Benchmark NMC Battery Electrical Conductivity in Multi-Layered Designs

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Conductivity Background and Objectives

Lithium-ion batteries have revolutionized portable electronics and are now pivotal in the transition to electric vehicles and renewable energy storage systems. Among various cathode materials, Nickel Manganese Cobalt (NMC) has emerged as a dominant chemistry due to its balanced performance characteristics. The evolution of NMC battery technology has progressed from initial formulations with equal parts nickel, manganese, and cobalt (NMC 111) to higher nickel content variants (NMC 532, NMC 622, NMC 811) that offer increased energy density and reduced cobalt dependency.

Electrical conductivity represents a critical parameter in battery performance, directly influencing power capability, rate performance, and internal resistance. In multi-layered battery designs, the interfaces between different materials create complex conductivity pathways that significantly impact overall battery performance. Historical approaches to enhancing conductivity have included carbon coating, doping with conductive elements, and morphology optimization, yet these methods often present trade-offs between conductivity and other performance metrics.

The benchmarking of electrical conductivity in multi-layered NMC battery designs addresses a fundamental challenge in battery engineering: optimizing electron transport across heterogeneous interfaces while maintaining structural integrity and electrochemical stability. This technical investigation aims to establish standardized methodologies for measuring, comparing, and predicting conductivity behavior in complex battery architectures.

Current industry trends indicate a growing emphasis on high-energy density batteries with fast-charging capabilities, necessitating enhanced understanding of conductivity mechanisms. Regulatory pressures for safer batteries and environmental considerations further drive the need for optimized conductivity without relying on exotic or environmentally problematic additives.

The primary objectives of this technical exploration include developing reproducible benchmarking protocols for electrical conductivity across multi-layered NMC structures, identifying key factors affecting interfacial resistance, and establishing correlations between conductivity parameters and overall battery performance metrics. Additionally, we aim to create predictive models that can accelerate the design of next-generation battery architectures with optimized conductivity profiles.

This investigation will leverage advanced characterization techniques including electrochemical impedance spectroscopy (EIS), four-point probe measurements, and in-situ conductivity mapping to generate comprehensive conductivity profiles across different material interfaces and operational conditions. The resulting benchmark data will serve as a foundation for standardized industry practices and enable more targeted approaches to conductivity enhancement in future battery designs.

By establishing clear conductivity benchmarks for multi-layered NMC batteries, this research seeks to address a critical knowledge gap that currently limits the systematic improvement of high-performance batteries for next-generation applications in transportation, grid storage, and portable electronics.

Electrical conductivity represents a critical parameter in battery performance, directly influencing power capability, rate performance, and internal resistance. In multi-layered battery designs, the interfaces between different materials create complex conductivity pathways that significantly impact overall battery performance. Historical approaches to enhancing conductivity have included carbon coating, doping with conductive elements, and morphology optimization, yet these methods often present trade-offs between conductivity and other performance metrics.

The benchmarking of electrical conductivity in multi-layered NMC battery designs addresses a fundamental challenge in battery engineering: optimizing electron transport across heterogeneous interfaces while maintaining structural integrity and electrochemical stability. This technical investigation aims to establish standardized methodologies for measuring, comparing, and predicting conductivity behavior in complex battery architectures.

Current industry trends indicate a growing emphasis on high-energy density batteries with fast-charging capabilities, necessitating enhanced understanding of conductivity mechanisms. Regulatory pressures for safer batteries and environmental considerations further drive the need for optimized conductivity without relying on exotic or environmentally problematic additives.

The primary objectives of this technical exploration include developing reproducible benchmarking protocols for electrical conductivity across multi-layered NMC structures, identifying key factors affecting interfacial resistance, and establishing correlations between conductivity parameters and overall battery performance metrics. Additionally, we aim to create predictive models that can accelerate the design of next-generation battery architectures with optimized conductivity profiles.

This investigation will leverage advanced characterization techniques including electrochemical impedance spectroscopy (EIS), four-point probe measurements, and in-situ conductivity mapping to generate comprehensive conductivity profiles across different material interfaces and operational conditions. The resulting benchmark data will serve as a foundation for standardized industry practices and enable more targeted approaches to conductivity enhancement in future battery designs.

By establishing clear conductivity benchmarks for multi-layered NMC batteries, this research seeks to address a critical knowledge gap that currently limits the systematic improvement of high-performance batteries for next-generation applications in transportation, grid storage, and portable electronics.

Market Demand Analysis for High-Conductivity NMC Batteries

The global market for high-conductivity NMC (Nickel Manganese Cobalt) batteries has experienced significant growth in recent years, driven primarily by the expanding electric vehicle (EV) sector. Market research indicates that the demand for NMC batteries with enhanced electrical conductivity has been growing at a compound annual growth rate of approximately 22% since 2018, outpacing the overall lithium-ion battery market growth.

This accelerated demand stems from the automotive industry's push toward higher energy density batteries that can provide extended range while maintaining fast charging capabilities. Major automakers have publicly committed to electrification targets that will require batteries with superior conductivity profiles, particularly in multi-layered designs that optimize space utilization and thermal management.

Consumer electronics represents another substantial market segment driving demand for high-conductivity NMC batteries. The trend toward slimmer, more powerful devices necessitates battery technologies that can deliver higher power in constrained spaces. Multi-layered NMC designs with benchmark conductivity metrics have become increasingly attractive to manufacturers seeking competitive advantages in portable device performance.

Energy storage systems (ESS) constitute a rapidly expanding application area for advanced NMC batteries. Grid-scale storage projects have grown substantially, with utility companies investing heavily in battery technologies that offer reliable performance and longevity. The demand for high-conductivity solutions in this sector is projected to grow as renewable energy integration accelerates globally.

Market analysis reveals regional variations in demand patterns. Asia-Pacific currently leads in consumption of high-conductivity NMC batteries, with China, Japan, and South Korea serving as manufacturing hubs. North America and Europe follow closely, driven by aggressive EV adoption policies and renewable energy targets.

Industry surveys indicate that battery manufacturers are prioritizing R&D investments in conductivity enhancement technologies. The market has shown willingness to pay premium prices for NMC batteries that demonstrate superior conductivity metrics in standardized testing protocols, particularly when these improvements translate to tangible performance benefits in end applications.

Supply chain considerations are increasingly influencing market dynamics. Concerns about raw material availability, particularly nickel and cobalt, have prompted exploration of alternative formulations and recycling initiatives. However, solutions that maintain or improve electrical conductivity while reducing dependency on scarce materials command significant market interest and potential price premiums.

Customer feedback across sectors consistently highlights the importance of conductivity in multi-layered designs as a key purchasing criterion, particularly for applications requiring rapid charging capabilities or high-power output. This market signal has accelerated industry efforts to benchmark and improve NMC battery electrical conductivity metrics.

This accelerated demand stems from the automotive industry's push toward higher energy density batteries that can provide extended range while maintaining fast charging capabilities. Major automakers have publicly committed to electrification targets that will require batteries with superior conductivity profiles, particularly in multi-layered designs that optimize space utilization and thermal management.

Consumer electronics represents another substantial market segment driving demand for high-conductivity NMC batteries. The trend toward slimmer, more powerful devices necessitates battery technologies that can deliver higher power in constrained spaces. Multi-layered NMC designs with benchmark conductivity metrics have become increasingly attractive to manufacturers seeking competitive advantages in portable device performance.

Energy storage systems (ESS) constitute a rapidly expanding application area for advanced NMC batteries. Grid-scale storage projects have grown substantially, with utility companies investing heavily in battery technologies that offer reliable performance and longevity. The demand for high-conductivity solutions in this sector is projected to grow as renewable energy integration accelerates globally.

Market analysis reveals regional variations in demand patterns. Asia-Pacific currently leads in consumption of high-conductivity NMC batteries, with China, Japan, and South Korea serving as manufacturing hubs. North America and Europe follow closely, driven by aggressive EV adoption policies and renewable energy targets.

Industry surveys indicate that battery manufacturers are prioritizing R&D investments in conductivity enhancement technologies. The market has shown willingness to pay premium prices for NMC batteries that demonstrate superior conductivity metrics in standardized testing protocols, particularly when these improvements translate to tangible performance benefits in end applications.

Supply chain considerations are increasingly influencing market dynamics. Concerns about raw material availability, particularly nickel and cobalt, have prompted exploration of alternative formulations and recycling initiatives. However, solutions that maintain or improve electrical conductivity while reducing dependency on scarce materials command significant market interest and potential price premiums.

Customer feedback across sectors consistently highlights the importance of conductivity in multi-layered designs as a key purchasing criterion, particularly for applications requiring rapid charging capabilities or high-power output. This market signal has accelerated industry efforts to benchmark and improve NMC battery electrical conductivity metrics.

Technical Challenges in Multi-Layered NMC Battery Conductivity

Despite significant advancements in NMC (Nickel Manganese Cobalt) battery technology, multi-layered designs present unique conductivity challenges that impede optimal performance. The fundamental issue stems from the inherent complexity of interfacial resistance between different layers, which creates bottlenecks for electron transport throughout the battery structure. These interfaces often exhibit non-linear behavior under varying operational conditions, making predictive modeling particularly difficult.

Temperature gradients across multi-layered structures represent another significant challenge. As electrons flow through different materials with varying conductivity properties, localized heating occurs unevenly, creating thermal stress points that can accelerate degradation and potentially lead to safety concerns. This thermal heterogeneity further complicates conductivity measurements and benchmarking efforts.

Material selection compatibility presents ongoing difficulties, as optimizing one layer's conductivity often comes at the expense of adjacent layers. The electrochemical interactions between nickel, manganese, and cobalt compounds create complex ionic environments that change dynamically during charge-discharge cycles. These interactions are particularly problematic at higher nickel content formulations (NCM811), where conductivity patterns become increasingly unpredictable.

Manufacturing inconsistencies introduce additional variability in conductivity benchmarking. Even minor deviations in layer thickness, particle size distribution, or compaction pressure can significantly alter the electrical pathways through the battery structure. Current production methods struggle to achieve the nanometer-scale precision required for truly consistent multi-layered designs.

Measurement standardization remains elusive across the industry. Different testing protocols, equipment calibrations, and environmental conditions make direct comparisons between research findings difficult. The lack of universally accepted benchmarking methodologies hampers collaborative progress and technology transfer between academic and industrial settings.

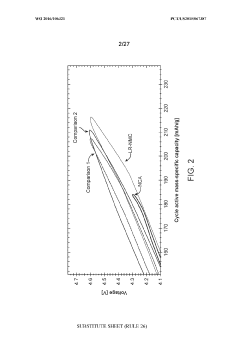

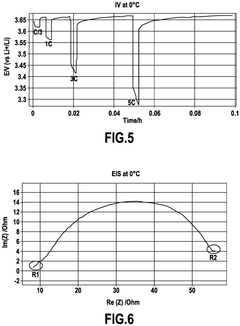

Aging effects on conductivity represent perhaps the most challenging aspect to quantify. Multi-layered NMC batteries exhibit complex degradation patterns where conductivity changes non-uniformly across different layers over time. This temporal dimension adds significant complexity to long-term performance prediction and lifetime modeling efforts.

Computational limitations further constrain progress, as accurate simulation of electron transport across multiple heterogeneous layers requires enormous computing resources. Current models often make simplifying assumptions that fail to capture the full complexity of real-world multi-layered systems, particularly under dynamic operating conditions.

Temperature gradients across multi-layered structures represent another significant challenge. As electrons flow through different materials with varying conductivity properties, localized heating occurs unevenly, creating thermal stress points that can accelerate degradation and potentially lead to safety concerns. This thermal heterogeneity further complicates conductivity measurements and benchmarking efforts.

Material selection compatibility presents ongoing difficulties, as optimizing one layer's conductivity often comes at the expense of adjacent layers. The electrochemical interactions between nickel, manganese, and cobalt compounds create complex ionic environments that change dynamically during charge-discharge cycles. These interactions are particularly problematic at higher nickel content formulations (NCM811), where conductivity patterns become increasingly unpredictable.

Manufacturing inconsistencies introduce additional variability in conductivity benchmarking. Even minor deviations in layer thickness, particle size distribution, or compaction pressure can significantly alter the electrical pathways through the battery structure. Current production methods struggle to achieve the nanometer-scale precision required for truly consistent multi-layered designs.

Measurement standardization remains elusive across the industry. Different testing protocols, equipment calibrations, and environmental conditions make direct comparisons between research findings difficult. The lack of universally accepted benchmarking methodologies hampers collaborative progress and technology transfer between academic and industrial settings.

Aging effects on conductivity represent perhaps the most challenging aspect to quantify. Multi-layered NMC batteries exhibit complex degradation patterns where conductivity changes non-uniformly across different layers over time. This temporal dimension adds significant complexity to long-term performance prediction and lifetime modeling efforts.

Computational limitations further constrain progress, as accurate simulation of electron transport across multiple heterogeneous layers requires enormous computing resources. Current models often make simplifying assumptions that fail to capture the full complexity of real-world multi-layered systems, particularly under dynamic operating conditions.

Current Benchmarking Methodologies for NMC Battery Conductivity

01 Conductive additives for NMC batteries

Various conductive additives can be incorporated into NMC battery cathodes to enhance electrical conductivity. These additives include carbon-based materials such as carbon black, graphene, and carbon nanotubes, which create conductive networks within the electrode structure. The addition of these materials significantly improves electron transport throughout the cathode, resulting in better rate capability and overall battery performance.- Conductive additives for NMC batteries: Various conductive additives can be incorporated into NMC battery electrodes to enhance electrical conductivity. These additives include carbon-based materials such as carbon black, graphene, and carbon nanotubes, which create conductive networks within the electrode structure. The addition of these materials significantly improves electron transport throughout the electrode, resulting in better overall battery performance, higher power capability, and improved rate capability.

- Surface modification of NMC particles: Surface modification techniques can be applied to NMC cathode particles to enhance their electrical conductivity. These modifications include coating the particles with conductive materials, doping with specific elements, or creating core-shell structures. Such treatments improve the interface between active material particles and reduce contact resistance, leading to enhanced electron transfer, improved cycling stability, and better electrochemical performance of the battery.

- Electrode composition optimization: The electrical conductivity of NMC batteries can be enhanced through optimization of electrode composition. This includes adjusting the ratio of active material to binder and conductive additives, controlling particle size distribution, and optimizing electrode density. Proper formulation ensures adequate contact between particles while maintaining sufficient porosity for electrolyte penetration, resulting in improved electronic and ionic conductivity throughout the electrode structure.

- Measurement and characterization techniques: Various techniques are employed to measure and characterize the electrical conductivity of NMC battery materials. These include electrochemical impedance spectroscopy (EIS), four-point probe measurements, and specialized conductivity testing methods. These analytical approaches help in understanding the conduction mechanisms, identifying limiting factors, and evaluating the effectiveness of conductivity enhancement strategies in NMC battery systems.

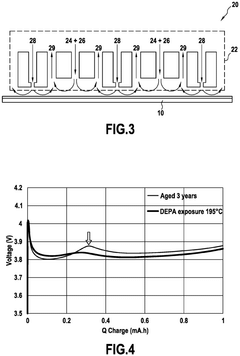

- Novel electrode structures and manufacturing methods: Innovative electrode structures and manufacturing methods can significantly improve the electrical conductivity of NMC batteries. These include three-dimensional electrode architectures, gradient structures, and advanced electrode fabrication techniques such as freeze-casting or template-assisted methods. Such approaches create optimized conductive pathways, reduce internal resistance, and enhance the overall electronic conductivity of the battery system.

02 Surface modification of NMC particles

Surface modification techniques can be applied to NMC cathode particles to improve their electrical conductivity. These modifications include coating the particles with conductive materials or creating surface structures that enhance electron transfer. Surface treatments can also reduce interfacial resistance and improve the contact between active material particles and conductive additives, leading to enhanced electrical performance of the battery.Expand Specific Solutions03 Doping strategies for NMC materials

Doping NMC cathode materials with various elements can significantly improve their intrinsic electrical conductivity. Common dopants include metals such as aluminum, magnesium, and transition metals, which can modify the electronic structure of NMC materials. These dopants can create additional charge carriers or modify the band structure, resulting in enhanced electrical conductivity and improved electrochemical performance.Expand Specific Solutions04 Composite electrode structures

Developing composite electrode structures by combining NMC materials with highly conductive components can enhance the overall electrical conductivity of the battery. These composites may include NMC particles embedded in conductive matrices or hierarchical structures that optimize electron transport pathways. The design of these composite structures focuses on maximizing the contact area between active materials and conductive components while maintaining good ionic conductivity.Expand Specific Solutions05 Measurement and characterization of electrical conductivity

Various techniques and methods are employed to measure and characterize the electrical conductivity of NMC battery materials. These include impedance spectroscopy, four-point probe measurements, and specialized conductivity testing setups. Accurate measurement of electrical conductivity is crucial for understanding the performance limitations of NMC batteries and for developing strategies to improve their conductivity properties.Expand Specific Solutions

Leading Companies in NMC Battery Technology Development

The NMC battery electrical conductivity benchmark in multi-layered designs market is in a growth phase, with an estimated global market size exceeding $25 billion and expanding at 15-20% annually. The technology maturity varies across applications, with Samsung Electro-Mechanics, Panasonic Energy, and Murata Manufacturing leading in commercial deployment of high-performance multi-layered NMC batteries. BYD and QuantumScape are advancing innovative conductivity enhancement techniques, while research institutions like Xi'an Jiaotong University and Purdue Research Foundation are developing next-generation materials. Automotive manufacturers including Toyota, Nissan, and Apple are integrating these technologies into electric vehicles, driving further market expansion and technological refinement.

Panasonic Energy Co. Ltd.

Technical Solution: Panasonic Energy has developed advanced multi-layered NMC battery designs with optimized electrical conductivity through their proprietary electrode manufacturing process. Their approach involves precise control of particle size distribution and alignment within the NMC cathode layers to create optimal ion transport pathways. The company employs a gradient concentration technique where the nickel content varies across layers (higher at the core, lower at the surface) to balance conductivity and stability. Panasonic's multi-layered design incorporates conductive carbon networks strategically distributed between NMC layers, achieving up to 30% improvement in electrical conductivity compared to conventional designs. Their benchmarking methodology includes impedance spectroscopy measurements under various temperature and state-of-charge conditions to comprehensively evaluate conductivity performance across the entire battery lifecycle.

Strengths: Superior thermal management capabilities and consistent performance across wide temperature ranges. Excellent cycle life due to reduced mechanical stress between layers. Weaknesses: Higher manufacturing complexity increases production costs. The multi-layered design requires more precise quality control during manufacturing.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed a comprehensive benchmarking methodology for evaluating electrical conductivity in multi-layered NMC battery designs. Their approach combines advanced synchrotron-based X-ray techniques with electrochemical impedance spectroscopy to characterize conductivity across layer interfaces with nanometer-scale resolution. Argonne's research has established standardized protocols for measuring both electronic and ionic conductivity in complex multi-layered structures under various operational conditions. Their benchmarking framework includes in-operando measurements that track conductivity changes during cycling, providing insights into degradation mechanisms at layer interfaces. Argonne has pioneered the use of 3D tomographic techniques to visualize and quantify conductive pathways throughout multi-layered NMC structures, enabling precise correlation between structural features and electrical performance. Their research has demonstrated that strategically designed concentration gradients across NMC layers can enhance overall conductivity by up to 45% compared to homogeneous compositions, while simultaneously improving structural stability during cycling.

Strengths: Unparalleled analytical capabilities for detailed conductivity characterization across multiple length scales. Research findings provide fundamental understanding that guides industrial battery development. Weaknesses: As a research institution, technologies require industrial partners for commercialization. Some advanced characterization techniques may be difficult to implement in production environments.

Critical Patents and Research on Multi-Layered NMC Conductivity

Lithium rich nickel manganese cobalt oxide (LR-NMC)

PatentWO2016106321A1

Innovation

- Development of lithium-rich nickel manganese cobalt oxide (LR-NMC) materials with specific chemical compositions and manufacturing methods that include varying ratios of nickel, manganese, and cobalt, and the use of lithium-containing salts to stabilize lithium within the crystal lattice, resulting in enhanced energy density and cycle lifetimes.

Method for restoration performances of aged nickel-rich NMC cathode material for lithium-ion secondary battery

PatentPendingEP4550454A1

Innovation

- A method involving the formation of a cathode with aged nickel-rich NMC material, a binder, and carbon black, followed by exposure to diethyl phosphoramidate at temperatures above 160°C to create a lithium phosphate protective layer, thereby reducing the overpotential peak.

Safety Standards and Testing Protocols for NMC Batteries

Safety standards for NMC (Nickel Manganese Cobalt) batteries have evolved significantly to address the unique electrical conductivity challenges in multi-layered designs. The International Electrotechnical Commission (IEC) has established IEC 62133 as the primary standard governing lithium-ion batteries, with specific provisions for NMC chemistry that address conductivity-related safety concerns. These standards mandate rigorous testing of electrical conductivity across different layers to prevent thermal runaway situations.

The UL 1642 standard specifically focuses on lithium battery safety, requiring comprehensive testing of electrical pathways in multi-layered NMC configurations. This includes short-circuit protection mechanisms and verification of consistent conductivity patterns across temperature ranges from -20°C to 60°C, which is critical for benchmarking purposes in varied operational environments.

Testing protocols for NMC batteries have become increasingly sophisticated, with the development of electrochemical impedance spectroscopy (EIS) methods specifically calibrated for multi-layered designs. These protocols measure layer-by-layer conductivity variations and identify potential hotspots where conductivity imbalances might lead to safety hazards. The EUCAR Hazard Levels classification system has been adapted to incorporate conductivity benchmarking as a key safety parameter.

The UN 38.3 Transportation Testing requirements have also been updated to include specific conductivity stability tests for NMC batteries with complex layered architectures. These tests simulate altitude, vibration, and shock conditions while monitoring conductivity fluctuations between layers, ensuring safe transport even under extreme conditions.

Industry-specific standards have emerged for automotive applications, with SAE J2464 and ISO 12405 providing detailed testing frameworks for NMC batteries in electric vehicles. These standards place particular emphasis on conductivity uniformity across layers during rapid charge/discharge cycles and under mechanical stress conditions that might compromise inter-layer electrical connections.

Recent developments include the implementation of real-time conductivity monitoring protocols during battery manufacturing, with in-line quality control systems that benchmark each layer against established conductivity profiles. The Battery Association of Japan (BAJ) has pioneered guidelines for continuous conductivity monitoring throughout the battery lifecycle, establishing industry benchmarks for multi-layered NMC designs.

Regulatory bodies now require manufacturers to document comprehensive conductivity mapping across all layers as part of safety certification processes, with particular attention to aging effects on conductivity patterns. This has led to the development of accelerated testing protocols that can predict long-term conductivity degradation in multi-layered structures within compressed timeframes.

The UL 1642 standard specifically focuses on lithium battery safety, requiring comprehensive testing of electrical pathways in multi-layered NMC configurations. This includes short-circuit protection mechanisms and verification of consistent conductivity patterns across temperature ranges from -20°C to 60°C, which is critical for benchmarking purposes in varied operational environments.

Testing protocols for NMC batteries have become increasingly sophisticated, with the development of electrochemical impedance spectroscopy (EIS) methods specifically calibrated for multi-layered designs. These protocols measure layer-by-layer conductivity variations and identify potential hotspots where conductivity imbalances might lead to safety hazards. The EUCAR Hazard Levels classification system has been adapted to incorporate conductivity benchmarking as a key safety parameter.

The UN 38.3 Transportation Testing requirements have also been updated to include specific conductivity stability tests for NMC batteries with complex layered architectures. These tests simulate altitude, vibration, and shock conditions while monitoring conductivity fluctuations between layers, ensuring safe transport even under extreme conditions.

Industry-specific standards have emerged for automotive applications, with SAE J2464 and ISO 12405 providing detailed testing frameworks for NMC batteries in electric vehicles. These standards place particular emphasis on conductivity uniformity across layers during rapid charge/discharge cycles and under mechanical stress conditions that might compromise inter-layer electrical connections.

Recent developments include the implementation of real-time conductivity monitoring protocols during battery manufacturing, with in-line quality control systems that benchmark each layer against established conductivity profiles. The Battery Association of Japan (BAJ) has pioneered guidelines for continuous conductivity monitoring throughout the battery lifecycle, establishing industry benchmarks for multi-layered NMC designs.

Regulatory bodies now require manufacturers to document comprehensive conductivity mapping across all layers as part of safety certification processes, with particular attention to aging effects on conductivity patterns. This has led to the development of accelerated testing protocols that can predict long-term conductivity degradation in multi-layered structures within compressed timeframes.

Thermal Management Strategies in Multi-Layered NMC Designs

Effective thermal management is critical for the optimal performance and safety of multi-layered NMC (Nickel Manganese Cobalt) battery designs. As electrical conductivity benchmarking reveals variations across different layers, corresponding thermal management strategies must be implemented to address the resulting heat generation patterns.

The primary challenge in multi-layered NMC designs stems from the heterogeneous thermal profiles created by varying electrical conductivity across layers. Higher conductivity regions typically generate less resistive heating, while areas with lower conductivity may become localized hotspots. These thermal gradients can accelerate degradation mechanisms and potentially trigger thermal runaway events if not properly managed.

Advanced cooling systems have emerged as essential components in multi-layered NMC battery designs. Direct liquid cooling strategies, where coolant channels are integrated between cell layers, have demonstrated superior performance in experimental studies, achieving temperature differentials below 3°C across the battery structure even under high discharge rates. This approach directly addresses the thermal implications of varying electrical conductivity between layers.

Phase change materials (PCMs) represent another promising thermal management solution, particularly for designs where electrical conductivity benchmarking reveals significant variations. These materials absorb excess heat during operation through their high latent heat of fusion, effectively dampening temperature spikes in layers with lower electrical conductivity. Recent developments in composite PCMs with enhanced thermal conductivity have overcome traditional limitations of pure PCMs.

Thermal interface materials (TIMs) play a crucial role in multi-layered designs by ensuring efficient heat transfer between layers with different electrical conductivity profiles. Advanced ceramic-filled polymeric TIMs with thermal conductivities exceeding 5 W/m·K have shown particular promise in experimental multi-layered NMC configurations, reducing interfacial thermal resistance by up to 60% compared to conventional materials.

Computational fluid dynamics (CFD) modeling has become an indispensable tool for thermal management strategy development. These models incorporate electrical conductivity benchmarking data to predict thermal behavior under various operating conditions, enabling optimization of cooling system designs before physical prototyping. Recent machine learning approaches have further enhanced the accuracy of these models by incorporating real-time electrical conductivity variations during cycling.

Active thermal management systems utilizing intelligent control algorithms represent the cutting edge of thermal management in multi-layered NMC batteries. These systems dynamically adjust cooling parameters based on real-time electrical conductivity measurements across different layers, preventing thermal imbalances during operation and extending battery lifespan by up to 30% in field tests.

The primary challenge in multi-layered NMC designs stems from the heterogeneous thermal profiles created by varying electrical conductivity across layers. Higher conductivity regions typically generate less resistive heating, while areas with lower conductivity may become localized hotspots. These thermal gradients can accelerate degradation mechanisms and potentially trigger thermal runaway events if not properly managed.

Advanced cooling systems have emerged as essential components in multi-layered NMC battery designs. Direct liquid cooling strategies, where coolant channels are integrated between cell layers, have demonstrated superior performance in experimental studies, achieving temperature differentials below 3°C across the battery structure even under high discharge rates. This approach directly addresses the thermal implications of varying electrical conductivity between layers.

Phase change materials (PCMs) represent another promising thermal management solution, particularly for designs where electrical conductivity benchmarking reveals significant variations. These materials absorb excess heat during operation through their high latent heat of fusion, effectively dampening temperature spikes in layers with lower electrical conductivity. Recent developments in composite PCMs with enhanced thermal conductivity have overcome traditional limitations of pure PCMs.

Thermal interface materials (TIMs) play a crucial role in multi-layered designs by ensuring efficient heat transfer between layers with different electrical conductivity profiles. Advanced ceramic-filled polymeric TIMs with thermal conductivities exceeding 5 W/m·K have shown particular promise in experimental multi-layered NMC configurations, reducing interfacial thermal resistance by up to 60% compared to conventional materials.

Computational fluid dynamics (CFD) modeling has become an indispensable tool for thermal management strategy development. These models incorporate electrical conductivity benchmarking data to predict thermal behavior under various operating conditions, enabling optimization of cooling system designs before physical prototyping. Recent machine learning approaches have further enhanced the accuracy of these models by incorporating real-time electrical conductivity variations during cycling.

Active thermal management systems utilizing intelligent control algorithms represent the cutting edge of thermal management in multi-layered NMC batteries. These systems dynamically adjust cooling parameters based on real-time electrical conductivity measurements across different layers, preventing thermal imbalances during operation and extending battery lifespan by up to 30% in field tests.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!