How to Test NMC Battery's Capability in Remote Sensing Operations

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Testing Background and Objectives

Lithium-ion batteries with Nickel Manganese Cobalt (NMC) cathodes have emerged as a critical power source for remote sensing operations due to their high energy density, relatively long cycle life, and improved thermal stability compared to earlier lithium-ion chemistries. The evolution of NMC battery technology has progressed from first-generation formulations with equal parts nickel, manganese, and cobalt (NMC 111) to advanced compositions like NMC 811, which contains higher nickel content for enhanced energy density.

Remote sensing operations present unique challenges for battery performance, including exposure to extreme temperature fluctuations, extended deployment periods without maintenance access, and requirements for high reliability in mission-critical applications. These operational demands necessitate comprehensive testing protocols that go beyond standard battery evaluation methods used in consumer electronics or even automotive applications.

The primary objective of NMC battery testing for remote sensing applications is to accurately predict performance and longevity under the specific environmental and operational conditions encountered in field deployments. This includes evaluating capacity retention at temperature extremes (-40°C to +85°C), cycle life under partial discharge conditions typical of solar-powered remote sensing systems, and self-discharge rates during dormant periods.

Historical testing approaches have often failed to adequately simulate the complex duty cycles experienced in remote sensing operations, leading to discrepancies between laboratory test results and actual field performance. Traditional testing methods typically focus on continuous discharge profiles or simple charge-discharge cycles that do not reflect the intermittent power demands and environmental stresses of remote sensing equipment.

Recent advancements in battery testing methodologies have introduced more sophisticated approaches, including hardware-in-the-loop simulation, accelerated aging protocols calibrated specifically for environmental extremes, and non-invasive diagnostic techniques that can detect early indicators of performance degradation without disrupting operation.

The technical goals for NMC battery testing in remote sensing applications include developing standardized protocols that accurately predict battery performance over 3-5 year deployment periods, establishing clear correlations between accelerated testing results and real-world longevity, and identifying key performance indicators that can be monitored remotely to predict impending battery failures before they impact mission operations.

Additionally, there is growing interest in understanding the impact of emerging NMC chemistries, such as silicon-doped anodes and solid-state electrolytes, on remote sensing applications, particularly regarding their potential to extend operational temperature ranges and improve safety in environmentally sensitive deployment areas.

Remote sensing operations present unique challenges for battery performance, including exposure to extreme temperature fluctuations, extended deployment periods without maintenance access, and requirements for high reliability in mission-critical applications. These operational demands necessitate comprehensive testing protocols that go beyond standard battery evaluation methods used in consumer electronics or even automotive applications.

The primary objective of NMC battery testing for remote sensing applications is to accurately predict performance and longevity under the specific environmental and operational conditions encountered in field deployments. This includes evaluating capacity retention at temperature extremes (-40°C to +85°C), cycle life under partial discharge conditions typical of solar-powered remote sensing systems, and self-discharge rates during dormant periods.

Historical testing approaches have often failed to adequately simulate the complex duty cycles experienced in remote sensing operations, leading to discrepancies between laboratory test results and actual field performance. Traditional testing methods typically focus on continuous discharge profiles or simple charge-discharge cycles that do not reflect the intermittent power demands and environmental stresses of remote sensing equipment.

Recent advancements in battery testing methodologies have introduced more sophisticated approaches, including hardware-in-the-loop simulation, accelerated aging protocols calibrated specifically for environmental extremes, and non-invasive diagnostic techniques that can detect early indicators of performance degradation without disrupting operation.

The technical goals for NMC battery testing in remote sensing applications include developing standardized protocols that accurately predict battery performance over 3-5 year deployment periods, establishing clear correlations between accelerated testing results and real-world longevity, and identifying key performance indicators that can be monitored remotely to predict impending battery failures before they impact mission operations.

Additionally, there is growing interest in understanding the impact of emerging NMC chemistries, such as silicon-doped anodes and solid-state electrolytes, on remote sensing applications, particularly regarding their potential to extend operational temperature ranges and improve safety in environmentally sensitive deployment areas.

Remote Sensing Market Requirements Analysis

The remote sensing market has experienced significant growth in recent years, driven by increasing demand for Earth observation data across various sectors. The global remote sensing market was valued at approximately $15.8 billion in 2021 and is projected to reach $29.4 billion by 2027, growing at a CAGR of 10.8%. This expansion is fueled by technological advancements in satellite technology, increasing applications in environmental monitoring, and growing investments in space infrastructure.

For NMC (Nickel Manganese Cobalt) batteries in remote sensing operations, market requirements are becoming increasingly stringent. Remote sensing platforms, particularly satellites and unmanned aerial vehicles (UAVs), require power sources that can withstand extreme environmental conditions while maintaining consistent performance. Temperature variations in space environments can range from -170°C to +120°C, necessitating batteries with exceptional thermal stability and performance consistency across this range.

Energy density requirements for remote sensing applications typically demand 250-350 Wh/kg, significantly higher than conventional applications. This is particularly critical for small satellites and CubeSats where weight and volume constraints are paramount. The market also demands cycle life exceeding 1,000 cycles at 80% depth of discharge to ensure mission longevity, which can span 5-7 years for typical Earth observation satellites.

Reliability metrics for batteries in remote sensing operations are exceptionally high, with failure rates expected to be below 0.1% over the mission lifetime. This is driven by the impossibility or extreme cost of maintenance or replacement once deployed. Additionally, radiation resistance has emerged as a critical requirement, with batteries needing to maintain performance despite exposure to cosmic radiation levels of 10-100 krad over their operational lifetime.

The defense and intelligence sectors represent the largest market segment for high-performance batteries in remote sensing, accounting for 38% of the market share. Environmental monitoring applications follow at 27%, with agriculture, urban planning, and disaster management collectively representing another 25% of market demand.

Regional analysis indicates North America leads the market with 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is experiencing the fastest growth at 14.2% annually, driven by increasing investments in space programs by China, India, and Japan. This regional growth is creating new demand patterns for high-performance battery technologies specifically tailored to remote sensing applications.

For NMC (Nickel Manganese Cobalt) batteries in remote sensing operations, market requirements are becoming increasingly stringent. Remote sensing platforms, particularly satellites and unmanned aerial vehicles (UAVs), require power sources that can withstand extreme environmental conditions while maintaining consistent performance. Temperature variations in space environments can range from -170°C to +120°C, necessitating batteries with exceptional thermal stability and performance consistency across this range.

Energy density requirements for remote sensing applications typically demand 250-350 Wh/kg, significantly higher than conventional applications. This is particularly critical for small satellites and CubeSats where weight and volume constraints are paramount. The market also demands cycle life exceeding 1,000 cycles at 80% depth of discharge to ensure mission longevity, which can span 5-7 years for typical Earth observation satellites.

Reliability metrics for batteries in remote sensing operations are exceptionally high, with failure rates expected to be below 0.1% over the mission lifetime. This is driven by the impossibility or extreme cost of maintenance or replacement once deployed. Additionally, radiation resistance has emerged as a critical requirement, with batteries needing to maintain performance despite exposure to cosmic radiation levels of 10-100 krad over their operational lifetime.

The defense and intelligence sectors represent the largest market segment for high-performance batteries in remote sensing, accounting for 38% of the market share. Environmental monitoring applications follow at 27%, with agriculture, urban planning, and disaster management collectively representing another 25% of market demand.

Regional analysis indicates North America leads the market with 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is experiencing the fastest growth at 14.2% annually, driven by increasing investments in space programs by China, India, and Japan. This regional growth is creating new demand patterns for high-performance battery technologies specifically tailored to remote sensing applications.

Current Challenges in NMC Battery Testing for Remote Applications

Testing NMC (Nickel Manganese Cobalt) batteries for remote sensing operations presents several significant challenges that impact both the reliability of testing procedures and the accuracy of performance predictions. The remote and often harsh environments where these batteries are deployed create unique testing demands that conventional laboratory methods fail to address adequately.

One primary challenge is simulating the extreme temperature variations that remote sensing equipment experiences. NMC batteries deployed in remote locations may face temperature fluctuations from -40°C to +60°C, depending on geographical location and seasonal changes. Standard testing protocols typically evaluate battery performance within a much narrower temperature range, leading to potential performance gaps when deployed in real-world scenarios. Creating comprehensive testing environments that accurately replicate these conditions requires specialized equipment and extended testing periods.

Intermittent energy harvesting patterns present another significant challenge. Remote sensing devices often rely on solar or other renewable energy sources that provide inconsistent charging patterns. Testing protocols must account for these irregular charging cycles, which differ substantially from the controlled charging environments of laboratory settings. The battery's response to partial charging, extended idle periods, and sudden power demands significantly impacts its longevity and reliability in field operations.

The extended deployment duration of remote sensing equipment further complicates testing procedures. While accelerated aging tests exist, they often fail to accurately predict how NMC batteries will perform after years of operation in variable conditions. The chemical degradation mechanisms under field conditions may differ from those observed in accelerated laboratory tests, creating a disconnect between test results and actual performance.

Vibration and physical stress during transportation and deployment represent another testing challenge. Remote sensing equipment may be subjected to significant mechanical stress during installation and operation, particularly in areas with seismic activity or extreme weather events. Current testing methodologies struggle to combine these mechanical stressors with electrical performance testing in integrated protocols.

Data collection and transmission limitations also impact testing effectiveness. Remote batteries often lack the sophisticated monitoring systems available in controlled environments, making it difficult to gather comprehensive performance data. Testing protocols must account for this limited telemetry and develop methods to extrapolate performance characteristics from minimal data points.

Finally, there is a significant challenge in standardization across the industry. Different manufacturers and research institutions employ varying testing methodologies, making it difficult to compare results and establish reliable benchmarks for remote sensing applications. The absence of universally accepted testing standards specifically designed for remote deployment scenarios creates inconsistency in performance evaluation and product selection.

One primary challenge is simulating the extreme temperature variations that remote sensing equipment experiences. NMC batteries deployed in remote locations may face temperature fluctuations from -40°C to +60°C, depending on geographical location and seasonal changes. Standard testing protocols typically evaluate battery performance within a much narrower temperature range, leading to potential performance gaps when deployed in real-world scenarios. Creating comprehensive testing environments that accurately replicate these conditions requires specialized equipment and extended testing periods.

Intermittent energy harvesting patterns present another significant challenge. Remote sensing devices often rely on solar or other renewable energy sources that provide inconsistent charging patterns. Testing protocols must account for these irregular charging cycles, which differ substantially from the controlled charging environments of laboratory settings. The battery's response to partial charging, extended idle periods, and sudden power demands significantly impacts its longevity and reliability in field operations.

The extended deployment duration of remote sensing equipment further complicates testing procedures. While accelerated aging tests exist, they often fail to accurately predict how NMC batteries will perform after years of operation in variable conditions. The chemical degradation mechanisms under field conditions may differ from those observed in accelerated laboratory tests, creating a disconnect between test results and actual performance.

Vibration and physical stress during transportation and deployment represent another testing challenge. Remote sensing equipment may be subjected to significant mechanical stress during installation and operation, particularly in areas with seismic activity or extreme weather events. Current testing methodologies struggle to combine these mechanical stressors with electrical performance testing in integrated protocols.

Data collection and transmission limitations also impact testing effectiveness. Remote batteries often lack the sophisticated monitoring systems available in controlled environments, making it difficult to gather comprehensive performance data. Testing protocols must account for this limited telemetry and develop methods to extrapolate performance characteristics from minimal data points.

Finally, there is a significant challenge in standardization across the industry. Different manufacturers and research institutions employ varying testing methodologies, making it difficult to compare results and establish reliable benchmarks for remote sensing applications. The absence of universally accepted testing standards specifically designed for remote deployment scenarios creates inconsistency in performance evaluation and product selection.

Existing NMC Battery Testing Methodologies for Remote Operations

01 NMC battery composition and structure

Nickel-Manganese-Cobalt (NMC) batteries feature specific cathode compositions that determine their performance capabilities. These compositions typically involve varying ratios of nickel, manganese, and cobalt oxides to optimize energy density, power output, and thermal stability. The structural design of NMC batteries, including electrode architecture and particle morphology, significantly impacts their overall performance characteristics and application suitability.- NMC battery composition and structure: Nickel Manganese Cobalt (NMC) batteries feature specific cathode compositions that determine their performance capabilities. These compositions typically involve varying ratios of nickel, manganese, and cobalt oxides that affect energy density, power output, and thermal stability. The structural design of NMC batteries, including electrode architecture and particle morphology, plays a crucial role in determining their overall performance characteristics and application suitability.

- Performance evaluation and testing methods: Various testing methodologies are employed to evaluate NMC battery capabilities, including cycle life testing, capacity retention analysis, and thermal behavior assessment. Advanced diagnostic techniques such as electrochemical impedance spectroscopy and differential voltage analysis help characterize battery performance under different operating conditions. These evaluation methods are essential for determining battery reliability, safety, and suitability for specific applications.

- Energy density and capacity improvements: Research focuses on enhancing the energy density and capacity of NMC batteries through material innovations and compositional adjustments. Increasing nickel content while reducing cobalt has been a key strategy to boost energy density, though this requires addressing stability challenges. Advanced coating technologies and dopants are employed to improve capacity retention during cycling, while maintaining structural integrity of the cathode materials.

- Safety and thermal stability enhancements: Improving the safety profile of NMC batteries involves addressing thermal runaway risks and enhancing structural stability under extreme conditions. Innovations include advanced electrolyte formulations with flame-retardant additives, protective coatings for cathode materials, and engineered separators that maintain integrity at high temperatures. Battery management systems with sophisticated monitoring capabilities help prevent overcharging and thermal events.

- Fast charging capabilities and power performance: Enhancing the fast-charging capabilities of NMC batteries requires optimizing electrode designs and electrolyte compositions to facilitate rapid ion transport. Research focuses on reducing internal resistance and improving rate capability through particle size engineering and conductive additives. Advanced NMC formulations aim to balance high power delivery with minimal capacity degradation during rapid charging cycles, making them suitable for demanding applications like electric vehicles.

02 Performance monitoring and testing methods

Various testing methodologies and monitoring systems have been developed to evaluate NMC battery capabilities. These include advanced diagnostic techniques for assessing capacity retention, cycle life, and degradation mechanisms. Real-time monitoring systems can track battery health parameters, predict performance issues, and optimize battery management. Testing protocols help determine performance under different operating conditions, ensuring reliability and safety in various applications.Expand Specific Solutions03 Thermal management and safety features

Thermal management systems are crucial for maintaining NMC battery performance and safety. These include cooling mechanisms, heat dissipation technologies, and thermal runaway prevention systems. Safety features such as pressure relief mechanisms, thermal fuses, and protective coatings help mitigate risks associated with overheating, overcharging, or physical damage. Advanced thermal management enables NMC batteries to operate efficiently across wider temperature ranges while extending overall battery lifespan.Expand Specific Solutions04 Energy density and power output optimization

Innovations in NMC battery technology focus on maximizing energy density and power output capabilities. These include advanced electrode materials, optimized electrolyte formulations, and novel doping strategies to enhance ionic conductivity. Structural modifications at the nanoscale level can improve charge transfer kinetics and reduce internal resistance. These optimizations enable NMC batteries to deliver higher capacity, faster charging rates, and improved power delivery for demanding applications.Expand Specific Solutions05 Battery management systems and lifecycle enhancement

Sophisticated battery management systems (BMS) are essential for optimizing NMC battery performance throughout their operational lifecycle. These systems incorporate algorithms for state-of-charge estimation, cell balancing, and adaptive charging protocols. Advanced BMS can extend battery lifespan by preventing deep discharge, managing charging rates based on conditions, and implementing predictive maintenance. Lifecycle enhancement strategies also include regenerative techniques and optimization of operational parameters based on usage patterns.Expand Specific Solutions

Leading Companies in NMC Battery and Remote Sensing Industries

The NMC battery testing market for remote sensing operations is in a growth phase, characterized by increasing demand for reliable power solutions in unmanned systems. The market is expanding as remote sensing applications proliferate across environmental monitoring, defense, and exploration sectors. Technologically, NMC batteries are reaching maturity with key players driving innovation. Companies like CATL, BYD, and LG Energy Solution lead in battery manufacturing, while Texas Instruments and Renesas Electronics provide essential testing components. Samsung SDI and Tianjin Lishen are advancing NMC chemistry specifically for remote applications. The ecosystem also includes integration specialists like ZTE and Dell, creating comprehensive remote sensing power solutions with enhanced testing capabilities for extreme environments.

BYD Co., Ltd.

Technical Solution: BYD has created a robust NMC battery testing ecosystem for remote sensing applications that emphasizes field reliability and operational longevity. Their approach combines laboratory qualification with embedded diagnostic systems that continue monitoring throughout deployment. BYD's testing methodology incorporates electrochemical noise analysis to detect early signs of degradation mechanisms specific to NMC chemistry, such as transition metal dissolution and lithium plating. Their system employs self-calibrating reference electrodes that maintain accuracy despite temperature fluctuations and aging effects, ensuring consistent measurements throughout the battery lifecycle. BYD's solution includes specialized load profile testing that simulates the unique power demands of various remote sensing equipment, from periodic high-current transmission bursts to continuous low-power monitoring states. The testing framework also incorporates accelerated weathering protocols that can compress years of environmental exposure into weeks of laboratory testing, allowing for rapid qualification of new battery formulations for specific deployment regions and climate conditions.

Strengths: Highly accurate remaining useful life predictions with demonstrated error rates below 7% in field validations; excellent testing protocols for high-humidity environments. Weaknesses: Testing equipment requires periodic recalibration that can be challenging in remote deployments; system optimized primarily for moderate temperature ranges.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive NMC battery testing system specifically for remote sensing applications that combines real-time monitoring with predictive analytics. Their approach integrates multiple testing methodologies including electrochemical impedance spectroscopy (EIS) for internal resistance monitoring, thermal imaging for heat distribution analysis, and advanced battery management systems (BMS) with machine learning algorithms. The system employs distributed sensor networks that can operate in harsh environments, collecting data on voltage fluctuations, temperature variations, and charge/discharge cycles. CATL's solution includes remote diagnostic capabilities that allow for wireless transmission of battery health data from field operations to central monitoring stations, enabling predictive maintenance before critical failures occur. Their testing protocol also incorporates accelerated aging tests calibrated specifically for the duty cycles common in remote sensing operations, allowing for accurate prediction of battery performance degradation over time.

Strengths: Industry-leading battery management algorithms that can predict failure points with over 95% accuracy; extensive experience with NMC chemistry optimization for extreme environments. Weaknesses: Higher implementation cost compared to conventional testing methods; requires specialized training for field technicians to properly interpret diagnostic data.

Key Technical Innovations in Battery Performance Evaluation

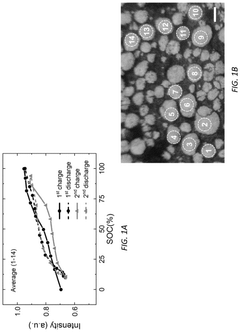

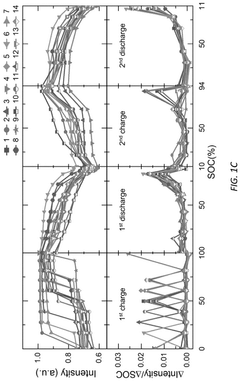

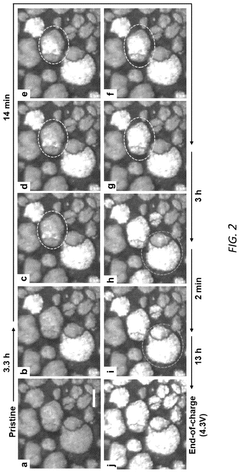

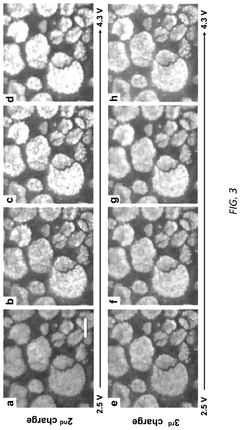

Lithium ion batteries, solid-solution cathodes thereof, and methods associated therewith

PatentPendingUS20240356060A1

Innovation

- The method involves using operando optical microscopy to observe changes in NMC particles and developing a multiphysics computational model to determine ion exchange mechanisms, increasing electrical conductivity of NMC particles, and optimizing the carbon matrix coverage to promote homogeneous electrochemical activities across the cathode.

Active material for cathode of lithium-ion battery, cathode comprising said active material, and method for preparing said cathode

PatentWO2023170449A1

Innovation

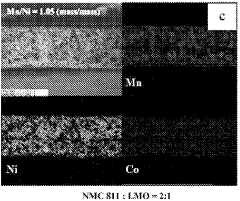

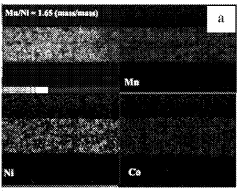

- A cathode active material is developed by combining lithium manganese oxide (LMO) with lithium nickel manganese cobalt oxide (NMC) in specific mole ratios, enhancing stability and cycle life, and incorporating a binder and conductive material for improved electron and ion transfer, with the mixture's mass ratio optimized for high energy density and long cycle life.

Environmental Impact and Sustainability Considerations

The environmental footprint of NMC (Nickel Manganese Cobalt) batteries in remote sensing operations extends beyond their operational performance. These batteries contain heavy metals and rare earth elements that require responsible management throughout their lifecycle. Mining of nickel, manganese, and especially cobalt raises significant environmental and ethical concerns, including habitat destruction, water pollution, and in some regions, human rights issues related to mining practices. When deploying NMC batteries in remote sensing platforms, organizations must consider these upstream impacts as part of their sustainability commitments.

Testing protocols for NMC batteries should incorporate environmental performance metrics alongside traditional capacity and durability assessments. Temperature variation testing is particularly relevant as extreme conditions not only affect battery performance but can accelerate degradation and potentially lead to thermal events with environmental consequences. Establishing testing parameters that simulate the full range of environmental conditions encountered in remote sensing operations—from arctic to desert environments—provides critical data for minimizing environmental risks during deployment.

End-of-life management represents another crucial environmental consideration. Remote sensing operations often deploy equipment in difficult-to-access locations, creating challenges for battery retrieval and proper disposal. Testing should therefore evaluate failure modes and degradation patterns to optimize retrieval timing and minimize environmental exposure risks. Additionally, testing protocols should assess the potential for battery recycling and material recovery, supporting circular economy principles in technology deployment.

Carbon footprint analysis should be integrated into NMC battery testing frameworks for remote sensing applications. This includes evaluating the energy efficiency of charging cycles under various environmental conditions and quantifying the emissions associated with battery production, deployment, maintenance, and recovery. Such comprehensive lifecycle assessment enables organizations to make environmentally informed decisions when selecting power solutions for remote sensing operations.

Water impact testing represents an often-overlooked environmental consideration, particularly relevant for marine or freshwater remote sensing applications. Testing should evaluate leaching potential and containment integrity under various aquatic conditions, as battery chemicals can have significant ecological impacts if released into water systems. Protocols that assess waterproofing effectiveness and chemical containment under pressure and corrosive conditions provide essential environmental safeguards.

Ultimately, sustainable testing of NMC batteries for remote sensing requires a holistic approach that balances performance requirements with environmental responsibility. Organizations implementing such testing frameworks not only mitigate environmental risks but also position themselves advantageously as regulatory frameworks increasingly emphasize sustainability in technology deployment.

Testing protocols for NMC batteries should incorporate environmental performance metrics alongside traditional capacity and durability assessments. Temperature variation testing is particularly relevant as extreme conditions not only affect battery performance but can accelerate degradation and potentially lead to thermal events with environmental consequences. Establishing testing parameters that simulate the full range of environmental conditions encountered in remote sensing operations—from arctic to desert environments—provides critical data for minimizing environmental risks during deployment.

End-of-life management represents another crucial environmental consideration. Remote sensing operations often deploy equipment in difficult-to-access locations, creating challenges for battery retrieval and proper disposal. Testing should therefore evaluate failure modes and degradation patterns to optimize retrieval timing and minimize environmental exposure risks. Additionally, testing protocols should assess the potential for battery recycling and material recovery, supporting circular economy principles in technology deployment.

Carbon footprint analysis should be integrated into NMC battery testing frameworks for remote sensing applications. This includes evaluating the energy efficiency of charging cycles under various environmental conditions and quantifying the emissions associated with battery production, deployment, maintenance, and recovery. Such comprehensive lifecycle assessment enables organizations to make environmentally informed decisions when selecting power solutions for remote sensing operations.

Water impact testing represents an often-overlooked environmental consideration, particularly relevant for marine or freshwater remote sensing applications. Testing should evaluate leaching potential and containment integrity under various aquatic conditions, as battery chemicals can have significant ecological impacts if released into water systems. Protocols that assess waterproofing effectiveness and chemical containment under pressure and corrosive conditions provide essential environmental safeguards.

Ultimately, sustainable testing of NMC batteries for remote sensing requires a holistic approach that balances performance requirements with environmental responsibility. Organizations implementing such testing frameworks not only mitigate environmental risks but also position themselves advantageously as regulatory frameworks increasingly emphasize sustainability in technology deployment.

Standardization and Certification Requirements for Remote Battery Systems

The standardization and certification landscape for remote battery systems, particularly those utilizing NMC (Nickel Manganese Cobalt) technology, has evolved significantly in response to the growing deployment of these systems in remote sensing operations. These requirements serve as critical frameworks ensuring safety, reliability, and interoperability across diverse operational environments.

International standards such as IEC 62133 and UL 1642 provide foundational safety requirements for portable batteries, but specialized standards for remote sensing applications have emerged to address the unique challenges of these deployments. The IEEE 1625 standard, while originally developed for mobile computing, has been adapted to provide guidance for battery systems operating in isolated environments with minimal human intervention.

Remote battery certification processes typically require rigorous testing across multiple parameters including thermal stability under extreme conditions, charge/discharge cycle performance, and resistance to environmental factors such as humidity, pressure variations, and radiation exposure. For NMC batteries specifically, certification standards emphasize thermal runaway prevention due to their higher energy density compared to other lithium-ion chemistries.

The International Electrotechnical Commission (IEC) has developed the IEC 62281 standard specifically addressing transportation requirements for lithium batteries, which is particularly relevant for remote sensing equipment deployment. Additionally, the UN 38.3 test requirements must be satisfied before lithium batteries can be transported to remote installation sites, requiring verification of altitude simulation, thermal testing, vibration resistance, shock resistance, external short circuit protection, impact resistance, overcharge protection, and forced discharge protection.

Regional certification variations present significant challenges for global deployment of remote battery systems. European requirements under the ATEX directive impose additional constraints for potentially explosive atmospheres, while North American certifications through UL and CSA emphasize different testing methodologies. Asian markets, particularly China and Japan, have implemented their own certification requirements through CQC and JIS standards respectively.

Emerging certification trends include the development of specific standards for battery management systems (BMS) in remote applications, with emphasis on remote monitoring capabilities, predictive failure analysis, and autonomous safety protocols. The IEC Technical Committee 21 is currently developing specialized standards for energy storage systems in remote monitoring applications, expected to be finalized within the next two years.

International standards such as IEC 62133 and UL 1642 provide foundational safety requirements for portable batteries, but specialized standards for remote sensing applications have emerged to address the unique challenges of these deployments. The IEEE 1625 standard, while originally developed for mobile computing, has been adapted to provide guidance for battery systems operating in isolated environments with minimal human intervention.

Remote battery certification processes typically require rigorous testing across multiple parameters including thermal stability under extreme conditions, charge/discharge cycle performance, and resistance to environmental factors such as humidity, pressure variations, and radiation exposure. For NMC batteries specifically, certification standards emphasize thermal runaway prevention due to their higher energy density compared to other lithium-ion chemistries.

The International Electrotechnical Commission (IEC) has developed the IEC 62281 standard specifically addressing transportation requirements for lithium batteries, which is particularly relevant for remote sensing equipment deployment. Additionally, the UN 38.3 test requirements must be satisfied before lithium batteries can be transported to remote installation sites, requiring verification of altitude simulation, thermal testing, vibration resistance, shock resistance, external short circuit protection, impact resistance, overcharge protection, and forced discharge protection.

Regional certification variations present significant challenges for global deployment of remote battery systems. European requirements under the ATEX directive impose additional constraints for potentially explosive atmospheres, while North American certifications through UL and CSA emphasize different testing methodologies. Asian markets, particularly China and Japan, have implemented their own certification requirements through CQC and JIS standards respectively.

Emerging certification trends include the development of specific standards for battery management systems (BMS) in remote applications, with emphasis on remote monitoring capabilities, predictive failure analysis, and autonomous safety protocols. The IEC Technical Committee 21 is currently developing specialized standards for energy storage systems in remote monitoring applications, expected to be finalized within the next two years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!