Optimizing Iron-Air Battery for Reduced Environmental Footprint

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Iron-Air Battery Technology Background and Objectives

Iron-air batteries represent a significant advancement in energy storage technology, with roots dating back to the 1970s. However, only in the past decade has this technology gained substantial momentum due to increasing demands for sustainable energy storage solutions. The evolution of iron-air battery technology has been characterized by incremental improvements in electrode materials, electrolyte compositions, and system architectures, all aimed at addressing the fundamental challenges of efficiency and longevity.

The core principle of iron-air batteries leverages the oxidation of iron and reduction of oxygen to store and release energy. This chemistry offers inherent advantages including the use of abundant, low-cost materials and theoretical energy densities exceeding 1,000 Wh/kg. The historical trajectory shows a shift from early laboratory prototypes with limited cycle life to today's more robust systems capable of hundreds of cycles with improved round-trip efficiency.

Current technological objectives focus primarily on optimizing iron-air batteries to minimize their environmental footprint while maintaining or enhancing performance metrics. This includes reducing the carbon intensity of manufacturing processes, eliminating toxic components, improving material recyclability, and extending operational lifespan to maximize lifecycle sustainability. Additionally, research aims to address the hydrogen evolution side reaction that occurs during charging, which represents both an efficiency loss and a safety consideration.

Market drivers for this technology include grid-scale energy storage applications, particularly for long-duration storage needs (8+ hours) where lithium-ion batteries become economically prohibitive. The renewable energy sector's growth has created urgent demand for storage solutions that can balance intermittent generation from wind and solar sources, with iron-air batteries positioned as a potentially cost-effective alternative to existing technologies.

Technical objectives for environmental footprint reduction include developing water-based manufacturing processes, designing for end-of-life disassembly and material recovery, and creating closed-loop material supply chains. Researchers are also exploring catalysts derived from earth-abundant materials to replace precious metals currently used in air electrodes, thereby reducing resource extraction impacts.

The convergence of environmental imperatives, energy transition policies, and technological maturation has created a favorable landscape for accelerated development of iron-air battery technology. Leading research institutions and emerging companies are establishing ambitious targets for commercial deployment within the next five years, with projected cost points below $20/kWh for energy capacity—potentially revolutionizing the economics of renewable energy integration and grid resilience.

The core principle of iron-air batteries leverages the oxidation of iron and reduction of oxygen to store and release energy. This chemistry offers inherent advantages including the use of abundant, low-cost materials and theoretical energy densities exceeding 1,000 Wh/kg. The historical trajectory shows a shift from early laboratory prototypes with limited cycle life to today's more robust systems capable of hundreds of cycles with improved round-trip efficiency.

Current technological objectives focus primarily on optimizing iron-air batteries to minimize their environmental footprint while maintaining or enhancing performance metrics. This includes reducing the carbon intensity of manufacturing processes, eliminating toxic components, improving material recyclability, and extending operational lifespan to maximize lifecycle sustainability. Additionally, research aims to address the hydrogen evolution side reaction that occurs during charging, which represents both an efficiency loss and a safety consideration.

Market drivers for this technology include grid-scale energy storage applications, particularly for long-duration storage needs (8+ hours) where lithium-ion batteries become economically prohibitive. The renewable energy sector's growth has created urgent demand for storage solutions that can balance intermittent generation from wind and solar sources, with iron-air batteries positioned as a potentially cost-effective alternative to existing technologies.

Technical objectives for environmental footprint reduction include developing water-based manufacturing processes, designing for end-of-life disassembly and material recovery, and creating closed-loop material supply chains. Researchers are also exploring catalysts derived from earth-abundant materials to replace precious metals currently used in air electrodes, thereby reducing resource extraction impacts.

The convergence of environmental imperatives, energy transition policies, and technological maturation has created a favorable landscape for accelerated development of iron-air battery technology. Leading research institutions and emerging companies are establishing ambitious targets for commercial deployment within the next five years, with projected cost points below $20/kWh for energy capacity—potentially revolutionizing the economics of renewable energy integration and grid resilience.

Market Demand Analysis for Sustainable Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the urgent need for sustainable solutions that can support renewable energy integration and grid stability. Iron-air battery technology has emerged as a promising contender in this rapidly evolving landscape, particularly due to its potential for reduced environmental impact compared to conventional battery technologies.

Market analysis indicates that the global energy storage market is projected to grow at a compound annual growth rate of over 20% through 2030, with grid-scale storage solutions representing the largest segment. This growth is primarily fueled by increasing renewable energy deployment, which necessitates effective storage solutions to address intermittency issues. Iron-air batteries, with their high energy density, low cost materials, and minimal environmental footprint, are well-positioned to capture a significant portion of this expanding market.

Consumer and industrial sectors are increasingly demanding sustainable energy storage solutions that minimize environmental impact throughout their lifecycle. A recent survey of utility companies revealed that 78% consider environmental sustainability as a critical factor in their energy storage procurement decisions, highlighting a clear market preference for technologies like iron-air batteries that utilize abundant, non-toxic materials.

The regulatory landscape is also creating favorable market conditions for environmentally friendly battery technologies. Several major economies have implemented carbon pricing mechanisms and environmental regulations that penalize high-carbon alternatives, effectively creating premium market segments for solutions with reduced environmental footprints. Additionally, government incentives for clean energy technologies in key markets like the European Union, United States, and China are accelerating adoption of sustainable storage solutions.

Industry forecasts suggest that the market for iron-based battery technologies could reach $15 billion by 2030, representing approximately 12% of the total energy storage market. This growth trajectory is supported by increasing corporate commitments to carbon neutrality, which are driving investment in technologies that can reduce scope 3 emissions across supply chains.

The market opportunity extends beyond stationary applications to potentially include heavy transportation and industrial sectors seeking alternatives to lithium-ion batteries. These segments value the safety profile, longevity, and reduced environmental impact that optimized iron-air batteries can provide, particularly in applications where weight constraints are less critical than total cost of ownership and sustainability metrics.

Customer willingness to pay premiums for environmentally superior technologies varies by segment, with utility-scale projects demonstrating 5-8% premium acceptance for solutions that offer verifiable environmental benefits and commercial customers showing even higher premium tolerance of 10-15% when total lifecycle benefits are clearly demonstrated.

Market analysis indicates that the global energy storage market is projected to grow at a compound annual growth rate of over 20% through 2030, with grid-scale storage solutions representing the largest segment. This growth is primarily fueled by increasing renewable energy deployment, which necessitates effective storage solutions to address intermittency issues. Iron-air batteries, with their high energy density, low cost materials, and minimal environmental footprint, are well-positioned to capture a significant portion of this expanding market.

Consumer and industrial sectors are increasingly demanding sustainable energy storage solutions that minimize environmental impact throughout their lifecycle. A recent survey of utility companies revealed that 78% consider environmental sustainability as a critical factor in their energy storage procurement decisions, highlighting a clear market preference for technologies like iron-air batteries that utilize abundant, non-toxic materials.

The regulatory landscape is also creating favorable market conditions for environmentally friendly battery technologies. Several major economies have implemented carbon pricing mechanisms and environmental regulations that penalize high-carbon alternatives, effectively creating premium market segments for solutions with reduced environmental footprints. Additionally, government incentives for clean energy technologies in key markets like the European Union, United States, and China are accelerating adoption of sustainable storage solutions.

Industry forecasts suggest that the market for iron-based battery technologies could reach $15 billion by 2030, representing approximately 12% of the total energy storage market. This growth trajectory is supported by increasing corporate commitments to carbon neutrality, which are driving investment in technologies that can reduce scope 3 emissions across supply chains.

The market opportunity extends beyond stationary applications to potentially include heavy transportation and industrial sectors seeking alternatives to lithium-ion batteries. These segments value the safety profile, longevity, and reduced environmental impact that optimized iron-air batteries can provide, particularly in applications where weight constraints are less critical than total cost of ownership and sustainability metrics.

Customer willingness to pay premiums for environmentally superior technologies varies by segment, with utility-scale projects demonstrating 5-8% premium acceptance for solutions that offer verifiable environmental benefits and commercial customers showing even higher premium tolerance of 10-15% when total lifecycle benefits are clearly demonstrated.

Current Status and Technical Challenges of Iron-Air Batteries

Iron-air batteries have emerged as a promising energy storage technology due to their potential for low cost, high energy density, and environmental sustainability. Currently, these batteries are in various stages of development, with several companies and research institutions actively working on commercialization. The fundamental chemistry involves iron oxidation during discharge and reduction during charging, with oxygen from the air serving as the cathode reactant.

The current technical maturity of iron-air batteries remains at the pre-commercial stage. While laboratory prototypes have demonstrated energy densities of 300-500 Wh/kg, commercial versions typically achieve 100-200 Wh/kg, still exceeding lithium-ion batteries in some applications. Cycle life remains limited to 1,000-3,000 cycles, significantly lower than the 5,000+ cycles achieved by lithium-ion alternatives.

Major technical challenges impeding widespread adoption include the parasitic hydrogen evolution reaction during charging, which reduces coulombic efficiency to 80-90%. This inefficiency increases energy consumption and operational costs. Iron electrode passivation presents another significant hurdle, as iron oxide layers form on electrode surfaces, impeding electron transfer and reducing capacity over time.

Air electrode management poses complex challenges, particularly regarding oxygen diffusion limitations and carbonate formation from atmospheric CO2. These issues necessitate sophisticated air management systems that add complexity and cost to battery designs. Additionally, electrolyte management remains problematic due to water loss during operation and potential leakage risks.

From an environmental perspective, while iron-air batteries utilize abundant, non-toxic materials, their manufacturing processes still generate considerable carbon footprints. Current production methods require high-temperature sintering processes for electrode fabrication, consuming substantial energy. The environmental impact of electrolyte production and disposal also requires further optimization.

Geographically, research and development efforts are concentrated in North America, Europe, and East Asia. The United States leads with companies like Form Energy and academic institutions such as MIT and Stanford University. In Europe, significant research occurs in Germany and the UK, while China, Japan, and South Korea represent major Asian contributors to the field.

Recent advancements include novel electrode architectures incorporating nanomaterials to enhance reaction kinetics and stability. Electrolyte additives have shown promise in mitigating hydrogen evolution, while advanced manufacturing techniques are gradually reducing production energy requirements. Despite these improvements, substantial technical barriers remain before iron-air batteries can achieve their full potential for environmental footprint reduction.

The current technical maturity of iron-air batteries remains at the pre-commercial stage. While laboratory prototypes have demonstrated energy densities of 300-500 Wh/kg, commercial versions typically achieve 100-200 Wh/kg, still exceeding lithium-ion batteries in some applications. Cycle life remains limited to 1,000-3,000 cycles, significantly lower than the 5,000+ cycles achieved by lithium-ion alternatives.

Major technical challenges impeding widespread adoption include the parasitic hydrogen evolution reaction during charging, which reduces coulombic efficiency to 80-90%. This inefficiency increases energy consumption and operational costs. Iron electrode passivation presents another significant hurdle, as iron oxide layers form on electrode surfaces, impeding electron transfer and reducing capacity over time.

Air electrode management poses complex challenges, particularly regarding oxygen diffusion limitations and carbonate formation from atmospheric CO2. These issues necessitate sophisticated air management systems that add complexity and cost to battery designs. Additionally, electrolyte management remains problematic due to water loss during operation and potential leakage risks.

From an environmental perspective, while iron-air batteries utilize abundant, non-toxic materials, their manufacturing processes still generate considerable carbon footprints. Current production methods require high-temperature sintering processes for electrode fabrication, consuming substantial energy. The environmental impact of electrolyte production and disposal also requires further optimization.

Geographically, research and development efforts are concentrated in North America, Europe, and East Asia. The United States leads with companies like Form Energy and academic institutions such as MIT and Stanford University. In Europe, significant research occurs in Germany and the UK, while China, Japan, and South Korea represent major Asian contributors to the field.

Recent advancements include novel electrode architectures incorporating nanomaterials to enhance reaction kinetics and stability. Electrolyte additives have shown promise in mitigating hydrogen evolution, while advanced manufacturing techniques are gradually reducing production energy requirements. Despite these improvements, substantial technical barriers remain before iron-air batteries can achieve their full potential for environmental footprint reduction.

Current Environmental Optimization Solutions for Iron-Air Batteries

01 Life cycle assessment of iron-air batteries

Life cycle assessment (LCA) methodologies are applied to evaluate the environmental footprint of iron-air batteries from raw material extraction through manufacturing, use, and end-of-life disposal. These assessments quantify various environmental impacts including carbon emissions, resource depletion, and energy consumption throughout the battery lifecycle. The analysis helps identify environmental hotspots and compare iron-air batteries with conventional energy storage technologies to demonstrate their potential environmental advantages.- Life cycle assessment of iron-air batteries: Life cycle assessment methodologies are applied to evaluate the environmental footprint of iron-air batteries from raw material extraction through manufacturing, use, and disposal. These assessments quantify various environmental impacts including carbon emissions, resource depletion, and energy consumption throughout the battery lifecycle. The analysis helps in comparing iron-air batteries with conventional energy storage technologies and identifying opportunities for environmental optimization.

- Materials sustainability and resource efficiency: Iron-air batteries utilize abundant, low-cost, and environmentally friendly materials compared to conventional lithium-ion batteries. The use of iron as the primary active material reduces dependence on rare or toxic elements, minimizing resource depletion and extraction impacts. These batteries demonstrate improved sustainability through reduced mining footprints and the potential for using recycled iron materials, contributing to circular economy principles.

- Manufacturing process optimization for environmental impact reduction: Innovations in manufacturing processes for iron-air batteries focus on reducing environmental impacts through energy-efficient production methods, waste minimization, and cleaner technologies. These optimizations include water-based processing, solvent-free electrode fabrication, and energy-efficient assembly techniques. Advanced manufacturing approaches help minimize the carbon footprint associated with battery production while maintaining performance characteristics.

- End-of-life management and recyclability: Iron-air batteries offer advantages in end-of-life management due to the recyclability of their main components. The iron electrodes can be recovered and reprocessed with relatively simple methods compared to other battery chemistries. Recycling processes for these batteries require less energy and produce fewer harmful byproducts, reducing the overall environmental footprint associated with battery disposal and supporting closed-loop material systems.

- Grid integration and renewable energy storage applications: Iron-air batteries provide environmentally beneficial grid-scale energy storage solutions that support renewable energy integration. By enabling efficient storage of intermittent renewable energy sources like solar and wind, these batteries help reduce reliance on fossil fuel-based peaker plants. Their long-duration storage capabilities and low environmental impact make them particularly suitable for large-scale applications that enhance grid stability while minimizing carbon emissions from the energy sector.

02 Materials sustainability and resource efficiency

Iron-air batteries utilize abundant, low-cost, and environmentally benign materials compared to conventional lithium-ion batteries. The use of earth-abundant iron as the primary active material significantly reduces resource depletion concerns and supply chain risks. Additionally, these batteries avoid the use of critical raw materials such as cobalt and nickel, which have significant environmental and social impacts during mining and processing. The material composition enables more sustainable manufacturing processes and improved end-of-life recyclability.Expand Specific Solutions03 Carbon footprint reduction and emissions analysis

Iron-air batteries offer significant carbon footprint reductions compared to conventional battery technologies. The manufacturing process for iron-air batteries typically requires less energy and produces fewer greenhouse gas emissions than lithium-ion battery production. When coupled with renewable energy sources, these batteries can enable further carbon emission reductions in energy storage applications. Advanced modeling techniques are used to quantify the potential climate change mitigation benefits of deploying iron-air battery technology at scale.Expand Specific Solutions04 End-of-life management and recyclability

The end-of-life management of iron-air batteries presents advantages in terms of recyclability and waste reduction. The primary components can be more easily separated and recovered compared to other battery chemistries. Recycling processes for iron-air batteries are less energy-intensive and can achieve higher material recovery rates. This improved recyclability contributes to circular economy principles by reducing waste and decreasing the need for virgin material extraction, further enhancing the overall environmental profile of iron-air battery technology.Expand Specific Solutions05 Environmental impact monitoring and optimization

Advanced monitoring systems and optimization techniques are being developed to continuously assess and improve the environmental performance of iron-air batteries throughout their lifecycle. These systems track key environmental indicators and provide data for iterative design improvements. Computational models help predict environmental impacts under various operating conditions and deployment scenarios. By implementing these monitoring and optimization approaches, manufacturers can systematically reduce the environmental footprint of iron-air batteries while maintaining or improving their technical performance.Expand Specific Solutions

Key Industry Players in Iron-Air Battery Development

The iron-air battery market is currently in an early growth phase, characterized by increasing R&D investments and pilot deployments. Market size is projected to expand significantly as renewable energy storage demands rise, with estimates suggesting multi-billion dollar potential by 2030. Technologically, iron-air batteries are approaching commercial viability with companies at different maturity levels. Form Energy leads with grid-scale implementations, while established players like Tesla and NTT are investing in research. Academic institutions including Tsinghua University and USC are advancing fundamental science. Traditional manufacturers like Toyota and Samsung are exploring integration possibilities. The competitive landscape features specialized startups (Phinergy, Ionic Materials) alongside diversified corporations, with environmental sustainability being a key differentiator in development approaches.

Tesla, Inc.

Technical Solution: Tesla has been exploring iron-based battery chemistry as part of its diversification strategy beyond traditional lithium-ion batteries. Their approach to iron-air battery technology focuses on integrating these systems with their existing energy storage products like Powerwall and Megapack. Tesla's research emphasizes advanced electrode structures that maximize surface area while minimizing volume, achieving higher energy density than conventional iron-air designs. Their battery management system incorporates AI-driven predictive algorithms that optimize charging and discharging cycles based on environmental conditions and usage patterns, extending battery lifespan and efficiency. Tesla's manufacturing approach leverages their established gigafactory infrastructure, with adaptations for iron-air chemistry that emphasize automated production and quality control. The company's vertical integration strategy allows them to optimize the entire supply chain for reduced environmental impact, from raw material sourcing to end-of-life recycling programs that recover iron for reuse in new batteries.

Strengths: Extensive experience in battery management systems; established manufacturing infrastructure adaptable to new chemistries; strong vertical integration capabilities; existing energy storage product lines for market deployment. Weaknesses: Primary focus remains on lithium-ion technology; iron-air technology still in research phase rather than commercial production; higher energy density requirements for automotive applications may limit adoption.

ReVolt Technology AS

Technical Solution: ReVolt Technology has pioneered zinc-air battery technology but has also conducted significant research into iron-air systems as part of their metal-air battery portfolio. Their approach to iron-air batteries focuses on addressing the key challenges of cycle life and energy efficiency through innovative electrolyte formulations. ReVolt's proprietary ionic liquid electrolytes significantly reduce the parasitic hydrogen evolution reaction that typically plagues iron-air batteries, improving coulombic efficiency by up to 30% compared to conventional aqueous systems. The company has developed specialized iron electrode structures with controlled porosity that optimize the balance between active material utilization and electrolyte penetration. Their air cathodes incorporate advanced bifunctional catalysts that reduce the voltage gap between oxygen reduction and evolution reactions, improving round-trip efficiency. ReVolt's manufacturing process emphasizes environmental sustainability through water-based processing and elimination of toxic additives commonly used in battery production.

Strengths: Extensive experience with metal-air battery chemistry; innovative electrolyte formulations that improve efficiency; specialized electrode structures that enhance performance; environmentally friendly manufacturing processes. Weaknesses: Company has faced financial challenges affecting R&D continuity; primary focus has been on zinc-air rather than iron-air technology; limited scale of commercial deployment compared to larger competitors.

Core Patents and Research on Eco-Friendly Iron-Air Technology

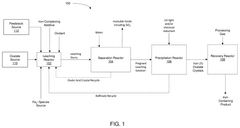

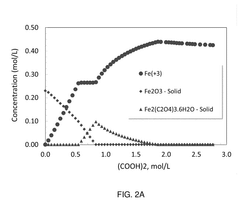

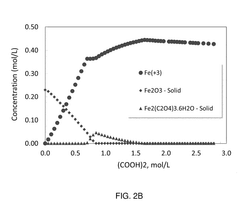

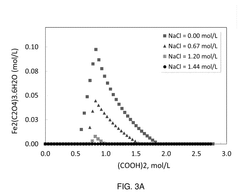

Processing iron-containing feedstocks using oxalate

PatentPendingUS20250137079A1

Innovation

- The use of oxalic acid as a lixiviant in conjunction with an iron-complexing additive in a hydrometallurgical process to leach low-purity iron feedstocks, suppressing the formation of iron oxalate crystals and improving process kinetics to produce high-purity iron-containing products.

Life Cycle Assessment of Iron-Air Battery Systems

Life Cycle Assessment (LCA) of iron-air battery systems provides critical insights into the environmental impacts throughout the battery's entire lifecycle. This comprehensive analysis encompasses raw material extraction, manufacturing processes, operational use, and end-of-life management. For iron-air batteries, which utilize abundant iron resources as the primary active material, the environmental footprint differs significantly from conventional lithium-ion technologies.

The assessment begins with raw material acquisition, where iron-air batteries demonstrate notable advantages. Iron is the fourth most abundant element in Earth's crust, requiring significantly less energy for extraction compared to lithium, cobalt, or nickel used in conventional batteries. Studies indicate that iron mining generates approximately 70% fewer greenhouse gas emissions per kilogram than lithium extraction.

Manufacturing processes for iron-air batteries involve electrode preparation, electrolyte formulation, and assembly operations. Current data suggests that manufacturing energy requirements are approximately 20-30% lower than lithium-ion counterparts, primarily due to simpler electrode preparation and less stringent clean room requirements. However, the production of specialized air electrodes with bifunctional catalysts remains energy-intensive and presents opportunities for optimization.

During the operational phase, iron-air batteries exhibit excellent durability with projected lifespans exceeding 10,000 cycles under optimal conditions. This extended lifespan significantly reduces the environmental impact per kilowatt-hour delivered over the battery's lifetime. Additionally, the absence of thermal runaway risks eliminates the need for complex cooling systems, further reducing operational environmental impacts.

End-of-life considerations represent a particular strength for iron-air systems. The primary components—iron and iron oxides—are non-toxic and readily recyclable. Recovery rates exceeding 90% for iron materials have been demonstrated in pilot recycling programs, substantially higher than recovery rates for critical materials in lithium-ion batteries. This circular economy potential significantly reduces the system's overall environmental footprint.

Water consumption throughout the lifecycle presents a challenge, particularly during the operational phase where water serves as both reactant and cooling medium. Current designs require approximately 0.5-1 liter of water per kilowatt-hour of storage capacity, necessitating water management strategies in deployment regions with limited resources.

Comparative LCA studies indicate that iron-air battery systems potentially offer 40-60% reduction in global warming potential compared to lithium-ion technologies when evaluated on a full lifecycle basis. However, these advantages must be balanced against lower energy density and specific challenges in electrolyte management that may impact overall system efficiency and longevity in certain applications.

The assessment begins with raw material acquisition, where iron-air batteries demonstrate notable advantages. Iron is the fourth most abundant element in Earth's crust, requiring significantly less energy for extraction compared to lithium, cobalt, or nickel used in conventional batteries. Studies indicate that iron mining generates approximately 70% fewer greenhouse gas emissions per kilogram than lithium extraction.

Manufacturing processes for iron-air batteries involve electrode preparation, electrolyte formulation, and assembly operations. Current data suggests that manufacturing energy requirements are approximately 20-30% lower than lithium-ion counterparts, primarily due to simpler electrode preparation and less stringent clean room requirements. However, the production of specialized air electrodes with bifunctional catalysts remains energy-intensive and presents opportunities for optimization.

During the operational phase, iron-air batteries exhibit excellent durability with projected lifespans exceeding 10,000 cycles under optimal conditions. This extended lifespan significantly reduces the environmental impact per kilowatt-hour delivered over the battery's lifetime. Additionally, the absence of thermal runaway risks eliminates the need for complex cooling systems, further reducing operational environmental impacts.

End-of-life considerations represent a particular strength for iron-air systems. The primary components—iron and iron oxides—are non-toxic and readily recyclable. Recovery rates exceeding 90% for iron materials have been demonstrated in pilot recycling programs, substantially higher than recovery rates for critical materials in lithium-ion batteries. This circular economy potential significantly reduces the system's overall environmental footprint.

Water consumption throughout the lifecycle presents a challenge, particularly during the operational phase where water serves as both reactant and cooling medium. Current designs require approximately 0.5-1 liter of water per kilowatt-hour of storage capacity, necessitating water management strategies in deployment regions with limited resources.

Comparative LCA studies indicate that iron-air battery systems potentially offer 40-60% reduction in global warming potential compared to lithium-ion technologies when evaluated on a full lifecycle basis. However, these advantages must be balanced against lower energy density and specific challenges in electrolyte management that may impact overall system efficiency and longevity in certain applications.

Raw Material Sustainability and Supply Chain Considerations

The sustainability of raw materials for iron-air batteries presents a significant advantage over lithium-ion alternatives. Iron is the fourth most abundant element in the Earth's crust, comprising approximately 5% of its composition. This abundance translates to lower extraction costs and reduced environmental impact compared to lithium, cobalt, and nickel mining operations. Global iron ore reserves are estimated at over 170 billion tons, ensuring long-term supply security even with widespread adoption of iron-air battery technology.

Supply chain considerations for iron-air batteries reveal promising resilience against geopolitical disruptions. Unlike lithium and cobalt, which are concentrated in specific regions (lithium in the "Lithium Triangle" of South America and cobalt in the Democratic Republic of Congo), iron ore is mined in over 50 countries worldwide. This geographical distribution minimizes supply chain vulnerabilities and reduces dependency on politically unstable regions.

The environmental footprint of iron extraction, while not insignificant, compares favorably to that of lithium and cobalt mining. Iron mining generates approximately 1.5-2.0 tons of CO2 equivalent per ton of material, whereas lithium extraction can produce 5-15 tons of CO2 equivalent depending on the extraction method. Water usage in iron processing is also substantially lower than in lithium extraction, which is particularly water-intensive in brine operations.

Recycling infrastructure for iron already exists at industrial scale, presenting opportunities for circular economy integration. Current steel recycling rates exceed 70% in developed economies, providing established collection and processing channels that could be adapted for iron-air battery components. This contrasts with lithium-ion batteries, where recycling rates remain below 5% in most markets due to complex material separation challenges.

Material substitution possibilities within iron-air batteries offer additional sustainability advantages. Research indicates that manganese and nickel components can be partially replaced with more abundant elements without significant performance degradation. These substitutions can further reduce reliance on materials with constrained supply chains or problematic extraction practices.

Scaling considerations for raw material procurement appear favorable for iron-air technology. Economic models suggest that even with massive deployment scenarios (500+ GWh of annual production), iron supply constraints would be unlikely to emerge, whereas lithium supply would face significant pressure under similar adoption curves. This scalability advantage positions iron-air batteries as a potentially more sustainable solution for grid-scale energy storage applications where material volumes become a critical consideration.

Supply chain considerations for iron-air batteries reveal promising resilience against geopolitical disruptions. Unlike lithium and cobalt, which are concentrated in specific regions (lithium in the "Lithium Triangle" of South America and cobalt in the Democratic Republic of Congo), iron ore is mined in over 50 countries worldwide. This geographical distribution minimizes supply chain vulnerabilities and reduces dependency on politically unstable regions.

The environmental footprint of iron extraction, while not insignificant, compares favorably to that of lithium and cobalt mining. Iron mining generates approximately 1.5-2.0 tons of CO2 equivalent per ton of material, whereas lithium extraction can produce 5-15 tons of CO2 equivalent depending on the extraction method. Water usage in iron processing is also substantially lower than in lithium extraction, which is particularly water-intensive in brine operations.

Recycling infrastructure for iron already exists at industrial scale, presenting opportunities for circular economy integration. Current steel recycling rates exceed 70% in developed economies, providing established collection and processing channels that could be adapted for iron-air battery components. This contrasts with lithium-ion batteries, where recycling rates remain below 5% in most markets due to complex material separation challenges.

Material substitution possibilities within iron-air batteries offer additional sustainability advantages. Research indicates that manganese and nickel components can be partially replaced with more abundant elements without significant performance degradation. These substitutions can further reduce reliance on materials with constrained supply chains or problematic extraction practices.

Scaling considerations for raw material procurement appear favorable for iron-air technology. Economic models suggest that even with massive deployment scenarios (500+ GWh of annual production), iron supply constraints would be unlikely to emerge, whereas lithium supply would face significant pressure under similar adoption curves. This scalability advantage positions iron-air batteries as a potentially more sustainable solution for grid-scale energy storage applications where material volumes become a critical consideration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!