How to Boost NMC Battery's Charge Acceptance Rates

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Technology Background and Objectives

Lithium-ion batteries have revolutionized portable electronics and are now powering the electric vehicle revolution. Among various cathode chemistries, Nickel Manganese Cobalt (NMC) batteries have emerged as a dominant technology due to their balanced performance characteristics. The development of NMC cathode materials began in the early 2000s as researchers sought alternatives to LiCoO2 that could offer improved safety and lower cost while maintaining high energy density.

NMC battery technology has evolved through several generations, from early NMC111 (equal parts nickel, manganese, and cobalt) to more recent high-nickel formulations like NMC811, which contains 80% nickel, 10% manganese, and 10% cobalt. This evolution has been driven by the need to increase energy density while reducing dependency on expensive and ethically problematic cobalt resources.

The charge acceptance rate of NMC batteries represents a critical performance parameter that directly impacts charging speed and overall user experience. Historically, NMC batteries have demonstrated moderate charge acceptance capabilities compared to other chemistries like LFP (Lithium Iron Phosphate), particularly at high charge rates or low temperatures. This limitation has become increasingly significant as consumer and industry demands for faster charging continue to grow.

Current technical objectives in NMC battery development focus on enhancing charge acceptance rates without compromising the battery's cycle life, safety, or energy density. Researchers aim to achieve charging speeds that allow electric vehicles to replenish 80% of their capacity in less than 15 minutes, comparable to the time spent at conventional gas stations.

The fundamental challenge lies in the complex electrochemical processes during fast charging. When lithium ions intercalate into the NMC cathode structure at high rates, several limiting factors emerge, including concentration polarization, charge transfer resistance, and mechanical stress from volume changes. These factors can lead to accelerated degradation, reduced capacity, and in extreme cases, safety hazards.

Recent technological breakthroughs have demonstrated promising pathways to improve charge acceptance rates. These include novel doping strategies to enhance ionic conductivity, advanced particle engineering to optimize lithium-ion diffusion pathways, and composite electrode designs that better accommodate volume changes during cycling.

The ultimate goal of current research efforts is to develop NMC battery technologies that can simultaneously deliver high energy density (>300 Wh/kg), fast charging capability (>3C rate without significant degradation), long cycle life (>1,000 cycles), and enhanced safety across a wide temperature range. Achieving these objectives would represent a significant leap forward in battery technology, enabling broader adoption of electric vehicles and other high-power applications.

NMC battery technology has evolved through several generations, from early NMC111 (equal parts nickel, manganese, and cobalt) to more recent high-nickel formulations like NMC811, which contains 80% nickel, 10% manganese, and 10% cobalt. This evolution has been driven by the need to increase energy density while reducing dependency on expensive and ethically problematic cobalt resources.

The charge acceptance rate of NMC batteries represents a critical performance parameter that directly impacts charging speed and overall user experience. Historically, NMC batteries have demonstrated moderate charge acceptance capabilities compared to other chemistries like LFP (Lithium Iron Phosphate), particularly at high charge rates or low temperatures. This limitation has become increasingly significant as consumer and industry demands for faster charging continue to grow.

Current technical objectives in NMC battery development focus on enhancing charge acceptance rates without compromising the battery's cycle life, safety, or energy density. Researchers aim to achieve charging speeds that allow electric vehicles to replenish 80% of their capacity in less than 15 minutes, comparable to the time spent at conventional gas stations.

The fundamental challenge lies in the complex electrochemical processes during fast charging. When lithium ions intercalate into the NMC cathode structure at high rates, several limiting factors emerge, including concentration polarization, charge transfer resistance, and mechanical stress from volume changes. These factors can lead to accelerated degradation, reduced capacity, and in extreme cases, safety hazards.

Recent technological breakthroughs have demonstrated promising pathways to improve charge acceptance rates. These include novel doping strategies to enhance ionic conductivity, advanced particle engineering to optimize lithium-ion diffusion pathways, and composite electrode designs that better accommodate volume changes during cycling.

The ultimate goal of current research efforts is to develop NMC battery technologies that can simultaneously deliver high energy density (>300 Wh/kg), fast charging capability (>3C rate without significant degradation), long cycle life (>1,000 cycles), and enhanced safety across a wide temperature range. Achieving these objectives would represent a significant leap forward in battery technology, enabling broader adoption of electric vehicles and other high-power applications.

Market Demand Analysis for Fast-Charging Batteries

The global market for fast-charging batteries has experienced exponential growth in recent years, primarily driven by the rapid adoption of electric vehicles (EVs) and portable electronic devices. Consumer demand for reduced charging times has become a critical factor influencing purchasing decisions across multiple sectors. Market research indicates that over 70% of potential EV buyers consider charging time as one of the top three decision factors, highlighting the commercial importance of improving charge acceptance rates in NMC (Nickel Manganese Cobalt) batteries.

The automotive sector represents the largest market segment for fast-charging NMC batteries, with projections showing the global EV market reaching 26.9 million units by 2030. This growth trajectory creates substantial demand for batteries with enhanced charge acceptance capabilities. Currently, the average charging time for mainstream EVs ranges from 30 minutes to several hours for a full charge, creating a significant market opportunity for technologies that can reduce this time without compromising battery life or safety.

Consumer electronics constitutes another major market segment driving demand for fast-charging NMC batteries. With smartphone users now exceeding 6.8 billion globally, and average daily device usage increasing year-over-year, consumers increasingly value rapid charging capabilities. Market surveys reveal that 85% of smartphone users consider fast charging an essential feature, with willingness to pay premium prices for devices offering this capability.

The industrial and grid storage sectors are emerging as significant growth areas for fast-charging battery technologies. As renewable energy integration accelerates, the need for energy storage systems that can rapidly absorb excess power during peak generation periods becomes critical. The global grid storage market is projected to reach 15.1 GWh by 2025, with fast-charging capabilities becoming increasingly important for grid stabilization applications.

Regional analysis shows Asia-Pacific leading the market demand for fast-charging NMC batteries, accounting for approximately 45% of global consumption. This dominance is attributed to the region's robust electronics manufacturing ecosystem and aggressive EV adoption policies in countries like China and South Korea. North America and Europe follow with 25% and 22% market share respectively, with both regions showing accelerated growth driven by stringent emission regulations and consumer preference shifts.

Market forecasts indicate that the global fast-charging battery market will maintain a compound annual growth rate of 21% through 2028, significantly outpacing the overall battery market growth rate of 14%. This premium growth rate underscores the strategic importance of developing enhanced charge acceptance technologies for NMC batteries, positioning it as a high-priority research area with substantial commercial potential.

The automotive sector represents the largest market segment for fast-charging NMC batteries, with projections showing the global EV market reaching 26.9 million units by 2030. This growth trajectory creates substantial demand for batteries with enhanced charge acceptance capabilities. Currently, the average charging time for mainstream EVs ranges from 30 minutes to several hours for a full charge, creating a significant market opportunity for technologies that can reduce this time without compromising battery life or safety.

Consumer electronics constitutes another major market segment driving demand for fast-charging NMC batteries. With smartphone users now exceeding 6.8 billion globally, and average daily device usage increasing year-over-year, consumers increasingly value rapid charging capabilities. Market surveys reveal that 85% of smartphone users consider fast charging an essential feature, with willingness to pay premium prices for devices offering this capability.

The industrial and grid storage sectors are emerging as significant growth areas for fast-charging battery technologies. As renewable energy integration accelerates, the need for energy storage systems that can rapidly absorb excess power during peak generation periods becomes critical. The global grid storage market is projected to reach 15.1 GWh by 2025, with fast-charging capabilities becoming increasingly important for grid stabilization applications.

Regional analysis shows Asia-Pacific leading the market demand for fast-charging NMC batteries, accounting for approximately 45% of global consumption. This dominance is attributed to the region's robust electronics manufacturing ecosystem and aggressive EV adoption policies in countries like China and South Korea. North America and Europe follow with 25% and 22% market share respectively, with both regions showing accelerated growth driven by stringent emission regulations and consumer preference shifts.

Market forecasts indicate that the global fast-charging battery market will maintain a compound annual growth rate of 21% through 2028, significantly outpacing the overall battery market growth rate of 14%. This premium growth rate underscores the strategic importance of developing enhanced charge acceptance technologies for NMC batteries, positioning it as a high-priority research area with substantial commercial potential.

Current Limitations and Challenges in NMC Charge Acceptance

Despite the numerous advantages of NMC (Nickel Manganese Cobalt) batteries in energy density and cycle life, their charge acceptance rates remain a significant limitation for widespread adoption in high-power applications. The primary challenge stems from the fundamental electrochemical processes occurring during fast charging, where lithium ions must rapidly intercalate into the layered structure of the cathode material. At high charging rates, this process becomes increasingly inefficient, leading to several interconnected issues.

The most prominent limitation is lithium plating, which occurs when lithium ions cannot be inserted into the graphite anode quickly enough during rapid charging. This results in metallic lithium deposition on the anode surface, causing irreversible capacity loss, increased internal resistance, and potential safety hazards including thermal runaway and short circuits. This phenomenon is particularly pronounced at low temperatures, further restricting the operational window of NMC batteries.

Structural degradation presents another major challenge. The crystal structure of NMC materials undergoes significant volume changes during rapid charging, leading to mechanical stress and eventual particle cracking. This degradation accelerates with increasing nickel content (as in NMC811), which, while beneficial for energy density, compromises structural stability during fast charging operations. The resulting particle isolation and loss of active material contribute to capacity fade and reduced cycle life.

Heat generation during fast charging exacerbates these issues. The increased internal resistance at high charging rates generates substantial heat that, if not properly managed, accelerates side reactions and degrades the electrolyte. This thermal management challenge becomes particularly critical in large-format batteries and battery packs where heat dissipation pathways are limited.

Electrolyte decomposition represents another significant barrier. The high voltages required for fast charging often exceed the electrochemical stability window of conventional carbonate-based electrolytes, leading to the formation of a thicker, more resistive solid-electrolyte interphase (SEI) layer. This not only consumes active lithium but also increases cell impedance, further limiting charge acceptance rates in subsequent cycles.

The transition metal dissolution from the cathode during high-voltage operation constitutes a less visible but equally important challenge. Dissolved metal ions can migrate to the anode and deposit on its surface, catalyzing undesirable side reactions and contributing to capacity fade. This issue is particularly pronounced in manganese-containing NMC variants under fast charging conditions.

These limitations collectively create a complex interdependent system where addressing one challenge often exacerbates others, necessitating a holistic approach to improving charge acceptance rates in NMC batteries.

The most prominent limitation is lithium plating, which occurs when lithium ions cannot be inserted into the graphite anode quickly enough during rapid charging. This results in metallic lithium deposition on the anode surface, causing irreversible capacity loss, increased internal resistance, and potential safety hazards including thermal runaway and short circuits. This phenomenon is particularly pronounced at low temperatures, further restricting the operational window of NMC batteries.

Structural degradation presents another major challenge. The crystal structure of NMC materials undergoes significant volume changes during rapid charging, leading to mechanical stress and eventual particle cracking. This degradation accelerates with increasing nickel content (as in NMC811), which, while beneficial for energy density, compromises structural stability during fast charging operations. The resulting particle isolation and loss of active material contribute to capacity fade and reduced cycle life.

Heat generation during fast charging exacerbates these issues. The increased internal resistance at high charging rates generates substantial heat that, if not properly managed, accelerates side reactions and degrades the electrolyte. This thermal management challenge becomes particularly critical in large-format batteries and battery packs where heat dissipation pathways are limited.

Electrolyte decomposition represents another significant barrier. The high voltages required for fast charging often exceed the electrochemical stability window of conventional carbonate-based electrolytes, leading to the formation of a thicker, more resistive solid-electrolyte interphase (SEI) layer. This not only consumes active lithium but also increases cell impedance, further limiting charge acceptance rates in subsequent cycles.

The transition metal dissolution from the cathode during high-voltage operation constitutes a less visible but equally important challenge. Dissolved metal ions can migrate to the anode and deposit on its surface, catalyzing undesirable side reactions and contributing to capacity fade. This issue is particularly pronounced in manganese-containing NMC variants under fast charging conditions.

These limitations collectively create a complex interdependent system where addressing one challenge often exacerbates others, necessitating a holistic approach to improving charge acceptance rates in NMC batteries.

Current Solutions for Improving Charge Acceptance Rates

01 Temperature-dependent charge acceptance optimization

NMC battery charge acceptance rates are significantly influenced by temperature conditions. Optimizing charging protocols based on battery temperature can enhance charge acceptance rates and extend battery life. Advanced thermal management systems monitor and adjust charging parameters in real-time to maintain optimal temperature ranges during charging cycles, preventing degradation while maximizing charge acceptance efficiency.- Charge acceptance rate optimization for NMC batteries: Various methods are employed to optimize the charge acceptance rate of NMC (Nickel Manganese Cobalt) batteries. These include adjusting charging parameters based on battery state, implementing adaptive charging algorithms, and utilizing specific charging profiles that account for the electrochemical properties of NMC cathode materials. These optimization techniques help maximize charging efficiency while preventing degradation mechanisms that can occur during rapid charging.

- Temperature management for improved charge acceptance: Temperature control systems are crucial for maintaining optimal charge acceptance rates in NMC batteries. These systems monitor and regulate battery temperature during charging to prevent overheating and ensure efficient lithium-ion intercalation. Thermal management techniques include active cooling systems, temperature-responsive charging protocols, and thermal insulation designs that help maintain the battery within the ideal temperature range for maximum charge acceptance.

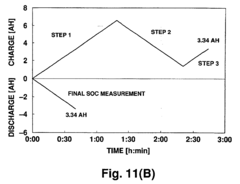

- Battery management systems for NMC charge rate control: Advanced battery management systems (BMS) are designed to monitor and control the charge acceptance rates of NMC batteries. These systems employ sensors to track battery parameters such as voltage, current, and state of charge, and adjust charging parameters accordingly. The BMS can implement various charging strategies including constant current-constant voltage (CC-CV) protocols, pulse charging, and multi-stage charging to optimize charge acceptance while preserving battery life.

- Electrode and electrolyte modifications for enhanced charge acceptance: Material modifications to NMC battery components can significantly improve charge acceptance rates. These include doping the NMC cathode material with various elements, applying specialized coatings to electrode surfaces, and developing advanced electrolyte formulations. Such modifications aim to enhance lithium-ion diffusion pathways, reduce internal resistance, and mitigate side reactions that can limit charge acceptance, particularly at high charging rates.

- Fast charging protocols specific to NMC chemistry: Specialized fast charging protocols have been developed specifically for NMC battery chemistry. These protocols account for the unique characteristics of NMC cathodes, including their voltage profiles and structural stability limits. The charging methods incorporate variable current rates, voltage thresholds, and rest periods designed to maximize charge acceptance while minimizing degradation mechanisms such as lithium plating, structural disordering, and electrolyte decomposition that can occur during rapid charging.

02 Fast charging protocols for NMC batteries

Specialized charging protocols have been developed to improve the charge acceptance rates of NMC batteries during fast charging scenarios. These protocols typically involve multi-stage charging processes with variable current rates that adapt to the battery's state of charge. By carefully controlling current and voltage parameters throughout the charging cycle, these methods maximize charge acceptance while minimizing degradation mechanisms such as lithium plating and structural damage to the cathode material.Expand Specific Solutions03 Electrode composition modifications for improved charge acceptance

The composition and structure of NMC battery electrodes significantly impact charge acceptance rates. Modifications to the cathode material, including doping with various elements, adjusting nickel-manganese-cobalt ratios, and optimizing particle morphology, can enhance lithium-ion diffusion pathways. These improvements allow for faster intercalation and deintercalation of lithium ions during charging, resulting in higher charge acceptance rates without compromising battery stability or cycle life.Expand Specific Solutions04 State of charge monitoring and adaptive charging systems

Advanced battery management systems employ real-time monitoring of NMC battery state of charge to optimize charge acceptance rates. These systems utilize sophisticated algorithms that analyze battery parameters such as voltage, current, and internal resistance to determine the optimal charging profile at any given moment. By continuously adapting charging parameters based on the battery's actual condition, these systems maximize charge acceptance rates while preventing overcharging and associated degradation mechanisms.Expand Specific Solutions05 Electrolyte formulations for enhanced charge acceptance

The composition of electrolytes plays a crucial role in determining NMC battery charge acceptance rates. Advanced electrolyte formulations incorporate additives that form stable solid-electrolyte interphase layers, reduce interfacial resistance, and enhance lithium-ion transport. These specialized electrolytes can significantly improve charge acceptance rates, particularly at low temperatures or during fast charging conditions, by facilitating more efficient ion movement between electrodes while minimizing unwanted side reactions.Expand Specific Solutions

Key Industry Players in NMC Battery Development

The NMC battery charge acceptance rate improvement landscape is evolving rapidly in a market transitioning from early adoption to growth phase. With global electric vehicle and energy storage markets expanding at 25-30% annually, this technology has become strategically important. Technical maturity varies significantly among key players, with BYD, CATL, and Toyota leading commercial implementation through advanced electrode design and electrolyte formulations. Panasonic Energy and QuantumScape are making breakthroughs in solid-state adaptations, while academic institutions like Xiamen University and Fudan University contribute fundamental research on surface chemistry modifications. Nissan and Hyundai are focusing on thermal management systems to enhance charge acceptance, creating a competitive ecosystem balancing innovation with commercialization demands.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery technology, which while primarily LFP-based, has informed their NMC battery development strategies for improved charge acceptance. For their NMC batteries, BYD employs a multi-faceted approach to enhance charge rates. They've developed proprietary single-crystal NMC cathode materials with optimized lithium diffusion channels and reduced surface reactivity. Their electrode design features ultra-thin coating techniques and precise control of porosity gradients across the electrode thickness. BYD's cell architecture incorporates innovative tab designs with multiple connection points to distribute current more evenly, reducing localized heating and lithium plating during fast charging. Additionally, they've implemented advanced thermal management systems using direct liquid cooling that maintains optimal temperature profiles during high-rate charging. BYD has also developed smart charging algorithms that dynamically adjust charging parameters based on real-time battery state and environmental conditions.

Strengths: Vertically integrated manufacturing allowing tight quality control; extensive experience with large-format cells for automotive applications; proven thermal management expertise. Weaknesses: Higher focus on LFP technology may have limited some NMC-specific optimizations; trade-offs between fast charging capability and overall energy density; potential cost implications of advanced thermal management systems.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced NMC battery technologies focusing on improving charge acceptance rates through multiple approaches. Their primary innovation involves nano-structured cathode materials with optimized particle morphology and size distribution, enabling faster lithium-ion diffusion pathways. CATL's gradient concentration cathode design features higher nickel content at the core and increased manganese at the surface, balancing fast charging capability with structural stability. They've implemented silicon-carbon composite anodes with void spaces to accommodate volume expansion during charging, significantly enhancing rate capability. Additionally, CATL utilizes advanced electrolyte formulations containing fluoroethylene carbonate and lithium difluorophosphate additives that form stable SEI layers, reducing impedance growth during fast charging cycles. Their cell design incorporates optimized electrode thickness and porosity specifically engineered to minimize concentration polarization during high-rate charging.

Strengths: Superior energy density while maintaining fast charging capability; advanced manufacturing capabilities allowing precise control of material properties; extensive real-world validation through partnerships with major automotive OEMs. Weaknesses: Higher production costs compared to standard NMC formulations; potential thermal management challenges during extreme fast charging conditions; slightly reduced cycle life compared to slower-charging alternatives.

Critical Patents and Research on NMC Fast-Charging

Nickel battery charging method and apparatus

PatentInactiveEP0905855A3

Innovation

- A charging method that involves initial full charging followed by discharging until a predetermined amount of initial charge, utilizing a nickel positive electrode with fine particles (1µm to 100µm diameters) to ensure charging occurs near the center of the material, increasing the reaction area and efficiency.

Nickel hydroxide active material for alkaline storage battery and positive plate

PatentWO1997019478A1

Innovation

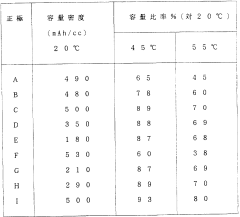

- A nickel hydroxide active material with a specific composition and treatment process, incorporating 10-40 mol% manganese, which shifts the charge potential to a negative direction, combined with a conductive support, enhances charge acceptance and capacity density, and is treated with a hot alkaline solution to achieve a higher density and improved crystal structure.

Thermal Management Strategies for Fast-Charging NMC Batteries

Effective thermal management is critical for enhancing the charge acceptance rates of NMC (Nickel Manganese Cobalt) batteries during fast-charging processes. Temperature control directly impacts the electrochemical reactions, ion diffusion rates, and overall battery performance. When NMC batteries operate outside their optimal temperature range (typically 15-35°C), their ability to accept charge diminishes significantly, potentially leading to accelerated degradation and safety risks.

Advanced cooling systems represent a primary approach to thermal management during fast charging. Liquid cooling solutions have demonstrated superior performance compared to traditional air cooling methods, offering more uniform temperature distribution and efficient heat dissipation. Recent developments include direct cell cooling technologies where coolant channels are integrated into battery modules, allowing for more precise temperature control at the cell level rather than just at the pack periphery.

Phase change materials (PCMs) have emerged as promising passive thermal management solutions. These materials absorb excess heat during charging through their phase transition process, effectively maintaining battery temperature within optimal ranges. Research indicates that PCMs with melting points between 30-40°C are particularly effective for NMC battery applications, providing thermal buffering during high-rate charging scenarios.

Predictive thermal modeling has revolutionized battery management systems by enabling preemptive cooling strategies. Machine learning algorithms can anticipate temperature spikes based on charging profiles and environmental conditions, allowing cooling systems to activate before critical temperature thresholds are reached. This proactive approach has shown to improve charge acceptance rates by up to 15% in laboratory testing environments.

Differential thermal management strategies address the inherent temperature gradients within battery packs. By applying targeted cooling to hotspots that typically develop during fast charging, these systems prevent localized overheating that would otherwise trigger battery management systems to throttle charging rates. Implementation of thermal imaging and distributed temperature sensors enables real-time identification of these hotspots.

Electrolyte engineering represents another frontier in thermal management. Advanced electrolyte formulations with improved thermal stability allow for higher operating temperatures without compromising safety or longevity. Additives that enhance thermal conductivity within the cell can facilitate more efficient heat transfer from internal components to external cooling systems.

Integration of these thermal management strategies into comprehensive battery management systems is essential for practical implementation. The most effective approaches combine active cooling technologies with intelligent control algorithms that adapt to varying charging conditions, battery state of health, and environmental factors. Such integrated systems have demonstrated the ability to maintain NMC batteries within 2°C of their optimal operating temperature even during ultra-fast charging at rates exceeding 3C.

Advanced cooling systems represent a primary approach to thermal management during fast charging. Liquid cooling solutions have demonstrated superior performance compared to traditional air cooling methods, offering more uniform temperature distribution and efficient heat dissipation. Recent developments include direct cell cooling technologies where coolant channels are integrated into battery modules, allowing for more precise temperature control at the cell level rather than just at the pack periphery.

Phase change materials (PCMs) have emerged as promising passive thermal management solutions. These materials absorb excess heat during charging through their phase transition process, effectively maintaining battery temperature within optimal ranges. Research indicates that PCMs with melting points between 30-40°C are particularly effective for NMC battery applications, providing thermal buffering during high-rate charging scenarios.

Predictive thermal modeling has revolutionized battery management systems by enabling preemptive cooling strategies. Machine learning algorithms can anticipate temperature spikes based on charging profiles and environmental conditions, allowing cooling systems to activate before critical temperature thresholds are reached. This proactive approach has shown to improve charge acceptance rates by up to 15% in laboratory testing environments.

Differential thermal management strategies address the inherent temperature gradients within battery packs. By applying targeted cooling to hotspots that typically develop during fast charging, these systems prevent localized overheating that would otherwise trigger battery management systems to throttle charging rates. Implementation of thermal imaging and distributed temperature sensors enables real-time identification of these hotspots.

Electrolyte engineering represents another frontier in thermal management. Advanced electrolyte formulations with improved thermal stability allow for higher operating temperatures without compromising safety or longevity. Additives that enhance thermal conductivity within the cell can facilitate more efficient heat transfer from internal components to external cooling systems.

Integration of these thermal management strategies into comprehensive battery management systems is essential for practical implementation. The most effective approaches combine active cooling technologies with intelligent control algorithms that adapt to varying charging conditions, battery state of health, and environmental factors. Such integrated systems have demonstrated the ability to maintain NMC batteries within 2°C of their optimal operating temperature even during ultra-fast charging at rates exceeding 3C.

Safety Standards and Certification Requirements

The safety standards and certification requirements for NMC (Nickel Manganese Cobalt) batteries have become increasingly stringent as the technology evolves to accommodate higher charge acceptance rates. Compliance with international standards such as IEC 62133, UL 1642, and UN 38.3 is mandatory for market entry, with each standard addressing specific safety aspects including thermal stability, electrical safety, and mechanical integrity during charging processes.

For NMC batteries designed with enhanced charge acceptance capabilities, additional testing protocols are required to verify safety under accelerated charging conditions. These include extended cycling tests at various charge rates, thermal runaway resistance evaluations, and abuse testing under extreme charging scenarios. The certification process typically requires demonstration that the battery can maintain structural integrity and thermal stability even when subjected to charge rates exceeding normal operating parameters.

Regulatory bodies have established specific thresholds for heat generation during fast charging, with requirements that batteries must not exceed critical temperature limits regardless of the charging speed. For instance, the surface temperature of NMC cells must typically remain below 45°C during consumer use and below 60°C under any charging condition to receive certification. These thermal management requirements become particularly challenging when developing batteries with higher charge acceptance rates.

Manufacturers seeking to boost NMC charge acceptance must also adhere to electromagnetic compatibility (EMC) standards, as faster charging systems often generate stronger electromagnetic fields. This necessitates compliance with standards like IEC 61000 to ensure the charging system does not interfere with other electronic devices and remains safe for consumer use.

The certification landscape varies significantly by region, with the European Union implementing the Battery Directive 2006/66/EC and its amendments, while North America follows UL standards, and Asia often requires compliance with country-specific regulations such as Japan's PSE or China's CQC. This regulatory fragmentation creates additional complexity for global deployment of advanced NMC battery technologies.

Recent updates to safety standards have begun to specifically address fast-charging capabilities, with new test protocols being developed to evaluate the long-term safety implications of repeated rapid charging cycles. These include accelerated aging tests that simulate years of fast-charging use to identify potential degradation mechanisms that might compromise safety over the battery's lifetime.

Certification requirements also extend to the battery management systems (BMS), which must demonstrate sophisticated control algorithms capable of preventing overcharging while maximizing charge acceptance rates. The BMS must pass rigorous validation testing to prove it can effectively monitor cell voltages, temperatures, and internal resistance during high-rate charging scenarios.

For NMC batteries designed with enhanced charge acceptance capabilities, additional testing protocols are required to verify safety under accelerated charging conditions. These include extended cycling tests at various charge rates, thermal runaway resistance evaluations, and abuse testing under extreme charging scenarios. The certification process typically requires demonstration that the battery can maintain structural integrity and thermal stability even when subjected to charge rates exceeding normal operating parameters.

Regulatory bodies have established specific thresholds for heat generation during fast charging, with requirements that batteries must not exceed critical temperature limits regardless of the charging speed. For instance, the surface temperature of NMC cells must typically remain below 45°C during consumer use and below 60°C under any charging condition to receive certification. These thermal management requirements become particularly challenging when developing batteries with higher charge acceptance rates.

Manufacturers seeking to boost NMC charge acceptance must also adhere to electromagnetic compatibility (EMC) standards, as faster charging systems often generate stronger electromagnetic fields. This necessitates compliance with standards like IEC 61000 to ensure the charging system does not interfere with other electronic devices and remains safe for consumer use.

The certification landscape varies significantly by region, with the European Union implementing the Battery Directive 2006/66/EC and its amendments, while North America follows UL standards, and Asia often requires compliance with country-specific regulations such as Japan's PSE or China's CQC. This regulatory fragmentation creates additional complexity for global deployment of advanced NMC battery technologies.

Recent updates to safety standards have begun to specifically address fast-charging capabilities, with new test protocols being developed to evaluate the long-term safety implications of repeated rapid charging cycles. These include accelerated aging tests that simulate years of fast-charging use to identify potential degradation mechanisms that might compromise safety over the battery's lifetime.

Certification requirements also extend to the battery management systems (BMS), which must demonstrate sophisticated control algorithms capable of preventing overcharging while maximizing charge acceptance rates. The BMS must pass rigorous validation testing to prove it can effectively monitor cell voltages, temperatures, and internal resistance during high-rate charging scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!