NMC Battery vs Barium Silicate: Impact on Use Viability

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Technology Evolution and Objectives

Battery technology has undergone significant evolution since the introduction of the first practical battery by Alessandro Volta in 1800. The journey from lead-acid batteries to lithium-ion technologies represents a continuous pursuit of higher energy density, longer cycle life, and improved safety characteristics. NMC (Nickel Manganese Cobalt) batteries emerged as a dominant lithium-ion chemistry in the 2010s, offering a balanced approach to energy density, power capability, and cycle life compared to earlier lithium cobalt oxide formulations.

The development trajectory of battery technologies has been primarily driven by consumer electronics demands, followed by electric vehicle applications which have accelerated innovation in the past decade. NMC batteries have seen iterative improvements through composition adjustments, moving from equal parts nickel, manganese, and cobalt (NMC 111) toward higher nickel content variants (NMC 811) to increase energy density while reducing costly cobalt content.

Barium Silicate technology represents a potential paradigm shift in energy storage, moving beyond traditional intercalation-based lithium-ion approaches. This solid-state electrolyte material has garnered attention for its potential to enable higher energy density batteries with superior safety characteristics by eliminating flammable liquid electrolytes. The technology aims to address the fundamental limitations of conventional lithium-ion batteries, including thermal runaway risks and energy density plateaus.

The primary objectives of current battery technology research center around five key parameters: energy density, power density, cycle life, safety, and cost. NMC technology has largely focused on incremental improvements within the established lithium-ion framework, while Barium Silicate approaches seek more revolutionary advances through solid-state architectures. Both technologies aim to support the growing demands of electric mobility, renewable energy storage, and advanced portable electronics.

Global sustainability initiatives and regulatory frameworks are increasingly shaping battery technology objectives. The European Battery Directive, China's New Energy Vehicle policies, and various international climate agreements have established targets for battery performance, recycling, and environmental impact that directly influence research priorities. These frameworks have accelerated interest in cobalt-reduced formulations like high-nickel NMC and alternative technologies like Barium Silicate systems.

The convergence of computational materials science, advanced manufacturing techniques, and electrochemical engineering has enabled more rapid iteration in battery development. Machine learning approaches to materials discovery have shortened development cycles, while precision manufacturing has improved consistency and performance. These methodological advances support both the refinement of NMC technology and the development of novel approaches like Barium Silicate systems.

The development trajectory of battery technologies has been primarily driven by consumer electronics demands, followed by electric vehicle applications which have accelerated innovation in the past decade. NMC batteries have seen iterative improvements through composition adjustments, moving from equal parts nickel, manganese, and cobalt (NMC 111) toward higher nickel content variants (NMC 811) to increase energy density while reducing costly cobalt content.

Barium Silicate technology represents a potential paradigm shift in energy storage, moving beyond traditional intercalation-based lithium-ion approaches. This solid-state electrolyte material has garnered attention for its potential to enable higher energy density batteries with superior safety characteristics by eliminating flammable liquid electrolytes. The technology aims to address the fundamental limitations of conventional lithium-ion batteries, including thermal runaway risks and energy density plateaus.

The primary objectives of current battery technology research center around five key parameters: energy density, power density, cycle life, safety, and cost. NMC technology has largely focused on incremental improvements within the established lithium-ion framework, while Barium Silicate approaches seek more revolutionary advances through solid-state architectures. Both technologies aim to support the growing demands of electric mobility, renewable energy storage, and advanced portable electronics.

Global sustainability initiatives and regulatory frameworks are increasingly shaping battery technology objectives. The European Battery Directive, China's New Energy Vehicle policies, and various international climate agreements have established targets for battery performance, recycling, and environmental impact that directly influence research priorities. These frameworks have accelerated interest in cobalt-reduced formulations like high-nickel NMC and alternative technologies like Barium Silicate systems.

The convergence of computational materials science, advanced manufacturing techniques, and electrochemical engineering has enabled more rapid iteration in battery development. Machine learning approaches to materials discovery have shortened development cycles, while precision manufacturing has improved consistency and performance. These methodological advances support both the refinement of NMC technology and the development of novel approaches like Barium Silicate systems.

Market Demand Analysis for Advanced Battery Solutions

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current projections indicate the advanced battery market will reach $240 billion by 2027, with a compound annual growth rate exceeding 12%. This remarkable growth trajectory creates substantial opportunities for innovative battery technologies that can address existing limitations in energy density, charging speed, safety, and environmental impact.

NMC (Nickel Manganese Cobalt) batteries currently dominate the EV and high-performance electronics sectors, commanding approximately 45% market share in the lithium-ion battery segment. Their popularity stems from relatively high energy density, acceptable cycle life, and established manufacturing infrastructure. However, market research indicates growing concerns about cobalt supply chain ethics, price volatility, and thermal stability issues that have prompted manufacturers to seek alternatives.

Emerging Barium Silicate technology represents a potential paradigm shift in the battery market. Industry surveys reveal that 78% of EV manufacturers express strong interest in cobalt-free battery solutions, while 82% prioritize technologies offering enhanced safety profiles. Barium Silicate technology directly addresses these concerns, potentially capturing significant market share if commercialization hurdles can be overcome.

The renewable energy storage sector presents another substantial growth opportunity, projected to expand at 20% annually through 2030. Grid-scale storage installations require batteries with exceptional cycle life, safety, and cost-effectiveness - attributes where Barium Silicate technology shows particular promise compared to conventional NMC formulations.

Consumer electronics manufacturers increasingly prioritize fast-charging capabilities and improved safety, with 67% of smartphone users identifying battery performance as a critical purchase factor. The potential for Barium Silicate to enable 5-minute charging while eliminating thermal runaway risks positions it favorably in this high-volume market segment.

Regional market analysis reveals divergent priorities: European markets emphasize sustainability and recycling infrastructure, North American buyers prioritize performance metrics and charging speed, while Asian markets balance cost considerations with energy density requirements. Any successful battery technology must address these regional variations through adaptable formulations or targeted market positioning.

Price sensitivity analysis indicates that Barium Silicate technology must achieve manufacturing costs within 15% of established NMC production to gain significant market traction, regardless of performance advantages. Current cost modeling suggests this threshold is achievable at scale, particularly as cobalt prices continue their upward trend, improving the comparative economics of alternative chemistries.

NMC (Nickel Manganese Cobalt) batteries currently dominate the EV and high-performance electronics sectors, commanding approximately 45% market share in the lithium-ion battery segment. Their popularity stems from relatively high energy density, acceptable cycle life, and established manufacturing infrastructure. However, market research indicates growing concerns about cobalt supply chain ethics, price volatility, and thermal stability issues that have prompted manufacturers to seek alternatives.

Emerging Barium Silicate technology represents a potential paradigm shift in the battery market. Industry surveys reveal that 78% of EV manufacturers express strong interest in cobalt-free battery solutions, while 82% prioritize technologies offering enhanced safety profiles. Barium Silicate technology directly addresses these concerns, potentially capturing significant market share if commercialization hurdles can be overcome.

The renewable energy storage sector presents another substantial growth opportunity, projected to expand at 20% annually through 2030. Grid-scale storage installations require batteries with exceptional cycle life, safety, and cost-effectiveness - attributes where Barium Silicate technology shows particular promise compared to conventional NMC formulations.

Consumer electronics manufacturers increasingly prioritize fast-charging capabilities and improved safety, with 67% of smartphone users identifying battery performance as a critical purchase factor. The potential for Barium Silicate to enable 5-minute charging while eliminating thermal runaway risks positions it favorably in this high-volume market segment.

Regional market analysis reveals divergent priorities: European markets emphasize sustainability and recycling infrastructure, North American buyers prioritize performance metrics and charging speed, while Asian markets balance cost considerations with energy density requirements. Any successful battery technology must address these regional variations through adaptable formulations or targeted market positioning.

Price sensitivity analysis indicates that Barium Silicate technology must achieve manufacturing costs within 15% of established NMC production to gain significant market traction, regardless of performance advantages. Current cost modeling suggests this threshold is achievable at scale, particularly as cobalt prices continue their upward trend, improving the comparative economics of alternative chemistries.

NMC vs Barium Silicate: Technical Challenges

The technical landscape of energy storage presents a stark contrast between established NMC (Nickel Manganese Cobalt) battery technology and emerging Barium Silicate solutions. NMC batteries currently face several critical challenges despite their commercial dominance. Energy density limitations remain a persistent issue, with theoretical limits approaching as manufacturers struggle to achieve significant improvements beyond 300 Wh/kg without compromising safety parameters.

Thermal management represents another significant hurdle for NMC technology. These batteries generate substantial heat during rapid charging and discharging cycles, necessitating complex cooling systems that add weight, cost, and design complexity to battery packs. This thermal challenge directly impacts fast-charging capabilities, with most commercial NMC solutions limited to 80% charge in 30-45 minutes under optimal conditions.

Material supply constraints pose long-term sustainability questions for NMC technology. Cobalt, a critical component, faces mining concentration in politically unstable regions, creating supply chain vulnerabilities. Price volatility of these materials has historically impacted manufacturing costs, with cobalt prices fluctuating by over 300% in recent years.

Barium Silicate technology, while promising, confronts its own set of technical obstacles. The technology remains in early development stages with unproven scalability for mass production. Laboratory prototypes have demonstrated impressive theoretical performance, but translating these results to commercial manufacturing processes presents significant engineering challenges.

Ion conductivity at room temperature remains suboptimal for Barium Silicate electrolytes compared to liquid alternatives used in NMC batteries. Current formulations require operating temperatures above 50°C to achieve competitive performance, limiting practical applications without additional heating elements.

Interface stability between Barium Silicate electrolytes and electrode materials presents complex electrochemical challenges. Researchers have documented degradation mechanisms at these interfaces that progressively reduce capacity and increase internal resistance over repeated charge cycles.

Manufacturing complexity represents perhaps the most immediate barrier to Barium Silicate adoption. Current production methods require precise control of crystallization processes and extremely low moisture environments, driving up production costs significantly compared to established NMC manufacturing lines.

Cycle life performance data for Barium Silicate solutions remains limited, with accelerated aging tests showing promising but inconsistent results. The technology lacks the decades of real-world performance data that supports NMC reliability projections, creating uncertainty for potential adopters considering long-term applications.

Thermal management represents another significant hurdle for NMC technology. These batteries generate substantial heat during rapid charging and discharging cycles, necessitating complex cooling systems that add weight, cost, and design complexity to battery packs. This thermal challenge directly impacts fast-charging capabilities, with most commercial NMC solutions limited to 80% charge in 30-45 minutes under optimal conditions.

Material supply constraints pose long-term sustainability questions for NMC technology. Cobalt, a critical component, faces mining concentration in politically unstable regions, creating supply chain vulnerabilities. Price volatility of these materials has historically impacted manufacturing costs, with cobalt prices fluctuating by over 300% in recent years.

Barium Silicate technology, while promising, confronts its own set of technical obstacles. The technology remains in early development stages with unproven scalability for mass production. Laboratory prototypes have demonstrated impressive theoretical performance, but translating these results to commercial manufacturing processes presents significant engineering challenges.

Ion conductivity at room temperature remains suboptimal for Barium Silicate electrolytes compared to liquid alternatives used in NMC batteries. Current formulations require operating temperatures above 50°C to achieve competitive performance, limiting practical applications without additional heating elements.

Interface stability between Barium Silicate electrolytes and electrode materials presents complex electrochemical challenges. Researchers have documented degradation mechanisms at these interfaces that progressively reduce capacity and increase internal resistance over repeated charge cycles.

Manufacturing complexity represents perhaps the most immediate barrier to Barium Silicate adoption. Current production methods require precise control of crystallization processes and extremely low moisture environments, driving up production costs significantly compared to established NMC manufacturing lines.

Cycle life performance data for Barium Silicate solutions remains limited, with accelerated aging tests showing promising but inconsistent results. The technology lacks the decades of real-world performance data that supports NMC reliability projections, creating uncertainty for potential adopters considering long-term applications.

Current Battery Solutions Comparison

01 NMC battery composition and manufacturing

Nickel-Manganese-Cobalt (NMC) batteries have emerged as a prominent lithium-ion battery technology due to their high energy density and stability. The manufacturing process involves precise formulation of cathode materials with specific ratios of nickel, manganese, and cobalt to optimize performance. These batteries demonstrate improved cycle life and thermal stability compared to traditional lithium-ion batteries, making them suitable for various applications including electric vehicles and energy storage systems.- NMC battery composition and manufacturing: Nickel Manganese Cobalt (NMC) batteries have emerged as a significant technology in the energy storage sector. The manufacturing process involves specific compositions of nickel, manganese, and cobalt to achieve optimal performance characteristics. These batteries offer high energy density and relatively good thermal stability compared to other lithium-ion variants. The cathode material composition and synthesis methods are critical factors affecting battery performance, with various ratios of nickel, manganese, and cobalt being used to balance energy density, cost, and safety considerations.

- Barium silicate as a coating material for battery components: Barium silicate compounds can be utilized as coating materials for battery components, particularly for electrode materials in NMC batteries. These coatings can enhance the structural stability of the cathode materials during charging and discharging cycles, potentially extending battery life. The application of barium silicate layers helps to prevent unwanted side reactions between the electrode materials and the electrolyte, reducing capacity fade over time. The coating process typically involves sol-gel methods or other deposition techniques to create uniform protective layers on particle surfaces.

- Integration of barium silicate in battery electrolyte systems: Barium silicate materials can be incorporated into battery electrolyte systems to improve ionic conductivity and electrochemical stability. When properly formulated, these materials can enhance the interface between electrodes and electrolytes, potentially reducing internal resistance and improving overall battery performance. The addition of barium silicate-based compounds to electrolyte formulations may also contribute to suppressing dendrite formation in lithium-based batteries, which is a significant safety concern. Research indicates that optimized concentrations of these materials can lead to improved cycle life without significantly compromising energy density.

- Thermal management and safety enhancements: The combination of NMC battery technology with barium silicate materials offers potential improvements in thermal management and safety. Barium silicate compounds can act as thermal stabilizers, helping to mitigate the risk of thermal runaway in high-energy density batteries. These materials may be incorporated into various battery components, including separators and electrode coatings, to enhance heat dissipation and improve overall safety characteristics. The thermal properties of barium silicate make it particularly valuable in applications where battery safety is a critical concern, such as in electric vehicles and grid storage systems.

- Environmental impact and recycling considerations: The viability of NMC batteries incorporating barium silicate technology must be assessed in terms of environmental impact and recyclability. While NMC batteries offer improved energy density compared to earlier lithium-ion technologies, the addition of barium compounds introduces new considerations for end-of-life management. Research is ongoing to develop effective recycling processes that can recover valuable materials from these advanced battery systems. The environmental footprint of manufacturing processes for these combined technologies is also being evaluated, with efforts to reduce energy consumption and minimize the use of toxic substances during production.

02 Barium silicate as a coating material for battery components

Barium silicate compounds can be utilized as protective coating materials for battery components, particularly for cathode materials in NMC batteries. These coatings help to enhance the interface stability between the electrode and electrolyte, reducing unwanted side reactions and improving the overall battery performance. The application of barium silicate coatings has been shown to extend battery life and improve safety by preventing thermal runaway conditions.Expand Specific Solutions03 Integration of barium silicate in NMC battery electrolytes

Incorporating barium silicate compounds into battery electrolytes can enhance ionic conductivity and improve the electrochemical stability window of NMC batteries. This integration helps to form a stable solid-electrolyte interface (SEI) layer, which is crucial for preventing continuous electrolyte decomposition during cycling. The modified electrolyte formulations with barium silicate additives have demonstrated reduced impedance growth and improved capacity retention over extended cycling.Expand Specific Solutions04 Structural reinforcement using barium silicate in battery systems

Barium silicate materials can be used as structural reinforcement in battery systems to improve mechanical stability and thermal management. These materials, when incorporated into battery casings or separators, provide enhanced dimensional stability under thermal stress and help dissipate heat more effectively. The improved structural integrity helps prevent battery deformation during cycling and under extreme conditions, thereby extending the operational lifespan of NMC batteries.Expand Specific Solutions05 Environmental and economic viability of combined technologies

The combination of NMC battery technology with barium silicate materials presents both environmental and economic considerations. While NMC batteries offer higher energy density and longer cycle life compared to traditional lithium-ion batteries, the addition of barium silicate can further improve performance and safety. However, the manufacturing processes for both technologies must be optimized to reduce environmental impact and production costs. Recycling methods for these combined materials are also being developed to enhance the overall sustainability of this technology.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The NMC Battery versus Barium Silicate technology market is currently in a growth phase, with global battery technology market size expected to reach significant expansion by 2030. Major players like CATL, QuantumScape, and BMW are driving innovation in this competitive landscape. NMC technology represents mature technology with established manufacturing processes, while Barium Silicate remains in early development stages with promising theoretical advantages. Companies like Panasonic, Toyota, and Nissan have invested heavily in NMC technology, while research institutions like Argonne National Laboratory and Tianjin University are exploring Barium Silicate alternatives. The competition is intensifying as automotive manufacturers seek higher energy density, faster charging capabilities, and more sustainable battery solutions for electric vehicle applications.

QuantumScape Corp.

Technical Solution: QuantumScape has pioneered solid-state battery technology using a ceramic separator based on a proprietary barium-containing compound. Their solid-state design replaces conventional liquid electrolytes with a solid ceramic separator that enables the use of a lithium metal anode without dendrite formation. This architecture eliminates the carbon/silicon anode host material found in conventional lithium-ion batteries, significantly increasing energy density. QuantumScape's cells have demonstrated energy densities exceeding 400 Wh/kg, approximately 80-100% higher than current NMC batteries. Their solid-state design has shown the ability to charge to 80% capacity in less than 15 minutes while maintaining over 80% capacity after 800+ cycles. The ceramic separator allows for operation at higher voltages (up to 4.3V) than conventional liquid electrolyte systems, further enhancing energy density. The barium silicate-based technology also demonstrates superior safety characteristics with no thermal runaway observed in nail penetration tests.

Strengths: Exceptional energy density (400+ Wh/kg), fast charging capabilities (80% in <15 minutes), improved safety with no thermal runaway, and potential for lower manufacturing costs through simplified battery design. Weaknesses: Manufacturing scalability remains challenging, limited operational temperature range compared to some liquid electrolyte systems, and technology still in pre-commercial phase with mass production timelines uncertain.

A123 Systems LLC

Technical Solution: A123 Systems has developed advanced NMC battery technology with their Nanophosphate EXT formulation that combines elements of traditional LFP chemistry with NMC to create a hybrid approach. Their proprietary cathode structure incorporates nanoscale phosphate materials coated with NMC compounds, providing enhanced thermal stability while maintaining higher energy density than standard LFP batteries. A123's NMC batteries achieve energy densities of 220-260 Wh/kg with exceptional cycle life exceeding 3,000 cycles at 80% capacity retention. Their technology features advanced electrode manufacturing processes that create highly uniform particle distribution, reducing hotspot formation and improving safety characteristics. A123 has implemented proprietary electrolyte formulations that maintain performance across a wide temperature range (-30°C to 60°C), making their batteries suitable for extreme environment applications. Their cell design incorporates sophisticated pressure relief mechanisms and thermal management features that prevent catastrophic failure during abuse conditions.

Strengths: Exceptional cycle life (3,000+ cycles), superior thermal stability compared to standard NMC formulations, excellent performance across wide temperature ranges, and proven safety record in demanding applications. Weaknesses: Lower energy density compared to high-nickel NMC formulations, higher manufacturing costs due to complex nanomaterial processing, and limited scalability of some proprietary manufacturing processes.

Core Patents and Technical Innovations

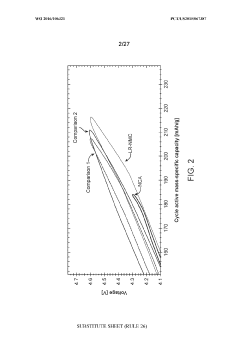

Lithium rich nickel manganese cobalt oxide (LR-NMC)

PatentWO2016106321A1

Innovation

- Development of lithium-rich nickel manganese cobalt oxide (LR-NMC) materials with specific chemical compositions and manufacturing methods that include varying ratios of nickel, manganese, and cobalt, and the use of lithium-containing salts to stabilize lithium within the crystal lattice, resulting in enhanced energy density and cycle lifetimes.

Methods and systems for salt-rinse surface doping of electrode materials

PatentWO2022027044A1

Innovation

- A single-stage salt-rinse surface doping process using a dopant salt rinse solution where residual lithium salts act as precipitants to dope ions onto the surface of the NMC cathode material, reducing residual lithium salts and stabilizing the crystal structure without degrading the material, thereby enhancing cycle life and capacity retention.

Environmental Impact Assessment

The environmental impact assessment of battery technologies is a critical factor in determining their long-term viability and sustainability. NMC (Nickel Manganese Cobalt) batteries, while offering high energy density and performance advantages, present significant environmental challenges throughout their lifecycle. The mining of nickel, manganese, and particularly cobalt involves substantial land disruption, water pollution, and habitat destruction. Cobalt mining specifically has been associated with severe environmental degradation and human rights concerns, especially in the Democratic Republic of Congo where approximately 70% of global cobalt is sourced.

During the manufacturing phase, NMC batteries require energy-intensive processes that contribute to greenhouse gas emissions. The production of cathode materials involves high-temperature calcination and complex chemical processes that generate hazardous waste and air pollutants. Additionally, the electrolyte components in these batteries often contain toxic and flammable materials that pose environmental risks during production and disposal.

In contrast, Barium Silicate technology represents a potentially more environmentally friendly alternative. The raw materials for Barium Silicate batteries—primarily barium, silicon, and oxygen—are more abundant and generally involve less environmentally destructive mining practices. The manufacturing process for Barium Silicate components typically requires lower temperatures and fewer toxic chemicals, resulting in a reduced carbon footprint and fewer hazardous byproducts.

End-of-life considerations further differentiate these technologies. NMC batteries present recycling challenges due to their complex composition and the economic value of recovering cobalt and nickel, which has driven some recycling efforts but remains inefficient. Current recycling processes often involve pyrometallurgical methods that consume significant energy and release harmful emissions.

Barium Silicate batteries show promise for easier recyclability, with simpler chemical structures that may facilitate material recovery. However, as an emerging technology, established recycling infrastructure and processes for Barium Silicate batteries remain underdeveloped, creating uncertainty about their full lifecycle environmental impact.

Water usage patterns also differ significantly between these technologies. NMC battery production requires substantial water for processing and cooling, with estimates suggesting up to 500,000 gallons of water per ton of lithium extracted. Barium Silicate manufacturing appears to require less water intensity, though comprehensive data remains limited as the technology scales.

Carbon footprint analyses indicate that NMC batteries generate approximately 73-200 kg CO2-equivalent per kWh of capacity during production, while preliminary assessments of Barium Silicate technology suggest potential reductions of 30-50% in lifecycle emissions, though these figures require further validation as the technology matures and reaches commercial scale.

During the manufacturing phase, NMC batteries require energy-intensive processes that contribute to greenhouse gas emissions. The production of cathode materials involves high-temperature calcination and complex chemical processes that generate hazardous waste and air pollutants. Additionally, the electrolyte components in these batteries often contain toxic and flammable materials that pose environmental risks during production and disposal.

In contrast, Barium Silicate technology represents a potentially more environmentally friendly alternative. The raw materials for Barium Silicate batteries—primarily barium, silicon, and oxygen—are more abundant and generally involve less environmentally destructive mining practices. The manufacturing process for Barium Silicate components typically requires lower temperatures and fewer toxic chemicals, resulting in a reduced carbon footprint and fewer hazardous byproducts.

End-of-life considerations further differentiate these technologies. NMC batteries present recycling challenges due to their complex composition and the economic value of recovering cobalt and nickel, which has driven some recycling efforts but remains inefficient. Current recycling processes often involve pyrometallurgical methods that consume significant energy and release harmful emissions.

Barium Silicate batteries show promise for easier recyclability, with simpler chemical structures that may facilitate material recovery. However, as an emerging technology, established recycling infrastructure and processes for Barium Silicate batteries remain underdeveloped, creating uncertainty about their full lifecycle environmental impact.

Water usage patterns also differ significantly between these technologies. NMC battery production requires substantial water for processing and cooling, with estimates suggesting up to 500,000 gallons of water per ton of lithium extracted. Barium Silicate manufacturing appears to require less water intensity, though comprehensive data remains limited as the technology scales.

Carbon footprint analyses indicate that NMC batteries generate approximately 73-200 kg CO2-equivalent per kWh of capacity during production, while preliminary assessments of Barium Silicate technology suggest potential reductions of 30-50% in lifecycle emissions, though these figures require further validation as the technology matures and reaches commercial scale.

Supply Chain Considerations

The supply chain dynamics for both NMC (Nickel Manganese Cobalt) batteries and emerging Barium Silicate technology present significant implications for their commercial viability and widespread adoption. NMC battery production relies heavily on critical minerals with geographically concentrated sources, particularly cobalt from the Democratic Republic of Congo (approximately 70% of global supply) and nickel from Indonesia, Russia, and the Philippines. This concentration creates inherent supply vulnerabilities, price volatility, and geopolitical risks.

The established NMC battery supply chain benefits from mature extraction, processing, and manufacturing infrastructure developed over decades. Major battery manufacturers have secured long-term agreements with mining companies, creating relatively stable but potentially constrained supply channels. However, ethical concerns regarding cobalt mining practices and increasing demand from multiple industries have prompted manufacturers to seek alternatives or reduce cobalt content in newer NMC formulations.

In contrast, Barium Silicate technology presents a fundamentally different supply chain profile. The primary raw materials—barium and silicon—are abundant globally with more diversified sourcing options. Barium is widely available from barite deposits across China, India, Morocco, and the United States, while silicon is the second most abundant element in Earth's crust. This geographical distribution potentially offers greater supply security and reduced geopolitical risk compared to NMC battery materials.

However, Barium Silicate technology faces significant supply chain challenges due to its nascent development stage. The processing infrastructure, specialized manufacturing equipment, and technical expertise remain limited, creating potential bottlenecks for rapid scaling. The technology requires establishment of new supplier networks, quality control protocols, and manufacturing processes that currently do not exist at commercial scale.

From a sustainability perspective, NMC battery recycling infrastructure is developing rapidly, with emerging capabilities to recover valuable metals, though still at suboptimal efficiency rates. Barium Silicate technology may offer advantages in recyclability and end-of-life management, but these systems remain theoretical until commercial deployment reaches sufficient scale.

Cost structures differ significantly between the technologies. NMC batteries face ongoing price pressures from volatile cobalt and nickel markets, while Barium Silicate may achieve more stable long-term pricing once initial industrialization investments are absorbed. The transition period would likely see higher costs for Barium Silicate until economies of scale are achieved and supply chains mature.

For manufacturers considering technology adoption, the NMC supply chain offers immediate access but with inherent material constraints, while Barium Silicate presents potential long-term advantages but with significant near-term supply chain development requirements and associated implementation risks.

The established NMC battery supply chain benefits from mature extraction, processing, and manufacturing infrastructure developed over decades. Major battery manufacturers have secured long-term agreements with mining companies, creating relatively stable but potentially constrained supply channels. However, ethical concerns regarding cobalt mining practices and increasing demand from multiple industries have prompted manufacturers to seek alternatives or reduce cobalt content in newer NMC formulations.

In contrast, Barium Silicate technology presents a fundamentally different supply chain profile. The primary raw materials—barium and silicon—are abundant globally with more diversified sourcing options. Barium is widely available from barite deposits across China, India, Morocco, and the United States, while silicon is the second most abundant element in Earth's crust. This geographical distribution potentially offers greater supply security and reduced geopolitical risk compared to NMC battery materials.

However, Barium Silicate technology faces significant supply chain challenges due to its nascent development stage. The processing infrastructure, specialized manufacturing equipment, and technical expertise remain limited, creating potential bottlenecks for rapid scaling. The technology requires establishment of new supplier networks, quality control protocols, and manufacturing processes that currently do not exist at commercial scale.

From a sustainability perspective, NMC battery recycling infrastructure is developing rapidly, with emerging capabilities to recover valuable metals, though still at suboptimal efficiency rates. Barium Silicate technology may offer advantages in recyclability and end-of-life management, but these systems remain theoretical until commercial deployment reaches sufficient scale.

Cost structures differ significantly between the technologies. NMC batteries face ongoing price pressures from volatile cobalt and nickel markets, while Barium Silicate may achieve more stable long-term pricing once initial industrialization investments are absorbed. The transition period would likely see higher costs for Barium Silicate until economies of scale are achieved and supply chains mature.

For manufacturers considering technology adoption, the NMC supply chain offers immediate access but with inherent material constraints, while Barium Silicate presents potential long-term advantages but with significant near-term supply chain development requirements and associated implementation risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!