Measure NMC Battery's Intrinsic Stability Using Quality Assurance

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Stability Assessment Background and Objectives

Lithium-ion batteries with nickel-manganese-cobalt (NMC) cathodes have emerged as a dominant technology in the energy storage landscape, powering everything from consumer electronics to electric vehicles and grid-scale storage systems. The evolution of NMC battery technology has been marked by continuous improvements in energy density, cycle life, and safety characteristics, driven by the growing demand for high-performance energy storage solutions across multiple industries.

The historical development of NMC batteries can be traced back to the early 2000s when researchers began exploring alternatives to traditional lithium cobalt oxide (LCO) cathodes. This exploration was motivated by concerns about cobalt's cost, supply chain vulnerabilities, and environmental impact. The introduction of nickel and manganese into the cathode composition represented a significant breakthrough, offering improved stability and reduced cobalt content while maintaining high energy density.

Over the past decade, NMC formulations have evolved from early NMC111 (equal parts nickel, manganese, and cobalt) to more nickel-rich compositions such as NMC532, NMC622, and NMC811. This trend toward higher nickel content has been driven by the pursuit of greater energy density, but it has simultaneously introduced new challenges related to thermal and structural stability.

The intrinsic stability of NMC batteries represents a critical factor in their performance, safety, and longevity. Stability issues can manifest in various forms, including capacity fade, thermal runaway, gas generation, and structural degradation of the cathode material. These phenomena are influenced by multiple factors, including chemical composition, synthesis methods, operating conditions, and aging mechanisms.

Quality assurance (QA) methodologies have traditionally focused on end-product testing rather than fundamental material properties. However, there is growing recognition that measuring intrinsic stability parameters during the manufacturing process could provide earlier indicators of potential performance issues and safety risks. This shift toward proactive stability assessment represents a paradigm change in battery quality control.

The primary objective of this technical research is to develop and validate comprehensive methodologies for measuring the intrinsic stability of NMC batteries within a quality assurance framework. This includes identifying key stability indicators, establishing standardized testing protocols, correlating intrinsic properties with long-term performance, and integrating these measurements into existing manufacturing processes without significantly impacting production efficiency or costs.

Additionally, this research aims to establish clear relationships between measurable stability parameters and real-world battery performance across various operating conditions and use cases. By developing predictive models based on these relationships, manufacturers could potentially identify and address stability issues earlier in the production process, leading to improved product quality, enhanced safety, and reduced warranty claims.

The historical development of NMC batteries can be traced back to the early 2000s when researchers began exploring alternatives to traditional lithium cobalt oxide (LCO) cathodes. This exploration was motivated by concerns about cobalt's cost, supply chain vulnerabilities, and environmental impact. The introduction of nickel and manganese into the cathode composition represented a significant breakthrough, offering improved stability and reduced cobalt content while maintaining high energy density.

Over the past decade, NMC formulations have evolved from early NMC111 (equal parts nickel, manganese, and cobalt) to more nickel-rich compositions such as NMC532, NMC622, and NMC811. This trend toward higher nickel content has been driven by the pursuit of greater energy density, but it has simultaneously introduced new challenges related to thermal and structural stability.

The intrinsic stability of NMC batteries represents a critical factor in their performance, safety, and longevity. Stability issues can manifest in various forms, including capacity fade, thermal runaway, gas generation, and structural degradation of the cathode material. These phenomena are influenced by multiple factors, including chemical composition, synthesis methods, operating conditions, and aging mechanisms.

Quality assurance (QA) methodologies have traditionally focused on end-product testing rather than fundamental material properties. However, there is growing recognition that measuring intrinsic stability parameters during the manufacturing process could provide earlier indicators of potential performance issues and safety risks. This shift toward proactive stability assessment represents a paradigm change in battery quality control.

The primary objective of this technical research is to develop and validate comprehensive methodologies for measuring the intrinsic stability of NMC batteries within a quality assurance framework. This includes identifying key stability indicators, establishing standardized testing protocols, correlating intrinsic properties with long-term performance, and integrating these measurements into existing manufacturing processes without significantly impacting production efficiency or costs.

Additionally, this research aims to establish clear relationships between measurable stability parameters and real-world battery performance across various operating conditions and use cases. By developing predictive models based on these relationships, manufacturers could potentially identify and address stability issues earlier in the production process, leading to improved product quality, enhanced safety, and reduced warranty claims.

Market Demand Analysis for High-Stability NMC Batteries

The global market for high-stability NMC (Nickel Manganese Cobalt) batteries has experienced significant growth in recent years, driven primarily by the expanding electric vehicle (EV) sector and increasing demand for high-performance energy storage solutions. Market research indicates that the NMC battery segment currently represents approximately 28% of the total lithium-ion battery market, with projections showing continued growth through 2030.

Consumer electronics manufacturers are increasingly demanding batteries with enhanced stability profiles, as device safety concerns remain paramount for brand reputation and regulatory compliance. This demand is particularly evident in premium smartphone and laptop segments, where manufacturers are willing to pay premium prices for batteries that demonstrate superior thermal stability and longer cycle life.

The automotive sector represents the largest and fastest-growing market segment for high-stability NMC batteries. Major automakers have publicly committed to electrification strategies that will require massive battery supply chain scaling. These manufacturers specifically seek NMC chemistries that balance energy density with stability, as vehicle applications demand both performance and safety assurances that can be verified through quality control processes.

Grid-scale energy storage represents another emerging market with substantial growth potential for stable NMC formulations. Utility companies are increasingly deploying battery storage systems to complement renewable energy generation, with stability and longevity being critical factors in technology selection due to the high replacement costs and safety requirements of large installations.

Market analysis reveals a clear price premium for NMC batteries with demonstrated stability advantages. Batteries that can verify their intrinsic stability through quality assurance processes command 15-20% higher prices compared to standard alternatives. This premium reflects the downstream value these batteries provide through reduced warranty claims, enhanced safety profiles, and improved brand reputation.

Regulatory trends are further accelerating market demand for stability verification methods. The European Union's proposed Battery Regulation includes provisions for battery passport systems that would require detailed documentation of performance characteristics, including stability metrics. Similar regulatory frameworks are under development in North America and Asia, creating a global compliance incentive for manufacturers to implement advanced stability testing.

Consumer awareness regarding battery safety has increased following high-profile incidents involving thermal runaway in portable electronics and EVs. This awareness translates to market pressure for transparent quality assurance processes that can verify battery stability before products reach end users, creating pull-through demand for measurement technologies that can reliably assess NMC stability during manufacturing.

Consumer electronics manufacturers are increasingly demanding batteries with enhanced stability profiles, as device safety concerns remain paramount for brand reputation and regulatory compliance. This demand is particularly evident in premium smartphone and laptop segments, where manufacturers are willing to pay premium prices for batteries that demonstrate superior thermal stability and longer cycle life.

The automotive sector represents the largest and fastest-growing market segment for high-stability NMC batteries. Major automakers have publicly committed to electrification strategies that will require massive battery supply chain scaling. These manufacturers specifically seek NMC chemistries that balance energy density with stability, as vehicle applications demand both performance and safety assurances that can be verified through quality control processes.

Grid-scale energy storage represents another emerging market with substantial growth potential for stable NMC formulations. Utility companies are increasingly deploying battery storage systems to complement renewable energy generation, with stability and longevity being critical factors in technology selection due to the high replacement costs and safety requirements of large installations.

Market analysis reveals a clear price premium for NMC batteries with demonstrated stability advantages. Batteries that can verify their intrinsic stability through quality assurance processes command 15-20% higher prices compared to standard alternatives. This premium reflects the downstream value these batteries provide through reduced warranty claims, enhanced safety profiles, and improved brand reputation.

Regulatory trends are further accelerating market demand for stability verification methods. The European Union's proposed Battery Regulation includes provisions for battery passport systems that would require detailed documentation of performance characteristics, including stability metrics. Similar regulatory frameworks are under development in North America and Asia, creating a global compliance incentive for manufacturers to implement advanced stability testing.

Consumer awareness regarding battery safety has increased following high-profile incidents involving thermal runaway in portable electronics and EVs. This awareness translates to market pressure for transparent quality assurance processes that can verify battery stability before products reach end users, creating pull-through demand for measurement technologies that can reliably assess NMC stability during manufacturing.

Current Challenges in NMC Battery Stability Measurement

The measurement of intrinsic stability in NMC (Nickel Manganese Cobalt) batteries presents significant challenges that impede accurate quality assurance processes. Current methodologies suffer from inconsistency across different testing environments, making standardization difficult. Temperature variations during testing can dramatically alter results, as NMC cathode materials exhibit different degradation patterns at varying thermal conditions. This creates substantial obstacles for establishing reliable baseline measurements across the industry.

Accelerated aging tests, widely used for stability assessment, often fail to accurately simulate real-world degradation mechanisms. The correlation between laboratory-induced stress conditions and actual field performance remains questionable, particularly for newer high-nickel NMC formulations (NMC811, NMC622) which demonstrate different failure modes than their predecessors. This disconnect between testing protocols and practical applications undermines confidence in stability predictions.

Measurement precision issues further complicate stability assessment. Detecting subtle changes in electrochemical performance that indicate early-stage degradation requires highly sensitive instrumentation. Many current testing systems lack sufficient resolution to identify incremental capacity changes that precede catastrophic failure. Additionally, the industry faces challenges in distinguishing between intrinsic material instability and degradation caused by external factors such as manufacturing defects or cell assembly variations.

Cross-contamination during sample preparation represents another significant challenge. Trace impurities introduced during electrode fabrication or electrolyte preparation can dramatically influence stability measurements, leading to false conclusions about material performance. The sensitivity of NMC materials to moisture and oxygen exposure during testing further complicates obtaining reproducible results.

Data interpretation presents perhaps the most complex challenge. The multifaceted nature of degradation mechanisms in NMC batteries—including structural changes, surface film formation, transition metal dissolution, and gas evolution—makes it difficult to develop comprehensive stability metrics. Current analytical approaches often focus on isolated parameters rather than integrating multiple degradation indicators into cohesive stability models.

The lack of industry-wide consensus on appropriate testing protocols creates additional barriers. Different manufacturers employ varied methodologies for stability assessment, making direct comparisons between products nearly impossible. This fragmentation hinders the development of universal quality assurance standards that could accelerate innovation and improve safety across the industry.

Finally, there exists a fundamental gap between accelerated testing timeframes and the expected service life of modern NMC batteries. Quality assurance protocols must predict stability over 8-10 years based on tests conducted over weeks or months, creating inherent uncertainty in long-term performance predictions.

Accelerated aging tests, widely used for stability assessment, often fail to accurately simulate real-world degradation mechanisms. The correlation between laboratory-induced stress conditions and actual field performance remains questionable, particularly for newer high-nickel NMC formulations (NMC811, NMC622) which demonstrate different failure modes than their predecessors. This disconnect between testing protocols and practical applications undermines confidence in stability predictions.

Measurement precision issues further complicate stability assessment. Detecting subtle changes in electrochemical performance that indicate early-stage degradation requires highly sensitive instrumentation. Many current testing systems lack sufficient resolution to identify incremental capacity changes that precede catastrophic failure. Additionally, the industry faces challenges in distinguishing between intrinsic material instability and degradation caused by external factors such as manufacturing defects or cell assembly variations.

Cross-contamination during sample preparation represents another significant challenge. Trace impurities introduced during electrode fabrication or electrolyte preparation can dramatically influence stability measurements, leading to false conclusions about material performance. The sensitivity of NMC materials to moisture and oxygen exposure during testing further complicates obtaining reproducible results.

Data interpretation presents perhaps the most complex challenge. The multifaceted nature of degradation mechanisms in NMC batteries—including structural changes, surface film formation, transition metal dissolution, and gas evolution—makes it difficult to develop comprehensive stability metrics. Current analytical approaches often focus on isolated parameters rather than integrating multiple degradation indicators into cohesive stability models.

The lack of industry-wide consensus on appropriate testing protocols creates additional barriers. Different manufacturers employ varied methodologies for stability assessment, making direct comparisons between products nearly impossible. This fragmentation hinders the development of universal quality assurance standards that could accelerate innovation and improve safety across the industry.

Finally, there exists a fundamental gap between accelerated testing timeframes and the expected service life of modern NMC batteries. Quality assurance protocols must predict stability over 8-10 years based on tests conducted over weeks or months, creating inherent uncertainty in long-term performance predictions.

Existing Quality Assurance Protocols for NMC Batteries

01 Composition modifications for enhanced NMC stability

Various compositional modifications can enhance the intrinsic stability of NMC batteries. These include doping with stabilizing elements, optimizing the nickel-manganese-cobalt ratio, and incorporating protective coatings on cathode particles. These modifications help mitigate structural degradation during cycling, reduce oxygen release at high voltages, and improve thermal stability, resulting in batteries with longer cycle life and improved safety characteristics.- Composition modifications for enhanced NMC stability: Various compositional modifications can enhance the intrinsic stability of NMC batteries. These include doping with stabilizing elements, optimizing the nickel-manganese-cobalt ratio, and incorporating protective coatings on cathode particles. Such modifications help mitigate structural degradation during cycling, reduce oxygen release at high voltages, and improve thermal stability, thereby enhancing the overall safety and longevity of NMC batteries.

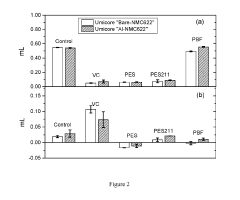

- Advanced electrolyte formulations for NMC stability: Specialized electrolyte formulations play a crucial role in maintaining NMC battery stability. These formulations may include additives that form stable solid-electrolyte interfaces, flame-retardant components that enhance safety, and compounds that prevent cathode dissolution. By optimizing the electrolyte composition, the chemical and electrochemical stability of NMC batteries can be significantly improved, leading to better cycling performance and reduced capacity fade.

- Structural engineering for improved NMC stability: Structural engineering approaches focus on modifying the crystal structure and morphology of NMC materials to enhance stability. These include developing core-shell structures, controlling particle size and shape, and engineering grain boundaries. Such structural modifications help prevent phase transitions during cycling, maintain structural integrity at high voltages, and improve resistance to mechanical stress, resulting in more stable NMC batteries with extended cycle life.

- Thermal management systems for NMC stability: Effective thermal management systems are essential for maintaining the intrinsic stability of NMC batteries. These systems include advanced cooling mechanisms, heat dissipation materials, and temperature monitoring technologies. By preventing thermal runaway and maintaining optimal operating temperatures, these systems help preserve the structural integrity of NMC cathodes, prevent unwanted side reactions, and significantly enhance the safety and stability of NMC batteries during operation.

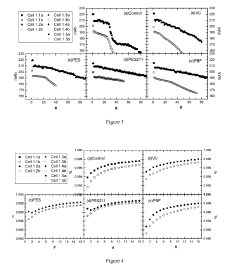

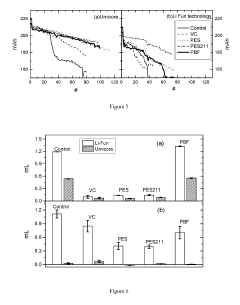

- Advanced characterization and testing methods for NMC stability: Sophisticated characterization and testing methodologies are crucial for evaluating and improving the intrinsic stability of NMC batteries. These include in-situ/operando spectroscopic techniques, accelerated aging protocols, and computational modeling approaches. Such methods enable researchers to understand degradation mechanisms at the atomic level, predict long-term stability, and develop targeted strategies to enhance the intrinsic stability of NMC battery materials under various operating conditions.

02 Structural engineering for improved thermal stability

Structural engineering approaches focus on creating more stable crystal structures in NMC cathode materials. This includes developing core-shell structures, concentration gradients, and single-crystal morphologies that resist cracking and degradation. These structural modifications help maintain cathode integrity during thermal stress and high-voltage operation, reducing capacity fade and enhancing the overall intrinsic stability of NMC batteries.Expand Specific Solutions03 Electrolyte formulations for stabilizing NMC interfaces

Specialized electrolyte formulations can significantly improve the stability of interfaces between NMC cathodes and electrolytes. These formulations include additives that form stable solid-electrolyte interphase layers, reduce transition metal dissolution, and suppress parasitic reactions. By protecting the cathode surface and preventing side reactions, these electrolyte systems enhance the intrinsic stability of NMC batteries during long-term cycling and storage.Expand Specific Solutions04 Advanced battery management systems for stability control

Advanced battery management systems (BMS) play a crucial role in maintaining NMC battery stability. These systems employ sophisticated algorithms to monitor and control charging/discharging parameters, temperature distribution, and cell balancing. By preventing operation in unstable voltage and temperature regions, these management systems extend battery life, enhance safety, and preserve the intrinsic stability of NMC cells under various operating conditions.Expand Specific Solutions05 Novel synthesis methods for stable NMC materials

Innovative synthesis methods can produce NMC cathode materials with superior intrinsic stability. These include co-precipitation techniques with precise control over particle morphology, sol-gel methods that ensure homogeneous element distribution, and low-temperature processing that minimizes defect formation. These advanced synthesis approaches result in cathode materials with more uniform structures, fewer defects, and enhanced resistance to degradation mechanisms that compromise battery stability.Expand Specific Solutions

Critical Technologies for Intrinsic Stability Measurement

Lithium ion batteries, electronic devices, and methods

PatentActiveUS20190207246A1

Innovation

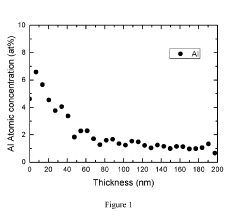

- A rechargeable lithium ion battery design featuring a positive electrode with surface-modified lithium nickel manganese cobalt oxide particles coated with Al2O3 and a nonaqueous liquid electrolyte containing specific additives, such as prop-1-ene-1,3-sultone, tris(trimethylsilyl)phosphite, and methylene methanedisulfonate, to enhance stability and reduce gas generation.

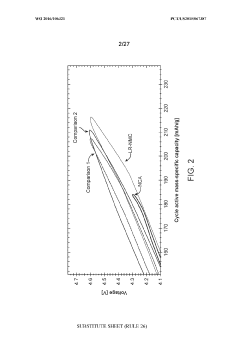

Lithium rich nickel manganese cobalt oxide (LR-NMC)

PatentWO2016106321A1

Innovation

- Development of lithium-rich nickel manganese cobalt oxide (LR-NMC) materials with specific chemical compositions and manufacturing methods that include varying ratios of nickel, manganese, and cobalt, and the use of lithium-containing salts to stabilize lithium within the crystal lattice, resulting in enhanced energy density and cycle lifetimes.

Safety Standards and Compliance Requirements

The safety standards and compliance requirements for NMC (Nickel Manganese Cobalt) batteries have evolved significantly in response to increasing concerns about battery safety in various applications. International standards such as IEC 62133, UL 1642, and UN 38.3 establish the baseline requirements for lithium-ion batteries, including NMC chemistry. These standards mandate specific testing protocols for evaluating intrinsic stability, including thermal abuse tests, short circuit tests, overcharge protection, and mechanical integrity assessments.

For measuring NMC battery's intrinsic stability within quality assurance frameworks, manufacturers must adhere to the IEC 61960 standard, which specifically addresses performance measurements for rechargeable lithium cells and batteries. This standard outlines procedures for capacity measurement, cycle life testing, and storage characteristics that directly correlate with stability metrics.

The automotive industry has implemented more stringent requirements through ISO 26262 and UN ECE R100, which specifically address functional safety and battery performance in electric vehicles. These standards require comprehensive stability testing under various operational conditions, including temperature extremes, vibration, and shock resistance.

Recent regulatory developments have placed greater emphasis on cell-level safety testing, with particular focus on thermal runaway prevention. The SAE J2464 standard provides detailed procedures for abuse testing of lithium-ion batteries, while EUCAR hazard levels classify the severity of battery failures from 0 (no effect) to 7 (explosion).

Quality assurance programs must incorporate these standards into systematic testing protocols. This includes accelerated aging tests under controlled conditions to predict long-term stability, differential scanning calorimetry (DSC) to measure thermal stability of electrode materials, and electrochemical impedance spectroscopy (EIS) to detect internal resistance changes indicative of degradation.

Compliance documentation requirements have also expanded, with manufacturers now expected to maintain detailed records of stability testing throughout the production process. This includes batch testing data, statistical process control charts, and traceability information linking raw materials to finished cells.

Emerging standards are increasingly focusing on in-situ monitoring capabilities, requiring battery management systems that can continuously evaluate stability parameters during operation. This trend reflects the growing recognition that intrinsic stability must be monitored throughout the battery lifecycle, not just during initial qualification testing.

For measuring NMC battery's intrinsic stability within quality assurance frameworks, manufacturers must adhere to the IEC 61960 standard, which specifically addresses performance measurements for rechargeable lithium cells and batteries. This standard outlines procedures for capacity measurement, cycle life testing, and storage characteristics that directly correlate with stability metrics.

The automotive industry has implemented more stringent requirements through ISO 26262 and UN ECE R100, which specifically address functional safety and battery performance in electric vehicles. These standards require comprehensive stability testing under various operational conditions, including temperature extremes, vibration, and shock resistance.

Recent regulatory developments have placed greater emphasis on cell-level safety testing, with particular focus on thermal runaway prevention. The SAE J2464 standard provides detailed procedures for abuse testing of lithium-ion batteries, while EUCAR hazard levels classify the severity of battery failures from 0 (no effect) to 7 (explosion).

Quality assurance programs must incorporate these standards into systematic testing protocols. This includes accelerated aging tests under controlled conditions to predict long-term stability, differential scanning calorimetry (DSC) to measure thermal stability of electrode materials, and electrochemical impedance spectroscopy (EIS) to detect internal resistance changes indicative of degradation.

Compliance documentation requirements have also expanded, with manufacturers now expected to maintain detailed records of stability testing throughout the production process. This includes batch testing data, statistical process control charts, and traceability information linking raw materials to finished cells.

Emerging standards are increasingly focusing on in-situ monitoring capabilities, requiring battery management systems that can continuously evaluate stability parameters during operation. This trend reflects the growing recognition that intrinsic stability must be monitored throughout the battery lifecycle, not just during initial qualification testing.

Economic Impact of Improved NMC Battery Stability

The economic implications of enhancing NMC (Nickel Manganese Cobalt) battery stability extend far beyond the immediate technological benefits, potentially transforming multiple sectors of the global economy. Improved stability in NMC batteries directly translates to extended battery life cycles, which significantly reduces the total cost of ownership for end users across consumer electronics, electric vehicles, and industrial applications.

In the electric vehicle sector, where battery costs represent approximately 30-40% of the vehicle's total cost, enhanced stability could reduce replacement frequency and warranty claims, potentially decreasing manufacturing costs by 15-20% over a five-year period. This cost reduction could accelerate EV adoption rates by making electric vehicles more financially competitive with traditional combustion engine vehicles, potentially expanding the global EV market from $140 billion in 2021 to an estimated $700 billion by 2030.

For grid storage applications, improved NMC battery stability addresses a critical economic barrier to renewable energy integration. Current limitations in battery longevity necessitate frequent replacements in large-scale energy storage systems, significantly impacting the levelized cost of stored energy (LCOSE). Enhanced stability could reduce LCOSE by up to 25%, making renewable energy storage economically viable for wider deployment and accelerating the transition away from fossil fuels.

The consumer electronics industry would also experience substantial economic benefits from improved NMC battery stability. With global smartphone sales exceeding 1.3 billion units annually, extending battery lifespan could reduce electronic waste by millions of tons per year, translating to significant savings in materials, manufacturing, and environmental remediation costs estimated at $8-12 billion annually.

From a macroeconomic perspective, advancements in NMC battery stability could reshape global supply chains and resource allocation. The reduced demand for raw materials per unit of energy storage capacity would alleviate pressure on critical mineral supplies, potentially stabilizing prices for nickel, cobalt, and lithium. This stability would have cascading effects throughout manufacturing ecosystems, potentially reducing inflationary pressures in technology sectors.

Furthermore, improved battery stability creates new economic opportunities in battery refurbishment, recycling, and second-life applications. The emergence of these circular economy business models could generate an estimated $15-20 billion market by 2030, creating thousands of specialized jobs while simultaneously reducing environmental impact and resource consumption.

In the electric vehicle sector, where battery costs represent approximately 30-40% of the vehicle's total cost, enhanced stability could reduce replacement frequency and warranty claims, potentially decreasing manufacturing costs by 15-20% over a five-year period. This cost reduction could accelerate EV adoption rates by making electric vehicles more financially competitive with traditional combustion engine vehicles, potentially expanding the global EV market from $140 billion in 2021 to an estimated $700 billion by 2030.

For grid storage applications, improved NMC battery stability addresses a critical economic barrier to renewable energy integration. Current limitations in battery longevity necessitate frequent replacements in large-scale energy storage systems, significantly impacting the levelized cost of stored energy (LCOSE). Enhanced stability could reduce LCOSE by up to 25%, making renewable energy storage economically viable for wider deployment and accelerating the transition away from fossil fuels.

The consumer electronics industry would also experience substantial economic benefits from improved NMC battery stability. With global smartphone sales exceeding 1.3 billion units annually, extending battery lifespan could reduce electronic waste by millions of tons per year, translating to significant savings in materials, manufacturing, and environmental remediation costs estimated at $8-12 billion annually.

From a macroeconomic perspective, advancements in NMC battery stability could reshape global supply chains and resource allocation. The reduced demand for raw materials per unit of energy storage capacity would alleviate pressure on critical mineral supplies, potentially stabilizing prices for nickel, cobalt, and lithium. This stability would have cascading effects throughout manufacturing ecosystems, potentially reducing inflationary pressures in technology sectors.

Furthermore, improved battery stability creates new economic opportunities in battery refurbishment, recycling, and second-life applications. The emergence of these circular economy business models could generate an estimated $15-20 billion market by 2030, creating thousands of specialized jobs while simultaneously reducing environmental impact and resource consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!