Measure NMC Battery's Moisture Resistance Using Scientific Metrics

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Moisture Resistance Background and Objectives

Lithium-ion batteries with nickel manganese cobalt oxide (NMC) cathodes have emerged as a dominant technology in the energy storage landscape, powering everything from consumer electronics to electric vehicles and grid-scale storage systems. The evolution of NMC battery technology has been marked by continuous improvements in energy density, cycle life, and safety characteristics. However, moisture sensitivity remains a critical vulnerability that affects manufacturing processes, battery performance, and long-term reliability.

The historical development of NMC cathode materials began in the early 2000s as researchers sought alternatives to lithium cobalt oxide (LCO) that could offer improved safety and lower cost. Through systematic compositional engineering, various NMC formulations (such as NMC 111, 532, 622, and 811) have been developed, each representing different ratios of nickel, manganese, and cobalt. This evolution has generally trended toward higher nickel content to increase energy density, but this has simultaneously increased moisture sensitivity.

Moisture interaction with NMC materials triggers several detrimental chemical reactions, including the formation of lithium hydroxide and metal hydroxides, which compromise structural integrity and electrochemical performance. The transition metal dissolution that occurs in the presence of moisture leads to capacity fade and increased cell impedance. Additionally, moisture-induced degradation of the electrolyte through hydrolysis reactions generates HF, which further attacks the cathode material.

Current industry practices for moisture control rely primarily on qualitative assessments or basic quantitative measures that lack standardization. Dew point measurements in dry rooms, Karl Fischer titration for residual moisture content, and accelerated aging tests provide useful but incomplete information about moisture resistance. The absence of comprehensive, standardized scientific metrics for evaluating moisture resistance creates challenges for quality control, material selection, and performance prediction.

The primary objective of this technical research is to develop and validate a systematic framework of scientific metrics for quantifying the moisture resistance of NMC battery materials. This framework aims to establish standardized testing protocols that can accurately characterize how different NMC formulations respond to moisture exposure across varying environmental conditions and time scales.

Secondary objectives include identifying the fundamental mechanisms of moisture-induced degradation at the molecular and microstructural levels, establishing correlations between moisture exposure and performance degradation, and developing predictive models that can estimate battery lifetime based on moisture resistance parameters. Additionally, this research seeks to compare different protective strategies, such as surface coatings and dopants, using the newly developed metrics to guide future material design.

By achieving these objectives, we anticipate enabling more informed material selection, optimized manufacturing processes, and improved battery management strategies that can significantly enhance the reliability and longevity of NMC-based energy storage systems.

The historical development of NMC cathode materials began in the early 2000s as researchers sought alternatives to lithium cobalt oxide (LCO) that could offer improved safety and lower cost. Through systematic compositional engineering, various NMC formulations (such as NMC 111, 532, 622, and 811) have been developed, each representing different ratios of nickel, manganese, and cobalt. This evolution has generally trended toward higher nickel content to increase energy density, but this has simultaneously increased moisture sensitivity.

Moisture interaction with NMC materials triggers several detrimental chemical reactions, including the formation of lithium hydroxide and metal hydroxides, which compromise structural integrity and electrochemical performance. The transition metal dissolution that occurs in the presence of moisture leads to capacity fade and increased cell impedance. Additionally, moisture-induced degradation of the electrolyte through hydrolysis reactions generates HF, which further attacks the cathode material.

Current industry practices for moisture control rely primarily on qualitative assessments or basic quantitative measures that lack standardization. Dew point measurements in dry rooms, Karl Fischer titration for residual moisture content, and accelerated aging tests provide useful but incomplete information about moisture resistance. The absence of comprehensive, standardized scientific metrics for evaluating moisture resistance creates challenges for quality control, material selection, and performance prediction.

The primary objective of this technical research is to develop and validate a systematic framework of scientific metrics for quantifying the moisture resistance of NMC battery materials. This framework aims to establish standardized testing protocols that can accurately characterize how different NMC formulations respond to moisture exposure across varying environmental conditions and time scales.

Secondary objectives include identifying the fundamental mechanisms of moisture-induced degradation at the molecular and microstructural levels, establishing correlations between moisture exposure and performance degradation, and developing predictive models that can estimate battery lifetime based on moisture resistance parameters. Additionally, this research seeks to compare different protective strategies, such as surface coatings and dopants, using the newly developed metrics to guide future material design.

By achieving these objectives, we anticipate enabling more informed material selection, optimized manufacturing processes, and improved battery management strategies that can significantly enhance the reliability and longevity of NMC-based energy storage systems.

Market Demand Analysis for Moisture-Resistant Battery Technologies

The global battery market is experiencing unprecedented growth, with the NMC (Nickel Manganese Cobalt) battery segment emerging as a critical component in the electric vehicle (EV) and energy storage sectors. Market research indicates that the global lithium-ion battery market is projected to reach $129.3 billion by 2027, with NMC batteries accounting for approximately 28% of this market. This significant market share underscores the importance of addressing moisture resistance challenges in NMC batteries.

Consumer demand for longer-lasting, safer, and more reliable batteries has intensified as EV adoption accelerates worldwide. A recent industry survey revealed that 76% of EV manufacturers consider moisture resistance as a top-five priority in battery selection criteria. This heightened focus stems from documented cases where moisture ingress has led to premature battery degradation, reduced capacity, and in extreme cases, safety incidents.

The automotive sector represents the largest market for moisture-resistant NMC batteries, with an estimated annual growth rate of 22% through 2025. This growth is primarily driven by stringent vehicle performance requirements and safety regulations. Additionally, the stationary energy storage market is emerging as a secondary growth driver, with utility companies increasingly deploying battery systems in varied environmental conditions that demand enhanced moisture resistance.

Regional market analysis shows Asia-Pacific leading the demand for moisture-resistant battery technologies, accounting for 43% of global consumption. This is followed by North America (27%) and Europe (21%), with the remaining markets constituting 9%. China, Japan, and South Korea are particularly significant markets due to their dominant positions in battery manufacturing and EV production.

Consumer willingness to pay premium prices for batteries with enhanced moisture resistance capabilities has been confirmed through multiple market studies. A price premium of 15-20% is considered acceptable by end-users when moisture resistance translates to demonstrable improvements in battery lifespan and safety performance. This price elasticity creates a compelling business case for investing in advanced moisture resistance technologies.

Industry forecasts suggest that the market for specialized moisture-resistant NMC batteries will grow at a compound annual growth rate of 31% over the next five years, outpacing the broader battery market. This accelerated growth is attributed to increasing awareness of moisture-related failure modes and the subsequent demand for scientifically validated moisture resistance metrics that can be used for product differentiation and quality assurance.

The aftermarket and replacement segments also present significant opportunities, with moisture damage being identified as a leading cause of warranty claims in certain applications. This has created demand for retrofit solutions and aftermarket treatments that enhance moisture resistance in existing battery installations.

Consumer demand for longer-lasting, safer, and more reliable batteries has intensified as EV adoption accelerates worldwide. A recent industry survey revealed that 76% of EV manufacturers consider moisture resistance as a top-five priority in battery selection criteria. This heightened focus stems from documented cases where moisture ingress has led to premature battery degradation, reduced capacity, and in extreme cases, safety incidents.

The automotive sector represents the largest market for moisture-resistant NMC batteries, with an estimated annual growth rate of 22% through 2025. This growth is primarily driven by stringent vehicle performance requirements and safety regulations. Additionally, the stationary energy storage market is emerging as a secondary growth driver, with utility companies increasingly deploying battery systems in varied environmental conditions that demand enhanced moisture resistance.

Regional market analysis shows Asia-Pacific leading the demand for moisture-resistant battery technologies, accounting for 43% of global consumption. This is followed by North America (27%) and Europe (21%), with the remaining markets constituting 9%. China, Japan, and South Korea are particularly significant markets due to their dominant positions in battery manufacturing and EV production.

Consumer willingness to pay premium prices for batteries with enhanced moisture resistance capabilities has been confirmed through multiple market studies. A price premium of 15-20% is considered acceptable by end-users when moisture resistance translates to demonstrable improvements in battery lifespan and safety performance. This price elasticity creates a compelling business case for investing in advanced moisture resistance technologies.

Industry forecasts suggest that the market for specialized moisture-resistant NMC batteries will grow at a compound annual growth rate of 31% over the next five years, outpacing the broader battery market. This accelerated growth is attributed to increasing awareness of moisture-related failure modes and the subsequent demand for scientifically validated moisture resistance metrics that can be used for product differentiation and quality assurance.

The aftermarket and replacement segments also present significant opportunities, with moisture damage being identified as a leading cause of warranty claims in certain applications. This has created demand for retrofit solutions and aftermarket treatments that enhance moisture resistance in existing battery installations.

Current Challenges in NMC Battery Moisture Protection

Despite significant advancements in NMC (Nickel Manganese Cobalt) battery technology, moisture resistance remains a critical challenge that impacts battery performance, safety, and longevity. Current moisture protection methods face several technical limitations that require innovative solutions and standardized measurement approaches.

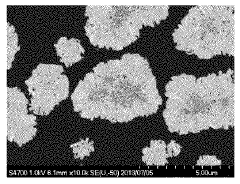

The primary challenge lies in the extreme sensitivity of NMC cathode materials to moisture exposure. When NMC materials interact with water molecules, they undergo hydrolysis reactions that release metal ions and lithium hydroxide, leading to structural degradation and capacity loss. This sensitivity increases proportionally with nickel content, making high-nickel NMC variants (NMC811, NMC622) particularly vulnerable compared to lower-nickel formulations.

Existing moisture measurement techniques lack standardization across the industry, creating inconsistencies in evaluating battery moisture resistance. Karl Fischer titration, while widely used, provides only bulk moisture content without spatial distribution information. Impedance spectroscopy offers real-time monitoring capabilities but requires complex data interpretation and cannot easily distinguish between different moisture-induced degradation mechanisms.

Manufacturing environments present additional challenges, as moisture control during electrode production, cell assembly, and electrolyte filling requires sophisticated environmental chambers and dry rooms with dew points below -40°C. These facilities demand significant energy consumption and precise control systems, increasing production costs substantially.

Current moisture barrier materials exhibit performance trade-offs between moisture protection and electrochemical properties. Conventional coatings that effectively block moisture often impede lithium-ion transport, reducing battery power capability. Conversely, more permeable coatings that maintain good ionic conductivity typically offer insufficient moisture protection.

The industry also lacks accelerated testing protocols that accurately predict long-term moisture resistance performance. Current methods either fail to replicate real-world conditions or require excessively long testing periods, creating bottlenecks in material development and qualification processes.

Quantitative metrics for moisture resistance remain inconsistently applied across research and industry. While some organizations focus on water vapor transmission rates, others prioritize dimensional stability after humidity exposure or capacity retention following moisture stress testing. This lack of standardized metrics complicates comparative analyses between different moisture protection solutions.

Emerging high-energy NMC formulations with increased nickel content exacerbate these challenges, as their enhanced reactivity with moisture requires even more robust protection strategies while maintaining electrochemical performance.

The primary challenge lies in the extreme sensitivity of NMC cathode materials to moisture exposure. When NMC materials interact with water molecules, they undergo hydrolysis reactions that release metal ions and lithium hydroxide, leading to structural degradation and capacity loss. This sensitivity increases proportionally with nickel content, making high-nickel NMC variants (NMC811, NMC622) particularly vulnerable compared to lower-nickel formulations.

Existing moisture measurement techniques lack standardization across the industry, creating inconsistencies in evaluating battery moisture resistance. Karl Fischer titration, while widely used, provides only bulk moisture content without spatial distribution information. Impedance spectroscopy offers real-time monitoring capabilities but requires complex data interpretation and cannot easily distinguish between different moisture-induced degradation mechanisms.

Manufacturing environments present additional challenges, as moisture control during electrode production, cell assembly, and electrolyte filling requires sophisticated environmental chambers and dry rooms with dew points below -40°C. These facilities demand significant energy consumption and precise control systems, increasing production costs substantially.

Current moisture barrier materials exhibit performance trade-offs between moisture protection and electrochemical properties. Conventional coatings that effectively block moisture often impede lithium-ion transport, reducing battery power capability. Conversely, more permeable coatings that maintain good ionic conductivity typically offer insufficient moisture protection.

The industry also lacks accelerated testing protocols that accurately predict long-term moisture resistance performance. Current methods either fail to replicate real-world conditions or require excessively long testing periods, creating bottlenecks in material development and qualification processes.

Quantitative metrics for moisture resistance remain inconsistently applied across research and industry. While some organizations focus on water vapor transmission rates, others prioritize dimensional stability after humidity exposure or capacity retention following moisture stress testing. This lack of standardized metrics complicates comparative analyses between different moisture protection solutions.

Emerging high-energy NMC formulations with increased nickel content exacerbate these challenges, as their enhanced reactivity with moisture requires even more robust protection strategies while maintaining electrochemical performance.

Existing Scientific Metrics for Battery Moisture Resistance

01 Protective coatings for NMC battery materials

Various coating technologies can be applied to NMC battery materials to enhance moisture resistance. These include polymer coatings, metal oxide layers, and composite coatings that create a physical barrier against moisture penetration. The coatings not only protect against humidity but also help maintain the structural integrity and electrochemical performance of the cathode materials under humid conditions.- Protective coatings for NMC battery materials: Various coating materials can be applied to NMC battery components to enhance moisture resistance. These protective layers act as barriers against moisture penetration, preventing degradation of the cathode materials. Common coating materials include metal oxides, polymers, and composite materials that form a hydrophobic barrier while maintaining electrochemical performance. These coatings can be applied through methods such as atomic layer deposition, solution processing, or vapor deposition techniques.

- Moisture-resistant binder systems: Specialized binder systems can significantly improve the moisture resistance of NMC batteries. These binders create strong adhesion between active materials while forming a moisture-repellent network throughout the electrode structure. Advanced fluoropolymer binders, modified PVDF formulations, and water-resistant polymer blends help maintain structural integrity under humid conditions. The binder selection and optimization are crucial for preventing moisture-induced degradation of NMC cathode materials.

- Encapsulation and packaging technologies: Innovative encapsulation and packaging solutions provide effective moisture barriers for NMC batteries. These technologies include multi-layer laminate pouches, hermetic sealing methods, and advanced moisture-absorbing materials integrated into the battery housing. Some designs incorporate desiccant materials within the battery packaging to trap any moisture that penetrates the outer barriers. These packaging approaches significantly extend battery life by maintaining a dry internal environment even under challenging external conditions.

- Surface modification of NMC particles: Surface modification techniques can enhance the inherent moisture resistance of NMC cathode particles. These methods involve chemical treatments that alter the surface properties of NMC materials to make them less reactive with moisture. Approaches include surface fluorination, phosphate treatments, and the creation of hydrophobic surface layers through chemical reactions. These modifications help maintain the crystal structure and electrochemical performance of NMC materials even when exposed to humid environments.

- Moisture detection and management systems: Advanced moisture detection and management systems help monitor and control humidity levels within NMC batteries. These systems incorporate sensors that can detect moisture ingress before significant damage occurs. Some designs include integrated heating elements to remove moisture through controlled evaporation or incorporate moisture-scavenging materials that actively absorb water molecules. These proactive approaches to moisture management help extend battery life and maintain performance in variable environmental conditions.

02 Moisture-resistant binder systems

Specialized binder formulations can significantly improve the moisture resistance of NMC batteries. These binders create hydrophobic interfaces between particles and reduce water absorption within the electrode structure. Advanced polymer binders with cross-linking capabilities or fluorinated compounds provide superior protection against moisture while maintaining good adhesion and electrical conductivity within the electrode.Expand Specific Solutions03 Encapsulation and packaging solutions

Innovative encapsulation and packaging technologies protect NMC batteries from environmental moisture. These include moisture-resistant cell casings, advanced sealing methods, and multi-layer barrier films that prevent water vapor ingress. Some solutions incorporate desiccant materials within the battery packaging to absorb any moisture that might penetrate the outer barriers, providing an additional layer of protection.Expand Specific Solutions04 Moisture-resistant electrode manufacturing processes

Specialized manufacturing processes can enhance the moisture resistance of NMC battery electrodes. These include dry-room processing, vacuum drying protocols, and heat treatment methods that minimize water content in the final product. Some approaches involve solvent selection and processing parameters that reduce hygroscopic properties of the electrode materials, resulting in batteries with improved stability under humid conditions.Expand Specific Solutions05 Moisture detection and monitoring systems

Advanced sensor technologies and monitoring systems can detect moisture ingress in NMC batteries before damage occurs. These systems use various detection principles including electrical impedance measurements, optical sensors, or chemical indicators that change properties when exposed to moisture. Early detection allows for preventive measures to be taken before battery performance is compromised, extending the operational lifetime in humid environments.Expand Specific Solutions

Leading Companies in Battery Moisture Protection Solutions

The NMC battery moisture resistance measurement market is currently in a growth phase, with increasing demand driven by electric vehicle and energy storage applications. The market size is expanding rapidly as battery manufacturers seek to enhance product reliability and safety. Technologically, the field is advancing with companies like Contemporary Amperex Technology (CATL), LG Energy Solution, and QuantumScape leading innovation in moisture resistance metrics. Robert Bosch and Toyota Motor Corp. are developing standardized testing protocols, while academic institutions such as Mississippi State University and Hong Kong Polytechnic University contribute fundamental research. The competition is intensifying as battery manufacturers and automotive companies collaborate to establish industry benchmarks for moisture resistance that can predict battery performance and longevity under various environmental conditions.

Contemporary Amperex Technology Co., Ltd.

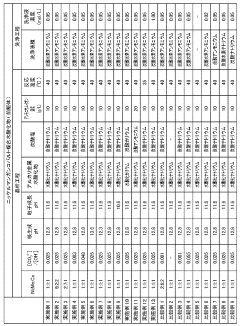

Technical Solution: CATL has developed a comprehensive moisture resistance evaluation system for NMC batteries that combines multiple scientific metrics. Their approach utilizes Karl Fischer titration to quantify trace water content with precision down to ppm levels, coupled with electrochemical impedance spectroscopy (EIS) to monitor internal resistance changes caused by moisture ingress. CATL implements accelerated aging tests in controlled humidity chambers (40-85% RH) to evaluate long-term moisture effects, while using differential scanning calorimetry to assess thermal stability changes due to moisture exposure. Their moisture resistance metrics include water vapor transmission rate (WVTR) measurements for packaging materials and specialized pouch cell testing with moisture sensors integrated into the cell architecture to provide real-time data on internal humidity levels. This multi-parameter approach allows for comprehensive qualification of battery moisture resistance across various operating conditions.

Strengths: Industry-leading comprehensive testing methodology combining multiple scientific parameters; real-time moisture monitoring capability; correlation of moisture metrics with battery performance degradation. Weaknesses: Complex testing protocols require specialized equipment; longer evaluation cycles compared to simplified testing; higher implementation costs for full moisture resistance characterization.

Robert Bosch GmbH

Technical Solution: Bosch has developed a systematic approach to measuring NMC battery moisture resistance using multiple scientific metrics. Their methodology incorporates precision dew point sensors with ±0.2°C accuracy to monitor moisture levels during manufacturing and testing processes. Bosch employs a proprietary impedance spectroscopy technique that isolates moisture-related degradation mechanisms from other aging factors, allowing for specific quantification of moisture impacts on cell performance. Their testing protocol includes controlled moisture exposure chambers where cells undergo cycling while exposed to precisely regulated humidity levels (30-90% RH), with continuous monitoring of capacity retention, internal resistance, and self-discharge rates. Bosch has established correlation models between moisture ingress rates and specific electrochemical signatures in differential voltage analysis (DVA) curves, enabling early detection of moisture-related degradation. Additionally, they utilize gas chromatography-mass spectrometry to analyze electrolyte composition changes resulting from moisture reactions, providing quantitative metrics for electrolyte degradation due to water contamination.

Strengths: Highly precise moisture measurement capabilities; established correlation between moisture metrics and specific degradation mechanisms; integration of moisture resistance testing into manufacturing quality control. Weaknesses: Proprietary testing methodologies limit standardization across industry; complex analytical equipment requirements; longer testing duration needed for comprehensive moisture resistance characterization.

Key Technical Innovations in Battery Moisture Testing

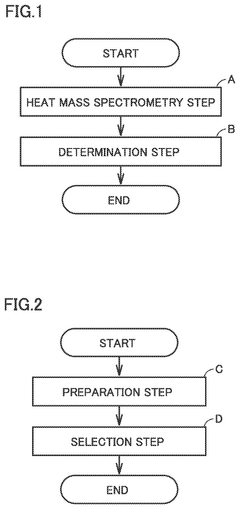

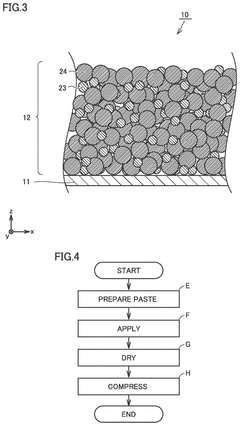

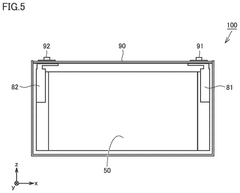

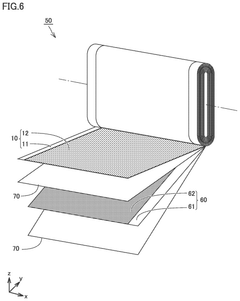

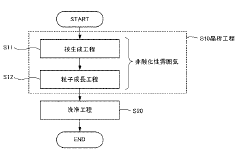

Selection method and production method of nickel-cobalt-manganese-based active material for positive electrode

PatentPendingUS20240347721A1

Innovation

- A selection and production method for nickel-cobalt-manganese-based active materials involving heat mass spectrometry to determine a mass decrease rate, ensuring the material satisfies a specific expression, which reduces storage gas production and enhances battery performance by using single crystal particles and optimizing nickel content.

Nickel manganese cobalt composite hydroxide, method for manufacturing the same, and lithium nickel manganese cobalt composite oxide

PatentActiveJP2019106241A

Innovation

- A method involving a controlled crystallization atmosphere and washing with an ammonium hydrogen carbonate solution to produce a nickel-manganese-cobalt composite hydroxide with a sodium content less than 0.0005% by mass, and a specific surface area of 10 to 20 m²/g, resulting in a precursor for a positive electrode active material with improved battery characteristics.

Environmental Impact of Moisture-Related Battery Degradation

The environmental implications of moisture-related battery degradation extend far beyond the immediate performance issues of NMC (Nickel Manganese Cobalt) batteries. When moisture compromises battery integrity, it initiates a cascade of environmental consequences that merit serious consideration in sustainability assessments.

Moisture-induced degradation accelerates the end-of-life timeline for NMC batteries, directly contributing to increased electronic waste generation. With global lithium-ion battery deployment expanding exponentially, premature battery failures due to moisture exposure could potentially add millions of units to waste streams annually. This represents not only a loss of valuable resources but also creates additional pressure on recycling infrastructure that is already struggling to keep pace with battery disposal volumes.

The environmental footprint of replacement batteries must also be considered. Manufacturing new NMC batteries to replace moisture-damaged units requires significant energy inputs and raw material extraction. Each kilogram of lithium-ion battery production generates approximately 75kg of CO2 equivalent emissions. Consequently, premature replacements due to moisture damage multiply these environmental impacts unnecessarily.

Water contamination presents another critical concern. When moisture-damaged batteries leak electrolyte solutions containing fluorinated compounds, heavy metals, and lithium salts, these substances can contaminate soil and water systems. Studies have documented that even small concentrations of these battery components can disrupt aquatic ecosystems and potentially enter food chains.

The carbon intensity of battery manufacturing makes moisture resistance particularly relevant to climate change mitigation efforts. Extending battery lifespan through improved moisture resistance directly translates to carbon emission reductions across the product lifecycle. Calculations suggest that each year of extended battery life can reduce lifecycle emissions by approximately 7-10% per battery unit.

Energy security dimensions also emerge when considering large-scale battery deployments. Grid storage systems and electric vehicle fleets vulnerable to moisture damage could experience unexpected capacity losses during critical periods, potentially triggering increased reliance on fossil fuel backup systems during transition periods.

Developing standardized moisture resistance metrics for NMC batteries would enable more accurate lifecycle assessments and environmental impact projections. Such metrics would allow manufacturers, policymakers, and consumers to make informed decisions that minimize the environmental footprint of battery technologies while maximizing their contribution to sustainable energy systems.

Moisture-induced degradation accelerates the end-of-life timeline for NMC batteries, directly contributing to increased electronic waste generation. With global lithium-ion battery deployment expanding exponentially, premature battery failures due to moisture exposure could potentially add millions of units to waste streams annually. This represents not only a loss of valuable resources but also creates additional pressure on recycling infrastructure that is already struggling to keep pace with battery disposal volumes.

The environmental footprint of replacement batteries must also be considered. Manufacturing new NMC batteries to replace moisture-damaged units requires significant energy inputs and raw material extraction. Each kilogram of lithium-ion battery production generates approximately 75kg of CO2 equivalent emissions. Consequently, premature replacements due to moisture damage multiply these environmental impacts unnecessarily.

Water contamination presents another critical concern. When moisture-damaged batteries leak electrolyte solutions containing fluorinated compounds, heavy metals, and lithium salts, these substances can contaminate soil and water systems. Studies have documented that even small concentrations of these battery components can disrupt aquatic ecosystems and potentially enter food chains.

The carbon intensity of battery manufacturing makes moisture resistance particularly relevant to climate change mitigation efforts. Extending battery lifespan through improved moisture resistance directly translates to carbon emission reductions across the product lifecycle. Calculations suggest that each year of extended battery life can reduce lifecycle emissions by approximately 7-10% per battery unit.

Energy security dimensions also emerge when considering large-scale battery deployments. Grid storage systems and electric vehicle fleets vulnerable to moisture damage could experience unexpected capacity losses during critical periods, potentially triggering increased reliance on fossil fuel backup systems during transition periods.

Developing standardized moisture resistance metrics for NMC batteries would enable more accurate lifecycle assessments and environmental impact projections. Such metrics would allow manufacturers, policymakers, and consumers to make informed decisions that minimize the environmental footprint of battery technologies while maximizing their contribution to sustainable energy systems.

Standardization Efforts for Moisture Resistance Testing

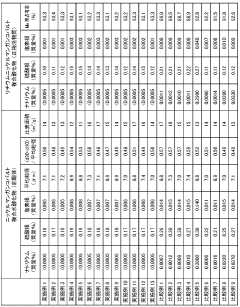

The standardization of moisture resistance testing for NMC (Nickel Manganese Cobalt) batteries represents a critical advancement in ensuring battery quality and safety across the industry. Currently, several international organizations are actively working to establish unified protocols and metrics for moisture resistance evaluation, including the International Electrotechnical Commission (IEC), ASTM International, and the IEEE Standards Association.

The IEC Technical Committee 21 has been particularly instrumental in developing standard IEC 62281, which addresses safety aspects of lithium batteries during transport, including moisture exposure considerations. This standard is being expanded to incorporate specific moisture resistance parameters for NMC cathode materials, with proposed metrics including water vapor transmission rate (WVTR) and moisture absorption capacity under controlled humidity conditions.

ASTM International's Committee D09 on Electrical and Electronic Insulating Materials has initiated a working group focused specifically on standardizing moisture resistance testing methodologies for battery materials. Their draft standard proposes a comprehensive testing framework that includes Karl Fischer titration protocols, environmental chamber testing parameters, and accelerated aging procedures to simulate long-term moisture exposure effects.

The Battery Standards Testing Committee within IEEE is developing a complementary standard that emphasizes reproducibility and comparability of moisture resistance data across different laboratory environments. Their approach incorporates statistical validation methods and round-robin testing among multiple facilities to ensure test reliability. This standard specifically addresses the unique challenges of NMC chemistry, including the varying moisture sensitivity of different NMC formulations (NMC 111, 532, 622, and 811).

Industry consortia, including the International Battery Materials Association (IBMA), have established technical committees dedicated to harmonizing proprietary testing methods from major battery manufacturers. Their efforts focus on creating a tiered classification system for moisture resistance, ranging from Level 1 (minimal resistance) to Level 5 (exceptional resistance), providing a standardized benchmark for material comparison.

The China Automotive Technology and Research Center (CATARC) has proposed national standards that are gaining international attention, particularly their detailed protocols for measuring moisture-induced gas generation and structural degradation in NMC materials. These standards incorporate innovative metrics such as moisture-induced impedance change (MIIC) and hygroscopic expansion coefficient (HEC) that provide more comprehensive evaluation of material performance under humid conditions.

The IEC Technical Committee 21 has been particularly instrumental in developing standard IEC 62281, which addresses safety aspects of lithium batteries during transport, including moisture exposure considerations. This standard is being expanded to incorporate specific moisture resistance parameters for NMC cathode materials, with proposed metrics including water vapor transmission rate (WVTR) and moisture absorption capacity under controlled humidity conditions.

ASTM International's Committee D09 on Electrical and Electronic Insulating Materials has initiated a working group focused specifically on standardizing moisture resistance testing methodologies for battery materials. Their draft standard proposes a comprehensive testing framework that includes Karl Fischer titration protocols, environmental chamber testing parameters, and accelerated aging procedures to simulate long-term moisture exposure effects.

The Battery Standards Testing Committee within IEEE is developing a complementary standard that emphasizes reproducibility and comparability of moisture resistance data across different laboratory environments. Their approach incorporates statistical validation methods and round-robin testing among multiple facilities to ensure test reliability. This standard specifically addresses the unique challenges of NMC chemistry, including the varying moisture sensitivity of different NMC formulations (NMC 111, 532, 622, and 811).

Industry consortia, including the International Battery Materials Association (IBMA), have established technical committees dedicated to harmonizing proprietary testing methods from major battery manufacturers. Their efforts focus on creating a tiered classification system for moisture resistance, ranging from Level 1 (minimal resistance) to Level 5 (exceptional resistance), providing a standardized benchmark for material comparison.

The China Automotive Technology and Research Center (CATARC) has proposed national standards that are gaining international attention, particularly their detailed protocols for measuring moisture-induced gas generation and structural degradation in NMC materials. These standards incorporate innovative metrics such as moisture-induced impedance change (MIIC) and hygroscopic expansion coefficient (HEC) that provide more comprehensive evaluation of material performance under humid conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!