Measure NMC Battery's Current Flow Within Nanostructured Systems

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Nanostructure Measurement Background and Objectives

The evolution of lithium-ion batteries has been a cornerstone of modern energy storage technology, with NMC (Nickel Manganese Cobalt) cathode materials emerging as a dominant chemistry due to their superior energy density and cycle life. Understanding current flow within these materials at the nanoscale represents a critical frontier in battery research, as it directly impacts performance, degradation mechanisms, and overall battery efficiency.

Historically, battery research has progressed from macroscopic to microscopic understanding, with recent advances in nanotechnology enabling unprecedented insights into electrochemical processes. The ability to measure and characterize current flow within nanostructured NMC systems has become increasingly important as manufacturers push the boundaries of energy density and fast-charging capabilities.

The primary objective of this technical investigation is to develop and validate methodologies for precise measurement of current distribution within NMC battery nanostructures during operation. This includes quantifying electron transport pathways, identifying rate-limiting steps in the charge transfer process, and mapping spatial heterogeneities in current density across active material interfaces.

Current measurement techniques face significant limitations when applied to nanoscale battery components. Traditional electrochemical methods provide bulk measurements but lack spatial resolution, while advanced microscopy techniques offer structural insights but struggle with dynamic electrical characterization during battery operation. This technological gap necessitates innovative approaches combining multiple measurement modalities.

Recent developments in scanning probe microscopy, operando transmission electron microscopy, and synchrotron-based X-ray techniques have begun to address these challenges, enabling researchers to visualize electrochemical processes at unprecedented resolution. However, correlating these measurements with actual current flow remains challenging due to the complex three-dimensional architecture of battery electrodes and the dynamic nature of ion movement during cycling.

The trajectory of measurement technology in this field shows a clear trend toward multi-modal characterization, combining electrical, chemical, and structural information to build comprehensive models of nanoscale current flow. This evolution parallels advances in computational modeling, which increasingly serves as both a predictive tool and an interpretive framework for experimental data.

This investigation aims to establish standardized protocols for nanoscale current measurement in NMC systems, enabling more accurate prediction of battery performance, identification of degradation mechanisms, and ultimately informing the design of next-generation high-performance battery materials with optimized nanostructures for specific applications.

Historically, battery research has progressed from macroscopic to microscopic understanding, with recent advances in nanotechnology enabling unprecedented insights into electrochemical processes. The ability to measure and characterize current flow within nanostructured NMC systems has become increasingly important as manufacturers push the boundaries of energy density and fast-charging capabilities.

The primary objective of this technical investigation is to develop and validate methodologies for precise measurement of current distribution within NMC battery nanostructures during operation. This includes quantifying electron transport pathways, identifying rate-limiting steps in the charge transfer process, and mapping spatial heterogeneities in current density across active material interfaces.

Current measurement techniques face significant limitations when applied to nanoscale battery components. Traditional electrochemical methods provide bulk measurements but lack spatial resolution, while advanced microscopy techniques offer structural insights but struggle with dynamic electrical characterization during battery operation. This technological gap necessitates innovative approaches combining multiple measurement modalities.

Recent developments in scanning probe microscopy, operando transmission electron microscopy, and synchrotron-based X-ray techniques have begun to address these challenges, enabling researchers to visualize electrochemical processes at unprecedented resolution. However, correlating these measurements with actual current flow remains challenging due to the complex three-dimensional architecture of battery electrodes and the dynamic nature of ion movement during cycling.

The trajectory of measurement technology in this field shows a clear trend toward multi-modal characterization, combining electrical, chemical, and structural information to build comprehensive models of nanoscale current flow. This evolution parallels advances in computational modeling, which increasingly serves as both a predictive tool and an interpretive framework for experimental data.

This investigation aims to establish standardized protocols for nanoscale current measurement in NMC systems, enabling more accurate prediction of battery performance, identification of degradation mechanisms, and ultimately informing the design of next-generation high-performance battery materials with optimized nanostructures for specific applications.

Market Analysis for Advanced Battery Characterization Technologies

The advanced battery characterization technology market is experiencing robust growth, driven by the increasing demand for high-performance energy storage solutions across multiple industries. Currently valued at approximately $2.3 billion, this market is projected to reach $4.1 billion by 2028, representing a compound annual growth rate of 12.3%. This growth is primarily fueled by the expanding electric vehicle (EV) sector, which requires sophisticated battery testing and measurement technologies to ensure safety, reliability, and optimal performance.

The demand for precise current flow measurement technologies within nanostructured battery systems, particularly for NMC (Nickel Manganese Cobalt) batteries, represents a significant segment of this market. As NMC batteries continue to dominate the EV and consumer electronics sectors due to their high energy density and relatively stable thermal properties, manufacturers are increasingly investing in advanced characterization tools to optimize battery design and performance.

Regional analysis reveals that Asia-Pacific currently leads the market with a 42% share, driven by the concentration of battery manufacturing facilities in China, South Korea, and Japan. North America follows with 28% market share, with significant research activities in national laboratories and academic institutions focusing on next-generation battery technologies. Europe accounts for 24% of the market, with strong growth potential due to stringent environmental regulations and substantial investments in renewable energy infrastructure.

Key customer segments include battery manufacturers (38%), automotive OEMs (27%), research institutions (18%), and consumer electronics companies (12%). The remaining 5% consists of aerospace, defense, and emerging energy storage applications. These stakeholders are increasingly demanding more sophisticated measurement tools capable of characterizing nanoscale phenomena within battery materials.

Market trends indicate a shift toward non-invasive measurement techniques that can provide real-time data on current distribution within battery cells without compromising structural integrity. Technologies such as magnetic resonance imaging (MRI), neutron diffraction, and synchrotron X-ray techniques are gaining traction, though their high cost remains a barrier to widespread adoption.

The competitive landscape features established analytical instrument manufacturers like Keysight Technologies, Bruker Corporation, and JEOL, alongside specialized battery testing equipment providers such as Arbin Instruments and Biologic. Recent market entrants include startups developing AI-enhanced measurement systems that can predict battery performance and degradation patterns based on nanoscale current flow data.

The demand for precise current flow measurement technologies within nanostructured battery systems, particularly for NMC (Nickel Manganese Cobalt) batteries, represents a significant segment of this market. As NMC batteries continue to dominate the EV and consumer electronics sectors due to their high energy density and relatively stable thermal properties, manufacturers are increasingly investing in advanced characterization tools to optimize battery design and performance.

Regional analysis reveals that Asia-Pacific currently leads the market with a 42% share, driven by the concentration of battery manufacturing facilities in China, South Korea, and Japan. North America follows with 28% market share, with significant research activities in national laboratories and academic institutions focusing on next-generation battery technologies. Europe accounts for 24% of the market, with strong growth potential due to stringent environmental regulations and substantial investments in renewable energy infrastructure.

Key customer segments include battery manufacturers (38%), automotive OEMs (27%), research institutions (18%), and consumer electronics companies (12%). The remaining 5% consists of aerospace, defense, and emerging energy storage applications. These stakeholders are increasingly demanding more sophisticated measurement tools capable of characterizing nanoscale phenomena within battery materials.

Market trends indicate a shift toward non-invasive measurement techniques that can provide real-time data on current distribution within battery cells without compromising structural integrity. Technologies such as magnetic resonance imaging (MRI), neutron diffraction, and synchrotron X-ray techniques are gaining traction, though their high cost remains a barrier to widespread adoption.

The competitive landscape features established analytical instrument manufacturers like Keysight Technologies, Bruker Corporation, and JEOL, alongside specialized battery testing equipment providers such as Arbin Instruments and Biologic. Recent market entrants include startups developing AI-enhanced measurement systems that can predict battery performance and degradation patterns based on nanoscale current flow data.

Current Challenges in Nano-scale Current Flow Measurement

Measuring current flow at the nanoscale within NMC (Nickel Manganese Cobalt) battery systems presents significant technical challenges that impede comprehensive understanding of electrochemical processes. The primary difficulty lies in the spatial resolution limitations of conventional current measurement techniques when applied to nanostructured battery components. Traditional methods such as electrochemical impedance spectroscopy (EIS) provide bulk measurements but fail to capture localized current distributions within individual nanoparticles or at critical interfaces.

The dynamic nature of electrochemical reactions in NMC batteries further complicates measurement efforts. Current flow patterns change rapidly during charge-discharge cycles, with reaction fronts moving through the material at varying rates depending on state of charge, temperature, and aging effects. Capturing these transient phenomena requires measurement techniques with both high spatial and temporal resolution—a combination that remains elusive with current technology.

Environmental sensitivity presents another major obstacle. NMC battery systems operate in sealed environments with specific electrolyte compositions and under controlled atmospheric conditions. Introducing measurement probes often disrupts these carefully balanced environments, potentially altering the very phenomena being measured. This observer effect creates significant uncertainty in data interpretation and limits the applicability of many advanced microscopy techniques.

Signal-to-noise ratio challenges are particularly acute at the nanoscale. Current flows in individual nanostructures can be in the pico to femtoampere range, requiring extremely sensitive detection systems. Background electrical noise, thermal fluctuations, and electromagnetic interference can easily overwhelm these minute signals, necessitating sophisticated shielding and signal processing approaches that add complexity to measurement systems.

Non-invasive measurement techniques remain underdeveloped for battery nanostructures. While scanning probe microscopy methods like conductive atomic force microscopy (C-AFM) offer nanoscale resolution, they typically require direct contact with the sample surface, potentially altering local electrical properties. Similarly, electron beam-based techniques can induce charging effects or damage sensitive battery materials.

Correlation challenges between different measurement scales further complicate comprehensive analysis. Researchers struggle to connect nanoscale current measurements with macroscale battery performance metrics, creating a significant gap in multi-scale modeling efforts. This disconnect limits the practical application of nanoscale insights to commercial battery development and optimization.

Calibration and standardization of nanoscale current measurements remain inconsistent across research groups, hampering reproducibility and comparative analysis. The lack of universally accepted reference materials and measurement protocols for nanostructured battery systems creates barriers to collaborative advancement in the field and slows the validation of new measurement methodologies.

The dynamic nature of electrochemical reactions in NMC batteries further complicates measurement efforts. Current flow patterns change rapidly during charge-discharge cycles, with reaction fronts moving through the material at varying rates depending on state of charge, temperature, and aging effects. Capturing these transient phenomena requires measurement techniques with both high spatial and temporal resolution—a combination that remains elusive with current technology.

Environmental sensitivity presents another major obstacle. NMC battery systems operate in sealed environments with specific electrolyte compositions and under controlled atmospheric conditions. Introducing measurement probes often disrupts these carefully balanced environments, potentially altering the very phenomena being measured. This observer effect creates significant uncertainty in data interpretation and limits the applicability of many advanced microscopy techniques.

Signal-to-noise ratio challenges are particularly acute at the nanoscale. Current flows in individual nanostructures can be in the pico to femtoampere range, requiring extremely sensitive detection systems. Background electrical noise, thermal fluctuations, and electromagnetic interference can easily overwhelm these minute signals, necessitating sophisticated shielding and signal processing approaches that add complexity to measurement systems.

Non-invasive measurement techniques remain underdeveloped for battery nanostructures. While scanning probe microscopy methods like conductive atomic force microscopy (C-AFM) offer nanoscale resolution, they typically require direct contact with the sample surface, potentially altering local electrical properties. Similarly, electron beam-based techniques can induce charging effects or damage sensitive battery materials.

Correlation challenges between different measurement scales further complicate comprehensive analysis. Researchers struggle to connect nanoscale current measurements with macroscale battery performance metrics, creating a significant gap in multi-scale modeling efforts. This disconnect limits the practical application of nanoscale insights to commercial battery development and optimization.

Calibration and standardization of nanoscale current measurements remain inconsistent across research groups, hampering reproducibility and comparative analysis. The lack of universally accepted reference materials and measurement protocols for nanostructured battery systems creates barriers to collaborative advancement in the field and slows the validation of new measurement methodologies.

State-of-the-Art Nanostructured Current Flow Measurement Methods

01 Current flow mechanisms in NMC battery electrodes

The current flow in NMC (Nickel Manganese Cobalt) battery electrodes involves complex electrochemical processes. During charging and discharging, lithium ions move between the cathode and anode, generating electrical current. The NMC cathode material's composition affects the efficiency of electron transfer and ion movement. The microstructure and crystalline arrangement of NMC materials significantly impact the pathways for current flow, influencing overall battery performance and capacity.- Current flow mechanisms in NMC battery electrodes: The current flow in NMC (Nickel Manganese Cobalt) battery electrodes involves complex electrochemical processes. The lithium ions move through the electrolyte while electrons flow through the external circuit during charge and discharge cycles. The conductivity of the electrode materials significantly affects the current flow efficiency. Understanding these mechanisms is crucial for optimizing battery performance and longevity.

- Monitoring and control systems for NMC battery current: Advanced monitoring and control systems are essential for managing current flow in NMC batteries. These systems typically include sensors to measure current, voltage, and temperature parameters in real-time. The collected data is processed to optimize charging protocols, prevent overcurrent conditions, and ensure safe operation. Implementing effective control mechanisms helps extend battery life and maintain performance efficiency.

- Thermal management related to current flow in NMC batteries: Current flow in NMC batteries generates heat that must be properly managed to maintain optimal performance and safety. Thermal management systems are designed to dissipate excess heat and maintain uniform temperature distribution across the battery cells. Effective thermal management prevents hotspots, reduces degradation mechanisms, and helps maintain consistent current flow throughout the battery's operational life.

- Current collector design for NMC battery applications: The design of current collectors significantly impacts the overall current flow in NMC batteries. Optimized current collector materials, geometries, and interfaces with active materials can reduce internal resistance and improve current distribution. Advanced current collector designs incorporate features that enhance electrical conductivity, mechanical stability, and electrochemical performance, resulting in more efficient energy storage and delivery.

- Degradation mechanisms affecting current flow in NMC batteries: Various degradation mechanisms can affect current flow in NMC batteries over time. These include electrode material structural changes, solid-electrolyte interphase (SEI) layer growth, and lithium plating. Understanding these degradation processes is essential for developing strategies to mitigate their effects and maintain efficient current flow throughout the battery's lifecycle. Advanced characterization techniques help identify and quantify these degradation mechanisms.

02 Monitoring and measurement of current flow in NMC batteries

Various techniques and systems have been developed to monitor and measure current flow in NMC batteries. These include advanced sensors that can detect current distribution across battery cells, diagnostic tools that analyze current patterns to identify potential issues, and measurement systems that provide real-time data on battery performance. Accurate current flow measurement is essential for battery management systems to optimize charging protocols, prevent overheating, and extend battery life.Expand Specific Solutions03 Current flow optimization in NMC battery systems

Optimizing current flow in NMC battery systems involves several approaches including electrode design modifications, electrolyte formulation improvements, and thermal management strategies. Enhanced current collectors with optimized geometries can reduce internal resistance and improve current distribution. Advanced electrolyte compositions facilitate better ion transport between electrodes. Thermal management systems help maintain optimal operating temperatures, preventing hotspots that can impede current flow and degrade battery performance.Expand Specific Solutions04 Current flow control in NMC battery management systems

Battery management systems for NMC batteries incorporate sophisticated current flow control mechanisms. These systems regulate charging and discharging rates to prevent damage from excessive current. Intelligent algorithms adjust current flow based on battery state, temperature, and usage patterns. Protection circuits prevent dangerous current surges and short circuits. Advanced control systems can balance current across multiple cells in a battery pack, ensuring uniform performance and extending overall battery lifespan.Expand Specific Solutions05 Current flow impacts on NMC battery degradation and safety

Current flow patterns significantly affect NMC battery degradation and safety. High current rates can accelerate capacity fade through increased mechanical stress on electrode materials and accelerated side reactions. Uneven current distribution can create localized heating and accelerate degradation in specific areas of the battery. Safety issues such as thermal runaway can result from excessive current flow. Understanding these relationships helps in developing safer NMC batteries with improved cycle life through better current management strategies and structural designs that distribute current more evenly.Expand Specific Solutions

Leading Research Groups and Companies in Battery Diagnostics

The NMC battery current flow measurement within nanostructured systems market is in a growth phase, characterized by increasing research activity and commercial interest. The market size is expanding as electric vehicle adoption accelerates, with projections indicating significant growth in the next decade. Technologically, this field remains in early maturity, with key players demonstrating varying levels of advancement. Panasonic, Texas Instruments, and Hitachi lead in commercial applications, while research institutions like CSIC, University of California, and Chongqing University drive fundamental innovations. Renesas and Siemens are developing specialized measurement systems, while Google's AI capabilities enhance data analysis. The convergence of academic research and industrial implementation suggests this technology is approaching broader commercialization despite remaining measurement challenges at nanoscale.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed advanced in-situ measurement techniques for NMC (Nickel Manganese Cobalt) battery systems that utilize nanoscale current collectors and specialized electrode architectures. Their approach incorporates high-precision impedance spectroscopy combined with scanning probe microscopy to map current distribution across nanostructured cathode materials at sub-100nm resolution. The technology employs custom-designed microelectrodes that can detect localized current flows within individual NMC particles during charge/discharge cycles. Panasonic's system integrates real-time data acquisition with thermal management controls to maintain stable measurement conditions, allowing researchers to observe dynamic changes in ionic and electronic conductivity pathways through the electrode matrix. Their proprietary algorithms compensate for measurement artifacts and provide three-dimensional current flow visualization within complex nanostructured battery systems.

Strengths: Superior spatial resolution allowing visualization of current pathways at nanoscale; integrated thermal management for stable measurements; comprehensive data analysis capabilities. Weaknesses: Requires specialized equipment with high maintenance costs; limited throughput for mass production testing; measurements can be affected by probe-sample interactions.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed a comprehensive solution for measuring current flow in NMC battery nanostructures through their precision analog front-end (AFE) technology. Their approach integrates ultra-low-noise current sensing amplifiers with high-resolution analog-to-digital converters specifically calibrated for the unique challenges of nanoscale battery measurements. The system employs a multi-channel architecture that can simultaneously monitor current distribution across different regions of nanostructured electrodes with picoampere sensitivity. TI's solution incorporates temperature compensation algorithms that adjust for thermal drift effects, ensuring measurement accuracy across operating conditions. Their specialized sensor interfaces are designed to minimize perturbation of the electrochemical system while maintaining signal integrity. The technology includes proprietary digital signal processing techniques that filter electromagnetic interference and extract meaningful current flow patterns from background noise. TI's system enables researchers to characterize localized current hotspots and identify preferential lithium-ion transport pathways within complex nanostructured NMC cathode materials.

Strengths: Industry-leading signal-to-noise ratio for detecting minute current variations; scalable architecture suitable for both laboratory and production environments; comprehensive software tools for data analysis. Weaknesses: Requires integration with specialized probes for nanoscale spatial resolution; limited direct visualization capabilities compared to microscopy-based approaches; higher power consumption during continuous monitoring.

Key Technologies for NMC Battery Nanoscale Current Mapping

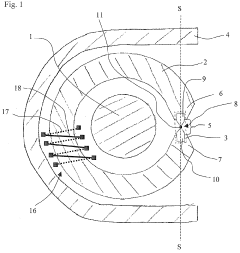

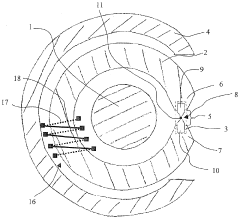

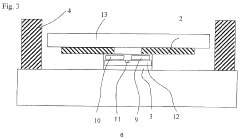

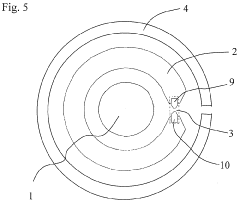

Device for measuring current flowing through current conductor for indicating charging condition of battery, has magnetic element and concentrator with end areas, and shield surrounding concentrator, where end areas overlap with each other

PatentInactiveCH702264A1

Innovation

- A compact and cost-effective current measurement device utilizing a ring concentrator made from ferromagnetic material with a thin, optimized design and a dual magnet field sensor setup, integrated with a Halbleiterchip, to measure currents with minimal magnetic resistance and reduced material usage, allowing for efficient measurement across a wide range of currents.

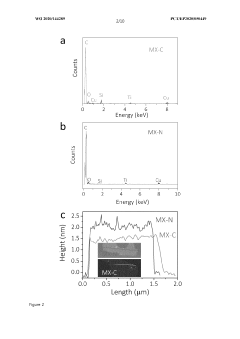

High capacity electrodes enabled by 2d materials in a viscous aqueous ink

PatentWO2020144289A1

Innovation

- Employing two-dimensional conductive materials like MXene nanosheets, transition metal dichalcogenides, or graphene as a conductive binder without additional polymeric binders or carbon black to form a segregated network that enhances mechanical properties and conductivity, allowing for the creation of thick electrodes with high areal capacity.

Safety and Reliability Considerations for Nanoscale Battery Testing

When conducting nanoscale testing of NMC (Nickel Manganese Cobalt) battery systems, safety and reliability considerations become paramount due to the unique challenges presented by nanostructured materials. The high energy density and reactive nature of NMC materials necessitate stringent safety protocols during current flow measurement experiments.

Primary safety concerns include thermal runaway risks, which are amplified at the nanoscale due to increased surface reactivity and reduced thermal dissipation pathways. Researchers must implement robust temperature monitoring systems with millisecond response times to detect early signs of thermal anomalies. Additionally, specialized containment systems designed specifically for nanoscale testing environments are essential to prevent potential hazardous material release.

Electrical safety presents another critical dimension, as measurement systems must be properly isolated and grounded to prevent unintended current paths or short circuits. The high precision instruments used for nanoscale current measurements are particularly susceptible to damage from electrical transients, requiring sophisticated protection circuitry and careful experimental design.

Reliability in nanoscale current flow measurements demands meticulous attention to environmental controls. Factors such as humidity, ambient electromagnetic fields, and mechanical vibrations can significantly impact measurement accuracy at the nanoscale. Advanced environmental chambers with precise control capabilities are typically required to ensure reproducible results.

Sample preparation consistency represents a major reliability challenge. The nanostructured nature of advanced NMC battery systems means that minor variations in sample preparation can lead to substantial differences in measured current flow characteristics. Standardized protocols with rigorous quality control checkpoints must be established to minimize these variations.

Data validation methodologies are equally important for reliable nanoscale testing. Multiple measurement techniques should be employed in parallel to cross-validate results, with statistical analysis frameworks specifically adapted for nanoscale phenomena. This multi-method approach helps distinguish genuine current flow patterns from measurement artifacts.

Long-term stability testing protocols must also be developed to assess how nanostructured NMC systems perform over extended operational periods. Accelerated aging techniques, when carefully calibrated, can provide insights into degradation mechanisms that might otherwise take years to manifest in real-world applications.

Finally, regulatory compliance must be considered, as nanomaterials often face additional scrutiny due to their unique properties. Testing protocols should align with emerging standards from organizations such as ISO, ASTM, and IEC that specifically address nanomaterial characterization and safety assessment methodologies.

Primary safety concerns include thermal runaway risks, which are amplified at the nanoscale due to increased surface reactivity and reduced thermal dissipation pathways. Researchers must implement robust temperature monitoring systems with millisecond response times to detect early signs of thermal anomalies. Additionally, specialized containment systems designed specifically for nanoscale testing environments are essential to prevent potential hazardous material release.

Electrical safety presents another critical dimension, as measurement systems must be properly isolated and grounded to prevent unintended current paths or short circuits. The high precision instruments used for nanoscale current measurements are particularly susceptible to damage from electrical transients, requiring sophisticated protection circuitry and careful experimental design.

Reliability in nanoscale current flow measurements demands meticulous attention to environmental controls. Factors such as humidity, ambient electromagnetic fields, and mechanical vibrations can significantly impact measurement accuracy at the nanoscale. Advanced environmental chambers with precise control capabilities are typically required to ensure reproducible results.

Sample preparation consistency represents a major reliability challenge. The nanostructured nature of advanced NMC battery systems means that minor variations in sample preparation can lead to substantial differences in measured current flow characteristics. Standardized protocols with rigorous quality control checkpoints must be established to minimize these variations.

Data validation methodologies are equally important for reliable nanoscale testing. Multiple measurement techniques should be employed in parallel to cross-validate results, with statistical analysis frameworks specifically adapted for nanoscale phenomena. This multi-method approach helps distinguish genuine current flow patterns from measurement artifacts.

Long-term stability testing protocols must also be developed to assess how nanostructured NMC systems perform over extended operational periods. Accelerated aging techniques, when carefully calibrated, can provide insights into degradation mechanisms that might otherwise take years to manifest in real-world applications.

Finally, regulatory compliance must be considered, as nanomaterials often face additional scrutiny due to their unique properties. Testing protocols should align with emerging standards from organizations such as ISO, ASTM, and IEC that specifically address nanomaterial characterization and safety assessment methodologies.

Environmental Impact of Advanced Battery Characterization Methods

The environmental implications of advanced battery characterization methods, particularly for measuring current flow in NMC (Nickel Manganese Cobalt) battery nanostructured systems, present significant considerations for sustainable technology development. These sophisticated measurement techniques often require specialized equipment and materials that carry their own environmental footprint.

Traditional characterization methods typically involve energy-intensive processes and potentially hazardous chemicals. For instance, electron microscopy techniques used to visualize nanostructured battery components require substantial energy consumption during operation and sample preparation. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) systems, essential for nanoscale current flow analysis, consume between 5-15 kW during operation, contributing to indirect carbon emissions.

Chemical processes involved in sample preparation for NMC battery characterization often utilize solvents like N-Methyl-2-pyrrolidone (NMP) and dimethyl carbonate, which can pose environmental risks if improperly handled or disposed. These chemicals may contribute to air quality degradation and water contamination if released into the environment without proper treatment protocols.

Advanced in-situ and operando measurement techniques, while providing valuable real-time data on current flow within nanostructured systems, typically require specialized containment systems and controlled environments that increase resource consumption. Synchrotron-based X-ray techniques, increasingly used for non-destructive battery analysis, require large-scale facilities with substantial energy demands, though they offer advantages through reduced sample preparation requirements.

Recent developments in green characterization methodologies show promising directions for reducing environmental impact. Non-destructive testing approaches enable multiple measurements on single samples, reducing material waste. Additionally, computational modeling and simulation techniques are increasingly complementing physical measurements, potentially reducing the need for extensive physical testing and associated environmental costs.

Life cycle assessment studies indicate that the environmental benefits of improved battery performance resulting from advanced characterization methods generally outweigh the environmental costs of the characterization processes themselves. By enabling more efficient NMC batteries with longer lifespans and improved energy density, these methods contribute to reduced overall environmental impact across battery life cycles.

Future development of characterization technologies should prioritize reduced energy consumption, minimized use of hazardous materials, and increased measurement efficiency to further mitigate environmental impacts while advancing our understanding of current flow in nanostructured battery systems.

Traditional characterization methods typically involve energy-intensive processes and potentially hazardous chemicals. For instance, electron microscopy techniques used to visualize nanostructured battery components require substantial energy consumption during operation and sample preparation. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) systems, essential for nanoscale current flow analysis, consume between 5-15 kW during operation, contributing to indirect carbon emissions.

Chemical processes involved in sample preparation for NMC battery characterization often utilize solvents like N-Methyl-2-pyrrolidone (NMP) and dimethyl carbonate, which can pose environmental risks if improperly handled or disposed. These chemicals may contribute to air quality degradation and water contamination if released into the environment without proper treatment protocols.

Advanced in-situ and operando measurement techniques, while providing valuable real-time data on current flow within nanostructured systems, typically require specialized containment systems and controlled environments that increase resource consumption. Synchrotron-based X-ray techniques, increasingly used for non-destructive battery analysis, require large-scale facilities with substantial energy demands, though they offer advantages through reduced sample preparation requirements.

Recent developments in green characterization methodologies show promising directions for reducing environmental impact. Non-destructive testing approaches enable multiple measurements on single samples, reducing material waste. Additionally, computational modeling and simulation techniques are increasingly complementing physical measurements, potentially reducing the need for extensive physical testing and associated environmental costs.

Life cycle assessment studies indicate that the environmental benefits of improved battery performance resulting from advanced characterization methods generally outweigh the environmental costs of the characterization processes themselves. By enabling more efficient NMC batteries with longer lifespans and improved energy density, these methods contribute to reduced overall environmental impact across battery life cycles.

Future development of characterization technologies should prioritize reduced energy consumption, minimized use of hazardous materials, and increased measurement efficiency to further mitigate environmental impacts while advancing our understanding of current flow in nanostructured battery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!