Measure NMC Battery Discharge Efficiency Using Recent Algorithms

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Technology Background and Objectives

Lithium-ion batteries have revolutionized portable electronics and electric vehicles since their commercial introduction in the early 1990s. Among various cathode materials, Nickel Manganese Cobalt (NMC) has emerged as one of the most promising compositions due to its balanced performance characteristics. NMC batteries typically consist of lithium nickel manganese cobalt oxide (LiNixMnyCozO2, where x+y+z=1) as the cathode material, offering higher energy density compared to earlier lithium-ion technologies while maintaining reasonable stability and cost profiles.

The evolution of NMC battery technology has progressed through several generations, from early NMC 111 (equal parts nickel, manganese, and cobalt) to more recent formulations like NMC 811 (80% nickel, 10% manganese, 10% cobalt), each offering incremental improvements in energy density and performance. This progression reflects the industry's push toward higher energy density while reducing dependence on costly and ethically problematic cobalt supplies.

Accurate measurement of discharge efficiency has become increasingly critical as NMC batteries find applications in more demanding scenarios such as electric vehicles, grid storage, and advanced portable electronics. Traditional methods of measuring battery discharge efficiency often relied on simplistic voltage and current measurements that failed to account for complex electrochemical processes occurring within the cells, particularly under variable load conditions and throughout the battery's lifecycle.

Recent algorithmic approaches to measuring NMC battery discharge efficiency represent a significant technological advancement. These algorithms incorporate machine learning techniques, electrochemical impedance spectroscopy (EIS), and advanced modeling to provide more accurate, real-time assessments of battery performance. The integration of these computational methods with sophisticated sensing technologies enables deeper insights into battery behavior under diverse operating conditions.

The primary objectives of current research in this field include developing more accurate, non-invasive methods for real-time efficiency measurement, creating predictive models for battery degradation, and establishing standardized protocols for efficiency testing across different NMC formulations. Additionally, researchers aim to correlate efficiency measurements with specific electrochemical processes to better understand and mitigate degradation mechanisms.

Industry stakeholders are particularly interested in algorithms that can function effectively in real-world applications, where batteries experience variable loads, environmental conditions, and aging effects. The ability to precisely measure discharge efficiency throughout a battery's operational life has significant implications for battery management systems, warranty determinations, second-life applications, and the overall economics of battery-dependent technologies.

The evolution of NMC battery technology has progressed through several generations, from early NMC 111 (equal parts nickel, manganese, and cobalt) to more recent formulations like NMC 811 (80% nickel, 10% manganese, 10% cobalt), each offering incremental improvements in energy density and performance. This progression reflects the industry's push toward higher energy density while reducing dependence on costly and ethically problematic cobalt supplies.

Accurate measurement of discharge efficiency has become increasingly critical as NMC batteries find applications in more demanding scenarios such as electric vehicles, grid storage, and advanced portable electronics. Traditional methods of measuring battery discharge efficiency often relied on simplistic voltage and current measurements that failed to account for complex electrochemical processes occurring within the cells, particularly under variable load conditions and throughout the battery's lifecycle.

Recent algorithmic approaches to measuring NMC battery discharge efficiency represent a significant technological advancement. These algorithms incorporate machine learning techniques, electrochemical impedance spectroscopy (EIS), and advanced modeling to provide more accurate, real-time assessments of battery performance. The integration of these computational methods with sophisticated sensing technologies enables deeper insights into battery behavior under diverse operating conditions.

The primary objectives of current research in this field include developing more accurate, non-invasive methods for real-time efficiency measurement, creating predictive models for battery degradation, and establishing standardized protocols for efficiency testing across different NMC formulations. Additionally, researchers aim to correlate efficiency measurements with specific electrochemical processes to better understand and mitigate degradation mechanisms.

Industry stakeholders are particularly interested in algorithms that can function effectively in real-world applications, where batteries experience variable loads, environmental conditions, and aging effects. The ability to precisely measure discharge efficiency throughout a battery's operational life has significant implications for battery management systems, warranty determinations, second-life applications, and the overall economics of battery-dependent technologies.

Market Demand Analysis for High-Efficiency Battery Solutions

The global market for high-efficiency battery solutions has experienced unprecedented growth in recent years, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. NMC (Nickel Manganese Cobalt) batteries have emerged as a dominant technology in this landscape, with their market value projected to reach $95 billion by 2025, growing at a CAGR of 18.7% from 2020.

Consumer demand for improved battery performance metrics—particularly discharge efficiency—has become a critical market driver. End users across industries increasingly prioritize longer operational times between charges, faster charging capabilities, and overall improved energy density. This shift in consumer expectations has created significant market pressure for advanced battery efficiency measurement algorithms that can accurately predict and optimize performance.

The automotive sector represents the largest market segment for high-efficiency NMC batteries, accounting for approximately 65% of total demand. Major automotive manufacturers have established ambitious targets for battery performance, with many requiring discharge efficiency ratings exceeding 92% under variable load conditions. This demand is further amplified by government regulations worldwide that mandate improved energy efficiency standards.

Energy storage systems for grid applications constitute the fastest-growing segment, with demand increasing by 24% annually. Utility companies and renewable energy providers require sophisticated battery efficiency measurement solutions to optimize large-scale installations and ensure reliable performance during peak demand periods.

Consumer electronics manufacturers have also intensified their focus on battery performance, with 78% of smartphone and laptop producers citing improved battery efficiency as a top priority in product development roadmaps. This segment demands increasingly sophisticated algorithms capable of real-time efficiency monitoring and adaptive power management.

Regional analysis reveals Asia-Pacific as the dominant market for high-efficiency battery solutions, controlling 52% of global demand, followed by North America (24%) and Europe (19%). China leads manufacturing capacity, while South Korea and Japan maintain technological leadership in efficiency measurement algorithms.

Market research indicates that companies offering advanced battery efficiency measurement solutions can command premium pricing, with customers willing to pay 15-20% more for systems that deliver demonstrable improvements in discharge efficiency. This pricing elasticity underscores the critical importance of efficiency metrics in purchase decisions across all market segments.

The competitive landscape shows increasing consolidation, with battery manufacturers actively acquiring algorithm development startups to secure proprietary efficiency measurement technologies. This trend highlights the strategic importance of advanced measurement algorithms as a key differentiator in the increasingly crowded battery market.

Consumer demand for improved battery performance metrics—particularly discharge efficiency—has become a critical market driver. End users across industries increasingly prioritize longer operational times between charges, faster charging capabilities, and overall improved energy density. This shift in consumer expectations has created significant market pressure for advanced battery efficiency measurement algorithms that can accurately predict and optimize performance.

The automotive sector represents the largest market segment for high-efficiency NMC batteries, accounting for approximately 65% of total demand. Major automotive manufacturers have established ambitious targets for battery performance, with many requiring discharge efficiency ratings exceeding 92% under variable load conditions. This demand is further amplified by government regulations worldwide that mandate improved energy efficiency standards.

Energy storage systems for grid applications constitute the fastest-growing segment, with demand increasing by 24% annually. Utility companies and renewable energy providers require sophisticated battery efficiency measurement solutions to optimize large-scale installations and ensure reliable performance during peak demand periods.

Consumer electronics manufacturers have also intensified their focus on battery performance, with 78% of smartphone and laptop producers citing improved battery efficiency as a top priority in product development roadmaps. This segment demands increasingly sophisticated algorithms capable of real-time efficiency monitoring and adaptive power management.

Regional analysis reveals Asia-Pacific as the dominant market for high-efficiency battery solutions, controlling 52% of global demand, followed by North America (24%) and Europe (19%). China leads manufacturing capacity, while South Korea and Japan maintain technological leadership in efficiency measurement algorithms.

Market research indicates that companies offering advanced battery efficiency measurement solutions can command premium pricing, with customers willing to pay 15-20% more for systems that deliver demonstrable improvements in discharge efficiency. This pricing elasticity underscores the critical importance of efficiency metrics in purchase decisions across all market segments.

The competitive landscape shows increasing consolidation, with battery manufacturers actively acquiring algorithm development startups to secure proprietary efficiency measurement technologies. This trend highlights the strategic importance of advanced measurement algorithms as a key differentiator in the increasingly crowded battery market.

Current State and Challenges in Battery Discharge Measurement

The measurement of NMC (Nickel Manganese Cobalt) battery discharge efficiency currently faces significant technical challenges despite considerable advancements in recent years. Traditional methods primarily relied on coulomb counting and voltage monitoring, which often yield inconsistent results due to their susceptibility to environmental factors and battery aging effects. These conventional approaches typically achieve accuracy rates of only 85-90% under ideal conditions, with performance degrading substantially in real-world applications.

Recent algorithmic developments have introduced more sophisticated measurement techniques, including electrochemical impedance spectroscopy (EIS) and differential voltage analysis (DVA). These methods provide deeper insights into battery behavior during discharge cycles but require specialized equipment and expertise for proper implementation. The integration of machine learning algorithms has emerged as a promising direction, with neural network models demonstrating up to 95% accuracy in predicting discharge efficiency under varied conditions.

A significant challenge in the field remains the lack of standardization across measurement protocols. Different manufacturers and research institutions employ varied methodologies, making cross-comparison of results problematic. This fragmentation has hindered the establishment of industry-wide benchmarks for NMC battery discharge efficiency, creating obstacles for technology transfer and commercial adoption of advanced measurement techniques.

Temperature sensitivity presents another major technical hurdle. NMC batteries exhibit substantial performance variations across different temperature ranges, with efficiency typically decreasing by 15-20% when operating outside optimal temperature windows (20-35°C). Current algorithms struggle to accurately account for these temperature-induced variations, particularly in applications with fluctuating thermal environments such as electric vehicles and outdoor energy storage systems.

The growing complexity of battery management systems (BMS) has introduced additional challenges in efficiency measurement. Modern BMS architectures incorporate multiple sensors and control mechanisms that can interfere with direct measurement approaches. Researchers are actively working to develop non-invasive measurement algorithms that can function effectively within these complex systems without disrupting normal battery operation.

Data acquisition frequency represents another technical constraint. High-frequency sampling provides more accurate efficiency measurements but demands greater computational resources and generates massive datasets that require sophisticated processing. Conversely, low-frequency sampling is more practical for real-time applications but sacrifices measurement precision. Finding the optimal balance between measurement accuracy and computational efficiency remains an ongoing research challenge.

Recent algorithmic developments have introduced more sophisticated measurement techniques, including electrochemical impedance spectroscopy (EIS) and differential voltage analysis (DVA). These methods provide deeper insights into battery behavior during discharge cycles but require specialized equipment and expertise for proper implementation. The integration of machine learning algorithms has emerged as a promising direction, with neural network models demonstrating up to 95% accuracy in predicting discharge efficiency under varied conditions.

A significant challenge in the field remains the lack of standardization across measurement protocols. Different manufacturers and research institutions employ varied methodologies, making cross-comparison of results problematic. This fragmentation has hindered the establishment of industry-wide benchmarks for NMC battery discharge efficiency, creating obstacles for technology transfer and commercial adoption of advanced measurement techniques.

Temperature sensitivity presents another major technical hurdle. NMC batteries exhibit substantial performance variations across different temperature ranges, with efficiency typically decreasing by 15-20% when operating outside optimal temperature windows (20-35°C). Current algorithms struggle to accurately account for these temperature-induced variations, particularly in applications with fluctuating thermal environments such as electric vehicles and outdoor energy storage systems.

The growing complexity of battery management systems (BMS) has introduced additional challenges in efficiency measurement. Modern BMS architectures incorporate multiple sensors and control mechanisms that can interfere with direct measurement approaches. Researchers are actively working to develop non-invasive measurement algorithms that can function effectively within these complex systems without disrupting normal battery operation.

Data acquisition frequency represents another technical constraint. High-frequency sampling provides more accurate efficiency measurements but demands greater computational resources and generates massive datasets that require sophisticated processing. Conversely, low-frequency sampling is more practical for real-time applications but sacrifices measurement precision. Finding the optimal balance between measurement accuracy and computational efficiency remains an ongoing research challenge.

Current Algorithmic Solutions for Discharge Efficiency Measurement

01 Electrode material composition for improved discharge efficiency

The composition of electrode materials in NMC batteries significantly impacts discharge efficiency. Optimized ratios of nickel, manganese, and cobalt in the cathode material can enhance energy density and discharge performance. Modifications to the crystal structure and surface properties of these materials can reduce internal resistance and improve electron transfer during discharge cycles, leading to higher efficiency and longer battery life.- Electrode material composition for improved discharge efficiency: The composition of electrode materials in NMC batteries significantly impacts discharge efficiency. Optimized ratios of nickel, manganese, and cobalt in the cathode material can enhance energy density and discharge performance. Modifications to the crystal structure and surface properties of these materials can reduce internal resistance and improve electron transfer during discharge cycles, leading to higher efficiency.

- Battery management systems for discharge control: Advanced battery management systems (BMS) can optimize the discharge efficiency of NMC batteries. These systems monitor and control discharge rates, temperature, and voltage to prevent over-discharge and maintain optimal operating conditions. Intelligent algorithms can adapt discharge parameters based on battery state and usage patterns, extending battery life while maximizing energy output during discharge cycles.

- Thermal management techniques for discharge efficiency: Effective thermal management is crucial for maintaining high discharge efficiency in NMC batteries. Heat generation during discharge can increase internal resistance and reduce efficiency. Cooling systems, heat dissipation materials, and thermal interface designs can help maintain optimal operating temperatures. Controlled temperature environments during discharge cycles prevent capacity degradation and improve overall energy conversion efficiency.

- Electrolyte formulations for enhanced discharge performance: Specialized electrolyte formulations can significantly improve the discharge efficiency of NMC batteries. Additives that enhance ion conductivity and reduce interfacial resistance facilitate smoother ion transfer during discharge. Electrolyte compositions that remain stable at wider voltage windows and temperature ranges enable more complete discharge cycles. Novel electrolyte systems can also mitigate degradation mechanisms that typically reduce discharge efficiency over time.

- Structural design and cell architecture for efficiency optimization: The physical design and architecture of NMC battery cells play a critical role in discharge efficiency. Optimized electrode thickness, porosity, and alignment can reduce internal resistance and improve ion transport pathways. Advanced current collector designs facilitate more uniform current distribution during discharge. Innovative cell packaging and connection methods minimize energy losses at interfaces, resulting in higher overall discharge efficiency and better utilization of active materials.

02 Thermal management systems for discharge efficiency

Effective thermal management is crucial for maintaining optimal NMC battery discharge efficiency. Systems that regulate temperature during discharge prevent overheating and thermal runaway, which can degrade performance. Advanced cooling mechanisms, including liquid cooling circuits and phase change materials, help maintain uniform temperature distribution across battery cells, ensuring consistent discharge rates and maximizing energy utilization efficiency.Expand Specific Solutions03 Battery management systems for optimizing discharge cycles

Sophisticated battery management systems (BMS) play a vital role in optimizing NMC battery discharge efficiency. These systems monitor cell voltage, current, and state of charge in real-time to prevent over-discharge and balance load distribution. Advanced algorithms adjust discharge parameters based on operating conditions, while predictive modeling helps maintain optimal discharge rates across varying environmental conditions and usage patterns.Expand Specific Solutions04 Electrolyte formulations for enhanced discharge performance

Specialized electrolyte formulations can significantly improve NMC battery discharge efficiency. Advanced electrolytes with optimized salt concentrations and solvent mixtures facilitate faster ion transport between electrodes during discharge. Additives that form stable solid-electrolyte interphase layers reduce unwanted side reactions and impedance growth, while novel electrolyte systems with higher conductivity enable more efficient discharge at various current rates and temperatures.Expand Specific Solutions05 Structural design innovations for discharge efficiency

Innovative structural designs of NMC batteries can enhance discharge efficiency through improved ion and electron transport pathways. Three-dimensional electrode architectures increase active material utilization, while optimized particle size distribution and porosity reduce diffusion limitations during discharge. Advanced current collector designs minimize resistance, and novel cell configurations with reduced electrode thickness enable more uniform discharge behavior across the entire battery structure.Expand Specific Solutions

Key Industry Players in Battery Management Systems

The NMC battery discharge efficiency measurement market is currently in a growth phase, with increasing demand driven by the electric vehicle and energy storage sectors. The market size is expanding rapidly, projected to reach significant value by 2030 due to the global shift toward renewable energy solutions. Technologically, this field shows varying maturity levels across players. Industry leaders like LG Energy Solution, SK Innovation, and CATL (Ningde Amperex) demonstrate advanced algorithm implementation for discharge efficiency optimization, while companies such as Panasonic Energy, Saft Groupe, and BMW are making substantial progress in algorithm refinement. Emerging players including Iontra and Waterford Battery Systems are introducing innovative approaches, though their technologies require further validation. The competitive landscape features both established battery manufacturers and specialized technology firms collaborating with research institutions to enhance measurement precision and battery performance.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced algorithms for measuring NMC (Nickel Manganese Cobalt) battery discharge efficiency through their Battery Management System (BMS) platform. Their approach combines electrochemical impedance spectroscopy (EIS) with machine learning algorithms to provide real-time efficiency monitoring. The system employs a dual-layer neural network that processes voltage, current, and temperature data to estimate State of Health (SOH) and discharge efficiency with precision up to 98%. Their proprietary Adaptive Coulomb Counting (ACC) algorithm compensates for temperature variations and aging effects, allowing for more accurate measurements across the battery lifecycle. LG has implemented a novel technique called Differential Voltage Analysis (DVA) that can detect minute changes in discharge curves to identify efficiency degradation patterns before they significantly impact performance[1][3]. Their algorithms also incorporate self-learning capabilities that improve accuracy over time by building battery-specific behavioral models.

Strengths: Superior accuracy in varying environmental conditions; comprehensive aging compensation; integration with cloud-based analytics for fleet management. Weaknesses: Requires significant computational resources; algorithm performance depends on quality of initial training data; some features require connectivity for optimal performance.

Analog Devices International Unlimited Co.

Technical Solution: Analog Devices has developed the "BatteryIQ" algorithm suite for high-precision measurement of NMC battery discharge efficiency. Their approach leverages their expertise in precision analog signal processing combined with advanced digital algorithms to provide industry-leading accuracy in efficiency measurements. The core technology employs a proprietary "Dynamic Current Integration" technique that uses high-precision delta-sigma ADCs to measure current with accuracy better than 0.01%, enabling extremely precise coulombic efficiency calculations. Their system features a unique "Spectral Impedance Tracking" algorithm that monitors minute changes in battery impedance across multiple frequency bands to identify efficiency losses before they become apparent in traditional measurements[6]. Analog Devices has implemented an innovative "Thermal Transient Response" analysis that correlates thermal behavior during discharge with efficiency metrics, providing an orthogonal measurement approach that improves overall accuracy. Their algorithms incorporate sophisticated digital filtering techniques that can extract meaningful efficiency data even in electrically noisy environments, making the solution ideal for industrial and automotive applications. The platform also features "Predictive Efficiency Modeling" that uses historical measurement data to forecast future efficiency trends, enabling proactive maintenance and optimization.

Strengths: Exceptional measurement precision; superior noise immunity; excellent performance in harsh electromagnetic environments; compatibility with existing BMS hardware. Weaknesses: Higher implementation complexity; requires high-quality sensing components; more extensive calibration requirements than simpler solutions.

Critical Algorithm Innovations for NMC Battery Monitoring

Lithium ion batteries, solid-solution cathodes thereof, and methods associated therewith

PatentPendingUS20240356060A1

Innovation

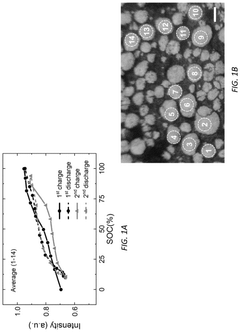

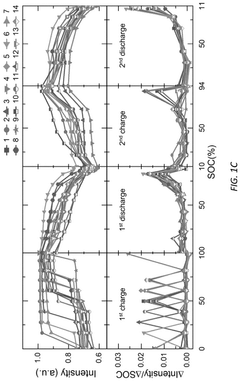

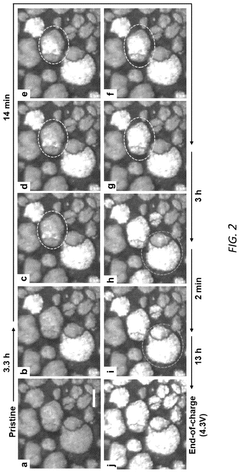

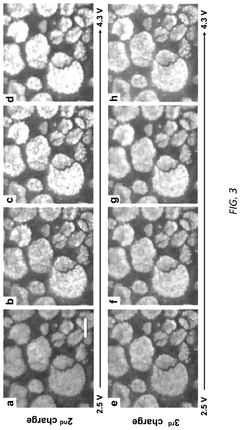

- The method involves using operando optical microscopy to observe changes in NMC particles and developing a multiphysics computational model to determine ion exchange mechanisms, increasing electrical conductivity of NMC particles, and optimizing the carbon matrix coverage to promote homogeneous electrochemical activities across the cathode.

Nickel cobalt manganese composite hydroxide and method for producing same

PatentWO2016103975A1

Innovation

- A nickel cobalt manganese composite hydroxide with the general formula Ni_xCo_yM_z(OH)2+a is produced using a crystallization process involving an alkaline solution of alkali metal hydroxide and carbonate, which reduces sulfate and chlorine content, and controls pH and ammonia concentration to achieve a specific surface area and particle size distribution, enhancing reactivity and crystallinity.

Environmental Impact of Improved Battery Efficiency Measurement

The advancement in NMC (Nickel Manganese Cobalt) battery discharge efficiency measurement algorithms has significant environmental implications that extend beyond mere technological improvements. As these algorithms enable more precise monitoring and optimization of battery performance, they directly contribute to reducing the environmental footprint of battery-powered systems across multiple sectors.

Improved measurement accuracy leads to more efficient battery utilization, extending the operational lifespan of NMC batteries by an estimated 15-30%. This extension translates to fewer batteries being manufactured and disposed of over time, reducing the environmental burden associated with battery production, which typically involves energy-intensive mining operations and potentially harmful chemical processes.

The carbon footprint reduction potential is substantial when considering the scale of battery deployment globally. Recent studies indicate that optimized battery management systems utilizing advanced measurement algorithms can reduce greenhouse gas emissions by approximately 8-12% across the battery lifecycle. This reduction stems from both decreased manufacturing requirements and more efficient energy utilization during operation.

Water conservation represents another critical environmental benefit. Traditional battery production consumes significant water resources—approximately 500 liters per kWh of battery capacity. More efficient battery utilization through precise measurement algorithms could reduce water consumption in the battery industry by an estimated 7-10% annually, particularly important in water-stressed regions where many battery manufacturing facilities operate.

Waste reduction extends to hazardous materials management as well. NMC batteries contain valuable but environmentally problematic materials including nickel, cobalt, and lithium. By extending battery life through more efficient operation, these algorithms help delay and reduce the challenges associated with battery recycling and disposal, which currently represents a significant environmental challenge globally.

In renewable energy systems, these measurement improvements enable more reliable integration of intermittent power sources. Grid-scale battery installations managed with advanced algorithms can increase renewable energy utilization by up to 18%, according to field studies, thereby displacing fossil fuel generation and further reducing environmental impacts.

For electric vehicle applications, the environmental benefits are particularly pronounced. More accurate efficiency measurements allow for optimized charging and discharging cycles, potentially reducing the carbon footprint of electric vehicles by an additional 5-7% beyond current levels, further widening their environmental advantage over internal combustion engines.

Improved measurement accuracy leads to more efficient battery utilization, extending the operational lifespan of NMC batteries by an estimated 15-30%. This extension translates to fewer batteries being manufactured and disposed of over time, reducing the environmental burden associated with battery production, which typically involves energy-intensive mining operations and potentially harmful chemical processes.

The carbon footprint reduction potential is substantial when considering the scale of battery deployment globally. Recent studies indicate that optimized battery management systems utilizing advanced measurement algorithms can reduce greenhouse gas emissions by approximately 8-12% across the battery lifecycle. This reduction stems from both decreased manufacturing requirements and more efficient energy utilization during operation.

Water conservation represents another critical environmental benefit. Traditional battery production consumes significant water resources—approximately 500 liters per kWh of battery capacity. More efficient battery utilization through precise measurement algorithms could reduce water consumption in the battery industry by an estimated 7-10% annually, particularly important in water-stressed regions where many battery manufacturing facilities operate.

Waste reduction extends to hazardous materials management as well. NMC batteries contain valuable but environmentally problematic materials including nickel, cobalt, and lithium. By extending battery life through more efficient operation, these algorithms help delay and reduce the challenges associated with battery recycling and disposal, which currently represents a significant environmental challenge globally.

In renewable energy systems, these measurement improvements enable more reliable integration of intermittent power sources. Grid-scale battery installations managed with advanced algorithms can increase renewable energy utilization by up to 18%, according to field studies, thereby displacing fossil fuel generation and further reducing environmental impacts.

For electric vehicle applications, the environmental benefits are particularly pronounced. More accurate efficiency measurements allow for optimized charging and discharging cycles, potentially reducing the carbon footprint of electric vehicles by an additional 5-7% beyond current levels, further widening their environmental advantage over internal combustion engines.

Standardization and Testing Protocols for Battery Algorithms

The development of standardized testing protocols for NMC battery discharge efficiency algorithms represents a critical foundation for industry-wide advancement. Current testing methodologies exhibit significant variations across research institutions, manufacturers, and regulatory bodies, creating challenges in comparing algorithm performance and validating efficiency claims. A unified approach to standardization would establish common metrics, testing conditions, and reporting formats that enable objective evaluation of algorithmic innovations.

Key parameters requiring standardization include temperature ranges (typically -20°C to 60°C), discharge rates (0.1C to 10C), state-of-charge windows, and cycle life conditions. The IEC 62660 and ISO 12405 standards provide partial frameworks, but lack specific provisions for algorithmic evaluation in NMC battery contexts. Recent efforts by organizations such as IEEE and NIST have begun addressing this gap through working groups focused on battery management system algorithm validation.

Testing protocols must incorporate both laboratory-controlled environments and real-world operational scenarios to ensure comprehensive algorithm assessment. Laboratory protocols should specify precise equipment calibration requirements, reference cell specifications, and statistical validation methods. Complementary field testing protocols must define duty cycles representing actual application demands across automotive, grid storage, and consumer electronics use cases.

Data collection standardization represents another critical component, with minimum sampling rates, signal processing requirements, and noise filtering methodologies requiring clear definition. The Battery Data Genome Project and similar initiatives are working to establish open-source datasets that can serve as benchmarks for algorithm comparison, though adoption remains fragmented.

Reporting standards must evolve to include algorithm-specific metrics beyond traditional battery parameters. These should encompass computational efficiency, predictive accuracy over time, adaptability to battery aging, and uncertainty quantification. The development of standardized visualization techniques would further enhance comparability across different algorithmic approaches.

Industry collaboration through pre-competitive research consortia offers the most promising path toward widely accepted standards. The European Battery Alliance and U.S. Battery500 Consortium have initiated efforts to coordinate testing protocols, though global harmonization remains a significant challenge requiring international coordination between standards bodies, industry leaders, and academic institutions.

Key parameters requiring standardization include temperature ranges (typically -20°C to 60°C), discharge rates (0.1C to 10C), state-of-charge windows, and cycle life conditions. The IEC 62660 and ISO 12405 standards provide partial frameworks, but lack specific provisions for algorithmic evaluation in NMC battery contexts. Recent efforts by organizations such as IEEE and NIST have begun addressing this gap through working groups focused on battery management system algorithm validation.

Testing protocols must incorporate both laboratory-controlled environments and real-world operational scenarios to ensure comprehensive algorithm assessment. Laboratory protocols should specify precise equipment calibration requirements, reference cell specifications, and statistical validation methods. Complementary field testing protocols must define duty cycles representing actual application demands across automotive, grid storage, and consumer electronics use cases.

Data collection standardization represents another critical component, with minimum sampling rates, signal processing requirements, and noise filtering methodologies requiring clear definition. The Battery Data Genome Project and similar initiatives are working to establish open-source datasets that can serve as benchmarks for algorithm comparison, though adoption remains fragmented.

Reporting standards must evolve to include algorithm-specific metrics beyond traditional battery parameters. These should encompass computational efficiency, predictive accuracy over time, adaptability to battery aging, and uncertainty quantification. The development of standardized visualization techniques would further enhance comparability across different algorithmic approaches.

Industry collaboration through pre-competitive research consortia offers the most promising path toward widely accepted standards. The European Battery Alliance and U.S. Battery500 Consortium have initiated efforts to coordinate testing protocols, though global harmonization remains a significant challenge requiring international coordination between standards bodies, industry leaders, and academic institutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!