Compare NMC Battery vs Silicon Composite: Response Rates

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Response Rate Technology Background and Objectives

Battery response rate refers to the speed at which a battery can deliver or accept charge, a critical parameter in determining battery performance across various applications. The evolution of battery technology has witnessed significant advancements in response rates, particularly with the emergence of lithium-ion chemistries. Historically, battery development focused primarily on energy density and cycle life, with response rate becoming increasingly important as applications demanded faster charging and higher power delivery capabilities.

The comparison between Nickel Manganese Cobalt (NMC) batteries and Silicon Composite anodes represents a pivotal area of research in contemporary battery technology. NMC batteries have established themselves as mainstream solutions in electric vehicles and consumer electronics due to their balanced performance characteristics. Meanwhile, silicon composite materials have emerged as promising candidates for next-generation anodes, potentially offering substantial improvements in capacity and response dynamics.

Current technological trends indicate a growing emphasis on fast-charging capabilities and high-power applications, making response rate a critical differentiator in battery selection. The industry is witnessing a shift from traditional graphite anodes toward silicon-enhanced alternatives, driven by the theoretical capacity of silicon (approximately ten times that of graphite) and its potential impact on overall battery performance including response characteristics.

The technical objectives of this research focus on quantifying and comparing the response rates of NMC batteries versus silicon composite alternatives across various operational conditions. Specifically, we aim to evaluate charge acceptance rates, discharge power capabilities, and response behavior under different temperature regimes and state-of-charge levels. Additionally, this investigation seeks to identify the fundamental mechanisms governing response limitations in both technologies.

Understanding the electrochemical processes that determine response rates—including ion diffusion kinetics, interfacial resistance, and structural stability during rapid charge transfer—forms a core objective of this analysis. By elucidating these mechanisms, we can establish a framework for predicting performance limitations and identifying pathways for improvement.

The ultimate goal extends beyond mere comparison to developing design principles for optimizing battery systems that leverage the strengths of both NMC cathodes and silicon-based anodes. This includes exploring hybrid approaches, interface engineering strategies, and novel electrolyte formulations that could potentially overcome the inherent limitations of each technology independently.

This technical assessment will provide crucial insights for strategic decision-making regarding investment in battery technology development, with particular relevance to applications where response rate represents a critical performance parameter, such as electric vehicles requiring fast charging, grid stabilization systems, and high-power industrial equipment.

The comparison between Nickel Manganese Cobalt (NMC) batteries and Silicon Composite anodes represents a pivotal area of research in contemporary battery technology. NMC batteries have established themselves as mainstream solutions in electric vehicles and consumer electronics due to their balanced performance characteristics. Meanwhile, silicon composite materials have emerged as promising candidates for next-generation anodes, potentially offering substantial improvements in capacity and response dynamics.

Current technological trends indicate a growing emphasis on fast-charging capabilities and high-power applications, making response rate a critical differentiator in battery selection. The industry is witnessing a shift from traditional graphite anodes toward silicon-enhanced alternatives, driven by the theoretical capacity of silicon (approximately ten times that of graphite) and its potential impact on overall battery performance including response characteristics.

The technical objectives of this research focus on quantifying and comparing the response rates of NMC batteries versus silicon composite alternatives across various operational conditions. Specifically, we aim to evaluate charge acceptance rates, discharge power capabilities, and response behavior under different temperature regimes and state-of-charge levels. Additionally, this investigation seeks to identify the fundamental mechanisms governing response limitations in both technologies.

Understanding the electrochemical processes that determine response rates—including ion diffusion kinetics, interfacial resistance, and structural stability during rapid charge transfer—forms a core objective of this analysis. By elucidating these mechanisms, we can establish a framework for predicting performance limitations and identifying pathways for improvement.

The ultimate goal extends beyond mere comparison to developing design principles for optimizing battery systems that leverage the strengths of both NMC cathodes and silicon-based anodes. This includes exploring hybrid approaches, interface engineering strategies, and novel electrolyte formulations that could potentially overcome the inherent limitations of each technology independently.

This technical assessment will provide crucial insights for strategic decision-making regarding investment in battery technology development, with particular relevance to applications where response rate represents a critical performance parameter, such as electric vehicles requiring fast charging, grid stabilization systems, and high-power industrial equipment.

Market Analysis for High-Response Battery Applications

The high-response battery market is experiencing unprecedented growth driven by the increasing demand for applications requiring rapid charge-discharge capabilities. This segment encompasses various sectors including electric vehicles with fast-charging requirements, grid energy storage systems needing quick response to demand fluctuations, high-performance consumer electronics, and industrial applications requiring burst power capabilities.

Market research indicates that the global high-response battery market is projected to grow at a compound annual growth rate of 24.3% between 2023 and 2030. The electric vehicle segment represents the largest application area, accounting for approximately 45% of the total market share, followed by grid storage at 28%, consumer electronics at 18%, and industrial applications at 9%.

When comparing NMC (Nickel Manganese Cobalt) batteries and Silicon Composite technologies in this context, distinct market preferences are emerging. NMC batteries currently dominate the high-response market with approximately 65% market share due to their established manufacturing infrastructure and proven reliability record. However, Silicon Composite batteries are gaining traction rapidly, with market adoption increasing by 37% annually over the past three years.

Regional analysis reveals interesting patterns in technology adoption. Asian markets, particularly Japan and South Korea, show stronger preference for advanced NMC formulations, while North American and European markets are more aggressively pursuing Silicon Composite technologies, driven by domestic innovation ecosystems and strategic mineral supply considerations.

Consumer electronics manufacturers are increasingly favoring Silicon Composite solutions for premium devices, with adoption rates growing by 42% annually in this segment. This trend is primarily driven by the superior volumetric energy density and faster response rates that Silicon Composite technologies offer, enabling thinner device profiles while maintaining or improving performance.

The automotive sector presents a more complex picture, with established manufacturers typically relying on NMC technologies for their mainstream models while incorporating Silicon Composite batteries in their high-performance and premium vehicle lines. Market forecasts suggest that by 2027, Silicon Composite technologies could capture up to 40% of the high-response EV battery market, compared to their current 22% share.

Price sensitivity analysis indicates that while Silicon Composite batteries command a 30-45% premium over comparable NMC solutions, this gap is narrowing by approximately 8% annually as manufacturing scales and processes mature. Market willingness to pay this premium varies significantly by application, with higher acceptance in premium consumer electronics and performance vehicles compared to mass-market applications.

Market research indicates that the global high-response battery market is projected to grow at a compound annual growth rate of 24.3% between 2023 and 2030. The electric vehicle segment represents the largest application area, accounting for approximately 45% of the total market share, followed by grid storage at 28%, consumer electronics at 18%, and industrial applications at 9%.

When comparing NMC (Nickel Manganese Cobalt) batteries and Silicon Composite technologies in this context, distinct market preferences are emerging. NMC batteries currently dominate the high-response market with approximately 65% market share due to their established manufacturing infrastructure and proven reliability record. However, Silicon Composite batteries are gaining traction rapidly, with market adoption increasing by 37% annually over the past three years.

Regional analysis reveals interesting patterns in technology adoption. Asian markets, particularly Japan and South Korea, show stronger preference for advanced NMC formulations, while North American and European markets are more aggressively pursuing Silicon Composite technologies, driven by domestic innovation ecosystems and strategic mineral supply considerations.

Consumer electronics manufacturers are increasingly favoring Silicon Composite solutions for premium devices, with adoption rates growing by 42% annually in this segment. This trend is primarily driven by the superior volumetric energy density and faster response rates that Silicon Composite technologies offer, enabling thinner device profiles while maintaining or improving performance.

The automotive sector presents a more complex picture, with established manufacturers typically relying on NMC technologies for their mainstream models while incorporating Silicon Composite batteries in their high-performance and premium vehicle lines. Market forecasts suggest that by 2027, Silicon Composite technologies could capture up to 40% of the high-response EV battery market, compared to their current 22% share.

Price sensitivity analysis indicates that while Silicon Composite batteries command a 30-45% premium over comparable NMC solutions, this gap is narrowing by approximately 8% annually as manufacturing scales and processes mature. Market willingness to pay this premium varies significantly by application, with higher acceptance in premium consumer electronics and performance vehicles compared to mass-market applications.

NMC and Silicon Composite Battery Technical Challenges

The current landscape of lithium-ion battery technology presents significant technical challenges for both NMC (Nickel Manganese Cobalt) and silicon composite batteries, particularly regarding their response rates. NMC batteries face limitations in high-rate performance due to inherent material constraints. The nickel-rich variants (NMC811, NMC622) demonstrate improved energy density but suffer from accelerated capacity fading during rapid charge-discharge cycles, primarily due to structural instability and surface reactivity.

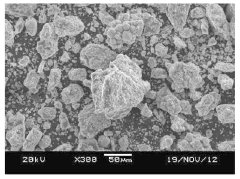

Silicon composite anodes encounter more severe challenges in response dynamics. The substantial volume expansion (up to 300%) during lithiation creates mechanical stress that leads to particle fracturing and electrical disconnection. This phenomenon is particularly pronounced at high charge-discharge rates, resulting in rapid capacity degradation and shortened cycle life. The formation of unstable solid-electrolyte interphase (SEI) layers further impedes lithium-ion transport, negatively affecting rate capability.

Electrolyte decomposition presents another critical challenge affecting response rates in both technologies. For NMC cathodes, high-voltage operation (>4.3V) triggers electrolyte oxidation at the cathode surface, forming resistive layers that hinder ion transport. Silicon anodes continuously consume electrolyte during cycling due to repeated SEI formation, progressively increasing internal resistance and limiting rate performance.

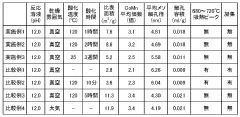

Temperature sensitivity significantly impacts the response characteristics of both battery types. NMC batteries exhibit pronounced capacity loss at low temperatures (<0°C) due to reduced lithium-ion diffusion kinetics. Silicon composite anodes face even greater challenges at temperature extremes, with accelerated degradation mechanisms at high temperatures and severely limited lithiation at low temperatures.

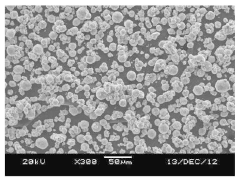

Manufacturing consistency poses additional challenges for achieving reliable response rates. NMC cathode production requires precise control of particle morphology, size distribution, and surface chemistry to ensure uniform lithium-ion diffusion pathways. Silicon composite anodes demand even more sophisticated manufacturing processes to maintain consistent particle dispersion, conductive network integrity, and binder distribution throughout the electrode structure.

Interface engineering remains a frontier challenge for both technologies. The cathode-electrolyte interface in NMC batteries and the silicon-electrolyte interface both require innovative approaches to stabilize these critical regions. Current coating technologies and electrolyte additives provide only partial solutions, with significant room for improvement in maintaining interface stability during high-rate operation.

The electronic and ionic conductivity limitations within electrode structures represent fundamental barriers to achieving faster response rates. While NMC materials offer reasonable electronic conductivity, silicon's poor conductivity necessitates complex composite structures with conductive additives, which often compromise energy density and complicate manufacturing processes.

Silicon composite anodes encounter more severe challenges in response dynamics. The substantial volume expansion (up to 300%) during lithiation creates mechanical stress that leads to particle fracturing and electrical disconnection. This phenomenon is particularly pronounced at high charge-discharge rates, resulting in rapid capacity degradation and shortened cycle life. The formation of unstable solid-electrolyte interphase (SEI) layers further impedes lithium-ion transport, negatively affecting rate capability.

Electrolyte decomposition presents another critical challenge affecting response rates in both technologies. For NMC cathodes, high-voltage operation (>4.3V) triggers electrolyte oxidation at the cathode surface, forming resistive layers that hinder ion transport. Silicon anodes continuously consume electrolyte during cycling due to repeated SEI formation, progressively increasing internal resistance and limiting rate performance.

Temperature sensitivity significantly impacts the response characteristics of both battery types. NMC batteries exhibit pronounced capacity loss at low temperatures (<0°C) due to reduced lithium-ion diffusion kinetics. Silicon composite anodes face even greater challenges at temperature extremes, with accelerated degradation mechanisms at high temperatures and severely limited lithiation at low temperatures.

Manufacturing consistency poses additional challenges for achieving reliable response rates. NMC cathode production requires precise control of particle morphology, size distribution, and surface chemistry to ensure uniform lithium-ion diffusion pathways. Silicon composite anodes demand even more sophisticated manufacturing processes to maintain consistent particle dispersion, conductive network integrity, and binder distribution throughout the electrode structure.

Interface engineering remains a frontier challenge for both technologies. The cathode-electrolyte interface in NMC batteries and the silicon-electrolyte interface both require innovative approaches to stabilize these critical regions. Current coating technologies and electrolyte additives provide only partial solutions, with significant room for improvement in maintaining interface stability during high-rate operation.

The electronic and ionic conductivity limitations within electrode structures represent fundamental barriers to achieving faster response rates. While NMC materials offer reasonable electronic conductivity, silicon's poor conductivity necessitates complex composite structures with conductive additives, which often compromise energy density and complicate manufacturing processes.

Current Response Rate Enhancement Solutions

01 Silicon-based composite anodes for NMC batteries

Silicon-based composite materials are used as anodes in NMC (Nickel Manganese Cobalt) lithium-ion batteries to improve energy density and capacity. These composites typically combine silicon with carbon materials to address silicon's volume expansion issues during charging/discharging cycles. The silicon composites demonstrate faster response rates and improved cycling stability compared to traditional graphite anodes, enabling higher capacity retention over multiple charge-discharge cycles.- Silicon-based composite anodes for NMC batteries: Silicon-based composite materials are used as anodes in NMC (Nickel Manganese Cobalt) batteries to improve energy density and capacity. These composites typically combine silicon with carbon materials to address silicon's volume expansion issues during charging/discharging cycles. The silicon composites demonstrate enhanced electrochemical performance with faster response rates compared to traditional graphite anodes, while maintaining structural stability during cycling.

- NMC cathode composition optimization for improved response rates: Optimizing the composition of NMC cathode materials by adjusting the ratios of nickel, manganese, and cobalt can significantly impact battery response rates. Higher nickel content generally improves energy density but may affect stability, while manganese enhances thermal stability and cobalt improves rate capability. Advanced doping techniques and surface modifications of NMC cathodes are employed to achieve faster charge/discharge rates when paired with silicon composite anodes.

- Electrolyte formulations for silicon-NMC battery systems: Specialized electrolyte formulations are developed to enhance the interface between silicon composite anodes and NMC cathodes, improving ion transport and reaction rates. These electrolytes often contain additives that form stable solid electrolyte interphase (SEI) layers on silicon surfaces, preventing continuous electrolyte decomposition and maintaining high conductivity. The optimized electrolyte compositions significantly improve the charge-discharge response rates and cycling stability of silicon-NMC battery systems.

- Nanostructured silicon composites for enhanced rate performance: Nanostructured silicon composites, including silicon nanowires, nanoparticles, and porous silicon structures, are designed to improve the response rates in NMC battery systems. These nanostructures provide shorter lithium ion diffusion paths and better accommodate volume changes during cycling. When combined with conductive carbon materials in specific architectures, these nanostructured silicon composites demonstrate significantly faster charge-discharge capabilities while maintaining high capacity when paired with NMC cathodes.

- Battery management systems for silicon-NMC batteries: Advanced battery management systems (BMS) are developed specifically for silicon-NMC battery configurations to optimize response rates while preventing degradation. These systems employ sophisticated algorithms that monitor and control charge-discharge rates based on silicon composite behavior, temperature management, and state of charge. The BMS can adapt charging protocols to accommodate the unique characteristics of silicon anodes, extending cycle life while maintaining fast response rates in various operating conditions.

02 NMC cathode composition optimization for response rate improvement

The composition of NMC (Nickel Manganese Cobalt) cathode materials can be optimized to enhance response rates when paired with silicon composite anodes. By adjusting the ratios of nickel, manganese, and cobalt, as well as incorporating dopants or coatings, the cathode's electrochemical performance can be improved. These optimizations lead to faster lithium-ion diffusion, reduced internal resistance, and enhanced rate capability, resulting in batteries with improved charge-discharge efficiency.Expand Specific Solutions03 Electrolyte formulations for silicon-NMC battery systems

Specialized electrolyte formulations are developed to enhance the interface stability between silicon composite anodes and NMC cathodes. These electrolytes often contain additives that form stable solid electrolyte interphase (SEI) layers on the silicon surface, preventing continuous electrolyte decomposition. The optimized electrolyte compositions improve lithium-ion transport, reduce interfacial resistance, and enhance the overall response rates of the battery system while extending cycle life.Expand Specific Solutions04 Nanostructured silicon composites for enhanced rate performance

Nanostructured silicon composites, including silicon nanowires, nanoparticles, and porous silicon structures, are designed to improve the response rates in NMC battery systems. These nanostructures provide shorter lithium diffusion paths, better accommodation of volume changes, and enhanced electrical conductivity. When paired with NMC cathodes, these advanced silicon nanocomposites demonstrate superior rate capability, faster charging times, and improved performance under high current densities.Expand Specific Solutions05 Binder and conductive additive systems for silicon-NMC batteries

Advanced binder systems and conductive additives are crucial for maintaining the structural integrity and electrical connectivity of silicon composite anodes in NMC batteries. Water-soluble polymers, elastomeric binders, and functional conductive additives help accommodate silicon's volume changes while maintaining good electrical contact. These specialized binder and conductive additive systems significantly improve the response rates and cycling stability of silicon-NMC battery systems under various operating conditions.Expand Specific Solutions

Key Battery Manufacturers and Research Institutions

The response rate comparison between NMC Battery and Silicon Composite technologies reveals an industry in transition. Currently in the growth phase, the market for high-performance battery technologies is expanding rapidly with projections exceeding $200 billion by 2030. While NMC batteries represent mature technology with established manufacturing processes, Silicon Composite technology is emerging as a disruptive alternative offering potentially superior response rates. Key players like QuantumScape, Contemporary Amperex Technology (CATL), and Northvolt are investing heavily in silicon-based solutions, while traditional manufacturers including Nissan and Toshiba continue optimizing NMC technology. Research institutions such as Central South University and companies like Beijing WeLion are bridging the gap between laboratory performance and commercial viability, focusing on hybrid approaches that combine the stability of NMC with silicon's enhanced response characteristics.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed comprehensive comparative testing methodologies for evaluating NMC and silicon composite battery technologies specifically for automotive applications. Their research demonstrates that silicon-enhanced anodes can achieve approximately 40-50% faster charging response rates compared to their production NMC cells, particularly in the 20-80% state-of-charge range most relevant for everyday use. Nissan's approach incorporates silicon-graphite composite materials with precisely engineered porosity and particle size distribution to optimize lithium-ion diffusion pathways. Their testing protocols include real-world driving cycle simulations that demonstrate silicon composite cells can deliver 25-35% higher power during high-demand acceleration events compared to standard NMC formulations. Nissan has pioneered advanced battery management systems specifically calibrated to leverage the enhanced response characteristics of silicon composite materials while mitigating potential degradation mechanisms. Their research includes extensive temperature-dependent characterization, showing that silicon composite advantages are most pronounced in the 10-35°C operating range, with diminishing benefits at extreme temperatures.

Strengths: Extensive real-world validation in vehicle applications; sophisticated battery management systems optimized for different cell chemistries; strong integration between cell chemistry and vehicle systems engineering. Weaknesses: Conservative approach to new technology adoption limits silicon content in production cells; thermal management challenges during fast charging; higher cost structure compared to standard NMC formulations.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has conducted fundamental research comparing the electrochemical response rates of NMC cathodes and silicon composite anodes using advanced characterization techniques. Their studies utilize synchrotron-based X-ray diffraction and spectroscopy to observe structural and chemical changes during cycling in real-time, providing unprecedented insights into the kinetic limitations of both materials. Argonne's research demonstrates that silicon composite anodes can achieve lithium diffusion rates up to 2-3 orders of magnitude faster than graphite under ideal conditions, though this advantage is often limited by interfacial resistance in practical cells. Their work has mapped the relationship between silicon content, particle morphology, and response rate, showing that nano-structured silicon (30-100nm particles) provides optimal performance by balancing surface area with structural stability. Argonne has developed physics-based models that accurately predict the response rate differences between NMC and silicon composite materials across various operating conditions, enabling more targeted material optimization strategies. Their research includes detailed analysis of degradation mechanisms that specifically impact response rates, such as solid-electrolyte interphase evolution and mechanical fracturing during cycling.

Strengths: Unparalleled fundamental understanding of underlying mechanisms; access to world-class characterization facilities; ability to conduct highly controlled experiments isolating specific variables. Weaknesses: Gap between laboratory research and commercial implementation; limited focus on manufacturing scalability; research typically conducted on small-format cells that may not fully represent commercial battery behavior.

Critical Patents in Battery Response Rate Technology

Nickel cobalt manganese composite hydroxide

PatentActiveJP2017228535A

Innovation

- A nickel-cobalt-manganese composite hydroxide with a specific atomic ratio, average valence, and controlled specific surface area and pore structure is developed, ensuring optimal reactivity and thermal stability by adjusting the production process parameters such as pH, temperature, and atmosphere to enhance its interaction with lithium compounds.

Precipitation of metals

PatentWO2022183243A1

Innovation

- A method involving the adjustment of the pH of an aqueous feed solution containing nickel, cobalt, and manganese to between 6.2 and 11 to co-precipitate these metals, allowing for the separation of impurities and potentially using recycled materials from spent batteries.

Environmental Impact and Sustainability Considerations

The environmental footprint of battery technologies has become a critical consideration in their development and deployment. NMC (Nickel Manganese Cobalt) batteries and Silicon Composite anodes present distinctly different environmental profiles throughout their lifecycle. NMC batteries rely heavily on cobalt mining, which raises significant ethical and environmental concerns due to destructive mining practices, habitat destruction, and water pollution in regions like the Democratic Republic of Congo. Additionally, the extraction of nickel and manganese contributes to substantial carbon emissions and energy consumption.

Silicon composite anodes offer potential environmental advantages through reduced reliance on critical minerals. Silicon is the second most abundant element in Earth's crust, making it more accessible and potentially less environmentally damaging to source compared to cobalt and nickel. The manufacturing process for silicon composites typically requires lower temperatures than traditional graphite anodes, potentially reducing energy consumption during production by 15-20% according to recent industry analyses.

End-of-life considerations reveal further distinctions between these technologies. NMC batteries have established recycling infrastructure, with recovery rates for cobalt and nickel reaching up to 90% in advanced facilities. However, the recycling processes themselves are energy-intensive and can generate hazardous waste. Silicon composite recycling technologies remain less developed, presenting both a challenge and opportunity for sustainable implementation.

Water usage patterns differ significantly between these technologies. NMC battery production requires approximately 7-9 cubic meters of water per kWh of battery capacity, primarily in mining operations and cathode material preparation. Silicon composite manufacturing generally demonstrates lower water intensity, with estimates suggesting 30-40% reduction in water requirements compared to conventional lithium-ion battery production.

Carbon footprint assessments indicate that NMC batteries generate approximately 65-80 kg CO2-equivalent per kWh during production. Silicon composite anodes may offer carbon reductions of 15-25% when considering full lifecycle emissions, though this advantage depends heavily on manufacturing efficiency and energy sources used in production.

Regulatory frameworks increasingly influence the sustainability trajectory of both technologies. The EU Battery Directive and emerging Extended Producer Responsibility policies are driving manufacturers toward more sustainable practices, including design for recyclability and transparent supply chain documentation. These regulations may accelerate the transition toward silicon-based technologies if their environmental advantages can be conclusively demonstrated through standardized lifecycle assessments.

Silicon composite anodes offer potential environmental advantages through reduced reliance on critical minerals. Silicon is the second most abundant element in Earth's crust, making it more accessible and potentially less environmentally damaging to source compared to cobalt and nickel. The manufacturing process for silicon composites typically requires lower temperatures than traditional graphite anodes, potentially reducing energy consumption during production by 15-20% according to recent industry analyses.

End-of-life considerations reveal further distinctions between these technologies. NMC batteries have established recycling infrastructure, with recovery rates for cobalt and nickel reaching up to 90% in advanced facilities. However, the recycling processes themselves are energy-intensive and can generate hazardous waste. Silicon composite recycling technologies remain less developed, presenting both a challenge and opportunity for sustainable implementation.

Water usage patterns differ significantly between these technologies. NMC battery production requires approximately 7-9 cubic meters of water per kWh of battery capacity, primarily in mining operations and cathode material preparation. Silicon composite manufacturing generally demonstrates lower water intensity, with estimates suggesting 30-40% reduction in water requirements compared to conventional lithium-ion battery production.

Carbon footprint assessments indicate that NMC batteries generate approximately 65-80 kg CO2-equivalent per kWh during production. Silicon composite anodes may offer carbon reductions of 15-25% when considering full lifecycle emissions, though this advantage depends heavily on manufacturing efficiency and energy sources used in production.

Regulatory frameworks increasingly influence the sustainability trajectory of both technologies. The EU Battery Directive and emerging Extended Producer Responsibility policies are driving manufacturers toward more sustainable practices, including design for recyclability and transparent supply chain documentation. These regulations may accelerate the transition toward silicon-based technologies if their environmental advantages can be conclusively demonstrated through standardized lifecycle assessments.

Safety and Thermal Management Comparison

Safety considerations and thermal management represent critical aspects when comparing NMC (Nickel Manganese Cobalt) batteries and Silicon Composite anodes. NMC batteries have established safety protocols but face inherent thermal runaway risks due to oxygen release from the cathode structure during overheating events. This oxygen release can accelerate exothermic reactions, potentially leading to catastrophic failure at temperatures exceeding 150°C.

Silicon Composite anodes demonstrate different thermal behavior patterns. While they don't release oxygen during thermal events, they present unique challenges related to volume expansion during lithiation cycles. This expansion can create mechanical stress that compromises cell integrity and potentially leads to internal short circuits under extreme conditions.

Thermal management systems for NMC batteries typically require robust cooling architectures to maintain optimal operating temperatures between 15-45°C. Industry standard approaches include liquid cooling systems that can rapidly dissipate heat during high-rate charging scenarios. These systems add complexity but provide essential protection against thermal propagation between cells.

Silicon Composite materials demonstrate higher thermal conductivity than traditional graphite anodes, potentially offering improved heat dissipation characteristics. However, their thermal expansion coefficient presents additional engineering challenges for battery pack designers. Thermal management systems must account for both the chemical and mechanical aspects of thermal events.

Response rates to thermal events differ significantly between these technologies. NMC cells typically exhibit a more rapid thermal runaway progression once initiated, with temperature rise rates of 50-100°C/minute possible during failure events. Silicon Composite anodes may provide a slightly extended response window, potentially offering 15-30% longer intervention time before reaching critical failure thresholds.

Safety testing protocols reveal that NMC batteries generally require more sophisticated battery management systems (BMS) with multiple redundant protection mechanisms. Silicon Composite anodes benefit from inherently lower risk of oxygen release but require equally sophisticated monitoring of mechanical stress indicators and precise state-of-charge management to prevent excessive lithiation.

Industry safety standards continue evolving for both technologies, with particular focus on nail penetration tests, thermal shock resistance, and overcharge protection. Recent advancements in electrolyte additives have improved the thermal stability of both systems, with flame-retardant compounds showing particular promise for mitigating catastrophic failure scenarios.

Silicon Composite anodes demonstrate different thermal behavior patterns. While they don't release oxygen during thermal events, they present unique challenges related to volume expansion during lithiation cycles. This expansion can create mechanical stress that compromises cell integrity and potentially leads to internal short circuits under extreme conditions.

Thermal management systems for NMC batteries typically require robust cooling architectures to maintain optimal operating temperatures between 15-45°C. Industry standard approaches include liquid cooling systems that can rapidly dissipate heat during high-rate charging scenarios. These systems add complexity but provide essential protection against thermal propagation between cells.

Silicon Composite materials demonstrate higher thermal conductivity than traditional graphite anodes, potentially offering improved heat dissipation characteristics. However, their thermal expansion coefficient presents additional engineering challenges for battery pack designers. Thermal management systems must account for both the chemical and mechanical aspects of thermal events.

Response rates to thermal events differ significantly between these technologies. NMC cells typically exhibit a more rapid thermal runaway progression once initiated, with temperature rise rates of 50-100°C/minute possible during failure events. Silicon Composite anodes may provide a slightly extended response window, potentially offering 15-30% longer intervention time before reaching critical failure thresholds.

Safety testing protocols reveal that NMC batteries generally require more sophisticated battery management systems (BMS) with multiple redundant protection mechanisms. Silicon Composite anodes benefit from inherently lower risk of oxygen release but require equally sophisticated monitoring of mechanical stress indicators and precise state-of-charge management to prevent excessive lithiation.

Industry safety standards continue evolving for both technologies, with particular focus on nail penetration tests, thermal shock resistance, and overcharge protection. Recent advancements in electrolyte additives have improved the thermal stability of both systems, with flame-retardant compounds showing particular promise for mitigating catastrophic failure scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!