Benchmark NMC Battery's Charge Retention Under Extreme Conditions

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Technology Evolution and Benchmarking Objectives

Lithium-ion batteries have undergone significant evolution since their commercial introduction in the early 1990s. Among various cathode chemistries, Nickel Manganese Cobalt (NMC) batteries have emerged as a dominant technology in the energy storage landscape. The development of NMC batteries represents a critical advancement in balancing energy density, power capability, cycle life, and safety considerations.

The evolution of NMC battery technology can be traced through several generations, beginning with the first-generation NMC111 (equal parts nickel, manganese, and cobalt) to more recent formulations such as NMC622 and NMC811, which feature increased nickel content to enhance energy density while reducing dependency on costly and ethically problematic cobalt resources.

This technological progression has been driven by market demands for higher energy density, improved safety profiles, and extended operational lifespans, particularly in electric vehicle applications where performance under varying conditions is paramount. The industry has witnessed a consistent annual improvement rate of approximately 5-8% in energy density, while simultaneously addressing thermal stability challenges inherent to high-nickel formulations.

Current benchmarking objectives for NMC batteries focus on evaluating charge retention capabilities under extreme environmental conditions, which represents a critical performance parameter for real-world applications. Temperature extremes, both high and low, significantly impact battery performance, safety, and longevity through mechanisms including accelerated side reactions, electrolyte degradation, and structural changes to electrode materials.

The primary goal of benchmarking NMC battery charge retention under extreme conditions is to establish standardized performance metrics that accurately reflect real-world usage scenarios. This includes evaluating capacity retention after extended storage at temperature extremes (-20°C to 60°C), cycle life performance across varied temperature ranges, and self-discharge rates under thermal stress conditions.

Additionally, benchmarking aims to identify the correlation between specific material compositions and their resilience to extreme conditions, potentially guiding future material development. By systematically comparing different NMC formulations under identical stress conditions, researchers can isolate key performance differentiators and failure mechanisms.

The ultimate objective extends beyond mere performance comparison to establishing predictive models for battery behavior under extreme conditions, enabling more accurate lifetime predictions and informing battery management system algorithms. This comprehensive benchmarking approach serves both immediate product development needs and longer-term research directions in advanced energy storage technologies.

The evolution of NMC battery technology can be traced through several generations, beginning with the first-generation NMC111 (equal parts nickel, manganese, and cobalt) to more recent formulations such as NMC622 and NMC811, which feature increased nickel content to enhance energy density while reducing dependency on costly and ethically problematic cobalt resources.

This technological progression has been driven by market demands for higher energy density, improved safety profiles, and extended operational lifespans, particularly in electric vehicle applications where performance under varying conditions is paramount. The industry has witnessed a consistent annual improvement rate of approximately 5-8% in energy density, while simultaneously addressing thermal stability challenges inherent to high-nickel formulations.

Current benchmarking objectives for NMC batteries focus on evaluating charge retention capabilities under extreme environmental conditions, which represents a critical performance parameter for real-world applications. Temperature extremes, both high and low, significantly impact battery performance, safety, and longevity through mechanisms including accelerated side reactions, electrolyte degradation, and structural changes to electrode materials.

The primary goal of benchmarking NMC battery charge retention under extreme conditions is to establish standardized performance metrics that accurately reflect real-world usage scenarios. This includes evaluating capacity retention after extended storage at temperature extremes (-20°C to 60°C), cycle life performance across varied temperature ranges, and self-discharge rates under thermal stress conditions.

Additionally, benchmarking aims to identify the correlation between specific material compositions and their resilience to extreme conditions, potentially guiding future material development. By systematically comparing different NMC formulations under identical stress conditions, researchers can isolate key performance differentiators and failure mechanisms.

The ultimate objective extends beyond mere performance comparison to establishing predictive models for battery behavior under extreme conditions, enabling more accurate lifetime predictions and informing battery management system algorithms. This comprehensive benchmarking approach serves both immediate product development needs and longer-term research directions in advanced energy storage technologies.

Market Demand Analysis for High-Performance NMC Batteries

The global market for high-performance NMC (Nickel Manganese Cobalt) batteries is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs) and energy storage systems. Current market valuations place the NMC battery sector at approximately 45 billion USD in 2023, with projections indicating a compound annual growth rate of 12-15% through 2030.

Demand for NMC batteries with superior charge retention capabilities under extreme conditions is particularly strong in regions with variable climate patterns. North America and Europe show increasing requirements for batteries that maintain performance in temperature ranges from -30°C to 60°C, especially for electric vehicles operating in diverse geographical locations.

The automotive sector represents the largest market segment, accounting for nearly 70% of high-performance NMC battery demand. Major automotive manufacturers are actively seeking battery solutions that can maintain at least 80% charge retention after 1000 cycles under varying temperature conditions, a significant improvement over current standards of 70% retention.

Consumer electronics manufacturers constitute the second-largest market segment, with growing emphasis on devices that maintain consistent performance in challenging environments. This sector values NMC batteries that can deliver stable power output across temperature fluctuations without compromising device safety or longevity.

Market research indicates that consumers are willing to pay a premium of 15-20% for batteries with proven extreme condition performance, highlighting the commercial viability of advanced NMC formulations. This premium pricing potential creates significant revenue opportunities for companies that can successfully develop and commercialize such technologies.

Industry surveys reveal that 85% of fleet operators consider battery performance under extreme conditions as a "critical" or "very important" factor in purchasing decisions for electric commercial vehicles. This represents a shift from earlier adoption phases where initial cost and standard range were primary considerations.

Regulatory trends are further accelerating market demand, with several jurisdictions implementing or considering performance standards that include extreme condition testing. The European Union's proposed Battery Regulation includes specific provisions for temperature performance declarations, while China's battery certification programs are increasingly incorporating extreme condition testing protocols.

Emerging markets in Southeast Asia, India, and parts of Africa present substantial growth opportunities, as these regions often experience extreme heat conditions that challenge conventional battery technologies. The market potential in these regions is expected to grow at 18-20% annually, outpacing global averages.

Demand for NMC batteries with superior charge retention capabilities under extreme conditions is particularly strong in regions with variable climate patterns. North America and Europe show increasing requirements for batteries that maintain performance in temperature ranges from -30°C to 60°C, especially for electric vehicles operating in diverse geographical locations.

The automotive sector represents the largest market segment, accounting for nearly 70% of high-performance NMC battery demand. Major automotive manufacturers are actively seeking battery solutions that can maintain at least 80% charge retention after 1000 cycles under varying temperature conditions, a significant improvement over current standards of 70% retention.

Consumer electronics manufacturers constitute the second-largest market segment, with growing emphasis on devices that maintain consistent performance in challenging environments. This sector values NMC batteries that can deliver stable power output across temperature fluctuations without compromising device safety or longevity.

Market research indicates that consumers are willing to pay a premium of 15-20% for batteries with proven extreme condition performance, highlighting the commercial viability of advanced NMC formulations. This premium pricing potential creates significant revenue opportunities for companies that can successfully develop and commercialize such technologies.

Industry surveys reveal that 85% of fleet operators consider battery performance under extreme conditions as a "critical" or "very important" factor in purchasing decisions for electric commercial vehicles. This represents a shift from earlier adoption phases where initial cost and standard range were primary considerations.

Regulatory trends are further accelerating market demand, with several jurisdictions implementing or considering performance standards that include extreme condition testing. The European Union's proposed Battery Regulation includes specific provisions for temperature performance declarations, while China's battery certification programs are increasingly incorporating extreme condition testing protocols.

Emerging markets in Southeast Asia, India, and parts of Africa present substantial growth opportunities, as these regions often experience extreme heat conditions that challenge conventional battery technologies. The market potential in these regions is expected to grow at 18-20% annually, outpacing global averages.

Current Challenges in NMC Battery Charge Retention

NMC (Nickel Manganese Cobalt) batteries face significant challenges in maintaining charge retention under extreme conditions, which has become a critical concern for industries relying on these energy storage solutions. Temperature extremes represent the foremost challenge, with high temperatures (above 45°C) accelerating side reactions between the electrolyte and electrode materials, leading to accelerated capacity fade and reduced charge retention. Conversely, low temperatures (below 0°C) dramatically increase internal resistance, limiting lithium-ion diffusion rates and causing severe power loss.

Cycling stress presents another major challenge, particularly in applications requiring frequent deep discharge-charge cycles. Repeated cycling causes structural degradation in the cathode material, with crystal lattice distortion and microcracking occurring as lithium ions are repeatedly inserted and extracted. This mechanical stress is especially pronounced under extreme temperature conditions, creating a compounding negative effect on charge retention.

Electrolyte decomposition accelerates under extreme conditions, forming resistive surface films on electrodes that impede ion transport. This solid electrolyte interphase (SEI) growth is particularly problematic at high temperatures, where the decomposition reactions proceed more rapidly, consuming active lithium and increasing cell impedance.

Transition metal dissolution from the NMC cathode represents a significant degradation mechanism, especially in high-nickel content formulations (e.g., NMC811) that offer higher energy density but reduced stability. Under extreme conditions, manganese and nickel ions can dissolve into the electrolyte and migrate to the anode, contaminating the SEI layer and causing irreversible capacity loss.

Thermal runaway risk increases substantially under extreme conditions, particularly when batteries are charged at high rates in elevated temperatures. The delicate balance between performance and safety becomes increasingly difficult to maintain as conditions deviate from optimal operating parameters.

Current battery management systems (BMS) struggle to accurately predict and compensate for degradation under extreme conditions, as most algorithms are calibrated for standard operating environments. This leads to inaccurate state-of-charge and state-of-health estimations, potentially resulting in unexpected performance failures in critical applications.

Manufacturing variability compounds these challenges, as inconsistencies in electrode coating, electrolyte distribution, and cell assembly can create weak points that become failure initiation sites under extreme conditions. These manufacturing variations may remain undetected during quality control processes conducted under standard conditions but manifest as performance issues when batteries are stressed.

Cycling stress presents another major challenge, particularly in applications requiring frequent deep discharge-charge cycles. Repeated cycling causes structural degradation in the cathode material, with crystal lattice distortion and microcracking occurring as lithium ions are repeatedly inserted and extracted. This mechanical stress is especially pronounced under extreme temperature conditions, creating a compounding negative effect on charge retention.

Electrolyte decomposition accelerates under extreme conditions, forming resistive surface films on electrodes that impede ion transport. This solid electrolyte interphase (SEI) growth is particularly problematic at high temperatures, where the decomposition reactions proceed more rapidly, consuming active lithium and increasing cell impedance.

Transition metal dissolution from the NMC cathode represents a significant degradation mechanism, especially in high-nickel content formulations (e.g., NMC811) that offer higher energy density but reduced stability. Under extreme conditions, manganese and nickel ions can dissolve into the electrolyte and migrate to the anode, contaminating the SEI layer and causing irreversible capacity loss.

Thermal runaway risk increases substantially under extreme conditions, particularly when batteries are charged at high rates in elevated temperatures. The delicate balance between performance and safety becomes increasingly difficult to maintain as conditions deviate from optimal operating parameters.

Current battery management systems (BMS) struggle to accurately predict and compensate for degradation under extreme conditions, as most algorithms are calibrated for standard operating environments. This leads to inaccurate state-of-charge and state-of-health estimations, potentially resulting in unexpected performance failures in critical applications.

Manufacturing variability compounds these challenges, as inconsistencies in electrode coating, electrolyte distribution, and cell assembly can create weak points that become failure initiation sites under extreme conditions. These manufacturing variations may remain undetected during quality control processes conducted under standard conditions but manifest as performance issues when batteries are stressed.

Existing Solutions for Extreme Condition Battery Performance

01 Electrode material composition for improved charge retention

Specific compositions of NMC (Nickel Manganese Cobalt) cathode materials can significantly improve charge retention in batteries. By optimizing the ratio of nickel, manganese, and cobalt in the lithium metal oxide structure, manufacturers can create batteries with enhanced capacity retention during cycling. These compositions often include dopants or coatings that stabilize the crystal structure during charge-discharge cycles, preventing capacity fade and improving long-term charge retention properties.- Electrode composition optimization for NMC batteries: Optimizing the composition of NMC (Nickel Manganese Cobalt) cathode materials can significantly improve charge retention. By adjusting the ratio of nickel, manganese, and cobalt, researchers have developed electrode formulations that minimize capacity fade during cycling. These optimized compositions help maintain structural stability during repeated charge-discharge cycles, reducing degradation mechanisms that lead to capacity loss over time.

- Surface coating and modification techniques: Surface coating and modification of NMC particles can enhance charge retention by creating protective barriers against electrolyte reactions. Various coating materials such as metal oxides, phosphates, and carbon-based materials can be applied to NMC particles to prevent surface degradation and electrolyte side reactions. These coatings help maintain the structural integrity of the cathode material during cycling, resulting in improved capacity retention and extended battery life.

- Electrolyte additives and formulations: Specialized electrolyte additives and formulations can significantly improve NMC battery charge retention. These additives form stable solid electrolyte interphase (SEI) layers that prevent continuous electrolyte decomposition and protect electrode surfaces. By incorporating specific compounds that enhance the stability of the electrode-electrolyte interface, the charge retention capabilities of NMC batteries can be substantially improved, particularly during high-temperature operation and fast charging conditions.

- Advanced battery management systems: Advanced battery management systems (BMS) play a crucial role in maintaining charge retention in NMC batteries. These systems monitor and control charging parameters, cell balancing, and temperature management to prevent conditions that accelerate capacity fade. By implementing sophisticated algorithms that optimize charging protocols based on battery state and usage patterns, BMS technology can significantly extend the usable life of NMC batteries and preserve their charge retention capabilities over time.

- Doping and structural stabilization methods: Doping NMC materials with various elements can enhance structural stability and improve charge retention. Elements such as aluminum, magnesium, zirconium, and titanium can be incorporated into the crystal structure to reduce lattice distortion during cycling. These dopants help maintain the layered structure of NMC materials, prevent phase transitions, and reduce transition metal dissolution, all of which contribute to better charge retention performance over extended cycling.

02 Battery management systems for charge retention

Advanced battery management systems (BMS) play a crucial role in maintaining charge retention in NMC batteries. These systems monitor and control charging parameters, cell balancing, and temperature management to prevent conditions that accelerate capacity loss. By implementing sophisticated algorithms that optimize charging profiles and prevent overcharging or deep discharging, BMS technology can significantly extend the charge retention capabilities of NMC batteries throughout their operational lifetime.Expand Specific Solutions03 Electrolyte formulations for enhanced charge retention

Specialized electrolyte formulations can substantially improve charge retention in NMC batteries. These formulations often include additives that form stable solid-electrolyte interphase (SEI) layers, reducing unwanted side reactions at electrode surfaces that lead to capacity loss. Advanced electrolytes may incorporate flame-retardant compounds, ionic liquids, or novel solvents that not only enhance safety but also minimize electrolyte decomposition during cycling, thereby maintaining charge retention capabilities over extended periods.Expand Specific Solutions04 Structural design innovations for charge retention

Innovative structural designs at both cell and pack levels can significantly improve charge retention in NMC batteries. These designs include optimized electrode architectures with controlled porosity, novel current collector configurations, and advanced cell packaging techniques that minimize mechanical stress during cycling. Some designs incorporate special pressure regulation mechanisms or thermal management systems that maintain optimal operating conditions, preventing accelerated degradation mechanisms that would otherwise compromise charge retention.Expand Specific Solutions05 Diagnostic and testing methods for charge retention

Advanced diagnostic and testing methodologies help evaluate and improve charge retention in NMC batteries. These techniques include electrochemical impedance spectroscopy, differential voltage analysis, and accelerated aging tests that can identify degradation mechanisms affecting charge retention. By implementing these diagnostic approaches during development and quality control processes, manufacturers can optimize battery designs specifically for long-term charge retention performance and develop more accurate predictive models for battery lifetime under various operating conditions.Expand Specific Solutions

Key Industry Players in Advanced NMC Battery Development

The NMC battery charge retention market under extreme conditions is currently in a growth phase, with increasing demand driven by electric vehicle and energy storage applications. The market size is projected to expand significantly as battery technology becomes more critical for renewable energy integration. Technologically, industry leaders like Samsung SDI, LG Chem, and Contemporary Amperex Technology (CATL) have made substantial advancements in NMC chemistry stability, while companies like QuantumScape and Toyota are developing next-generation solutions. Traditional battery manufacturers including Toshiba, Maxell, and Hitachi are competing with automotive specialists like BMW and research-focused entities such as Sion Power and Innolith Technology to improve extreme condition performance. University collaborations with National University of Singapore and research organizations like Argonne are accelerating innovation in this competitive landscape.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced NMC battery technology with enhanced charge retention capabilities under extreme conditions. Their proprietary "Z-Fold" separator design and high-temperature electrolyte formulations enable stable performance between -30°C to 60°C. Samsung's NMC batteries incorporate silicon-carbon composite anodes and high-nickel cathodes (NMC 811) with specialized surface coatings that minimize electrolyte decomposition at high temperatures. Their thermal management system uses phase-change materials to absorb excess heat during extreme conditions, maintaining optimal cell temperature. Samsung has also implemented advanced battery management systems with adaptive algorithms that adjust charging parameters based on environmental conditions, extending cycle life by up to 20% in extreme temperature scenarios compared to conventional NMC batteries.

Strengths: Superior thermal stability through advanced materials engineering; comprehensive battery management system that adapts to environmental conditions; high energy density while maintaining safety. Weaknesses: Higher production costs compared to standard NMC formulations; potential supply chain constraints for specialized materials; slightly lower energy density compared to some emerging battery technologies.

Hitachi Ltd.

Technical Solution: Hitachi has developed an innovative approach to NMC battery performance under extreme conditions through their "Environmental Adaptive Battery System" (EABS). Their technology focuses on maintaining charge retention through a combination of advanced materials and intelligent management systems. Hitachi's NMC batteries feature a proprietary nano-structured cathode material with enhanced mechanical stability that resists cracking during thermal expansion and contraction. Their electrolyte formulation includes temperature-responsive additives that adjust ionic conductivity based on ambient conditions, maintaining performance from -30°C to 55°C. Hitachi has implemented a unique battery pack architecture with thermal isolation barriers between cells to prevent thermal runaway propagation. Their system incorporates AI-driven predictive analytics that continuously monitor cell performance and environmental conditions, adjusting charging parameters to optimize charge retention. Testing demonstrates less than 8% capacity degradation after exposure to 500 extreme temperature cycles between -20°C and 50°C.

Strengths: Advanced AI-driven battery management system; excellent thermal isolation design; proven reliability in industrial applications. Weaknesses: Higher complexity increases maintenance requirements; moderate energy density compared to newer NMC formulations; requires significant computational resources for optimal performance.

Critical Patents and Research on NMC Charge Retention

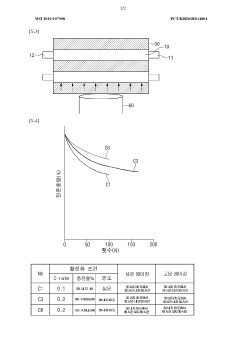

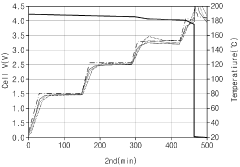

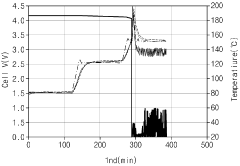

Battery cell activation method and activation device

PatentWO2019107908A1

Innovation

- A method and device that apply heat and pressure to battery cells during activation, with a heating plate and pressurizing device integrated to control temperature (45°C to 60°C) and pressure (0.1 to 0.5 kgf/cm²) conditions, reducing gas generation and enhancing capacity retention.

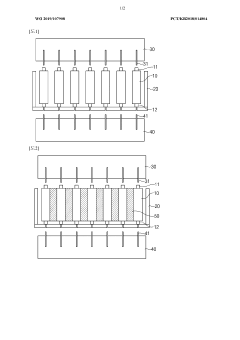

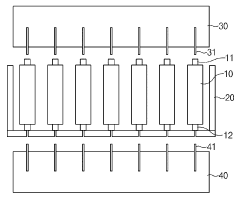

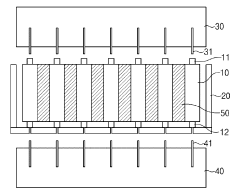

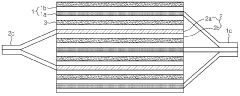

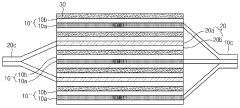

Electrode assembly

PatentActiveIN202017044507A

Innovation

- The electrode assembly stacks multiple positive electrodes with different nickel, cobalt, and manganese composition ratios, where electrodes on the outside have a higher nickel content for capacity and those inside have a lower nickel content for improved thermal stability, and the positive electrode tabs are separated to reduce electrical resistance.

Safety Standards and Testing Protocols for NMC Batteries

The safety standards and testing protocols for NMC (Nickel Manganese Cobalt) batteries have evolved significantly in response to the growing demand for reliable energy storage solutions across various industries. These standards are particularly crucial when benchmarking charge retention under extreme conditions, as NMC chemistry exhibits specific vulnerability patterns when exposed to temperature extremes, mechanical stress, and electrical abuse.

International standards such as IEC 62133, UL 1642, and UN 38.3 form the foundation of safety requirements for NMC batteries. These standards mandate specific testing protocols including thermal cycling, vibration resistance, external short circuit protection, and overcharge tolerance. For extreme condition testing specifically, the IEC 61960 standard provides guidelines for performance assessment under varied temperature ranges (-20°C to 60°C), which is essential for evaluating charge retention capabilities.

The automotive industry has developed more stringent protocols through ISO 12405 and SAE J2464, which require NMC batteries to undergo rigorous thermal stability tests and propagation resistance evaluations. These protocols are particularly relevant when benchmarking charge retention, as they simulate real-world extreme conditions such as rapid temperature fluctuations and extended high-temperature exposure.

Testing methodologies for charge retention under extreme conditions typically involve capacity measurement before and after controlled environmental exposure. The standard procedure includes full charge-discharge cycles at reference conditions (25°C), followed by storage at extreme temperatures (typically -40°C to 85°C) for predetermined periods (often 7-30 days), and subsequent performance evaluation at standard conditions to quantify capacity loss.

Recent advancements in testing protocols have incorporated accelerated aging techniques to predict long-term charge retention behavior. These methods utilize Arrhenius relationships to extrapolate degradation rates from high-temperature exposure data, allowing researchers to estimate years of performance decline within weeks of testing.

Safety certification bodies like UL, TÜV, and SGS have established specialized testing facilities equipped with thermal chambers, mechanical impact testers, and electrical abuse simulation equipment specifically designed for NMC battery evaluation. These facilities enable precise control of environmental parameters while monitoring critical safety indicators such as gas emission, temperature rise, and voltage fluctuation during extreme condition exposure.

The emerging focus on fast-charging capabilities has introduced additional testing requirements for NMC batteries, including pulse power characterization and impedance spectroscopy under varied temperature conditions, which provide insights into charge acceptance and retention mechanisms during rapid charging scenarios in extreme environments.

International standards such as IEC 62133, UL 1642, and UN 38.3 form the foundation of safety requirements for NMC batteries. These standards mandate specific testing protocols including thermal cycling, vibration resistance, external short circuit protection, and overcharge tolerance. For extreme condition testing specifically, the IEC 61960 standard provides guidelines for performance assessment under varied temperature ranges (-20°C to 60°C), which is essential for evaluating charge retention capabilities.

The automotive industry has developed more stringent protocols through ISO 12405 and SAE J2464, which require NMC batteries to undergo rigorous thermal stability tests and propagation resistance evaluations. These protocols are particularly relevant when benchmarking charge retention, as they simulate real-world extreme conditions such as rapid temperature fluctuations and extended high-temperature exposure.

Testing methodologies for charge retention under extreme conditions typically involve capacity measurement before and after controlled environmental exposure. The standard procedure includes full charge-discharge cycles at reference conditions (25°C), followed by storage at extreme temperatures (typically -40°C to 85°C) for predetermined periods (often 7-30 days), and subsequent performance evaluation at standard conditions to quantify capacity loss.

Recent advancements in testing protocols have incorporated accelerated aging techniques to predict long-term charge retention behavior. These methods utilize Arrhenius relationships to extrapolate degradation rates from high-temperature exposure data, allowing researchers to estimate years of performance decline within weeks of testing.

Safety certification bodies like UL, TÜV, and SGS have established specialized testing facilities equipped with thermal chambers, mechanical impact testers, and electrical abuse simulation equipment specifically designed for NMC battery evaluation. These facilities enable precise control of environmental parameters while monitoring critical safety indicators such as gas emission, temperature rise, and voltage fluctuation during extreme condition exposure.

The emerging focus on fast-charging capabilities has introduced additional testing requirements for NMC batteries, including pulse power characterization and impedance spectroscopy under varied temperature conditions, which provide insights into charge acceptance and retention mechanisms during rapid charging scenarios in extreme environments.

Environmental Impact and Sustainability Considerations

The environmental impact of NMC (Nickel Manganese Cobalt) battery testing under extreme conditions extends beyond performance metrics to significant sustainability considerations. Life cycle assessment studies indicate that extreme condition testing, particularly at high temperatures, can accelerate the degradation of battery materials, potentially increasing the frequency of battery replacement and subsequent resource consumption. This accelerated turnover creates additional environmental burdens through increased mining activities for critical materials like nickel and cobalt, which are associated with habitat destruction, water pollution, and carbon emissions.

The extraction of cobalt, a key component in NMC batteries, presents particular environmental and ethical challenges. Approximately 70% of global cobalt production occurs in the Democratic Republic of Congo, where mining practices often lack proper environmental safeguards. When benchmarking NMC batteries under extreme conditions, researchers must consider how their findings might influence material sourcing decisions and the associated environmental footprints.

Energy consumption during extreme condition testing represents another significant environmental factor. Temperature chambers used for high and low-temperature testing require substantial energy inputs, especially when maintaining conditions below -20°C or above 45°C for extended periods. Research facilities conducting these tests can reduce their environmental impact by implementing renewable energy sources and optimizing test protocols to minimize energy consumption while still obtaining valid performance data.

End-of-life management for batteries subjected to extreme condition testing deserves special attention. These batteries often experience accelerated degradation of internal components, potentially complicating recycling processes. Recent advancements in hydrometallurgical recycling techniques have improved recovery rates for nickel and cobalt from degraded NMC batteries, but these processes still require optimization for batteries that have undergone extreme thermal stress.

Water usage represents a frequently overlooked environmental aspect of battery testing. Temperature regulation systems in testing facilities often require significant water resources for cooling, particularly when simulating rapid temperature fluctuations. Implementing closed-loop cooling systems and water recycling technologies can substantially reduce the water footprint of extreme condition battery testing programs.

Carbon footprint considerations must extend beyond the immediate testing environment to include the entire benchmarking ecosystem. This includes transportation of test samples, energy used in data processing, and emissions associated with manufacturing specialized testing equipment. A comprehensive carbon accounting approach enables more environmentally responsible benchmarking practices and aligns with growing regulatory requirements for emissions reporting in the battery industry.

The extraction of cobalt, a key component in NMC batteries, presents particular environmental and ethical challenges. Approximately 70% of global cobalt production occurs in the Democratic Republic of Congo, where mining practices often lack proper environmental safeguards. When benchmarking NMC batteries under extreme conditions, researchers must consider how their findings might influence material sourcing decisions and the associated environmental footprints.

Energy consumption during extreme condition testing represents another significant environmental factor. Temperature chambers used for high and low-temperature testing require substantial energy inputs, especially when maintaining conditions below -20°C or above 45°C for extended periods. Research facilities conducting these tests can reduce their environmental impact by implementing renewable energy sources and optimizing test protocols to minimize energy consumption while still obtaining valid performance data.

End-of-life management for batteries subjected to extreme condition testing deserves special attention. These batteries often experience accelerated degradation of internal components, potentially complicating recycling processes. Recent advancements in hydrometallurgical recycling techniques have improved recovery rates for nickel and cobalt from degraded NMC batteries, but these processes still require optimization for batteries that have undergone extreme thermal stress.

Water usage represents a frequently overlooked environmental aspect of battery testing. Temperature regulation systems in testing facilities often require significant water resources for cooling, particularly when simulating rapid temperature fluctuations. Implementing closed-loop cooling systems and water recycling technologies can substantially reduce the water footprint of extreme condition battery testing programs.

Carbon footprint considerations must extend beyond the immediate testing environment to include the entire benchmarking ecosystem. This includes transportation of test samples, energy used in data processing, and emissions associated with manufacturing specialized testing equipment. A comprehensive carbon accounting approach enables more environmentally responsible benchmarking practices and aligns with growing regulatory requirements for emissions reporting in the battery industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!