte formulations. These improvements have collectively addressed historical challenges related to capacity fade, parasitic hydrogen evolution, and limited round-trip efficiency.

The primary objective of current iron-air battery development is to create economically viable systems capable of providing 100+ hours of energy storage at costs below $20/kWh - a target that would revolutionize renewable energy integration. Secondary goals include improving round-trip efficiency from current levels (approximately 50-60%) to 70-80%, extending cycle life to 5,000+ cycles, and developing manufacturing processes suitable for gigawatt-scale production.

In the context of renewable integration benchmarking, iron-air technology aims to provide the missing link between intermittent renewable generation and reliable grid operation. By enabling cost-effective multi-day storage, these systems could fundamentally transform how renewable energy is deployed and utilized, potentially eliminating the need for fossil fuel backup generation and enabling truly carbon-free electrical grids.

The technology roadmap anticipates commercial deployment of grid-scale iron-air systems beginning in 2024-2025, with widespread adoption potentially occurring in the latter half of this decade if current development trajectories are maintained.

Renewable Energy Market Integration Analysis

The renewable energy market is experiencing unprecedented growth, with global investments reaching $366 billion in 2021 and projected to exceed $1 trillion annually by 2030. This expansion creates both opportunities and challenges for energy storage technologies like iron-air batteries. Market analysis reveals that grid-scale storage demand is expected to grow at a CAGR of 32.8% through 2030, driven by increasing renewable penetration and grid stability requirements.

Iron-air batteries are entering this market at a critical juncture when utilities and grid operators are actively seeking long-duration energy storage solutions to complement the intermittent nature of wind and solar generation. Current market penetration of long-duration storage remains below 5% of total storage deployments, presenting significant growth potential for iron-air technology.

Integration analysis shows that regions with high renewable penetration, particularly those exceeding 30% of generation capacity, experience the greatest need for long-duration storage solutions. California, Texas, and European markets like Germany and Denmark represent prime initial markets for iron-air battery deployment due to their aggressive renewable targets and existing grid challenges.

Economic modeling indicates that iron-air batteries become particularly competitive in markets with high renewable curtailment rates, where the technology's low cost per kWh for long-duration storage (projected at $20-30/kWh) provides substantial value compared to lithium-ion alternatives ($150-200/kWh). The value proposition strengthens in markets with time-of-use rate structures and capacity markets that reward dispatchable power.

Regulatory frameworks significantly impact market viability. Jurisdictions with capacity markets, renewable portfolio standards, and energy storage mandates create favorable conditions for iron-air battery integration. The technology benefits particularly from policies that recognize and compensate for multiple value streams including energy arbitrage, capacity value, and grid services.

Market segmentation analysis identifies three primary integration pathways: utility-scale renewable firming (estimated at 60% of potential deployments), transmission and distribution deferral applications (25%), and behind-the-meter commercial and industrial applications (15%). Each segment presents distinct integration requirements and value propositions that must be addressed in deployment strategies.

Adoption barriers include grid interconnection challenges, regulatory uncertainty regarding storage classification, and competition from established technologies. Market acceptance will require demonstrated reliability through pilot projects and partnerships with established utilities and renewable developers to validate performance in real-world grid integration scenarios.

Iron-air batteries are entering this market at a critical juncture when utilities and grid operators are actively seeking long-duration energy storage solutions to complement the intermittent nature of wind and solar generation. Current market penetration of long-duration storage remains below 5% of total storage deployments, presenting significant growth potential for iron-air technology.

Integration analysis shows that regions with high renewable penetration, particularly those exceeding 30% of generation capacity, experience the greatest need for long-duration storage solutions. California, Texas, and European markets like Germany and Denmark represent prime initial markets for iron-air battery deployment due to their aggressive renewable targets and existing grid challenges.

Economic modeling indicates that iron-air batteries become particularly competitive in markets with high renewable curtailment rates, where the technology's low cost per kWh for long-duration storage (projected at $20-30/kWh) provides substantial value compared to lithium-ion alternatives ($150-200/kWh). The value proposition strengthens in markets with time-of-use rate structures and capacity markets that reward dispatchable power.

Regulatory frameworks significantly impact market viability. Jurisdictions with capacity markets, renewable portfolio standards, and energy storage mandates create favorable conditions for iron-air battery integration. The technology benefits particularly from policies that recognize and compensate for multiple value streams including energy arbitrage, capacity value, and grid services.

Market segmentation analysis identifies three primary integration pathways: utility-scale renewable firming (estimated at 60% of potential deployments), transmission and distribution deferral applications (25%), and behind-the-meter commercial and industrial applications (15%). Each segment presents distinct integration requirements and value propositions that must be addressed in deployment strategies.

Adoption barriers include grid interconnection challenges, regulatory uncertainty regarding storage classification, and competition from established technologies. Market acceptance will require demonstrated reliability through pilot projects and partnerships with established utilities and renewable developers to validate performance in real-world grid integration scenarios.

Current Status and Technical Challenges

Iron-Air battery technology has emerged as a promising solution for large-scale energy storage, particularly for renewable energy integration. Currently, the technology has progressed from laboratory-scale demonstrations to pilot projects, with several companies advancing toward commercial deployment. Form Energy, a leading player in this space, has developed 100-hour iron-air battery systems with projected costs below $20/kWh, significantly undercutting lithium-ion alternatives for long-duration storage applications.

Despite these advancements, iron-air battery technology faces several critical technical challenges. The primary issue remains the relatively low round-trip efficiency, typically ranging from 40-60%, compared to lithium-ion batteries that achieve 85-95%. This efficiency gap represents a substantial barrier to widespread adoption, particularly in applications where energy losses translate directly to increased operational costs.

Another significant challenge is the degradation of electrodes over extended cycling. Iron electrodes undergo volume changes during charge-discharge cycles, leading to mechanical stress and potential structural failure. Current research indicates that after 1,000 cycles, capacity retention may decrease to 80-85%, necessitating further improvements for grid-scale applications requiring decades of reliable operation.

The reaction kinetics of the iron-air chemistry present additional hurdles. The oxygen reduction and evolution reactions at the air electrode occur at relatively slow rates, limiting power density capabilities. Most current systems deliver power densities of 50-100 W/L, substantially below the 250-500 W/L achieved by lithium-ion technologies, restricting their applicability in scenarios requiring rapid response to grid fluctuations.

System integration with renewable energy sources introduces further complexities. The intermittent nature of wind and solar generation creates variable charging profiles that can accelerate degradation mechanisms in iron-air batteries. Field tests have demonstrated that performance variability increases by 15-25% under realistic renewable integration scenarios compared to controlled laboratory conditions.

Globally, research efforts are concentrated in North America, with significant activity also occurring in Europe and China. The United States leads with approximately 45% of patents and research publications in this field, followed by China (25%) and Germany (15%). This geographical distribution reflects both the technical expertise and strategic importance different regions place on long-duration energy storage for renewable integration.

Manufacturing scalability represents another substantial challenge, as current production methods for iron-air batteries remain largely manual or semi-automated. The transition to gigawatt-scale production will require significant advances in manufacturing processes, quality control systems, and supply chain development to achieve the cost targets necessary for widespread deployment.

Despite these advancements, iron-air battery technology faces several critical technical challenges. The primary issue remains the relatively low round-trip efficiency, typically ranging from 40-60%, compared to lithium-ion batteries that achieve 85-95%. This efficiency gap represents a substantial barrier to widespread adoption, particularly in applications where energy losses translate directly to increased operational costs.

Another significant challenge is the degradation of electrodes over extended cycling. Iron electrodes undergo volume changes during charge-discharge cycles, leading to mechanical stress and potential structural failure. Current research indicates that after 1,000 cycles, capacity retention may decrease to 80-85%, necessitating further improvements for grid-scale applications requiring decades of reliable operation.

The reaction kinetics of the iron-air chemistry present additional hurdles. The oxygen reduction and evolution reactions at the air electrode occur at relatively slow rates, limiting power density capabilities. Most current systems deliver power densities of 50-100 W/L, substantially below the 250-500 W/L achieved by lithium-ion technologies, restricting their applicability in scenarios requiring rapid response to grid fluctuations.

System integration with renewable energy sources introduces further complexities. The intermittent nature of wind and solar generation creates variable charging profiles that can accelerate degradation mechanisms in iron-air batteries. Field tests have demonstrated that performance variability increases by 15-25% under realistic renewable integration scenarios compared to controlled laboratory conditions.

Globally, research efforts are concentrated in North America, with significant activity also occurring in Europe and China. The United States leads with approximately 45% of patents and research publications in this field, followed by China (25%) and Germany (15%). This geographical distribution reflects both the technical expertise and strategic importance different regions place on long-duration energy storage for renewable integration.

Manufacturing scalability represents another substantial challenge, as current production methods for iron-air batteries remain largely manual or semi-automated. The transition to gigawatt-scale production will require significant advances in manufacturing processes, quality control systems, and supply chain development to achieve the cost targets necessary for widespread deployment.

Current Integration Solutions with Renewable Systems

01 Iron-Air Battery Design and Components

Iron-air batteries consist of specific components and design elements that affect their performance. These batteries typically include iron electrodes, air electrodes, and electrolyte systems. The design considerations include electrode structure, electrolyte composition, and cell configuration to optimize energy density, cycle life, and efficiency. Advanced materials and manufacturing techniques are employed to enhance the electrochemical reactions between iron and oxygen.- Iron-Air Battery Design and Components: Iron-air batteries consist of iron electrodes that react with oxygen to store and release energy. These batteries typically include iron anodes, air cathodes, and electrolyte systems. The design focuses on optimizing the iron electrode structure, air electrode catalysts, and electrolyte composition to enhance performance metrics such as energy density, cycle life, and charge/discharge efficiency. Various approaches to component design and material selection are employed to overcome challenges like iron passivation and oxygen reduction kinetics.

- Performance Evaluation and Testing Methods: Benchmarking iron-air batteries involves standardized testing protocols to evaluate key performance parameters. These include capacity retention, round-trip efficiency, self-discharge rates, and operational stability under various conditions. Testing methods may involve accelerated aging tests, temperature variation studies, and comparative analysis against other battery technologies. The evaluation frameworks help quantify the practical viability of iron-air batteries for different applications and identify areas for improvement in the technology.

- Grid-Scale Energy Storage Applications: Iron-air batteries show significant potential for grid-scale energy storage applications due to their low cost, abundant materials, and high theoretical energy density. Benchmarking studies focus on their suitability for load leveling, renewable energy integration, and backup power systems. The evaluation includes scalability assessments, economic analyses, and integration capabilities with existing power infrastructure. These batteries are particularly promising for long-duration energy storage needs where cost-effectiveness is prioritized over energy density.

- Comparative Analysis with Other Battery Technologies: Benchmarking studies compare iron-air batteries against other energy storage technologies such as lithium-ion, flow batteries, and other metal-air systems. The comparisons evaluate metrics including cost per kilowatt-hour, lifetime, environmental impact, safety, and resource availability. These analyses help position iron-air technology within the broader energy storage landscape and identify specific applications where iron-air batteries may offer competitive advantages over established technologies.

- Performance Management and Monitoring Systems: Advanced monitoring and management systems are developed to optimize iron-air battery performance in real-world applications. These systems include battery management software, predictive analytics for maintenance, and diagnostic tools for performance evaluation. The technologies enable real-time monitoring of battery health, adaptive control strategies, and data-driven optimization of operational parameters. Such systems are crucial for maximizing battery lifespan and ensuring reliable performance in various deployment scenarios.

02 Performance Evaluation Metrics for Iron-Air Batteries

Various metrics are used to benchmark iron-air battery performance, including energy density, power density, cycle life, charge/discharge efficiency, and self-discharge rate. These parameters are measured under standardized testing conditions to enable objective comparison between different battery designs. Performance evaluation also considers operational factors such as temperature range, response to varying loads, and long-term stability under different environmental conditions.Expand Specific Solutions03 Comparative Analysis with Other Battery Technologies

Iron-air batteries are benchmarked against other energy storage technologies such as lithium-ion, lead-acid, and flow batteries. The comparative analysis focuses on cost-effectiveness, environmental impact, safety, and scalability. Iron-air batteries typically offer advantages in terms of material abundance, environmental friendliness, and theoretical energy density, while facing challenges related to practical efficiency and cycle life compared to more established technologies.Expand Specific Solutions04 Testing Protocols and Standards for Iron-Air Batteries

Standardized testing protocols are essential for reliable benchmarking of iron-air batteries. These protocols define specific conditions for measuring capacity, cycle life, efficiency, and other performance parameters. Testing standards include procedures for accelerated aging tests, temperature performance evaluation, and safety assessments. Consistent application of these protocols enables meaningful comparison between different iron-air battery designs and technologies.Expand Specific Solutions05 Commercial Viability and Market Analysis

Assessment of iron-air batteries includes analysis of their commercial viability and market potential. This involves evaluation of manufacturing costs, scalability of production, and integration capabilities with existing energy systems. Market analysis considers potential applications in grid storage, renewable energy integration, and other sectors where the specific characteristics of iron-air batteries might provide competitive advantages. Economic benchmarking includes lifecycle cost analysis and return on investment calculations.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The iron-air battery renewable integration market is in an early growth phase, characterized by increasing research activity and commercial development. The global market for long-duration energy storage is projected to reach significant scale as renewable energy penetration increases, with iron-air technology emerging as a cost-effective solution for grid-scale applications. From a technological maturity perspective, companies like Form Energy are leading commercialization efforts with their multi-day storage solutions, while established players such as Tesla and BMW are exploring integration possibilities. Academic institutions including Caltech, Tsinghua University, and Northwestern University are advancing fundamental research, while specialized firms like Alumapower and Liox Power focus on material innovations. Government laboratories including the Naval Research Laboratory are contributing to technological validation, indicating growing institutional support for this promising renewable integration pathway.

Form Energy, Inc.

Technical Solution: Form Energy has developed a pioneering iron-air battery technology specifically designed for grid-scale renewable energy storage. Their solution utilizes the reversible rusting process of iron to store energy for up to 100 hours at system costs competitive with conventional power plants. The company's technology involves cells filled with iron pellets that, when exposed to air, rust (discharge) and when supplied with electrical current, turn back to iron (charge). Form Energy has secured over $800 million in funding and is deploying 10MW/1000MWh systems with utilities like Great River Energy and Georgia Power. Their benchmarking approach focuses on measuring round-trip efficiency (approximately 30%), levelized cost of storage (targeting <$20/kWh), cycle life (>5,000 cycles), and integration performance with renewable sources.

Strengths: Extremely low-cost materials (iron, water, air), exceptional duration capability (100+ hours), and minimal degradation over thousands of cycles. Weaknesses: Lower round-trip efficiency compared to lithium-ion batteries, requiring larger installations for equivalent output and relatively slow response time limiting applications in frequency regulation.

Tesla, Inc.

Technical Solution: Tesla has developed comprehensive benchmarking methodologies for evaluating energy storage systems including emerging technologies like iron-air batteries. Their approach integrates these systems with renewable energy sources through their Autobidder platform, which optimizes battery dispatch based on energy market conditions and renewable generation forecasts. Tesla's benchmarking framework evaluates iron-air batteries against metrics including round-trip efficiency, response time, depth of discharge impact on longevity, and total cost of ownership when paired with solar and wind generation. While Tesla primarily deploys lithium-ion technology in their Megapack systems, they actively research alternative chemistries including iron-based solutions for longer-duration storage applications, recognizing the complementary role these technologies could play alongside their existing products for renewable integration at different timescales.

Strengths: Industry-leading software integration capabilities, extensive real-world deployment experience with renewable energy systems, and sophisticated predictive analytics for optimizing battery performance. Weaknesses: Current focus primarily on lithium-ion technology limits direct experience with iron-air systems, and their benchmarking may emphasize metrics (like response time) where iron-air batteries underperform compared to lithium-ion solutions.

Core Patents and Technical Literature Analysis

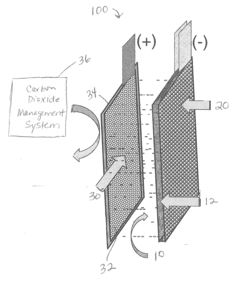

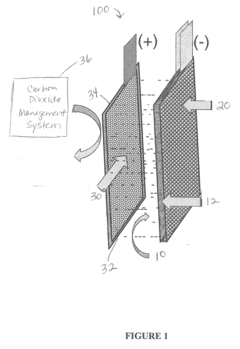

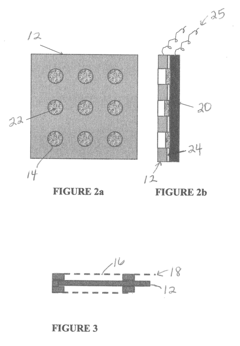

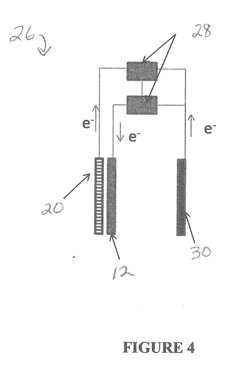

Iron-air rechargeable battery

PatentActiveUS20120187918A1

Innovation

- Incorporating self-assembling organic sulfur-based additives to inhibit hydrogen evolution, using non-toxic bismuth additives to suppress parasitic reactions, integrating a bilayer composite electrode for hydrogen utilization, employing nano-structured corrosion-resistant substrates for the air electrode, and implementing a carbon dioxide management system to enhance efficiency and durability.

Iron-air rechargeable battery

PatentWO2012012731A2

Innovation

- Incorporating self-assembling organic sulfur-based additives to inhibit hydrogen evolution, using non-toxic bismuth additives to suppress parasitic reactions, integrating a bilayer composite electrode for hydrogen utilization, employing nano-structured corrosion-resistant substrates for the air electrode, and implementing a thin film nano-structured catalyst layer with a carbon dioxide management system to enhance efficiency and durability.

Grid-Scale Implementation Feasibility

The implementation of iron-air battery technology at grid scale presents both significant opportunities and challenges for renewable energy integration. Current feasibility assessments indicate that iron-air batteries could potentially provide 100+ hour duration storage at approximately $20/kWh, making them substantially more cost-effective than lithium-ion alternatives for long-duration applications. This economic advantage positions iron-air technology as particularly valuable for grid stabilization during extended renewable generation gaps.

Technical readiness evaluations reveal that while prototype systems have demonstrated promising performance metrics, scaling to utility-grade installations requires further engineering refinement. Form Energy's 1MW/150MWh pilot project with Great River Energy represents the first major grid-connected deployment, providing critical operational data for future implementations. The physical footprint requirements remain larger than competing technologies, with current designs requiring approximately 40-50 square feet per MWh of storage capacity.

Grid integration studies highlight several implementation considerations. Iron-air batteries exhibit relatively slow response times compared to lithium-ion systems, with typical ramp rates of 10-15% capacity per minute versus 100% for lithium-ion. This characteristic makes them more suitable for energy shifting rather than frequency regulation applications. Additionally, the technology's round-trip efficiency of 50-60% necessitates careful placement within the grid architecture to maximize economic value.

Regulatory frameworks present varying levels of support for grid-scale deployment. Several jurisdictions have begun modifying capacity market rules to accommodate long-duration storage assets, though comprehensive policies specifically addressing multi-day storage technologies remain underdeveloped. The technology benefits from minimal supply chain constraints, with iron being the fifth most abundant element in Earth's crust.

Infrastructure requirements for widespread adoption include enhanced grid interconnection capabilities and potential modifications to existing transmission systems. Most installations would require medium-voltage connections (13.8-34.5kV) with appropriate power conversion systems. The technology's modularity allows for phased implementation, enabling utilities to incrementally scale storage capacity as renewable penetration increases.

Financial modeling suggests that iron-air batteries become economically viable for grid applications when renewable penetration exceeds approximately 60-70% of generation capacity. At these penetration levels, the marginal value of additional short-duration storage diminishes while the need for multi-day backup increases substantially, creating the economic conditions where iron-air's lower capital costs offset its efficiency disadvantages.

Technical readiness evaluations reveal that while prototype systems have demonstrated promising performance metrics, scaling to utility-grade installations requires further engineering refinement. Form Energy's 1MW/150MWh pilot project with Great River Energy represents the first major grid-connected deployment, providing critical operational data for future implementations. The physical footprint requirements remain larger than competing technologies, with current designs requiring approximately 40-50 square feet per MWh of storage capacity.

Grid integration studies highlight several implementation considerations. Iron-air batteries exhibit relatively slow response times compared to lithium-ion systems, with typical ramp rates of 10-15% capacity per minute versus 100% for lithium-ion. This characteristic makes them more suitable for energy shifting rather than frequency regulation applications. Additionally, the technology's round-trip efficiency of 50-60% necessitates careful placement within the grid architecture to maximize economic value.

Regulatory frameworks present varying levels of support for grid-scale deployment. Several jurisdictions have begun modifying capacity market rules to accommodate long-duration storage assets, though comprehensive policies specifically addressing multi-day storage technologies remain underdeveloped. The technology benefits from minimal supply chain constraints, with iron being the fifth most abundant element in Earth's crust.

Infrastructure requirements for widespread adoption include enhanced grid interconnection capabilities and potential modifications to existing transmission systems. Most installations would require medium-voltage connections (13.8-34.5kV) with appropriate power conversion systems. The technology's modularity allows for phased implementation, enabling utilities to incrementally scale storage capacity as renewable penetration increases.

Financial modeling suggests that iron-air batteries become economically viable for grid applications when renewable penetration exceeds approximately 60-70% of generation capacity. At these penetration levels, the marginal value of additional short-duration storage diminishes while the need for multi-day backup increases substantially, creating the economic conditions where iron-air's lower capital costs offset its efficiency disadvantages.

Economic Viability Assessment

The economic viability of iron-air battery integration with renewable energy systems represents a critical factor in determining widespread adoption potential. Current cost analyses indicate that iron-air batteries offer a compelling value proposition with estimated levelized cost of storage (LCOS) ranging from $20-40/kWh, significantly lower than lithium-ion alternatives ($150-200/kWh) and comparable to pumped hydro storage systems. This cost advantage stems primarily from the abundant and inexpensive raw materials—iron, water, and air—which mitigate supply chain vulnerabilities and price volatility risks.

Investment requirements for iron-air battery deployment show favorable trends, with capital expenditure (CAPEX) projections decreasing from approximately $200/kWh in early commercial deployments to potentially under $100/kWh at scale. Operational expenditures (OPEX) benefit from minimal maintenance requirements and long cycle life expectations exceeding 10,000 cycles, translating to 20+ years of operational lifespan under typical renewable integration scenarios.

Return on investment (ROI) calculations demonstrate particularly strong economics in specific use cases. Grid-scale applications paired with wind and solar generation show payback periods of 5-8 years, with internal rates of return (IRR) between 12-18% depending on regional electricity market structures and renewable penetration levels. The long duration storage capability (100+ hours) creates additional value streams through energy arbitrage opportunities that shorter-duration technologies cannot capture.

Sensitivity analysis reveals that economic viability is most influenced by three key factors: installation scale, renewable generation curtailment rates, and regional capacity market structures. Installations exceeding 100MWh demonstrate significantly improved economics through manufacturing and operational efficiencies. In regions with high renewable curtailment (>5% annually), the value proposition strengthens considerably as iron-air systems can absorb otherwise wasted generation.

Regulatory frameworks and incentive structures substantially impact economic outcomes. Jurisdictions with capacity markets or specific long-duration storage incentives improve project economics by 15-30%. The Inflation Reduction Act in the United States, for instance, provides investment tax credits that can reduce effective capital costs by up to 30%, accelerating payback periods by 1-3 years depending on project specifics.

Comparative economic analysis against alternative long-duration storage technologies (pumped hydro, compressed air, flow batteries) positions iron-air batteries favorably when considering full lifecycle costs, deployment flexibility, and scalability. While pumped hydro remains slightly less expensive on a pure LCOS basis, geographic constraints and environmental permitting challenges limit its application, whereas iron-air systems can be deployed virtually anywhere with minimal environmental impact.

Investment requirements for iron-air battery deployment show favorable trends, with capital expenditure (CAPEX) projections decreasing from approximately $200/kWh in early commercial deployments to potentially under $100/kWh at scale. Operational expenditures (OPEX) benefit from minimal maintenance requirements and long cycle life expectations exceeding 10,000 cycles, translating to 20+ years of operational lifespan under typical renewable integration scenarios.

Return on investment (ROI) calculations demonstrate particularly strong economics in specific use cases. Grid-scale applications paired with wind and solar generation show payback periods of 5-8 years, with internal rates of return (IRR) between 12-18% depending on regional electricity market structures and renewable penetration levels. The long duration storage capability (100+ hours) creates additional value streams through energy arbitrage opportunities that shorter-duration technologies cannot capture.

Sensitivity analysis reveals that economic viability is most influenced by three key factors: installation scale, renewable generation curtailment rates, and regional capacity market structures. Installations exceeding 100MWh demonstrate significantly improved economics through manufacturing and operational efficiencies. In regions with high renewable curtailment (>5% annually), the value proposition strengthens considerably as iron-air systems can absorb otherwise wasted generation.

Regulatory frameworks and incentive structures substantially impact economic outcomes. Jurisdictions with capacity markets or specific long-duration storage incentives improve project economics by 15-30%. The Inflation Reduction Act in the United States, for instance, provides investment tax credits that can reduce effective capital costs by up to 30%, accelerating payback periods by 1-3 years depending on project specifics.

Comparative economic analysis against alternative long-duration storage technologies (pumped hydro, compressed air, flow batteries) positions iron-air batteries favorably when considering full lifecycle costs, deployment flexibility, and scalability. While pumped hydro remains slightly less expensive on a pure LCOS basis, geographic constraints and environmental permitting challenges limit its application, whereas iron-air systems can be deployed virtually anywhere with minimal environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!